Stress concentration study of holes and slots in iron rotors

#1

Le Mans Master

Thread Starter

Member Since: Feb 2000

Location: Bedford NH

Posts: 5,708

Likes: 0

Received 1 Like

on

1 Post

Cruise-In II Veteran

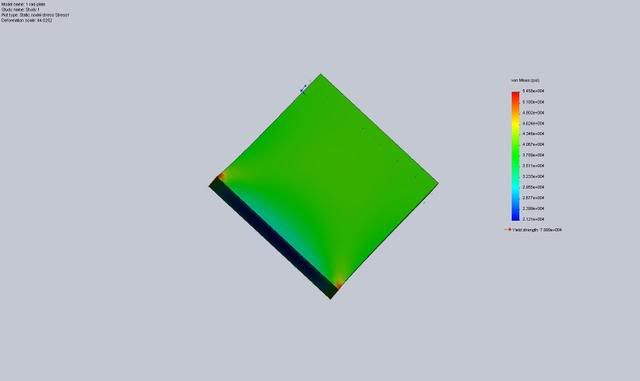

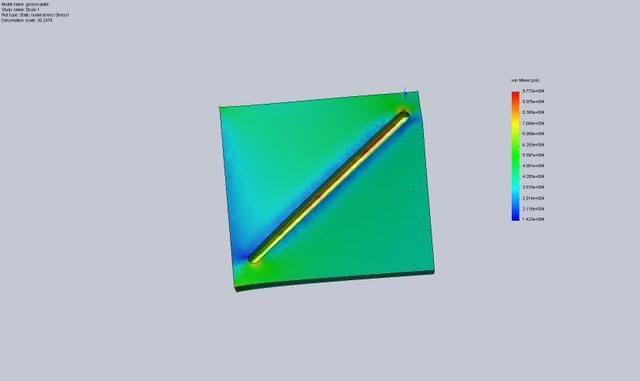

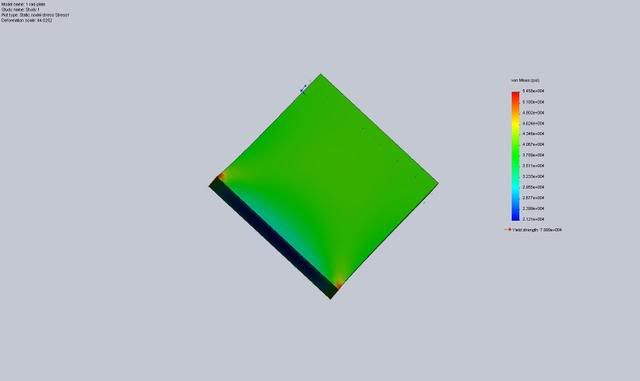

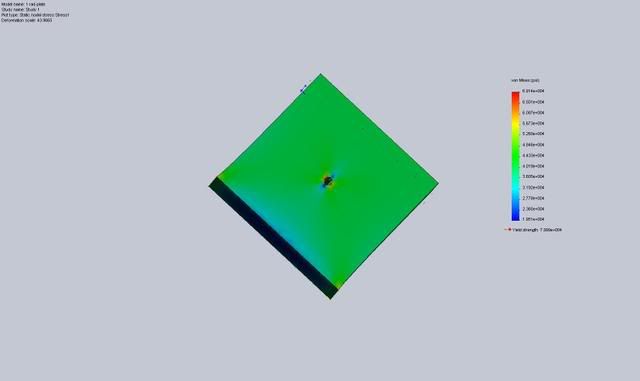

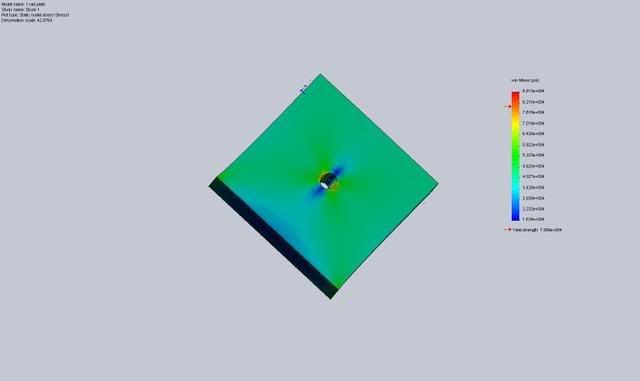

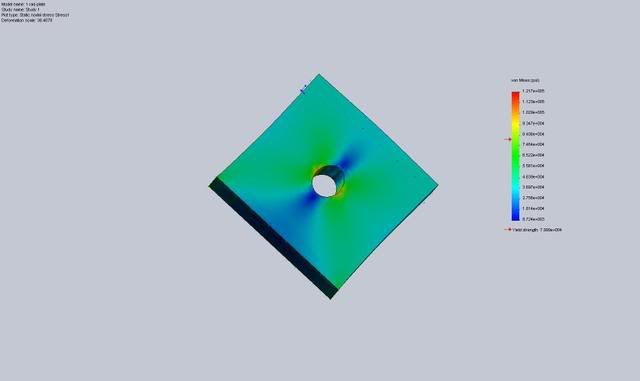

I just did some simple Solidworks models to demonstrate the effects of holes and slots in iron rotors. I made a malleable iron plate 2 inch by 2 inch by 1/4 inch thick and constrained in on one