C8 Corvette Z06 LT6 Break in RPM Redline Revealed

The C8 Corvette Z06’s LT6 break in RPM redline is quite a bit higher than the Stingray’s LT2, as expected.

By: Brett Foote | February 24, 2022

The C8 Corvette Z06’s LT6 break in RPM redline is quite a bit higher than the Stingray’s LT2, as expected.

By: Brett Foote | February 24, 2022

This custom 1957 Corvette – dubbed “Bali Hai” was a regular on the show car circuit prior to its disappearance.

By: Brett Foote | February 23, 2022

The brand new Cadillac CT5-V Blackwing and C8 put on one heck of a show in this interesting racing format.

By: Brett Foote | February 22, 2022

C8 Corvette prices have declined over the past five months as supply improves, which is a good sign for prospective buyers.

By: Brett Foote | February 18, 2022

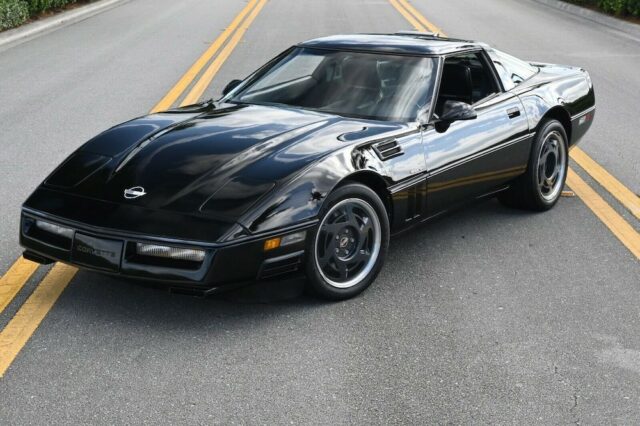

This ultra-rare C4 Corvette ZR1 prototype was used to test an early active suspension system.

By: Brett Foote | February 18, 2022

Callaway Competition is pulling out of GT3 racing for a while to develop the special track-prepped C8.

By: Brett Foote | February 18, 2022

Five years ago, the theft of one restorer’s award-winning 1960 Corvette almost caused him to lose his passion for cars.

By: Brett Foote | February 18, 2022