Engine Oil Cooler hose & fitting size?

#1

Burning Brakes

Thread Starter

Member Since: Jan 2005

Location: Littleton CO

Posts: 1,170

Likes: 0

Received 0 Likes

on

0 Posts

St. Jude Donor '07

I am a little unclear as to proper hose size for engine oil coolers...

Someone mentioned;

"Anytime external lines are used for plumbing engine oil, -8 is marginal for short runs and few/no bends. -10 is average and -12 is preferred."

in a post at http://forums.corvetteforum.com/show...R-1+oil+cooler

However I was talking with Tom Dewitt (Dewitts Radiator) and he said "#12 is WAY to big for something that only flows a 2-4 gpm. GM used 3/8 (#6) lines on the C6 (2005) with EOC."

The reason I asked Tom is because he is the one who made my custom radiator with an integrated engine oil cooler...

Talked to another shop who sells aeroquip products and they recommeded -8 hosing...

So what size is it?

To the main reason in deciding is the radiator fittings for the integrated EOC are 3/4-16 (#8 sae) straight thread o'ring seal fitting. 3/4 is about the same size as -12 from what I understand. Nobody seems to carry and adapter fitting that goes from this size to a -12 hose, but they do for -10 and smaller... I just want to make sure the hose size and flow is correct for my track use application. Keep in mind the engine is not highly modified...

Some feedback on what others are running would definately help...

Also I notice many running air coolers run a thermostat so the oil does not stay too cold. Would this be necessary with an integrated EOC within the radiator? I would think not since it will help warm the oil faster, but keep it cool when need too...

Someone mentioned;

"Anytime external lines are used for plumbing engine oil, -8 is marginal for short runs and few/no bends. -10 is average and -12 is preferred."

in a post at http://forums.corvetteforum.com/show...R-1+oil+cooler

However I was talking with Tom Dewitt (Dewitts Radiator) and he said "#12 is WAY to big for something that only flows a 2-4 gpm. GM used 3/8 (#6) lines on the C6 (2005) with EOC."

The reason I asked Tom is because he is the one who made my custom radiator with an integrated engine oil cooler...

Talked to another shop who sells aeroquip products and they recommeded -8 hosing...

So what size is it?

To the main reason in deciding is the radiator fittings for the integrated EOC are 3/4-16 (#8 sae) straight thread o'ring seal fitting. 3/4 is about the same size as -12 from what I understand. Nobody seems to carry and adapter fitting that goes from this size to a -12 hose, but they do for -10 and smaller... I just want to make sure the hose size and flow is correct for my track use application. Keep in mind the engine is not highly modified...

Some feedback on what others are running would definately help...

Also I notice many running air coolers run a thermostat so the oil does not stay too cold. Would this be necessary with an integrated EOC within the radiator? I would think not since it will help warm the oil faster, but keep it cool when need too...

#2

Le Mans Master

I'm running -8 lines for my 45000 btu external cooler (stock LS-1, 317 rwhp). I measured the oil pressure before/after and found a 1-2 psi difference from 1000 to 5000 rpm.

I've not had any problems with low OPs when at track temps. I honestlly think that people go with -10 hoses just because "bigger is better", not any measurable differences.

Obviously modded motors may need bigger equipment.

HTH, and have a good one,

Mike

I've not had any problems with low OPs when at track temps. I honestlly think that people go with -10 hoses just because "bigger is better", not any measurable differences.

Obviously modded motors may need bigger equipment.

HTH, and have a good one,

Mike

#7

Race Director

Originally Posted by VetteDrmr

I'm running -8 lines for my 45000 btu external cooler

...redvetracr

#9

Burning Brakes

Thread Starter

Member Since: Jan 2005

Location: Littleton CO

Posts: 1,170

Likes: 0

Received 0 Likes

on

0 Posts

St. Jude Donor '07

Anyone have any C4 pictures of how you ran the hoses from the oil filter adapter to your EOC? Am looking to see how you kept it within the body area as so not of it hangs down below it.

As to finding longer hoses, most places sell it $ per foot and you can buy just about any length you want.

As to finding longer hoses, most places sell it $ per foot and you can buy just about any length you want.

#10

Melting Slicks

Member Since: Dec 1999

Location: Austin, TX

Posts: 2,813

Likes: 0

Received 0 Likes

on

0 Posts

I don't have any pics, but on mine, I routed the lines from the sandwich adaptor (-10 lines as supplied from DRM) directly forward along the block, past the PS pump, and cut a hole through the driver's side of the radiator shroud just forward of the three relays.