end and put a 20K lb tensile force on the other. The first model was run with no holes or slots and we had 54K psi stress.

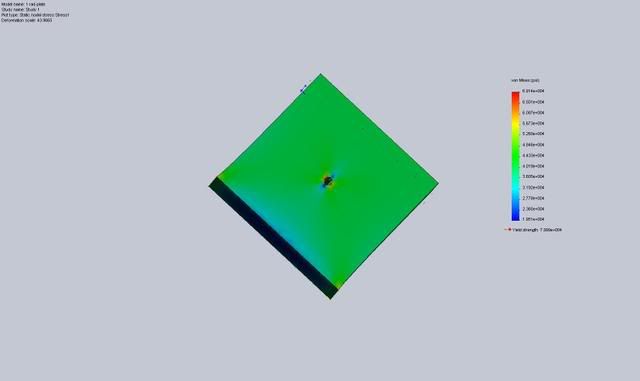

The next model had a .05 inch radius hole and the stress was 69Ksi

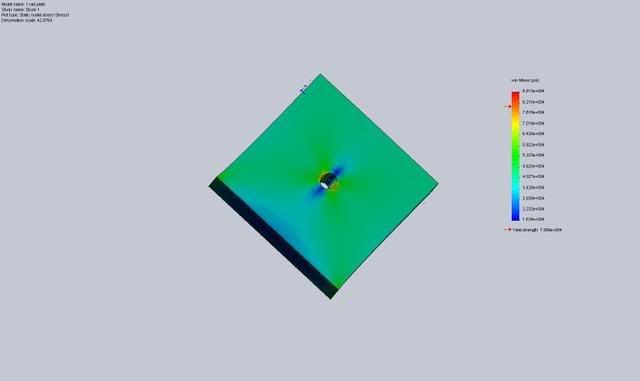

I then changed the hole to a .1 inch radius and the stress went to 88Ksi

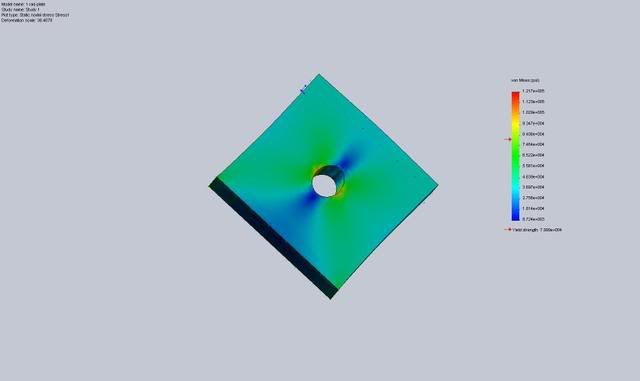

Then a .2 inch radius hole and the stress went to 122 Ksi

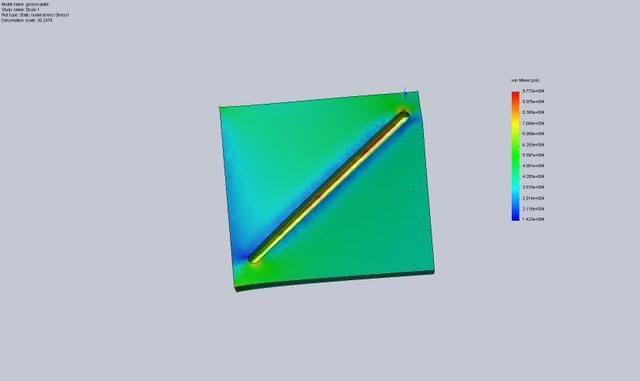

Lastly I got rid of the hole and put in a diagonal slot .1 inch wide, .1 inch deep with a full radius on the ends and at the bottom of the groove and the stress is 97Ksi.

