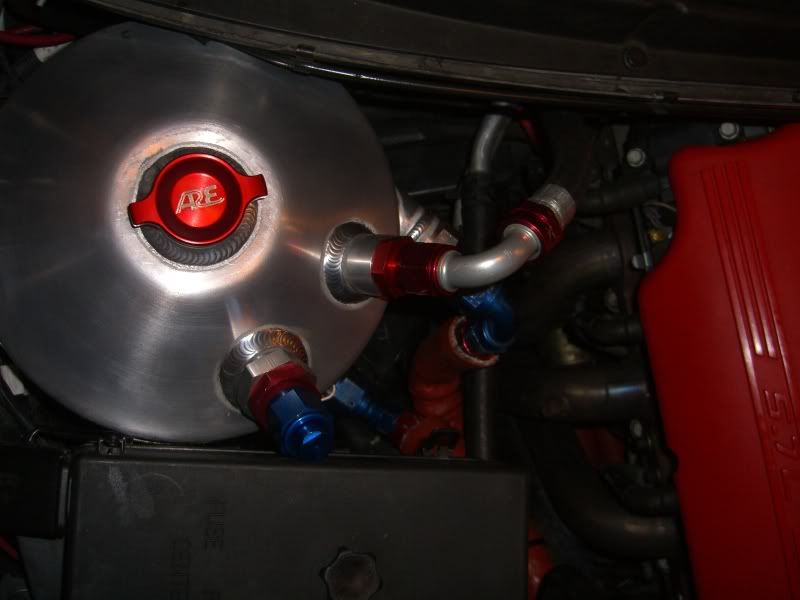

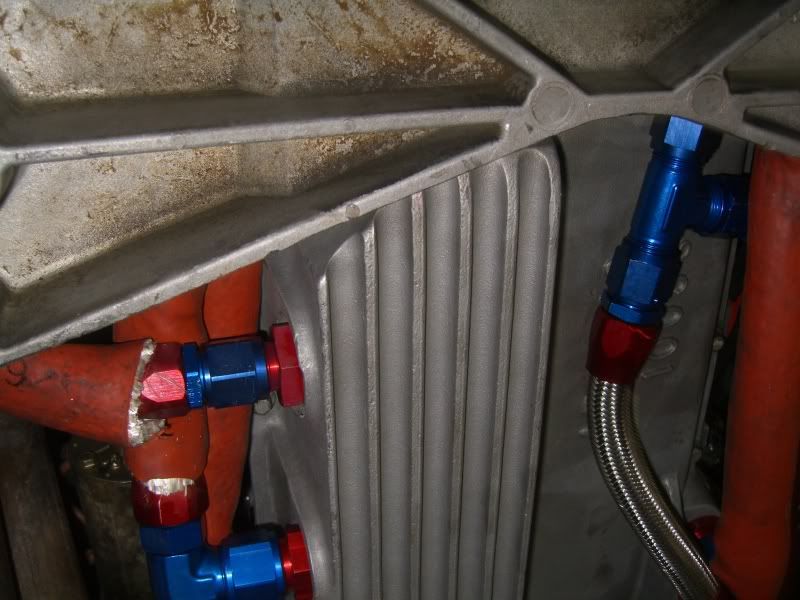

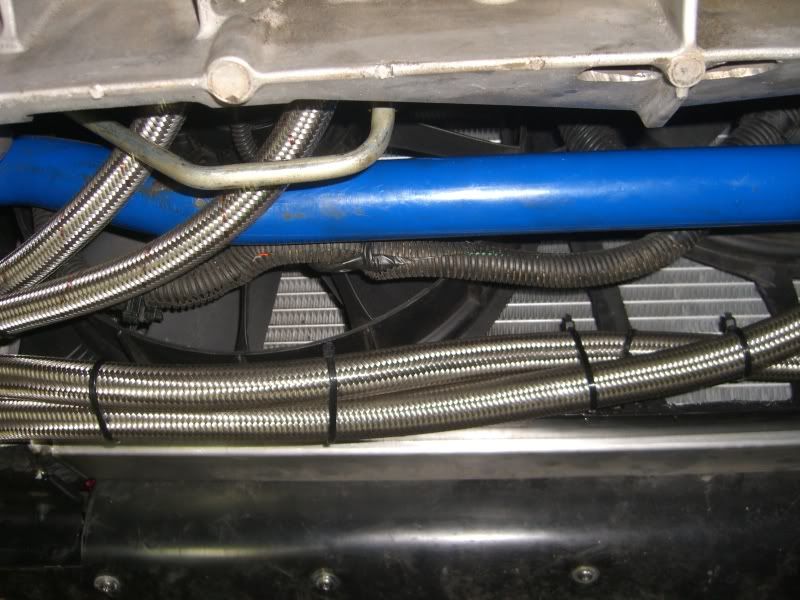

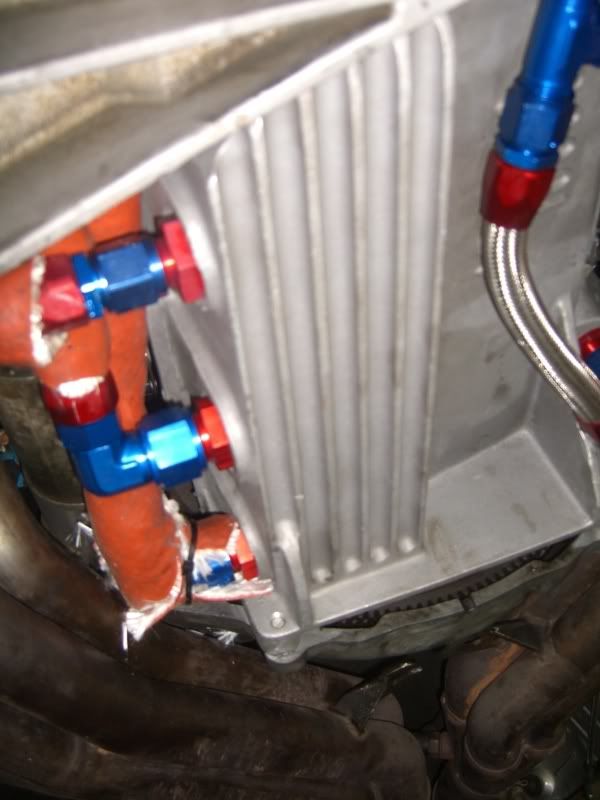

C5 Dry Sump install

#3

Burning Brakes

Nice pics! Sweet looking pump too

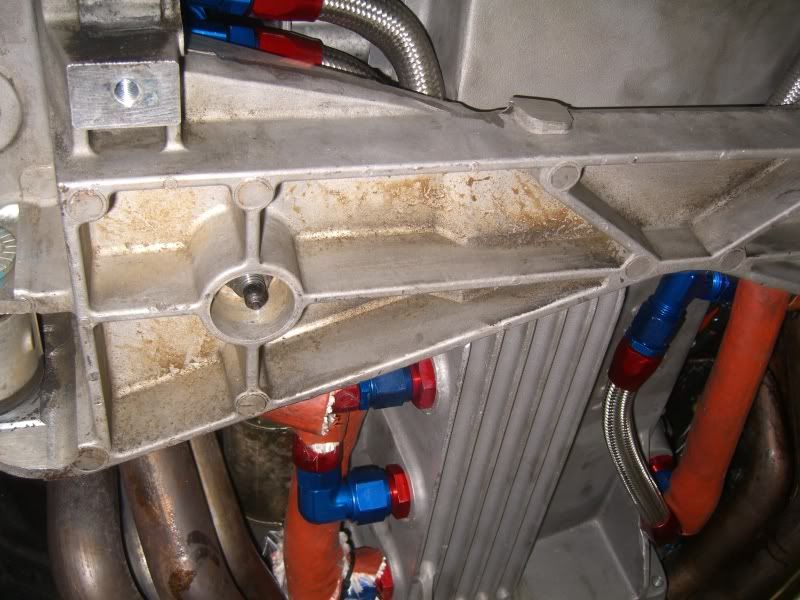

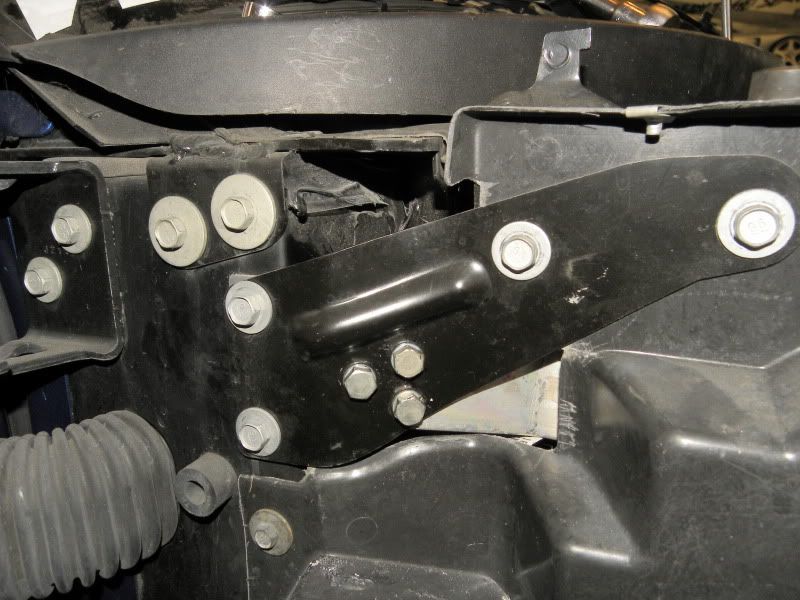

Similar to your pics, I went solid diff on the passenger side (which I may have to monitor for NVH looseness).

I differed from your pics by having a 3 gallon tank set off in my trunk. Which necessitated having the lines hug between engine block and headers, and strap to the torque tube. PITA really. At the point in time where I installed, I had only seen the tanks put in passenger seat location or in the trunk; and I wanted hot oil as far away from me as possible lol.

You trim any of the front subframe assy for install so the lines could clear? What pump model are you running?

Similar to your pics, I went solid diff on the passenger side (which I may have to monitor for NVH looseness).

I differed from your pics by having a 3 gallon tank set off in my trunk. Which necessitated having the lines hug between engine block and headers, and strap to the torque tube. PITA really. At the point in time where I installed, I had only seen the tanks put in passenger seat location or in the trunk; and I wanted hot oil as far away from me as possible lol.

