T1 sway bar links question.

#1

Race Director

Thread Starter

I put the GM T1 links on about a year ago & they had the click/clunk right from the start. I expected that so no biggie.

I was doing front end work & disconnected both sides and I was surprised to note that there was some wear on all the heim joints. Maybe a mm of play, maybe even less, but you could feel the play. I know when they were new they were solid (noisy but solid).

So WTF do these things wear out that fast? I did maybe 20 or 30 autox events & a few track days & maybe 5000 miles street.

You know these are not cheap so does anyone have this kind of experience?

Any recommendation for an adj link that'll last better?

Thanks.

I was doing front end work & disconnected both sides and I was surprised to note that there was some wear on all the heim joints. Maybe a mm of play, maybe even less, but you could feel the play. I know when they were new they were solid (noisy but solid).

So WTF do these things wear out that fast? I did maybe 20 or 30 autox events & a few track days & maybe 5000 miles street.

You know these are not cheap so does anyone have this kind of experience?

Any recommendation for an adj link that'll last better?

Thanks.

#2

Race Director

they are just generic 1/2" heims, unless they've changed them. They are marketed for race cars, and noise isn't an issue. LG has high-dollar quiet heims, and you can probably shop around for other expensive ones.

also of note, while the T1 heims are 1/2", the actual holes in your a-arm are Metric, so obviously GM wasn't too concerned about keeping things quiet.

also of note, while the T1 heims are 1/2", the actual holes in your a-arm are Metric, so obviously GM wasn't too concerned about keeping things quiet.

#3

On my c5 with T1 bars i had the dreaded clink/clunk, just lived with it. Recently I bought new set of T1 bars for my c6 and no noise. Never could understand it. I would say, check and make sure all your heim joints are absolutely installed perfect, mostly make sure all accompaning washers, tapered and flat, are installed in a fashion that they will not bind in anyway. You could also put small amount of lubricant on rubber or neoprene bushings. (The new bars have a cool looking fabric lining on inside of bushings and I'm assuming it replaces the need of lub.)

#4

Melting Slicks

Midwest control products has heim joints for very reasonable prices and they sell rubber boots that protect the joints and keep grease in and crap out of the joints. They also have metric sizes which would address the looseness in the stock joints. They also have teflon, bronze or nylon or chrome wear surfaces, so you can pick whatever you want in that regard.

I've used their stuff on some of my test stand hardware and it was very good quality.

As I was driving the car in to work this morning I was just thinking that I ought to replace mine and get a set of boots and grease them so that the didn't make as much noise.

I'm assuming that we need 14mm bolting since the holes on our sway bars must be 14mm, because 1/2 inch joints are sloppy in there.

I've used their stuff on some of my test stand hardware and it was very good quality.

As I was driving the car in to work this morning I was just thinking that I ought to replace mine and get a set of boots and grease them so that the didn't make as much noise.

I'm assuming that we need 14mm bolting since the holes on our sway bars must be 14mm, because 1/2 inch joints are sloppy in there.

#5

Melting Slicks

According to LG's web site, those are simply teflon lined joints (available at Midwest for a lot less). A long time ago I bought a set of teflon lined end links for my first gen RX7. After a while the teflon was pounded or ground out from crap getting in them. At any rate they wore out and got real loose. If I was going to go with teflon lined joints I would for sure put rubber boots over them to keep the dirt out and hope the loads weren't so bad that they got pounded out. I would think that the loads in the bars of a Corvette are much larger than what they were in my RX7, so if you are doing teflon lined links I'd try to get the biggest ones that you can get, and then put boots on them to keep the crap out of them. JMHO

#6

Race Director

Thread Starter

Thanks all. Is there such a thing as a link where you DO NOT have to detach one end to make it longer/shorter?

That would be a nice feature.

EDIT: I guess that would be a turnbuckle, and it does not seem there would be enough length available to use one.

http://www.midwestcontrol.com/

Nevermind. Got it.

That would be a nice feature.

EDIT: I guess that would be a turnbuckle, and it does not seem there would be enough length available to use one.

http://www.midwestcontrol.com/

Nevermind. Got it.

Last edited by froggy47; 10-25-2010 at 02:00 PM.

