'01 LS6 Tear Down - Piston Damage (pics)

#1

Racer

Thread Starter

Here are a few pictures of my engine tear down. 2001 LS6 Corvette, 23k miles, with about 15k miles in HPDE / Road Racing. Motor is stock, stock induction system, Kooks headers, and a lightweight Quartermaster clutch. Tuned to 375 rwhp. This is my first time getting deep into the motor Ė so Iíd welcome any assessments or recommendations from those with more experience.

Problem: While driving on the track I had high oil consumption and oil smoke out the tailpipe on deceleration at the end of the straight. Problem was getting progressively worse (frequency and volume of smoke). No noticeable decrease in power or engine performance.

I did a leakdown test on all cylinders. Cylinder #7 was 92% leakdown. Pulled the heads and had them checked Ė everything was fine. Close up examination of the piston face #7 showed a very slight amount of material missing at about 10 oíclock (see picture). Decided I most likely had a ring problem and decided to pull all the pistons to further examine.

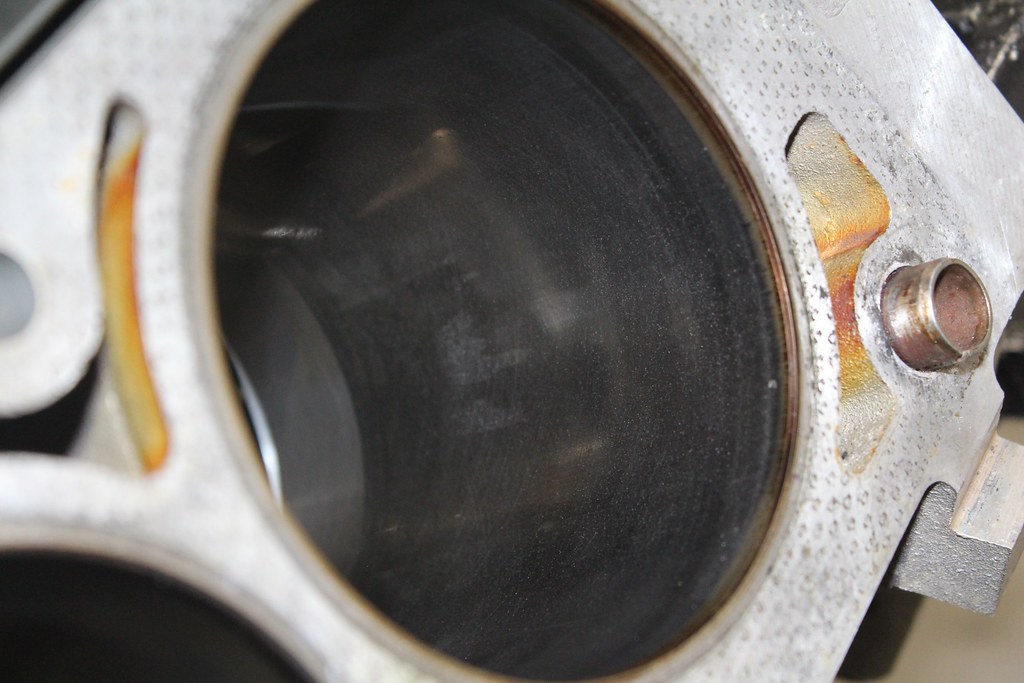

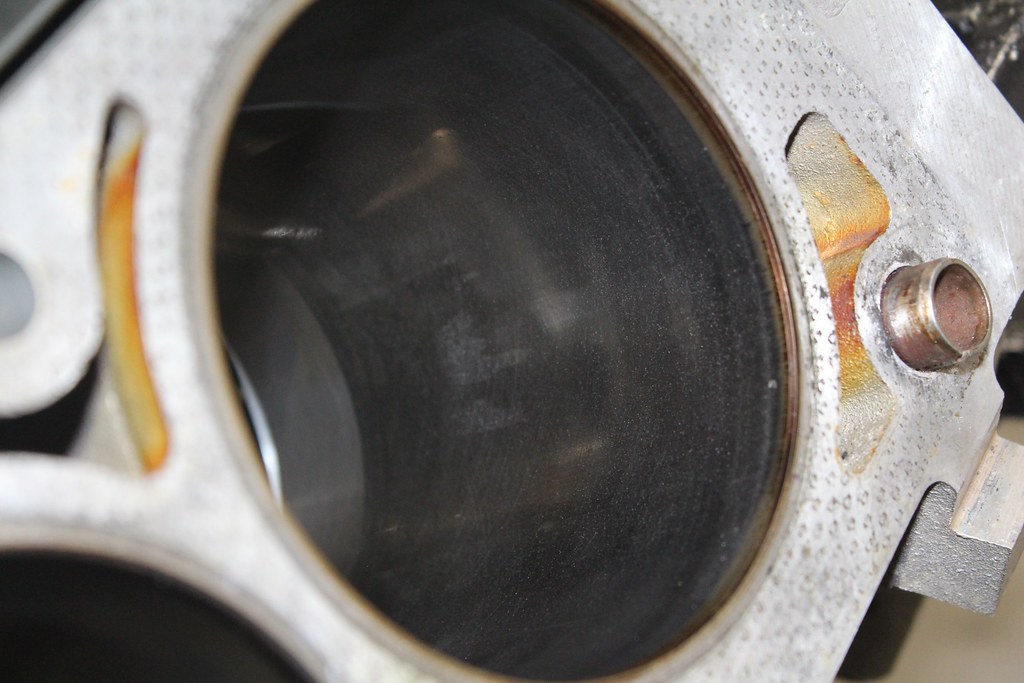

#7 Piston Face in cylinder bore by go blue vettes, on Flickr

#7 Piston Face in cylinder bore by go blue vettes, on Flickr

#7 Piston Face by go blue vettes, on Flickr

#7 Piston Face by go blue vettes, on Flickr

#7 Piston Damage by go blue vettes, on Flickr

#7 Piston Damage by go blue vettes, on Flickr

Result: Insides of the motor looked remarkably clean. Pistons #1-#6, and #8 all had some carbon buildup, but generally look to be in good shape. Piston #7 is pictured below. The top compression ring was still intact, but the second ring, top of the oil control ring, and a chunk of the piston (right in the 10 oíclock area) are damaged. Iím amazed that the engine ran as well as it did with so much metal coming off the piston. I cut open the oil filter and there were some tiny chunks of metal and some quicksilver looking oil (Wix Filter). When draining the oil from the motor, I carefully examined it. No chunks, no metal bits, no quicksilver at all, very uneventful.

#7 Piston Pulled by go blue vettes, on Flickr

#7 Piston Pulled by go blue vettes, on Flickr

#7 Piston with second ring chewed up by go blue vettes, on Flickr

#7 Piston with second ring chewed up by go blue vettes, on Flickr

