Finally! a properly build roll bar by Tollefab

#1

Pro

Thread Starter

When I first acquire my Z06 Carbon I thought to myself I should not have any problem finding a properly build roll bar for track. I could not be more wrong. There are many roll bar or "chassis stiffening" bars on the market but they are either build for street or drag racing and if they are for the track I found them to lack some proper design to protect my spine in a case of roll over. What's worst than not having a roll bar in a roll over is to have a poorly engineered metal pipes behind you that could either pierce the floor or becomes a potential dagger pointing at your torso.

I then decided to do this right and commission Mike Tolle at Tollefab to custom make a roll bar that meets SCCA requirement where I can build on the roll bar to a cage in the future if needed. I got to know Mike from Driving Ambition's red twin turbo NSX. It has the best roll cage I have seen other than my GT3 Cup. Shad at Driving Ambition told me when they tech their NSX the inspector will have all the driver gather around their NSX and said "this is how you should build a roll cage!"

What I wanted from this roll bar was the following

Well, I pick up the car today and I was floored by how well the roll bar fits. It is totally functional as a added safety equipment and what an work of art and weigh 45 lbs without mounting hardware which adds another 5 lbs and best of all ... well under $2500

Here is a photo journal of the build.

Removing the interior and getting a proper racing seat

The OMP seat in the Z06 looks great next to my GT3 Cup

Mike prepping the floor at the trunk and B-pillar to accept the bolt on roll bar

Mike welded in attachment points on the bottom of B-pillar for maximum strength

Tig welded custom foot plates for the floor of the B-pillar

Roll bar attachment at foot of B-pillar

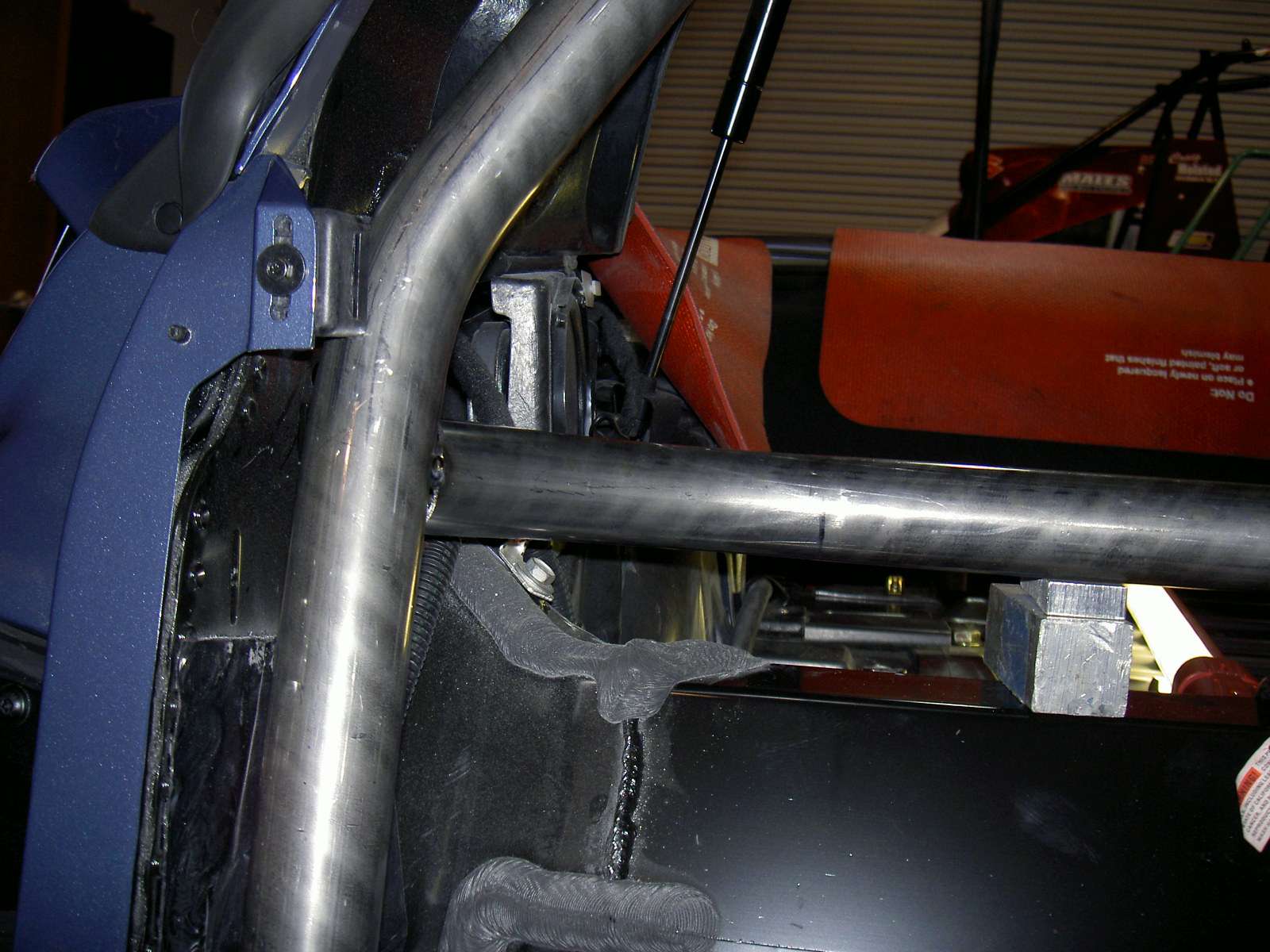

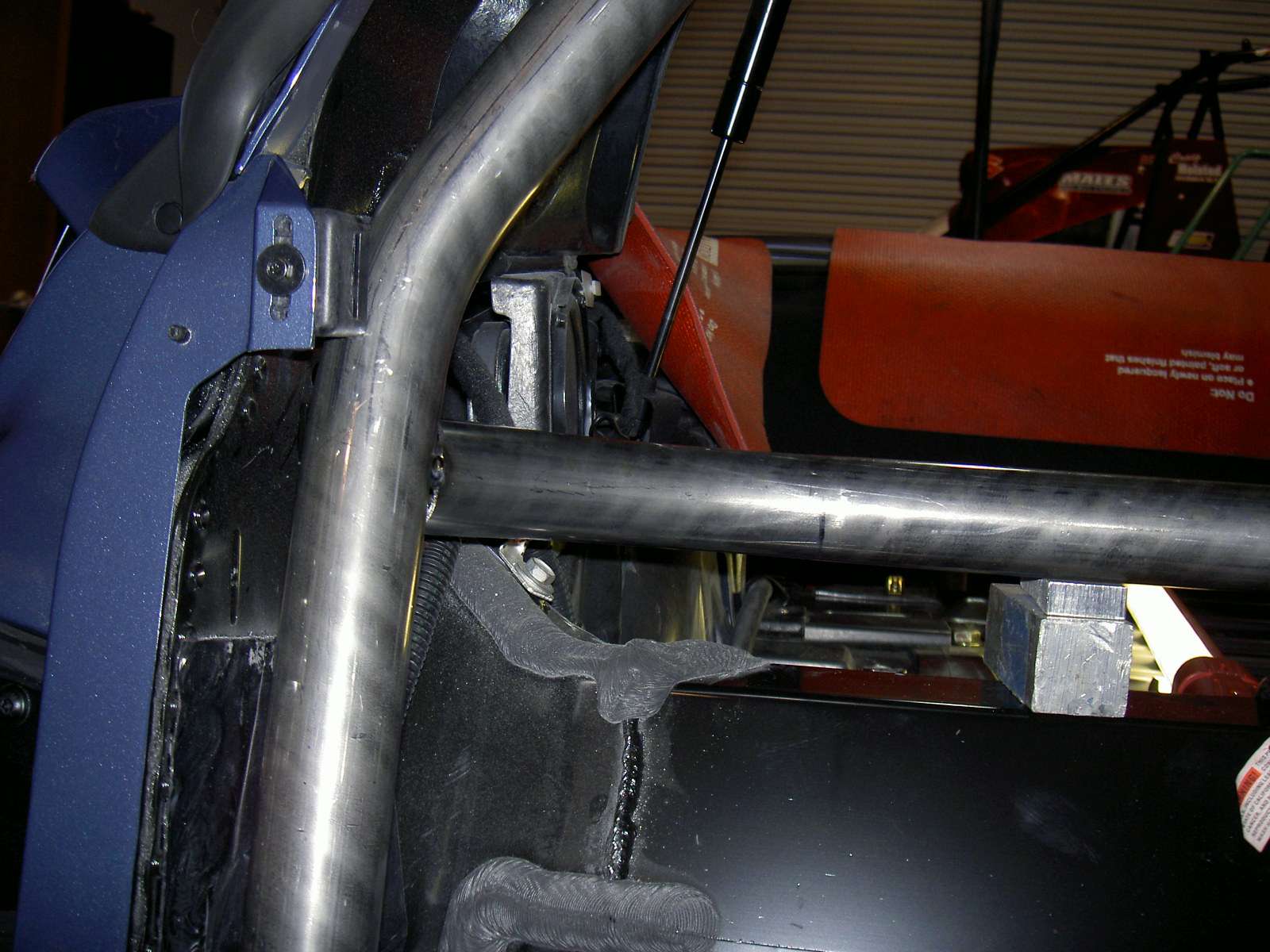

Tight clearance of the roll bar and it has to be the right distance to the back of my OMP chair