#7

Race Director

Thread Starter

On my c5 with T1 bars i had the dreaded clink/clunk, just lived with it. Recently I bought new set of T1 bars for my c6 and no noise. Never could understand it. I would say, check and make sure all your heim joints are absolutely installed perfect, mostly make sure all accompaning washers, tapered and flat, are installed in a fashion that they will not bind in anyway. You could also put small amount of lubricant on rubber or neoprene bushings. (The new bars have a cool looking fabric lining on inside of bushings and I'm assuming it replaces the need of lub.)

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------

I just took some measurements off extra stuff I had in the garage.

12mm is the hole size in the STOCK c5z and c6z bars.

12.7mm is the hole size on the STOCK c5z lower control arm.

11.6mm is the width of the stud on the STOCK METAL end links

Add to that all those sleeves you need to put on each side of each ball of each heim and you have a LOT of tolerances going on that are off between 1-2mm.

I just had a thought, I wonder if you packed those sleeves with teflon or silicone or rubber (Right Stuff) if that would quiet things down. The sleeves are a pretty loose fit as they slide on over the bolts. My T1 is all back together now so I can't measure any of that.

If anyone has a QUIET set up, T1, Pfadt, other can you look and see if there are spacer sleeves on yours like what comes with the T1?

None of the stock bars have any spacer sleeves on their links, the link is built with the correct offsets.

Last edited by froggy47; 10-25-2010 at 02:25 PM.

#8

Melting Slicks

The lower control arm is 1/2 inch (12.7 mm is 1/2 of an inch by my claculator). So buy 1/2 inch links if that's what fits the control arm and then ream the sway bar so that you can fit a 1/2 inch bolt thru the bar and that should make everything tight.

If are going to try to put something in the control arm it's going to have to be pretty strong to stay there and not get pounded to death by the forces involved. More like a rubber material like dip and grip as opposed to silicone.

Ream the bar a bit and go to 1/2 inch stuff and walk away from it. The rod ends are going to be a bit bigger and tougher than the metric ones anyway. Get the proper rubber boots and grease the ends and let us know what part numbers you ordered and what works so I can do it next weekend....

If are going to try to put something in the control arm it's going to have to be pretty strong to stay there and not get pounded to death by the forces involved. More like a rubber material like dip and grip as opposed to silicone.

Ream the bar a bit and go to 1/2 inch stuff and walk away from it. The rod ends are going to be a bit bigger and tougher than the metric ones anyway. Get the proper rubber boots and grease the ends and let us know what part numbers you ordered and what works so I can do it next weekend....

Last edited by Solofast; 10-25-2010 at 03:37 PM.

#9

Race Director

Thread Starter

Here ya go.

Below is what I got from Midwest Control Products Corp.

The sales rep that helped me pick out the right ones (they have LOTS) said they use these on the Baja trophy trucks and buggys, tough links.

These are Chrome Moly with slotted nylon race (insert from the looks, still mostly metal race). All 1/2 inch.

MXM-8 male

MXF-8 female

$88. shipped

He said don't bother with grease & seals, but you could if you wanted to.

