Trans pilot bearing

#21

Hey Alex.

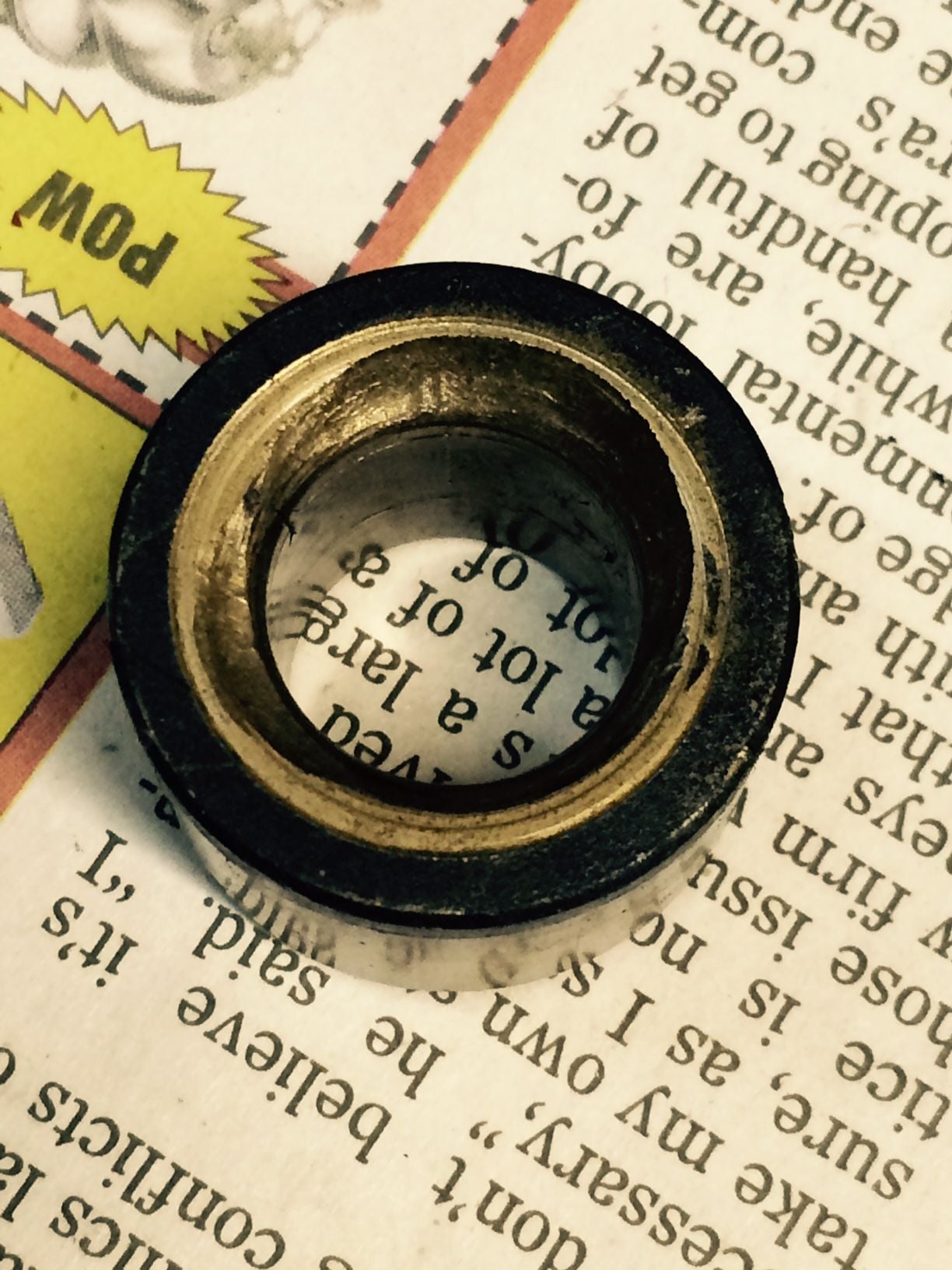

You can see the bushing is worn unevenly between the 6 and 9 o' clock positions. If you've had the car together and running for a long time, and there were no shift issues from 3rd to 4th gear, then it might be okay to do the same.

IF your input gear was worn out, or you had 3 - 4 shift issues, then I would be willing to say that the bellhousing is 'out' a little too far. Acceptable bellhousing runout is +/- .010.