Clearance check from the back. Trunk supporting bars are bolt on to the main hoop. Tig welds was completed once roll bars are removed from the inside of the car

Finished products and powder coat to black. What a great looking roll bar

It looks stunning in the car and there are no noise while driving. I can't be more pleased and can't wait to take her on the track. Thanks again Mike for completing the project in less than 2 weeks and under budget.

I then decided to do this right and commission Mike Tolle at Tollefab to custom make a roll bar that meets SCCA requirement where I can build on the roll bar to a cage in the future if needed. I got to know Mike from Driving Ambition's red twin turbo NSX. It has the best roll cage I have seen other than my GT3 Cup. Shad at Driving Ambition told me when they tech their NSX the inspector will have all the driver gather around their NSX and said "this is how you should build a roll cage!"

What I wanted from this roll bar was the following

- Functional safety roll bar

- Use the best material for roll bar/cage which is mild steel

- Not heavy

- Not intrude on rear view or the cabin

- Bolt in design, tig weld and a work of art

- Budget under $2500 all said and done

Well, I pick up the car today and I was floored by how well the roll bar fits. It is totally functional as a added safety equipment and what an work of art and weigh 45 lbs without mounting hardware which adds another 5 lbs and best of all ... well under $2500

Here is a photo journal of the build.

Removing the interior and getting a proper racing seat

The OMP seat in the Z06 looks great next to my GT3 Cup

Mike prepping the floor at the trunk and B-pillar to accept the bolt on roll bar

Mike welded in attachment points on the bottom of B-pillar for maximum strength

Tig welded custom foot plates for the floor of the B-pillar

Roll bar attachment at foot of B-pillar

Tight clearance of the roll bar and it has to be the right distance to the back of my OMP chair