So, the results show that no matter what you do, holes and slots will increase the peak stress on the rotor and reduce it's life.

Now we could do all sorts of fatigue due to thermal cycles, gradients through the Z axis etc, but the simple tensile model demonstrates why I will not buy, use or sell rotors with stress risers built in from the start.

The next model had a .05 inch radius hole and the stress was 69Ksi

I then changed the hole to a .1 inch radius and the stress went to 88Ksi

Then a .2 inch radius hole and the stress went to 122 Ksi

Lastly I got rid of the hole and put in a diagonal slot .1 inch wide, .1 inch deep with a full radius on the ends and at the bottom of the groove and the stress is 97Ksi.

So, the results show that no matter what you do, holes and slots will increase the peak stress on the rotor and reduce it's life.

Now we could do all sorts of fatigue due to thermal cycles, gradients through the Z axis etc, but the simple tensile model demonstrates why I will not buy, use or sell rotors with stress risers built in from the start.

#2

Personally I don't understand the math but I understand your concept and that of stress risers. However, there are so many other factors that may be important like the shape of a rotor is so different from and iron plate. The stresses placed on the rotor due to its shape may be so much more than the stresses placed on the wear surface that it may not be appropriate to draw conclusions. Similarly if the overall stresses are under the stresses the rotor sees during a race while your math is right it may not be significant. Rotor design is a compromise just like everything else in racing. The trick is to engineer the rotor for exactly the thermal load you need from a math prospective. I do understand your point and basically you will except no compromise in your rotors that means no slots no holes. Further you will do nothing to make a product potentially more unsafe or fail. That's kind of like my pet peeve of always bolting the race seat to the rollcage not to the floor of the chassis.

#3

Drifting

Personally I don't understand the math but I understand your concept and that of stress risers. However, there are so many other factors that may be important like the shape of a rotor is so different from and iron plate. The stresses placed on the rotor due to its shape may be so much more than the stresses placed on the wear surface that it may not be appropriate to draw conclusions. Similarly if the overall stresses are under the stresses the rotor sees during a race while your math is right it may not be significant. Rotor design is a compromise just like everything else in racing. The trick is to engineer the rotor for exactly the thermal load you need from a math prospective. I do understand your point and basically you will except no compromise in your rotors that means no slots no holes. Further you will do nothing to make a product potentially more unsafe or fail. That's kind of like my pet peeve of always bolting the race seat to the rollcage not to the floor of the chassis.

I also think this simple model does not fit the scenario of rotor failure as we were discussing earlier. Drilled rotors got an initial bad rap from arm chair participants who really had very little experience with them. They decided they were bling and that was it.

If you look at a stock Z51 rotor as compared to a stock C5 rotor you must agree that the Z51 rotor is outlasting the C5 rotor by a factor as much as 4. I am sure, however, that either can be forced to fail immediately and then the holes will be blamed for the Z51 failure and made in China for the C5 rotor. The point being that objective data needs to have the variables removed so the only difference is the rotor itself. I have not seen that data yet.

Objective and meaningful data needs to come from a working model of a real rotor in use with the only variable being the drilling or slots. The data and argument to date is subjective and largely biased on opinion. My data is based only on personal experience and that does not mean everyone else will get the same result. I am not using too aggressive of a pad for example (PFC Z) and that may contribute as well.

#4

Drifting

#9

Drifting

Come on .. go find your head man. You're looking for an argument with a smart *** remark like that ... no thanks.

See the other post. Picture are there.

#10

Drifting

My data is based only on personal experience and that does not mean everyone else will get the same result.

I'm done with this now since johninar has changed the tone.

#11

Tech Contributor

Member Since: Oct 1999

Location: Charlotte, NC (formerly Endicott, NY)

Posts: 40,085

Received 8,926 Likes

on

5,332 Posts

Bill

#12

Melting Slicks

then why do they make holes into structual bridge members? like the big i-beam members, they cut holes into them to lighten them, or make them look fancy, or something ???