You trim any of the front subframe assy for install so the lines could clear? What pump model are you running?

Last edited by OKsweetrides; 01-18-2011 at 08:36 PM.

#5

Former Vendor

Thread Starter

Randy

#6

Former Vendor

Thread Starter

Nice pics! Sweet looking pump too

Similar to your pics, I went solid diff on the passenger side (which I may have to monitor for NVH looseness).

I differed from your pics by having a 3 gallon tank set off in my trunk. Which necessitated having the lines hug between engine block and headers, and strap to the torque tube. PITA really. At the point in time where I installed, I had only seen the tanks put in passenger seat location or in the trunk; and I wanted hot oil as far away from me as possible lol.

You trim any of the front subframe assy for install so the lines could clear? What pump model are you running?

Similar to your pics, I went solid diff on the passenger side (which I may have to monitor for NVH looseness).

I differed from your pics by having a 3 gallon tank set off in my trunk. Which necessitated having the lines hug between engine block and headers, and strap to the torque tube. PITA really. At the point in time where I installed, I had only seen the tanks put in passenger seat location or in the trunk; and I wanted hot oil as far away from me as possible lol.

You trim any of the front subframe assy for install so the lines could clear? What pump model are you running?

A tick of subframe work was needed.

I will check for a part number in the AM. I just got home

Randy

#8

Melting Slicks

Shortly thereafter yes, the pump on this system pulls all of the oil out of the engine and returns it to the oil tank which in turn gravity feeds the oil pump which is still internal to the motor. So what would happen is that the engine will fill up with oil first and then run out of oil for the pump to feed the bearings.

This whole get-up looks very similiar to mine, engine mounts, KS location and all.....my tank is different and slightly different location , but.....

#9

Former Vendor

Thread Starter

Shortly thereafter yes, the pump on this system pulls all of the oil out of the engine and returns it to the oil tank which in turn gravity feeds the oil pump which is still internal to the motor. So what would happen is that the engine will fill up with oil first and then run out of oil for the pump to feed the bearings.

This whole get-up looks very similiar to mine, engine mounts, KS location and all.....my tank is different and slightly different location , but.....

This whole get-up looks very similiar to mine, engine mounts, KS location and all.....my tank is different and slightly different location , but.....

99 times out of a 100 you will get oil on the windshield with enough time to shut it off. This is one of the main reasons why 95 percent of the time we don't use the dry-sump pump for oil pressure.