Mine is also a '96

Mine is also a '96

#11

Le Mans Master

Originally Posted by qwik96GS

...#12 is WAY to big for something that only flows a 2-4 gpm.

that an LSx oil pump flows? My understanding is that a SBC flows

more in the range of 8 gallons per minute at max RPM and I am

unaware of the LSx engines being substantially more efficient in

the lube dept..

Smaller lines are easier to plumb and add less weight. But fittings and

hose lengths contribute to pressure drop in the circuit - if the

measured or anticipated pressure drop is unacceptable, larger lines

ought to be used.

Keep in mind that flow rises with RPM. The test is not whether

pressure drop is adequate at 77% of max RPM, the proof is that

flow is adequate at 100% of max RPM.

Another thought is that if choosing to run the smallest line possible,

it isn't enough to rely on what works for someone else unless you

exactly duplicate their configuration. Hose runs or fittings may mean

the difference between adequate lubrication and failure.

One rule of thumb is to anticipate a 5 PSI drop for every sharp 90º, 2

PSI for every 45º. Where there is a choice, extending the hose is

better than inserting an angled fitting. This R-o-T dates back to the

days before many of the newer fitting designs, so fancy fittings may

result in lower pressure drop, but it is still illustrative.

If I intended to test pressure drop, I would try -8, otherwise I would

use -10 as a minimum.

Originally Posted by qwik96GS

Also I notice many running air coolers run a thermostat so the oil

does not stay too cold. Would this be necessary with an integrated

EOC within the radiator?

does not stay too cold. Would this be necessary with an integrated

EOC within the radiator?

exchanger - on startup, engine coolant will gain heat faster than the

oil and help the oil come up to operating temperature more rapidly.

So a thermostat in the oil line of an oil/water exchanger would be

redundant, IMO.

I use a Mocal thermostat in the oil line of an oil/air system.

.

#12

Le Mans Master

Originally Posted by Slalom4me

Keep in mind that flow rises with RPM. The test is not whether

pressure drop is adequate at 77% of max RPM, the proof is that

flow is adequate at 100% of max RPM.

pressure drop is adequate at 77% of max RPM, the proof is that

flow is adequate at 100% of max RPM.

another thought is that if choosing to run the smallest line possible, it isn't enough to rely on what works for someone else unless you exactly duplicate their configuration. Hose runs or fittings may mean the difference between adequate lubrication and failure.

, to a point. Assuming that every installation that doesn't use the most popular mentality (i.e. bigger is always better) towards a mod is riskier is a fallacy. You need to understand why decisions were made to determine if the install works for your situation.

, to a point. Assuming that every installation that doesn't use the most popular mentality (i.e. bigger is always better) towards a mod is riskier is a fallacy. You need to understand why decisions were made to determine if the install works for your situation.

One rule of thumb is to anticipate a 5 PSI drop for every sharp 90º, 2 PSI for every 45º. Where there is a choice, extending the hose is better than inserting an angled fitting. This R-o-T dates back to the

days before many of the newer fitting designs, so fancy fittings may

result in lower pressure drop, but it is still illustrative.

days before many of the newer fitting designs, so fancy fittings may

result in lower pressure drop, but it is still illustrative.

I vote that the thermostat is not necessary for an integral oil/water exchanger - on startup, engine coolant will gain heat faster than the oil and help the oil come up to operating temperature more rapidly. So a thermostat in the oil line of an oil/water exchanger would be redundant, IMO.

Most unregulated engine oil coolers (whether integrated or external to the radiator) will only allow the engine oil temps to get up into the low 100s during daily driving (it needs to be around 190). Even with my thermostat I have to run a cover over the cooler for daily driving (thermostat always passes a minimum of 5%).

No flames, just info.

Have a good one,

Mike

#13

Burning Brakes

Thread Starter

Member Since: Jan 2005

Location: Littleton CO

Posts: 1,170

Likes: 0

Received 0 Likes

on

0 Posts

St. Jude Donor '07

I can't imagine the coolant temperature being that much cooler in the radiator than in the block. Perhaps slightly different, but my temps range in the 205-215F range on the street. Even if there were a 20 degree difference it still would be within proper oil temp range.

I asked Tom DeWitt's opinion on it to see what he would suggest.

--------------------------------------------------------------------

From: Tom DeWitt

Sent: Sunday, November 12, 2006 8:02:02 PM

Subject: Re: Intigrated engine oil cooler hookup?

A thermostat is used with air type coolers because you have no control over the ambient air. It could be a variable of over 100 degree (0-100f). With internal cooling the water temperature isn't going to vary that much, maybe 190-230. Not enough to worry about over cooling.

I asked Tom DeWitt's opinion on it to see what he would suggest.