Bits of the second ring from #7 - worn down like river rocks by go blue vettes, on Flickr

Bits of the second ring from #7 - worn down like river rocks by go blue vettes, on Flickr

Untitled by go blue vettes, on Flickr

Untitled by go blue vettes, on Flickr

#7 Cylinder Bore by go blue vettes, on Flickr

#7 Cylinder Bore by go blue vettes, on Flickr

#5 Cylinder Bore by go blue vettes, on Flickr

#5 Cylinder Bore by go blue vettes, on Flickr

#7 Cylinder bore, away from damaged ring by go blue vettes, on Flickr

#7 Cylinder bore, away from damaged ring by go blue vettes, on Flickr

Examining the #7 cylinder bore, in the same area as ring/piston damage, there are some vertical wear marks (pictured) that disturb the cross hatch pattern. Rubbing a bare finger over the entire area and the entire cylinder, I canít feel any kind of ridges or scratches. It is completely smooth.

Now Iím at the decision point for rebuild. Minimum actions I plan to take are:

1. Replace all rings

2. Replace #7 piston

3. Replace rod bearings

4. New LS7 lifters

5. New LS3 springs

6. New valve stem seals

7. New gaskets

Since Iím this far into the motor, additional items Iím considering to do are:

1. ARP Rod bolts

2. Pull the crank, inspect, replace main bearings, new rear seal

3. Upgrade oil pump or port existing oil pump

4. Replace timing chain and gear

5. Maybe put in a new cam to increase torque from 4k-5.5k rpm. I donít need any more peak HP.

6. Have the block checked out by a engine builder

7. Hone #7 or all cylinders if necessary (not sure if its needed)

Should I do my minimum list, get back on the track and thrash the motor until it pops? Or do a more complete rebuild with additional upgrades and hope for some additional longevityÖ Opinions?

Problem: While driving on the track I had high oil consumption and oil smoke out the tailpipe on deceleration at the end of the straight. Problem was getting progressively worse (frequency and volume of smoke). No noticeable decrease in power or engine performance.

I did a leakdown test on all cylinders. Cylinder #7 was 92% leakdown. Pulled the heads and had them checked Ė everything was fine. Close up examination of the piston face #7 showed a very slight amount of material missing at about 10 oíclock (see picture). Decided I most likely had a ring problem and decided to pull all the pistons to further examine.

