L-76 rebuild. 1964 327/365hp

#1

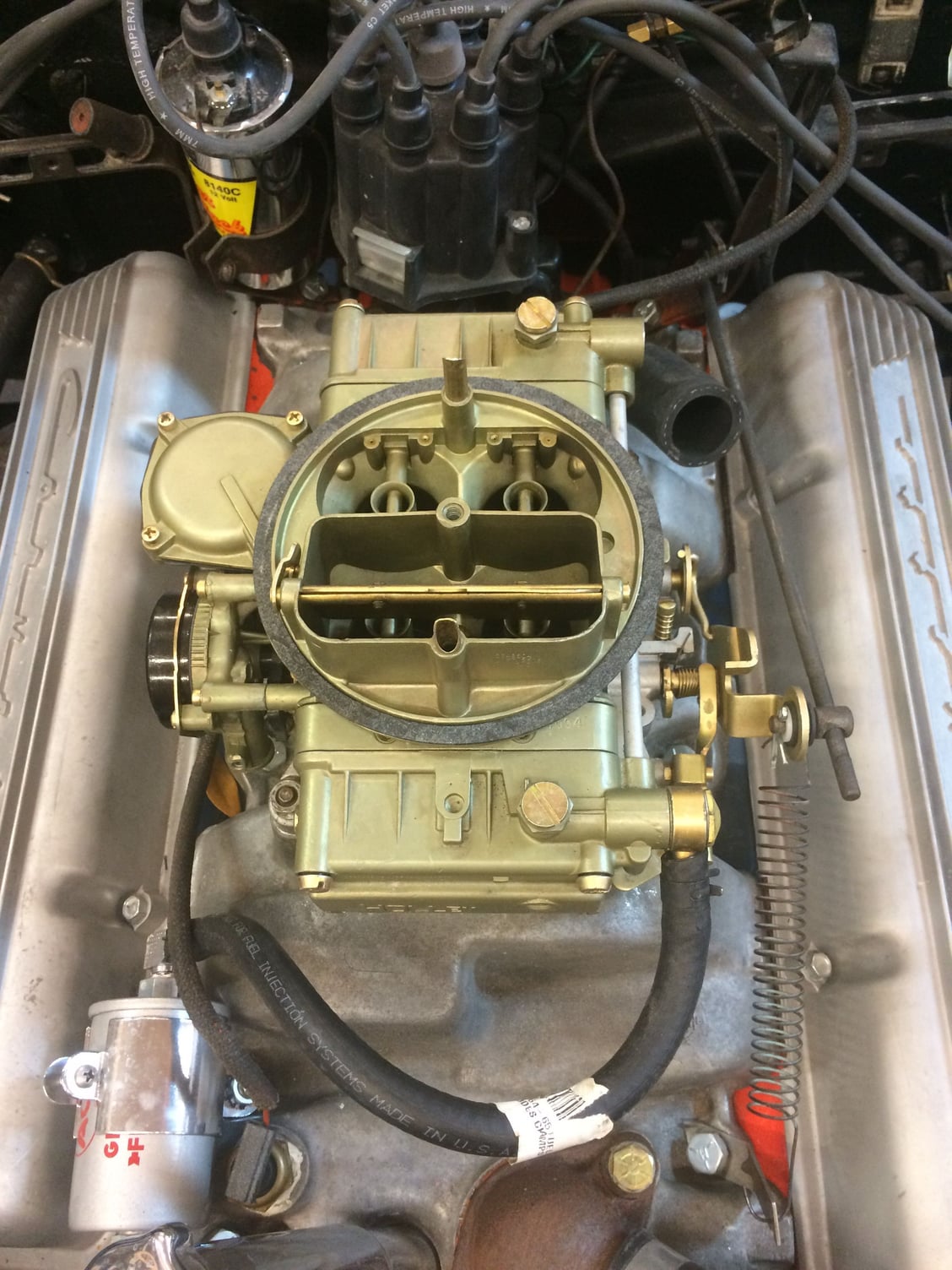

I just purchased a new air cleaner base for my 327/365 engine. I have rebuilt the engine to the original specs including the Holly 2818,carb. The problem is the float adjustment screws (on the bowls) hit the underside of the air cleaner base keeping it from seating properly on the Holly carb. Anyone know what I've done wrong?