--------------------------------------------------------------------

From: Tom DeWitt

Sent: Sunday, November 12, 2006 8:02:02 PM

Subject: Re: Intigrated engine oil cooler hookup?

A thermostat is used with air type coolers because you have no control over the ambient air. It could be a variable of over 100 degree (0-100f). With internal cooling the water temperature isn't going to vary that much, maybe 190-230. Not enough to worry about over cooling.

#14

Le Mans Master

You don't have to put the t'stat inline at the very beginning. Just watch your oil temps. On the LS-1 they need to be around 190; not too sure about the LT-x engines.

However, you need the oil to be at least around 170 or so to dry out the condensation you get in the crankcase from normal blow-by. Otherwise the water will mix with the oils and form acids. This is one of the reasons a short-haul drive mix (where the engine oil doesn't get up to temp long enough to dry out) is considered a hard-use environment.

In any case, let us know how it goes!

Have a good one,

Mike

However, you need the oil to be at least around 170 or so to dry out the condensation you get in the crankcase from normal blow-by. Otherwise the water will mix with the oils and form acids. This is one of the reasons a short-haul drive mix (where the engine oil doesn't get up to temp long enough to dry out) is considered a hard-use environment.

In any case, let us know how it goes!

Have a good one,

Mike

#16

Burning Brakes

Thread Starter

Member Since: Jan 2005

Location: Littleton CO

Posts: 1,170

Likes: 0

Received 0 Likes

on

0 Posts

St. Jude Donor '07

Great advise everyone and it is truly appreciated. Just bought some dummy 1/2" rubber hose to test and plan where the lines are going to run. With the Radiator EOC the hookups are on the passenger side. Doesn't look too difficult to get it there, but I like the idea someone gave me about using rubber hose to prior to using the real stuff!

#17

Le Mans Master

Originally Posted by VetteDrmr

This is the most common misconception that I come across. The

engine coolant temperature is measured in the engine, not in the

radiator. High performance radiators are very efficient. As

such, in normal street driving it will be much cooler than the engine

coolant, and will cool the engine oil too much. Only when the coolant

thermostat is fully open will the radiator coolant be close to the engine

coolant temp.

engine coolant temperature is measured in the engine, not in the

radiator. High performance radiators are very efficient. As

such, in normal street driving it will be much cooler than the engine

coolant, and will cool the engine oil too much. Only when the coolant

thermostat is fully open will the radiator coolant be close to the engine

coolant temp.

oil/water heat exchanger mounted in the radiator. As VetteDrmr

points out, the coolant in the rad takes longer to warm up

than the coolant that recirculates in the engine.

As the engine coolant reaches the temperature necessary to begin

to open the thermostat, only a portion of the engine's coolant

is exchanged with the radiator before the thermostat closes.

On cold days, this cycle repeats continuously with the rad always

being decidely colder than the engine. Even on hot days with

high demand on the engine, the cycle occurs several times before

the engine side and the rad side of the cooling systems begin to

approach equilibrium and the thermostat remains open constantly.

My comment about a thermostat being redundant for oil/water heat

exchangers would only be applicable for coolers that are plumbed

into the engine side of the cooling system. The coolant would

heat up rapidly to operating temperature, helping to warm the oil.

This is how jet boats are configured as well as one car I know of.

The L98 oil cooler works this way, too, I believe.

Fluidyne Therm-Hx Fluid Coolers p/n DB-30500

Incidently, C&R offers a nice blend valve p/n 1037000010

Originally Posted by VetteDrmr

Most unregulated engine oil coolers (whether integrated or external

to the radiator) will only allow the engine oil temps to get up into the

low 100s during daily driving (it needs to be around 190). Even with my

thermostat I have to run a cover over the cooler for daily driving

(thermostat always passes a minimum of 5%).

to the radiator) will only allow the engine oil temps to get up into the

low 100s during daily driving (it needs to be around 190). Even with my

thermostat I have to run a cover over the cooler for daily driving

(thermostat always passes a minimum of 5%).

used coolers like the OEM one GM offered with towing packages for

BBC pickups and found it suitable for summer use in the climate here,

covering it in the off-season except, say, when pulling sleds in the

mountains. A temperature gauge being my guide as to when to

cover or expose the cooler.

.

#18

Le Mans Master

Originally Posted by VetteDrmr

Based upon that I should have seen approximately a 25 psi drop

(1 45 fitting (2 psi), 6 90 degree hose ends (guessing at half the 5 psi

drop you mention). Again I measured only about a 2 psi drop.

No flames, just info.

(1 45 fitting (2 psi), 6 90 degree hose ends (guessing at half the 5 psi

drop you mention). Again I measured only about a 2 psi drop.