#7 Piston Face in cylinder bore by go blue vettes, on Flickr

#7 Piston Face in cylinder bore by go blue vettes, on Flickr #7 Piston Face by go blue vettes, on Flickr

#7 Piston Face by go blue vettes, on Flickr #7 Piston Damage by go blue vettes, on Flickr

#7 Piston Damage by go blue vettes, on FlickrResult: Insides of the motor looked remarkably clean. Pistons #1-#6, and #8 all had some carbon buildup, but generally look to be in good shape. Piston #7 is pictured below. The top compression ring was still intact, but the second ring, top of the oil control ring, and a chunk of the piston (right in the 10 oíclock area) are damaged. Iím amazed that the engine ran as well as it did with so much metal coming off the piston. I cut open the oil filter and there were some tiny chunks of metal and some quicksilver looking oil (Wix Filter). When draining the oil from the motor, I carefully examined it. No chunks, no metal bits, no quicksilver at all, very uneventful.

#7 Piston Pulled by go blue vettes, on Flickr

#7 Piston Pulled by go blue vettes, on Flickr #7 Piston with second ring chewed up by go blue vettes, on Flickr

#7 Piston with second ring chewed up by go blue vettes, on Flickr Bits of the second ring from #7 - worn down like river rocks by go blue vettes, on Flickr

Bits of the second ring from #7 - worn down like river rocks by go blue vettes, on Flickr Untitled by go blue vettes, on Flickr

Untitled by go blue vettes, on Flickr #7 Cylinder Bore by go blue vettes, on Flickr

#7 Cylinder Bore by go blue vettes, on Flickr #5 Cylinder Bore by go blue vettes, on Flickr

#5 Cylinder Bore by go blue vettes, on Flickr #7 Cylinder bore, away from damaged ring by go blue vettes, on Flickr

#7 Cylinder bore, away from damaged ring by go blue vettes, on FlickrExamining the #7 cylinder bore, in the same area as ring/piston damage, there are some vertical wear marks (pictured) that disturb the cross hatch pattern. Rubbing a bare finger over the entire area and the entire cylinder, I canít feel any kind of ridges or scratches. It is completely smooth.

Now Iím at the decision point for rebuild. Minimum actions I plan to take are:

1. Replace all rings

2. Replace #7 piston

3. Replace rod bearings

4. New LS7 lifters

5. New LS3 springs

6. New valve stem seals

7. New gaskets

Since Iím this far into the motor, additional items Iím considering to do are:

1. ARP Rod bolts

2. Pull the crank, inspect, replace main bearings, new rear seal

3. Upgrade oil pump or port existing oil pump

4. Replace timing chain and gear

5. Maybe put in a new cam to increase torque from 4k-5.5k rpm. I donít need any more peak HP.

6. Have the block checked out by a engine builder

7. Hone #7 or all cylinders if necessary (not sure if its needed)

Should I do my minimum list, get back on the track and thrash the motor until it pops? Or do a more complete rebuild with additional upgrades and hope for some additional longevityÖ Opinions?

#2

Race Director

Member Since: Oct 2000

Location: Deal's Gap 2004 NCM Motorsports track supporter

Posts: 13,915

Received 1,103 Likes

on

717 Posts

#7 is the leanest. Mine traveled through the whole engine. Make sure the AFR is conservative and/or put a larger injector in that one cylinder. My whole engine was trash except for camshaft. Other than that, the LS6 is great. Just tune conservatively.

#3

Drifting

Be sure to get #7 bore checked out before committing to re-use of that block.

Last edited by C5ZEE06; 01-10-2015 at 02:09 PM.

#5

I'd definitely be putting either a new or upgraded oil pump on it, especially as some metal was found in the filter (and obviously missing from cyl #7). Your pump my not be at 100% anymore and with the track duty seems like a no brainer not to carry that part over IMHO.

My opinion may be biased as last summer I wrecked my LS7 due to a failing/failed pump. Track/street duty Z06, lost oil pressure at the track about 10 seconds after hearing heavy knocking. When we pulled the short block apart most of the bearings were done, mains, cam bearings and the inside of the pump was very worn. Chunky metal deposits in the oil and lots of sparkle, not good. Whether the metal from the bearings foiled the pump, or the pump wasn't 100% when I needed it to be and the bearings weren't getting the required oiling, who knows. I bought a new short block and slapped a Katech red pump on it with the LS9 sprocket. Hopefully some insurance for the new motor.