#2

Melting Slicks

I just purchased a new air cleaner base for my 327/365 engine. I have rebuilt the engine to the original specs including the Holly 2818,carb. The problem is the float adjustment screws (on the bowls) hit the underside of the air cleaner base keeping it from seating properly on the Holly carb. Anyone know what I've done wrong?

Maybe later Holley style, or aftermarket stuff.

Have you tried using 2 gaskets on the air horn?

Got a photo?

#7

Have you tried to lift (to avoid scratching the underside) and then rotate the air cleaner base about 3º clockwise (if you're standing on driver's side)? The raised bump is supposed to be directly over the bowl screw. While yours is in the vicinity, it doesn't look like it's directly over it. Put your finger under the base and feel for the screw, but try not to scratch it. The incorrect position might be caused by how much you've inserted the rubber hose into the crankcase tube. If so, try backing off a bit.

EDIT: How about a pic of the carb only? Let's see what that screw looks like.

BTW, you're missing the flame arrestor metal screen that goes over that larger tube on the right for the air cleaner base.

EDIT: How about a pic of the carb only? Let's see what that screw looks like.

BTW, you're missing the flame arrestor metal screen that goes over that larger tube on the right for the air cleaner base.

Last edited by ifitgoesfast; 07-30-2015 at 09:15 AM.

#8

Team Owner

Member Since: Mar 2003

Location: Greenville, Indiana

Posts: 26,118

Received 1,843 Likes

on

1,398 Posts

Most air cleaner bases have tangs that lock into a notch in the carb air horn. I don't see that happening here. Looks like the bumps for the float screws are way out of alignment.

#10

Have you tried to lift (to avoid scratching the underside) and then rotate the air cleaner base about 3º clockwise (if you're standing on driver's side)? The raised bump is supposed to be directly over the bowl screw. While yours is in the vicinity, it doesn't look like it's directly over it. Put your finger under the base and feel for the screw, but try not to scratch it. The incorrect position might be caused by how much you've inserted the rubber hose into the crankcase tube. If so, try backing off a bit.

EDIT: How about a pic of the carb only? Let's see what that screw looks like.

BTW, you're missing the flame arrestor metal screen that goes over that larger tube on the right for the air cleaner base.

EDIT: How about a pic of the carb only? Let's see what that screw looks like.

BTW, you're missing the flame arrestor metal screen that goes over that larger tube on the right for the air cleaner base.

#11

Team Owner

Member Since: Mar 2003

Location: Greenville, Indiana

Posts: 26,118

Received 1,843 Likes

on

1,398 Posts

Maybe that hose nipple is for the hot air choke tube?

#12

The L76 air cleaner base only has the one bump for the screw on the forward bowl. Not sure how the rear clears, but it does on mine. The OP's base isn't way out of alignment, just a little. I was guessing about 3º because I know where the bowl screw is, which is driver's side just in front of the air horn.

#13

It connects to a skinny rubber hose which goes over the passenger side valve cover, behind the passenger side exhaust manifold and to a metal tube, then connects to it near where the spark plugs are and bottom of exhaust manifold. I don't have an AIM at work, but you can find the details there.

http://www.parts123.com/corvettecent...0050b&ukey=751

Steel tube from beneath exhaust manifold to top of engine near valve cover, with rubber hose to top of carburetor air horn or air cleaner. This tube provides warm clean air for the choke.

#14

Melting Slicks

OK this problem intrigued me to the point of getting off my butt and popping the hood on the 365.

In the photo, you have the base rotated too far clockwise (from a front of the car view).

This is causing interference with not the float screws, but the fuel inlet banjo fitting. That's what the relief bump is for.

The small nipple, which is indeed for the hot air choke inlet tube, should be at 10 o'clock.