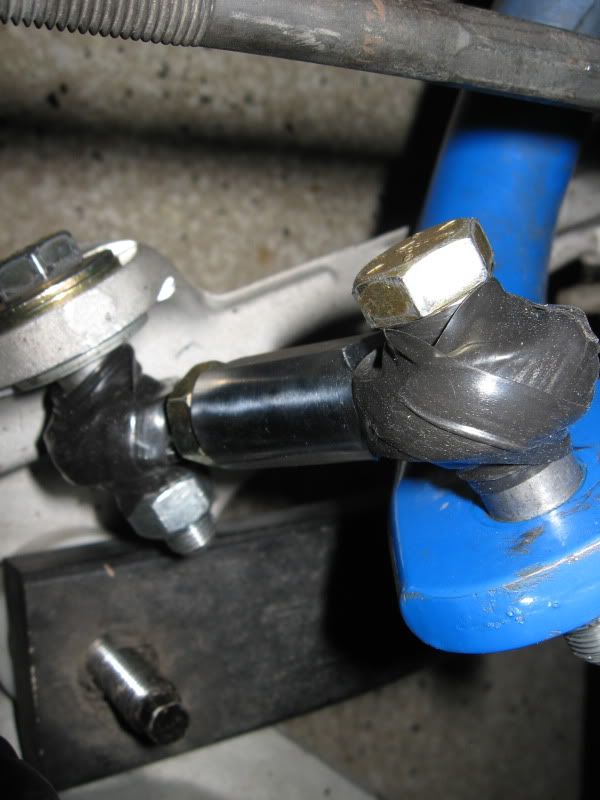

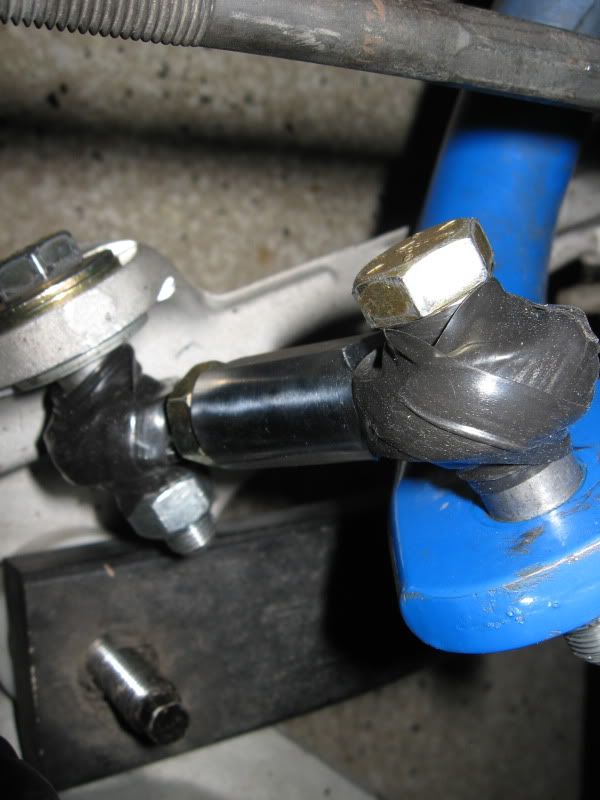

Here is a side by side of the new ones & GM Performance T1 links, pretty similar.

Each time I work on these I learn something.

The stock original (metal non adj) links (not pictured) allow for a GREATER angle of misalignment by about 15 degrees.

I think the click noise may have to do with the sleeve/spacer coming in contact with the link (as you see in my side by side picture as an example) during the motion/misalignment of the link as it works with the suspension.

To further this theory I closely examined the T1 links I took off and can clearly see one one that this was happening as the race was SLIGHTLY dented by the repeated contact. Very small so no pic.

Putting these on a car with stock (soft ) springs as opposed to T1 springs probably also allows for more movement, lowering may exacerbate too.

Also when you tighten the jam nut make sure you are holding both ends of the link so that max turning radius is kept, don't **** one end so that it is near to the point of running out of movement space before it even starts to move, it'll hit. On my original install I had one side out of "optimum" alignment.

Hope this helps. All my noise is GONE!

Below is what I got from Midwest Control Products Corp.

The sales rep that helped me pick out the right ones (they have LOTS) said they use these on the Baja trophy trucks and buggys, tough links.

These are Chrome Moly with slotted nylon race (insert from the looks, still mostly metal race). All 1/2 inch.

MXM-8 male

MXF-8 female

$88. shipped

He said don't bother with grease & seals, but you could if you wanted to.

Here is a side by side of the new ones & GM Performance T1 links, pretty similar.

Each time I work on these I learn something.

The stock original (metal non adj) links (not pictured) allow for a GREATER angle of misalignment by about 15 degrees.

I think the click noise may have to do with the sleeve/spacer coming in contact with the link (as you see in my side by side picture as an example) during the motion/misalignment of the link as it works with the suspension.

To further this theory I closely examined the T1 links I took off and can clearly see one one that this was happening as the race was SLIGHTLY dented by the repeated contact. Very small so no pic.

Putting these on a car with stock (soft ) springs as opposed to T1 springs probably also allows for more movement, lowering may exacerbate too.

Also when you tighten the jam nut make sure you are holding both ends of the link so that max turning radius is kept, don't **** one end so that it is near to the point of running out of movement space before it even starts to move, it'll hit. On my original install I had one side out of "optimum" alignment.