We should have more Oilite bushings in stock by this time ext week. If you need it sooner, grab a small magnet and head to your local Napa. Pioneer HD are okay as far as size, but Id still check with a magnet. Make sure that the chamfer on the ID faces OUT, this chamfer is to help install the input gear.

Here is a tutorial on bellhousing alignment:

You can see the bushing is worn unevenly between the 6 and 9 o' clock positions. If you've had the car together and running for a long time, and there were no shift issues from 3rd to 4th gear, then it might be okay to do the same.

IF your input gear was worn out, or you had 3 - 4 shift issues, then I would be willing to say that the bellhousing is 'out' a little too far. Acceptable bellhousing runout is +/- .010.

We should have more Oilite bushings in stock by this time ext week. If you need it sooner, grab a small magnet and head to your local Napa. Pioneer HD are okay as far as size, but Id still check with a magnet. Make sure that the chamfer on the ID faces OUT, this chamfer is to help install the input gear.

Here is a tutorial on bellhousing alignment:

#22

The clutch disk spline does not need grease. In turn the grease will and up on the clutch disk.

If the pilot bushings ware is as bad as it looks to me. I would have some one check out the input shaft mating surface to the pilot bushing along with the front input shaft bearing of the trans..

Is that your crankshaft or a replacement part?

If the pilot bushings ware is as bad as it looks to me. I would have some one check out the input shaft mating surface to the pilot bushing along with the front input shaft bearing of the trans..

Is that your crankshaft or a replacement part?

#23

Pro

Thread Starter

Excellent question - take the new bushing and put it in your coldest deep freeze for a day. Get everything prepared - clean out the crank recess, determine what you are going to use to set it with - the bottom end of a large socket works or a large wooden dowel. The chamfer on the bushing hole goes to the outside when installed. Very lightly lube the crank recess, pull the bushing out of the deep freeze, and as quickly as possible drive it into the end of the crank. It should go in without a lot of effort but make sure it's seated all the way in.

It's always a good idea to check the alignment of the bellhousing but from my limited experience and what I've read on here, the GM factory bellhousing is usually dialed in reasonably close. With a bushing it's not as critical. If you were planning to run a pilot bearing in the end of the crank it would pretty much be mandatory to dial it in.

It's always a good idea to check the alignment of the bellhousing but from my limited experience and what I've read on here, the GM factory bellhousing is usually dialed in reasonably close. With a bushing it's not as critical. If you were planning to run a pilot bearing in the end of the crank it would pretty much be mandatory to dial it in.

Thanks for the cryogenic method tip; makes sense. As I said earlier, I'm not attempting the alignment exercise you mention. By your great pictures, I see how and what you're taking about. Thanks.

#24

Safety Car

Little bugger popped right out. Got some runout and I don't know how to read it.

Thanks for the cryogenic method tip; makes sense. As I said earlier, I'm not attempting the alignment exercise you mention. By your great pictures, I see how and what you're taking about. Thanks.

Thanks for the cryogenic method tip; makes sense. As I said earlier, I'm not attempting the alignment exercise you mention. By your great pictures, I see how and what you're taking about. Thanks.

Never mind the grease, this photo is of my needle bearing pilot for a RS600 trans.

Last edited by 65tripleblack; 07-02-2015 at 11:32 AM.

#25

Pro

Thread Starter

The clutch disk spline does not need grease. In turn the grease will and up on the clutch disk.

If the pilot bushings ware is as bad as it looks to me. I would have some one check out the input shaft mating surface to the pilot bushing along with the front input shaft bearing of the trans..

Is that your crankshaft or a replacement part?

If the pilot bushings ware is as bad as it looks to me. I would have some one check out the input shaft mating surface to the pilot bushing along with the front input shaft bearing of the trans..

Is that your crankshaft or a replacement part?

#27

Pro

Thread Starter

Hey Alex.

You can see the bushing is worn unevenly between the 6 and 9 o' clock positions. If you've had the car together and running for a long time, and there were no shift issues from 3rd to 4th gear, then it might be okay to do the same.

IF your input gear was worn out, or you had 3 - 4 shift issues, then I would be willing to say that the bellhousing is 'out' a little too far. Acceptable bellhousing runout is +/- .010.

We should have more Oilite bushings in stock by this time ext week. If you need it sooner, grab a small magnet and head to your local Napa. Pioneer HD are okay as far as size, but Id still check with a magnet. Make sure that the chamfer on the ID faces OUT, this chamfer is to help install the input gear.