The base has 7 cutout windows -- the middle cutout should be close to centered with the distributor. You can see how far yours is rotated CW.

Try that and see if it helps.

BTW: put on the correct bracket for the throttle return spring and it won't be over-stretched. Also, can't tell if you have the metered orifice fitting on the driver's side of that gorgeous 2818. Eric Jackson's work??

In the photo, you have the base rotated too far clockwise (from a front of the car view).

This is causing interference with not the float screws, but the fuel inlet banjo fitting. That's what the relief bump is for.

The small nipple, which is indeed for the hot air choke inlet tube, should be at 10 o'clock.

The base has 7 cutout windows -- the middle cutout should be close to centered with the distributor. You can see how far yours is rotated CW.

Try that and see if it helps.

BTW: put on the correct bracket for the throttle return spring and it won't be over-stretched. Also, can't tell if you have the metered orifice fitting on the driver's side of that gorgeous 2818. Eric Jackson's work??

#15

Sorry for the confusion. I'm at work and assumed it was for the screw, and was guessing it had to rotate the other way. What Mike posted makes sense, and would answer why the rear screw clears, which puzzled me, because both clear.

If you look at how your base is angled, it indeed looks like it's coming from the fuel connection.

If you look at how your base is angled, it indeed looks like it's coming from the fuel connection.

#16

Former Vendor

OK this problem intrigued me to the point of getting off my butt and popping the hood on the 365.

In the photo, you have the base rotated too far clockwise (from a front of the car view).

This is causing interference with not the float screws, but the fuel inlet banjo fitting. That's what the relief bump is for.

The small nipple, which is indeed for the hot air choke inlet tube, should be at 10 o'clock.

The base has 7 cutout windows -- the middle cutout should be close to centered with the distributor. You can see how far yours is rotated CW.

Try that and see if it helps.

BTW: put on the correct bracket for the throttle return spring and it won't be over-stretched. Also, can't tell if you have the metered orifice fitting on the driver's side of that gorgeous 2818. Eric Jackson's work??

In the photo, you have the base rotated too far clockwise (from a front of the car view).

This is causing interference with not the float screws, but the fuel inlet banjo fitting. That's what the relief bump is for.

The small nipple, which is indeed for the hot air choke inlet tube, should be at 10 o'clock.

The base has 7 cutout windows -- the middle cutout should be close to centered with the distributor. You can see how far yours is rotated CW.

Try that and see if it helps.

BTW: put on the correct bracket for the throttle return spring and it won't be over-stretched. Also, can't tell if you have the metered orifice fitting on the driver's side of that gorgeous 2818. Eric Jackson's work??

I see that the inner portion of the base is spot welded at an angle, could this particular piece have been welded in the opposite angle?

#17

Melting Slicks

You are correct about the "clocking" of the air cleaner base in photo provided---but--- the photo was used to show the attitude of the base to carb not seating----trust me, I rotated the base in all directions to attain seating--- but to no avail. Big but; if the base is rotated 180 degrees, it flops right down.

I see that the inner portion of the base is spot welded at an angle, could this particular piece have been welded in the opposite angle?

I see that the inner portion of the base is spot welded at an angle, could this particular piece have been welded in the opposite angle?

This is quite the mystery. My next step would be to shoot the underside of the base with some quick-dry paint and then try to seat it.

The exact area of interference will be clear from the witness marks.

If it is ONLY the forward float adj. screw head, that suggests to me that the air cleaner housing has a problem. Maybe a new vendor with new tooling.

Here's a reference photo to compare your side view against:

Is your fuel inlet maybe rotated too far up, causing interference with the hose? Seem to recall that happening to me once.

Note the spring and bracket.

Last edited by Mike Geary; 07-31-2015 at 04:44 PM.

#18

Sorry I forgot to respond to this some time back..... It actually turns out that Mike Geary was right. The fuel inlet was rotated to far up! A quick adjustment turning the fuel inlet down fixed the problem. Thank you all for the help. I just need to get a few of the engine pieces that will finish my 327/365.