Hope this helps. All my noise is GONE!

Last edited by froggy47; 11-28-2010 at 12:06 AM.

#11

Melting Slicks

I posted this on the other end link thread and did pretty much the same thing as froggy but with a slight twist.

I got a set of male and female QA1 rod ends, the XFR8 (female) and the XMR8 (male). I paid just under $14 each for them from a place I found on the net, I can post it if anybody wants to know. Added a jam nut and screwed them together.

These rod ends are Teflon lined and are supposed to keep crap from getting into the ball race. If you believe that one I’ve got a tower in Paris I want to sell you. The only reason I didn't use the Midwest nylon ones is that I wanted to try the teflon as opposed to the nylon liner. My links look exactly the same as the ones froggy showed. Odd that the part numbers are almost the same. Probably all made in the same place in China.....

To keep crap out and lube the rod ends I bought the rod end boots from Midwest for a ˝ inch rod end. Those cost $1.69 each when you buy 10 of them. I had to rework the spacers to insure that the seals worked and didn’t restrict the misalignment of the rod ends. If you just put the seals on the rod ends they will hit the rod end housing. As froggy noted, the standard postitoin has a good bit of misalignment.

If you use too long a spacer between the seal boot and the ball, then the seal won’t hit the housing and seal at high misalignment angles (like we have here). If you don't put in some spacer the washer built into the boot will hit the housing and that will be a mess.

I cut the short spacers in half with a die grinder and ended up with a spacer length of about .060 inches. You still need the long spacer on the bar to keep the rod end from hitting the bar lower edge. When Danny put my T1 links he put the short spacer between the control arm and the end link and the longer one on the back side of end link just to act as a spacer for the nut. This puts some additional angle in the end link, but reduces the misalignment angle and that the rod ends see.

I cut one of the longer spacers in half and used it on each side between the control arm and the end link along with a short (.060 spacer) and the rubber boot. On the other side of the link I put just the small spacer and the rubber boot, and then the nut.

I put grease into the boots and put it all together with short spacers between the ball and the covers.

The rod ends are quiet now, just a matter of seeing how long it will last. I do like the idea of grease and boots, after hearing the clunking for more than a few years I'm done with that and if it helps keep the links from making noise longer then it was worth it.

I did see some boots that fit over the entire rod end. They weren’t cheap, and looked like a PITA to get on, but if I had it to do all over again I’d probably go that way since it wouldn’t have involved cutting the spacers to get the covers into a proper space range, and they would have probably sealed the rod end better.

As you can see, Froggy and I have redone this for less than $100, so obviously you can do this for not much money if you look around a bit. If you have a hundred bucks to blow, pick up the phone wand buy the LG ones.

I got a set of male and female QA1 rod ends, the XFR8 (female) and the XMR8 (male). I paid just under $14 each for them from a place I found on the net, I can post it if anybody wants to know. Added a jam nut and screwed them together.

These rod ends are Teflon lined and are supposed to keep crap from getting into the ball race. If you believe that one I’ve got a tower in Paris I want to sell you. The only reason I didn't use the Midwest nylon ones is that I wanted to try the teflon as opposed to the nylon liner. My links look exactly the same as the ones froggy showed. Odd that the part numbers are almost the same. Probably all made in the same place in China.....

To keep crap out and lube the rod ends I bought the rod end boots from Midwest for a ˝ inch rod end. Those cost $1.69 each when you buy 10 of them. I had to rework the spacers to insure that the seals worked and didn’t restrict the misalignment of the rod ends. If you just put the seals on the rod ends they will hit the rod end housing. As froggy noted, the standard postitoin has a good bit of misalignment.

If you use too long a spacer between the seal boot and the ball, then the seal won’t hit the housing and seal at high misalignment angles (like we have here). If you don't put in some spacer the washer built into the boot will hit the housing and that will be a mess.

I cut the short spacers in half with a die grinder and ended up with a spacer length of about .060 inches. You still need the long spacer on the bar to keep the rod end from hitting the bar lower edge. When Danny put my T1 links he put the short spacer between the control arm and the end link and the longer one on the back side of end link just to act as a spacer for the nut. This puts some additional angle in the end link, but reduces the misalignment angle and that the rod ends see.