Clearance check from the back. Trunk supporting bars are bolt on to the main hoop. Tig welds was completed once roll bars are removed from the inside of the car

Finished products and powder coat to black. What a great looking roll bar

It looks stunning in the car and there are no noise while driving. I can't be more pleased and can't wait to take her on the track. Thanks again Mike for completing the project in less than 2 weeks and under budget.

#2

Burning Brakes

looks like first class work, but I have a question about the rear down bars. Doesn't the SCCA require that if the rear bars bolt on that they have two bolts in each tube?

Dave

Dave

#3

Race Director

I also have a concern about how the main hoop attaches to the frame, I hope those bolts go all the way through, not just screw into the inner sidewall.

Also, the really tall guys would need a bar that goes through the bulkhead, not in front of it.

Very nice setup though, albeit pricey. I'd just do a local fab before spending that kind of money on a 4-pt setup. I DO think there is a DEMAND for something like this though..........

Also, the really tall guys would need a bar that goes through the bulkhead, not in front of it.

Very nice setup though, albeit pricey. I'd just do a local fab before spending that kind of money on a 4-pt setup. I DO think there is a DEMAND for something like this though..........

#5

Safety Car

Not sure I like that... I mean it looks good, but it seems like it could still tear out and punch through in a real roll-over.

Not sure I like that... I mean it looks good, but it seems like it could still tear out and punch through in a real roll-over.There aren't many good ways to put a bar in one of these ars w/o cutting it up

#6

Melting Slicks

#7

Melting Slicks

Also, correct, Tom.

And you can't tell from the pics but the mounting plates and the backup (sandwitch) plates must be 3/16ths min.

Also, (but may not be shown in the pics), there is no inspection hole in the main hoop.

The bottom line is that this bar will not pass SCCA tech for Time Trials.