No flames, just info.

and one reaps as one sows.

With 6 x 90º fittings, 1 x 45º fitting, perhaps 10' of hose, the cooler

and an adapter at the block, a pressure drop of only 2 psi seems like

a very good achievement. When you tested the drop, did you use two

gauges with one plumbed before the adapter leading out to the cooler

and one after?

My remark about 77% was prompted by the 5K RPM figure in the earlier

post (typo?), 6,000 RPM is getting up there.

I did qualify the Rule of Thumb by noting that it predates many of

the fittings available to us now. Below are different examples of

fittings that we currently have to choose from. Someone who didn't

know any better might think that the first item is equal to the fourth

choice.

Weatherhead Male Elbow

Perma-Cool PRM-15158 1/2" NPT

Earl's Performance Plumbing 1/2". NPT

Earl's Performance Swivel-Seal Hose Ends -10 AN

I have been looking again for up-to-date figures about flow or pressure

drop without success. If anyone can provide references, please do so.

Originally Posted by VetteDrmr

You need to understand why decisions were made

to determine if the install works for your situation.

to determine if the install works for your situation.

obvious location. Words to live by ...

.

#19

Le Mans Master

Originally Posted by Slalom4me

No flame perceived. If anything, my initial tone was provocative and one reaps as one sows.

With 6 x 90º fittings, 1 x 45º fitting, perhaps 10' of hose, the cooler and an adapter at the block, a pressure drop of only 2 psi seems like a very good achievement. When you tested the drop, did you use two gauges with one plumbed before the adapter leading out to the cooler and one after?

I also remembered that, in addition to recommendations from others, I went with -8 lines because they're 1/2 inch ID, larger than the galleries within the engine itself.

In any case, I've had no problems with low oil pressure during my autocross/track days. Idle OP with oil temps around 250 range around 18-20 psi, up in the high 30s on track (when I have time to look).

Have a good one,

Mike

#20

Burning Brakes

Thread Starter

Member Since: Jan 2005

Location: Littleton CO

Posts: 1,170

Likes: 0

Received 0 Likes

on

0 Posts

St. Jude Donor '07

Originally Posted by Slalom4me

My comment about a thermostat being redundant for oil/water heat

exchangers would only be applicable for coolers that are plumbed

into the engine side of the cooling system. The coolant would

heat up rapidly to operating temperature, helping to warm the oil.

This is how jet boats are configured as well as one car I know of.

The L98 oil cooler works this way, too, I believe.

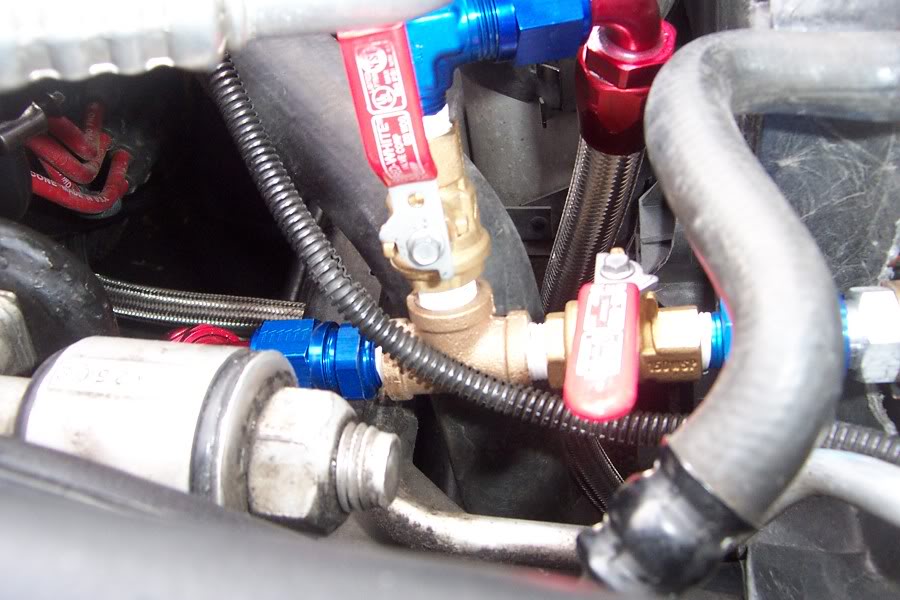

On My Dewitt radiator both the inlet and outlet of the EOC is on the passenger side of the radiator.

The run from the oil filter adapter and up over the power steering assembly to the fittings on the radiator fittings does not require any sharp bends and only 2 - 4' hose lengths. Simple enough to add a thermostat if needed.