#13

Safety Car

I provided a valuable comment here where I mentioned that having the rotors on the right direction is important or I see significantly increased rotor wear (heat checking). The C6 Z51 and Z06 rotors do not come in left/right pairs...

#15

Le Mans Master

Thread Starter

Member Since: Feb 2000

Location: Bedford NH

Posts: 5,708

Likes: 0

Received 1 Like

on

1 Post

Cruise-In II Veteran

Because of the "neutral axis theorem" permits a weight savings. Look at your finger as you bend it, the skin on the outside is in tension and the inside goes into compression, so therefore the center is under zero stress. To put it another way, the sliding stack of leaf springs is no where near as stiff as a solid block of steel would be of the same height. The holes and slots multiply whatever stress you have by the above amount, no matter what and have zero benefit with today's pads.

The other thing is that cast iron (as opposed to "isotropic" materials like steel and aluminum) is very poor in tension and very good in compression. When the outside of the rotor gets hot and the inside starts to cool first, the surface of the rotor is in tension and the holes increase the stress by about 1.5-2x depending on the size as demonstrated above.

Last edited by ghoffman; 09-08-2008 at 08:37 AM.

#16

Safety Car

The stress concentration at holes, radii, and other risers is well established in engineering literature. Peterson's Stress Concentration factors is the leading publication and has been out since the 60's. I don't know why so many insist to try the holes/slots, maybe there was some thermal gain that they thought outweighed the structural considerations?

#17

Team Owner

Member Since: Sep 2003

Location: Raleigh / Rolesville NC

Posts: 43,084

Likes: 0

Received 24 Likes

on

24 Posts

The stress concentration at holes, radii, and other risers is well established in engineering literature. Peterson's Stress Concentration factors is the leading publication and has been out since the 60's. I don't know why so many insist to try the holes/slots, maybe there was some thermal gain that they thought outweighed the structural considerations?

#18

Le Mans Master

Thread Starter

Member Since: Feb 2000

Location: Bedford NH

Posts: 5,708

Likes: 0

Received 1 Like

on

1 Post

Cruise-In II Veteran

The stress concentration at holes, radii, and other risers is well established in engineering literature. Peterson's Stress Concentration factors is the leading publication and has been out since the 60's. I don't know why so many insist to try the holes/slots, maybe there was some thermal gain that they thought outweighed the structural considerations?

That as well as Roark's formulas for Stress and Strain have been around forever. I also have and use Formulas for Natural Frequency and Mode Shape by Robert D. Blevins. I have to say, I don't use them as much as I used to because of the ease of Solidworks/Cosmos. I was going to just show some of the stress conentration cases listed on the net, but it was easier to do the small cupon models above and then I could do the diagonal slot ("power slots"!) model as well and show a graphic of each for the benefit of this forum. These models took about 15 minutes to do and post.

#19

Melting Slicks

Member Since: Sep 2004

Location: Southeastern Pennsylvania

Posts: 2,533

Likes: 0

Received 0 Likes

on

0 Posts

The stress concentration at holes, radii, and other risers is well established in engineering literature. Peterson's Stress Concentration factors is the leading publication and has been out since the 60's. I don't know why so many insist to try the holes/slots, maybe there was some thermal gain that they thought outweighed the structural considerations?

The holes (or slots) provided a place for the gases to be evacuated from the pad-rotor interface, thus increasing effectiveness.

So much for history.

Today, the pads are mostly metal-ceramic and hardly outgas at all. The benefits of the holes and slots is essentially nil in terms of improved braking, but they still promote cracking in the rotor as has been shown by the OP.

As Au-N-Egl posted, big names are still pushing them (as a superior solution) when in fact they are mostly BLING.

Now back to your regularly scheduled program.

#20

Drifting

Thanks for the info. I'm new to HPDE and I still use the stock rotors w/ no holes or slots. I chew through HP+ pads about every 2-3 track days and I've yet to crack a rotor.

So is there any value to holes/slots for any level of street or performance driving other than the bling factor? Of course they advertise outgassing as the purpose.

FM

So is there any value to holes/slots for any level of street or performance driving other than the bling factor? Of course they advertise outgassing as the purpose.

FM