The car can be run in Club Trials (which is for street cars) and PDX (HPDE) but since it is a coupe, there is no rollbar requirement.

And you can't tell from the pics but the mounting plates and the backup (sandwitch) plates must be 3/16ths min.

Also, (but may not be shown in the pics), there is no inspection hole in the main hoop.

The bottom line is that this bar will not pass SCCA tech for Time Trials.

The car can be run in Club Trials (which is for street cars) and PDX (HPDE) but since it is a coupe, there is no rollbar requirement.

#9

Safety Car

No need to drill holese these days. When I had my cage inspected at VIR for my annual tech the NASA-MA crew had a digital thickness gauge that was accurate enough to tell me how many mils of paint I had put on.

#10

Pro

Thread Starter

Yes, there are sandwich plates for the rear down tubes and I will be surprised if ths rooll bar does not pass tech. The pictures I shown does nto include all the back ground work to ensure proper mounting. It is a super solid build but I will defer all tech questions to Mike Tolle. He can be reached at 916-524-5315. He insisted on building the roll bar per SCCA regulation be it thickness of tube, weld or attachment points

#11

Melting Slicks

Yes, there are sandwich plates for the rear down tubes and I will be surprised if ths rooll bar does not pass tech. The pictures I shown does nto include all the back ground work to ensure proper mounting. It is a super solid build but I will defer all tech questions to Mike Tolle. He can be reached at 916-524-5315. He insisted on building the roll bar per SCCA regulation be it thickness of tube, weld or attachment points

They may be, if so, the bar probably will pass Time Trials tech provided that the mounting plate thickness is to the GCR.

I'm not judging the quality of the build.

#12

Melting Slicks

And I haven't looked at NASA rules in quite a while.

However, the SCCA rules still require the hole.

That's also understandable as not all SCCA regions have the digital gauge.

It's possible that NASA has that requirement for their "Tech Box" , at this time SCCA does not (we're still using a digital caliper).

#13

Melting Slicks

Pics for the double lug are in the GCR pages 110 & 111.

SCCA Time Trials rules just call for the double lug and do not show the pics.

#14

Race Director

I don't consider it "floor mounted" like those Drag-racing kits on ebay, and I've used similar angle-iron methods for mounting main hoops. But the frame-rail must be sandwiched. Perhaps they threaded the inner side of the rail, but the bolt also goes all the way through and is reinforced/bolted on the outer surface as well.

I like the design, but it is difficult in these cars. It's hard to access the outer frame rail without cutting at least a bit of the rocker panel.

I like the design, but it is difficult in these cars. It's hard to access the outer frame rail without cutting at least a bit of the rocker panel.

#16

where can you buy those double lugs for bolt in cages? anyone??? I say nice looking job except the harness bar looks low relative to the seat holesbut maybe it is just the picture. This builder does some really nice work. I like his level of precision and how he properly fishmouths the tubing . I hate it when builders fill up the fishmouth with MIG weld and hide sloppy work.

#17

many of the off road shops offer some nice fabrication parts. These are not the clevis style, but are well done:

http://www.ballisticfabrication.com/...mp_p_1467.html

They can be weak if a load is applied from the side so that only the bolts and friction are holding everything together. What I would do, in the case above is install one side pair (top and bottom) perpendicular to the opposing side and after its all in weld an X in between the down bars to hold everything together. For installation the assembly would need to be rotated into place.

For the clevis style this is one option commonly used on swing out door bars for the street/drag cars. http://www.appliedracing.com/roll-ba...vis-mount.html

The slot in the clevis and the male piece would need to be appropriately sized. It doesn't say in the description what it is.

http://www.ballisticfabrication.com/...mp_p_1467.html

They can be weak if a load is applied from the side so that only the bolts and friction are holding everything together. What I would do, in the case above is install one side pair (top and bottom) perpendicular to the opposing side and after its all in weld an X in between the down bars to hold everything together. For installation the assembly would need to be rotated into place.

For the clevis style this is one option commonly used on swing out door bars for the street/drag cars. http://www.appliedracing.com/roll-ba...vis-mount.html

The slot in the clevis and the male piece would need to be appropriately sized. It doesn't say in the description what it is.

Last edited by trackboss; 03-02-2012 at 05:09 AM.

#18

Safety Car

http://www.schrothracing.com/sdocs/2...structions.pdf