I cut one of the longer spacers in half and used it on each side between the control arm and the end link along with a short (.060 spacer) and the rubber boot. On the other side of the link I put just the small spacer and the rubber boot, and then the nut.

I put grease into the boots and put it all together with short spacers between the ball and the covers.

The rod ends are quiet now, just a matter of seeing how long it will last. I do like the idea of grease and boots, after hearing the clunking for more than a few years I'm done with that and if it helps keep the links from making noise longer then it was worth it.

I did see some boots that fit over the entire rod end. They weren’t cheap, and looked like a PITA to get on, but if I had it to do all over again I’d probably go that way since it wouldn’t have involved cutting the spacers to get the covers into a proper space range, and they would have probably sealed the rod end better.

As you can see, Froggy and I have redone this for less than $100, so obviously you can do this for not much money if you look around a bit. If you have a hundred bucks to blow, pick up the phone wand buy the LG ones.

Last edited by Solofast; 11-28-2010 at 08:41 AM.

#12

Burning Brakes

Member Since: Nov 2008

Location: Gaithersburg MD

Posts: 862

Likes: 0

Received 0 Likes

on

0 Posts

QA1 claims:

The TeflonŽ liner in my three piece rod ends always pounds out

when I run my car on dirt, leaving the rod end loose. What can

I do to avoid this?

TeflonŽ "pounding out" on dirt applications is a common problem. It occurs

because the TeflonŽ fabric liner and the three piece design of these rod ends

are not engineered to withstand the introduction of sand, dirt, etc. QA1 has

addressed this problem with the Endura series rod ends, engineered

specifically for racing applications. This series of rod ends includes a selflubricating,

maintenance-free TeflonŽ/KevlarŽ injection-molded liner, and is

constructed in such a manner that it is nearly impossible for the liner to ever

"pound out".

when I run my car on dirt, leaving the rod end loose. What can

I do to avoid this?

TeflonŽ "pounding out" on dirt applications is a common problem. It occurs

because the TeflonŽ fabric liner and the three piece design of these rod ends

are not engineered to withstand the introduction of sand, dirt, etc. QA1 has

addressed this problem with the Endura series rod ends, engineered

specifically for racing applications. This series of rod ends includes a selflubricating,

maintenance-free TeflonŽ/KevlarŽ injection-molded liner, and is

constructed in such a manner that it is nearly impossible for the liner to ever

"pound out".

#13

Melting Slicks

QA1 claims: This series of rod ends includes a selflubricating, maintenance-free TeflonŽ/KevlarŽ injection-molded liner, and is

constructed in such a manner that it is nearly impossible for the liner to ever"pound out".

constructed in such a manner that it is nearly impossible for the liner to ever"pound out".

Note that they say "nearly impossible"... If it was that good they would be offering a guarantee. I don't see that, so who knows.

I just figure that one of the biggest issues with any rod ends is dirt getting in there and after a while the rod end wears and starts clunking. It doesn't take much clearance to allow the rod ends to clunk. The QA1 rod ends are supposed to not need boots, but if you splash road junk on them while driving on the street in the rain, you are going to get grit on them and sooner or later they are going to wear out. That's why I put the boots and grease on mine. Every so often I'll check behind the boots and see if the grease is still there, but for now I think I'm good.

#14

Race Director

Thread Starter

Yea, that's what prompted me to buy them, but...

Note that they say "nearly impossible"... If it was that good they would be offering a guarantee. I don't see that, so who knows.

I just figure that one of the biggest issues with any rod ends is dirt getting in there and after a while the rod end wears and starts clunking. It doesn't take much clearance to allow the rod ends to clunk. The QA1 rod ends are supposed to not need boots, but if you splash road junk on them while driving on the street in the rain, you are going to get grit on them and sooner or later they are going to wear out. That's why I put the boots and grease on mine. Every so often I'll check behind the boots and see if the grease is still there, but for now I think I'm good.

Note that they say "nearly impossible"... If it was that good they would be offering a guarantee. I don't see that, so who knows.

I just figure that one of the biggest issues with any rod ends is dirt getting in there and after a while the rod end wears and starts clunking. It doesn't take much clearance to allow the rod ends to clunk. The QA1 rod ends are supposed to not need boots, but if you splash road junk on them while driving on the street in the rain, you are going to get grit on them and sooner or later they are going to wear out. That's why I put the boots and grease on mine. Every so often I'll check behind the boots and see if the grease is still there, but for now I think I'm good.