99 times out of a 100 you will get oil on the windshield with enough time to shut it off. This is one of the main reasons why 95 percent of the time we don't use the dry-sump pump for oil pressure. Randy

#11

Melting Slicks

You could even wire up an RPM meter and hook it up to your data aq to flash a light if it goes below a certain RPM.

#12

Instructor

Member Since: May 2009

Location: Philly'ish

Posts: 128

Likes: 0

Received 0 Likes

on

0 Posts

Its the first part I'm trying to understand.. why would the windshield get covered in oil if the pump stops due to a broken belt?

John

#13

Melting Slicks

I haven't ever monitored this, but I wander if there is a measurable pressure from the dry sump pump back to the tank that a low pressure hob switch would be able to monitor. If there is the solution to this would be quite simple with an idiot light.

I know that I would feel alot better knowing that the belt fell off/broke before it emptied my tank and possibly sprayed oil all over the windshield.

Additionally on this I was not a big fan of what ARE's only pulley retension methods were, so my pulley got some nylon washers and a bolt and washer on the end of the pump shaft to make sure that the pulley does not wander causing the belt to be launched...I haven't thrown a belt yet.....and dont want to. But if I did I would want to know early as my motor is no $3500 LS6...

I know that I would feel alot better knowing that the belt fell off/broke before it emptied my tank and possibly sprayed oil all over the windshield.

Additionally on this I was not a big fan of what ARE's only pulley retension methods were, so my pulley got some nylon washers and a bolt and washer on the end of the pump shaft to make sure that the pulley does not wander causing the belt to be launched...I haven't thrown a belt yet.....and dont want to. But if I did I would want to know early as my motor is no $3500 LS6...

Last edited by RAFTRACER; 01-19-2011 at 09:29 PM.

#15

Pro

Member Since: Sep 2003

Location: boiling springs sc

Posts: 560

Likes: 0

Received 0 Likes

on

0 Posts

St. Jude Donor '06

I haven't ever monitored this, but I wander if there is a measurable pressure from the dry sump pump back to the tank that a low pressure hob switch would be able to monitor. If there is the solution to this would be quite simple with an idiot light.

I know that I would feel alot better knowing that the belt fell off/broke before it emptied my tank and possibly sprayed oil all over the windshield.

Additionally on this I was not a big fan of what ARE's only pulley retension methods were, so my pulley got some nylon washers and a bolt and washer on the end of the pump shaft to make sure that the pulley does not wander causing the belt to be launched...I haven't thrown a belt yet.....and dont want to. But if I did I would want to know early as my motor is no $3500 LS6...

I know that I would feel alot better knowing that the belt fell off/broke before it emptied my tank and possibly sprayed oil all over the windshield.

Additionally on this I was not a big fan of what ARE's only pulley retension methods were, so my pulley got some nylon washers and a bolt and washer on the end of the pump shaft to make sure that the pulley does not wander causing the belt to be launched...I haven't thrown a belt yet.....and dont want to. But if I did I would want to know early as my motor is no $3500 LS6...

#16

Former Vendor

Thread Starter

Randy, I can understand the second point you made about not using a the sump pump for the pressure side... (belt breaks, no oil pressure, bye-bye engine). The crank driven pump eliminates that issue.

Its the first part I'm trying to understand.. why would the windshield get covered in oil if the pump stops due to a broken belt?

As a new dry sump user (LS2 in an M3), I've been trying to figure out a clever way to do this and I'm surprised no one has an off the shelf solution for dry sump owners. Any one know of one?

John

Its the first part I'm trying to understand.. why would the windshield get covered in oil if the pump stops due to a broken belt?

As a new dry sump user (LS2 in an M3), I've been trying to figure out a clever way to do this and I'm surprised no one has an off the shelf solution for dry sump owners. Any one know of one?

John

Randy

#20

[QUOTE=Wasserott;1576564921]

Would you happen to have the part number of that sump tank?

What is the capacity?

I have a stock LS7 pan with a baffle installed, so I will just have 2 lines, plus the large DRM oil cooler, which will be plumbed into the stock oil filter location.

Where can I get custom lines made?

Thanks for any help I can get.

Would you happen to have the part number of that sump tank?

What is the capacity?

I have a stock LS7 pan with a baffle installed, so I will just have 2 lines, plus the large DRM oil cooler, which will be plumbed into the stock oil filter location.

Where can I get custom lines made?

Thanks for any help I can get.