Here is a tutorial on bellhousing alignment:

Part 17 How To Align The Bellhousing Using Offset Dowel Pins For The Big Block Chevy - YouTube

You can see the bushing is worn unevenly between the 6 and 9 o' clock positions. If you've had the car together and running for a long time, and there were no shift issues from 3rd to 4th gear, then it might be okay to do the same.

IF your input gear was worn out, or you had 3 - 4 shift issues, then I would be willing to say that the bellhousing is 'out' a little too far. Acceptable bellhousing runout is +/- .010.

We should have more Oilite bushings in stock by this time ext week. If you need it sooner, grab a small magnet and head to your local Napa. Pioneer HD are okay as far as size, but Id still check with a magnet. Make sure that the chamfer on the ID faces OUT, this chamfer is to help install the input gear.

Here is a tutorial on bellhousing alignment:

Part 17 How To Align The Bellhousing Using Offset Dowel Pins For The Big Block Chevy - YouTube

My confidence with the rebuilder is not where it should be. I really did my homework on this rebuild, choosing someone who had a good reputation, a great shop and sounded like they'd GAS about my project. I know things happen, I get that. The pilot bearing is a small thing but when combined with other issues, leave me with a feeling I didn't get what I asked and paid for. I have no idea how well either the engine or the trans will perform. This is exactly where I did not want to be after 5K, days of lost work and 1,000+ miles of travel. However, in the end, I will get this right.

#28

Pro

Thread Starter

Pilot shaft was not fully engaged with the bushing. How far in was that bushing driven? It should be flush with the crank. Take a picture of the input shaft on the trans and post it.

Never mind the grease, this photo is of my needle bearing pilot for a RS600 trans.

Never mind the grease, this photo is of my needle bearing pilot for a RS600 trans.

Input shaft has some wiggle to it. Is this acceptable?

Last edited by Spike66; 07-02-2015 at 12:17 PM. Reason: more info

#30

Le Mans Master

Alex - As TripleBlack mentioned, from the serious wear on your old bushing, it seems that it was never fully inserted into the back of the crank, is that what you noticed before you pulled it out or was it 'almost' all the way in? Did you have any trans or shifting problems prior to this work being done, if not, maybe this 'gouged' bushing has been in there for a long time and the damage occurred a long time ago? Have you had a talk with the 'machinist' lately, telling him about the overlooked pilot bushing and how screwed up it was? Curious as to what he'll have to say.

Mike T - Prescott AZ

Mike T - Prescott AZ

Last edited by Vet65te; 07-02-2015 at 01:06 PM.

#31

Le Mans Master

Member Since: Nov 2003

Location: Maryland

Posts: 5,657

Received 613 Likes

on

368 Posts

St. Jude Donor '05, '09, '15

Get a new bushing from Auto Gear. Very nicely made and real Oilite. I used one in the 65 and my RG 5spd has never shifted as well as it does now. Same clutch, same bellhousing.

Tom

Tom

#32

Race Director

Member Since: Nov 2000

Location: Beverly Hills (Pine Ridge) Florida

Posts: 10,152

Received 525 Likes

on

374 Posts

The OP's pilot bushing may of been installed that way (very poorly)......

Those gouges do not look like "running" gouges from the input shaft. They look to me like they were "hammered" in.

Also, the OP states that the old pilot bushing "just popped out". What method did you use to get it to pop out? The bushing should have an interferance (press) fit to the bore in the crank, and should never be so loose that they just "pop out".

Also, the input shaft "pilot bushing's running surface" looks too coarse, like someone used 100 grit sandpaper on it. It should have a much finer finish, and should look polished (polish with succeeding finer papers up to at least 400 grit, or more).

Plasticman

Those gouges do not look like "running" gouges from the input shaft. They look to me like they were "hammered" in.

Also, the OP states that the old pilot bushing "just popped out". What method did you use to get it to pop out? The bushing should have an interferance (press) fit to the bore in the crank, and should never be so loose that they just "pop out".

Also, the input shaft "pilot bushing's running surface" looks too coarse, like someone used 100 grit sandpaper on it. It should have a much finer finish, and should look polished (polish with succeeding finer papers up to at least 400 grit, or more).

Plasticman

Last edited by Plasticman; 07-02-2015 at 04:59 PM.