My opinion may be biased as last summer I wrecked my LS7 due to a failing/failed pump. Track/street duty Z06, lost oil pressure at the track about 10 seconds after hearing heavy knocking. When we pulled the short block apart most of the bearings were done, mains, cam bearings and the inside of the pump was very worn. Chunky metal deposits in the oil and lots of sparkle, not good. Whether the metal from the bearings foiled the pump, or the pump wasn't 100% when I needed it to be and the bearings weren't getting the required oiling, who knows. I bought a new short block and slapped a Katech red pump on it with the LS9 sprocket. Hopefully some insurance for the new motor.

Last edited by Phoenix1911; 01-10-2015 at 09:37 PM.

#6

Racer

Thread Starter

Thanks for the replies so far.

Any opinions on the wear marks in the #7 cylinder? hone or not to hone?

Do I need to pull the main bearings given the wear in the motor?

Any opinions on the wear marks in the #7 cylinder? hone or not to hone?

Do I need to pull the main bearings given the wear in the motor?

#7

Safety Car

As mentioned, ensure that the scratches in #7 are not too deep before doing anything else. If they are ok, get all cylinders honed, new rings and bearings all around.

You can put in a Katech blueprinted oil pump if you are so inclined, but I would definitely replace it as well.

You can put in a Katech blueprinted oil pump if you are so inclined, but I would definitely replace it as well.

#8

Racer

Thread Starter

As mentioned, ensure that the scratches in #7 are not too deep before doing anything else. If they are ok, get all cylinders honed, new rings and bearings all around.

You can put in a Katech blueprinted oil pump if you are so inclined, but I would definitely replace it as well.

You can put in a Katech blueprinted oil pump if you are so inclined, but I would definitely replace it as well.

I can see the scratches, but running my bare fingers in both cylinder #7 and the other cylinders, I can't tell the difference.

I suppose I could buy a mic set and try to measure bore diameters where the scratches are and compare to that of the other areas. Not sure how to define an acceptance criterion....

#10

Instructor

Not sure if this was implied or not in your mention of replacing the rod bearings, but you'll want to hone the big ends of the connecting rods when you have that done. The big end on powdered metal rods generally isn't round after you pull it apart and put it back together, no matter how careful you are with the rod/cap interface. Make sure you have them honed with the fasteners you will use for final assembly, torqued to spec.

#11

Racer

Thread Starter

Not sure if this was implied or not in your mention of replacing the rod bearings, but you'll want to hone the big ends of the connecting rods when you have that done. The big end on powdered metal rods generally isn't round after you pull it apart and put it back together, no matter how careful you are with the rod/cap interface. Make sure you have them honed with the fasteners you will use for final assembly, torqued to spec.

#12

Instructor

Good luck!

#13

Drifting

bring the block to a shop for evaluation.

When you have details on the cylinder size and roundness you can start a cost estimate.

It may end up that a LS3 crate with a 24 tooth wheel is the same price as the work and parts required to make this engine right.

When you have details on the cylinder size and roundness you can start a cost estimate.

It may end up that a LS3 crate with a 24 tooth wheel is the same price as the work and parts required to make this engine right.

#14

Racer

Kurt Urban, TFS, and others sell a steam crossover kit for the back. That's the fix for number 7. AFR is part of it, but small waterjacketing around the rear is the bigger one.

I just had #7 go as well after several years of beating on it. I was also doing some extremely aggressive VE calibration at WOT and high RPM in early 2014 and this sped it's demise.

I just had #7 go as well after several years of beating on it. I was also doing some extremely aggressive VE calibration at WOT and high RPM in early 2014 and this sped it's demise.

#15

Racer

Thread Starter

Kurt Urban, TFS, and others sell a steam crossover kit for the back. That's the fix for number 7. AFR is part of it, but small waterjacketing around the rear is the bigger one.

I just had #7 go as well after several years of beating on it. I was also doing some extremely aggressive VE calibration at WOT and high RPM in early 2014 and this sped it's demise.

I just had #7 go as well after several years of beating on it. I was also doing some extremely aggressive VE calibration at WOT and high RPM in early 2014 and this sped it's demise.

Were you doing tuning using the torque control feature to limit peak HP at some point of power band?

#16

Racer

Nope, no torque control action up until this point. It's something I've been interested in playing with, but I have other issues to sort through first with my new engine.

#19

FWIW I run the LS4 high volume pump with the lower 42 psi relief spring. Basically the same as the Melling high volume pump and others, but it's only like $80 from GM. Car never drops below 50 psi even when the oil is hot racing in the summer. I run Amsoil 10w40 and a K&N racing oil filter.

That has to be over 400 hours track time Holy smokes that is fantastic!

That has to be over 400 hours track time Holy smokes that is fantastic!