I am thinking I may skip the grease (grit magnet) and just wrap the ends with that silicone tape that sticks to itself (Tommy tape/ Rescue Tape). Just to keep the area clean.

Aurora is the "major" company for these, but I googled the web site & the phone number was disconnected. Never a good thing. Anyone know what's up with Aurora?

Anyway it's a good upgrade, not to pricy & seem's like we have got the click figured out at least in the short run.

#15

Melting Slicks

One thing about the misalignment, if you put the tall bushing between the lower control arm and the rod end you will be maxing out the misalignment, but if you put the short bushing between the control arm and the rod end, it angles the rod end like I said. Danny did that when he put mine in and they never reached the end of the misalignment range. As I was putting on the new rod ends I almost screwed up and put the long bushing between the control arm and the rod end and the lower rod end was almost vertical, but the top rod end on the bar was at the very end of the misalignment range. If you use the short one on the lower, both ends have some misalignment, but the top one is a lot less and that's what counts.

#16

Race Director

Thread Starter

One thing about the misalignment, if you put the tall bushing between the lower control arm and the rod end you will be maxing out the misalignment, but if you put the short bushing between the control arm and the rod end, it angles the rod end like I said. Danny did that when he put mine in and they never reached the end of the misalignment range. As I was putting on the new rod ends I almost screwed up and put the long bushing between the control arm and the rod end and the lower rod end was almost vertical, but the top rod end on the bar was at the very end of the misalignment range. If you use the short one on the lower, both ends have some misalignment, but the top one is a lot less and that's what counts.

Do you think this is dependent on which brand of bar is used or do they all have the same shape/curve on the ends?

#17

Race Director

Thread Starter

Here is how I wrapped the Rescue tape & a couple of pics of the old tape I took off. Note there is zero residue, no glue on this stuff & also note how if "fuses" to itself, you don't have to wire or zip tie it to keep it on.

I did not grease them as the nylon will have a certain "slippery effect" to it. I think this is a little easier than trying to fit all those little grease/dirt seals to the part.

I did not grease them as the nylon will have a certain "slippery effect" to it. I think this is a little easier than trying to fit all those little grease/dirt seals to the part.

Last edited by froggy47; 11-28-2010 at 08:19 PM.

#18

Melting Slicks

If the tape stays and doesn't crack you are good to go. What you have done with tape is amost the same as the boots that go over the entire rod end.

#19

Race Director

Thread Starter

I'm just using the stock bars and that's what I'm referring too. If your bars are different than stock your mileage may vary.

If the tape stays and doesn't crack you are good to go. What you have done with tape is amost the same as the boots that go over the entire rod end.

If the tape stays and doesn't crack you are good to go. What you have done with tape is amost the same as the boots that go over the entire rod end.

http://www.rescuetape.com/?gclid=CL7...FQUmbAodR2hgaQ

I blew a coolant hose at one event, 3 inch rip, wrapped it with tape & drove 60 miles home. I kept the hose as a spare the repair was that good.

#20

Race Director

Thread Starter

Update, as soon as I wrapped the links with rescue tape the clunk/knock is back.

Wrapping must have made the clearance smaller to where the link reaches max misalignment and hits itself or maybe I did such a GREAT JOB wrapping that they can't move much now.

Anyway wrap is coming off and I'll run them uncovered & ungreased & see what happens.

Cheap enough to replace now that we have a source for the individual parts instead of a "kit"

I'll post back if/when the noise goes away unwrapped.

BTW you can order these with zerks I believe (and I think the race has a grease groove cut in it).

Wrapping must have made the clearance smaller to where the link reaches max misalignment and hits itself or maybe I did such a GREAT JOB wrapping that they can't move much now.

Anyway wrap is coming off and I'll run them uncovered & ungreased & see what happens.

Cheap enough to replace now that we have a source for the individual parts instead of a "kit"

I'll post back if/when the noise goes away unwrapped.

BTW you can order these with zerks I believe (and I think the race has a grease groove cut in it).

Last edited by froggy47; 12-04-2010 at 08:44 PM.