#33

Race Director

#34

Pro

Thread Starter

Alex - As TripleBlack mentioned, from the serious wear on your old bushing, it seems that it was never fully inserted into the back of the crank, is that what you noticed before you pulled it out or was it 'almost' all the way in? Did you have any trans or shifting problems prior to this work being done, if not, maybe this 'gouged' bushing has been in there for a long time and the damage occurred a long time ago? Have you had a talk with the 'machinist' lately, telling him about the overlooked pilot bushing and how screwed up it was? Curious as to what he'll have to say.

Mike T - Prescott AZ

Mike T - Prescott AZ

#35

Pro

Thread Starter

The OP's pilot bushing may of been installed that way (very poorly)......

Those gouges do not look like "running" gouges from the input shaft. They look to me like they were "hammered" in.

Also, the OP states that the old pilot bushing "just popped out". What method did you use to get it to pop out? The bushing should have an interferance (press) fit to the bore in the crank, and should never be so loose that they just "pop out".

Also, the input shaft "pilot bushing's running surface" looks too coarse, like someone used 100 grit sandpaper on it. It should have a much finer finish, and should look polished (polish with succeeding finer papers up to at least 400 grit, or more).

Plasticman

Those gouges do not look like "running" gouges from the input shaft. They look to me like they were "hammered" in.

Also, the OP states that the old pilot bushing "just popped out". What method did you use to get it to pop out? The bushing should have an interferance (press) fit to the bore in the crank, and should never be so loose that they just "pop out".

Also, the input shaft "pilot bushing's running surface" looks too coarse, like someone used 100 grit sandpaper on it. It should have a much finer finish, and should look polished (polish with succeeding finer papers up to at least 400 grit, or more).

Plasticman

I used a 1/4" drive 3/8" socket and long extension, grease, some keilbasa, a light duty mechanics hammer and whacked it a couple times, nothing crazy, and it walked out enough where I grabbed it with needle nose. I thought it was too easy. Keilbasa!!

#36

Race Director

Member Since: Nov 2000

Location: Beverly Hills (Pine Ridge) Florida

Posts: 10,152

Received 525 Likes

on

374 Posts

I can see circumferential grooves on the bushing, and that is not "normal" (those bushings are powered metal, formed in a press, and would have a pretty smooth exterior). Looks to me like someone put it into a lathe to reduce the diameter for a looser fit.

That would be the reason for it coming out so easily.

I would surmise that someone had a hard time trying to install it originally (hence the hammered gouges on the rear edge of the bore), and then they decided to reduce the diameter for an easier fit (now making too loose).

Plasticman

That would be the reason for it coming out so easily.

I would surmise that someone had a hard time trying to install it originally (hence the hammered gouges on the rear edge of the bore), and then they decided to reduce the diameter for an easier fit (now making too loose).

Plasticman

#37

Race Director

Ha ha - that was also my experience the only time I've used that method myself. I wacked the end of the extension a couple times and out it popped. Surprised the heck out of me how easily it came out. Hydraulic pressure does all the work.

#38

Pro

Thread Starter

I can see circumferential grooves on the bushing, and that is not "normal" (those bushings are powered metal, formed in a press, and would have a pretty smooth exterior). Looks to me like someone put it into a lathe to reduce the diameter for a looser fit.

That would be the reason for it coming out so easily.

I would surmise that someone had a hard time trying to install it originally (hence the hammered gouges on the rear edge of the bore), and then they decided to reduce the diameter for an easier fit (now making too loose).

Plasticman

That would be the reason for it coming out so easily.

I would surmise that someone had a hard time trying to install it originally (hence the hammered gouges on the rear edge of the bore), and then they decided to reduce the diameter for an easier fit (now making too loose).

Plasticman

#39

Safety Car

Yup. Muncie input shaft has play in it. Perfectly normal. I would polish the pilot shaft with 1000 grit using some WD40 or light machine oil as lube. Then mike it. I don't have the correct diameter, but remember that the proper clearance between shaft and INSTALLED bushing should be no more than about 3 thousandths.

#40

Many a transmission shop would took at a customers gearbox, wobble the input up and down and shake their head "Yup she needs a rebuild."

The input is supported by a ballbearing at one end, which allows the wobble.

The input is supported by a ballbearing at one end, which allows the wobble.

I think you're right.

I think you're right.