Front Wheel Bearing Torque

#1

Instructor

Thread Starter

Hello,

I have a '65 small block coupe. I had the front end rebuilt last year by a Chevy mechanic, who also replaced the wheel bearings, he used timkins. I've put around 500 miles on the car since. I noticed a popping sound/vibration last night when I turn left and right. Jacked the car up and the driver side wheel has about 1/2" play when rocked back and forth. I'm thinking the mechanic didn't torque the bearings correctly. I'm going to replace them this time. Anybody have a good method of torquing the wheel bearings correctly? Also, any idea why the bearing may have failed? Thanks Joe

I have a '65 small block coupe. I had the front end rebuilt last year by a Chevy mechanic, who also replaced the wheel bearings, he used timkins. I've put around 500 miles on the car since. I noticed a popping sound/vibration last night when I turn left and right. Jacked the car up and the driver side wheel has about 1/2" play when rocked back and forth. I'm thinking the mechanic didn't torque the bearings correctly. I'm going to replace them this time. Anybody have a good method of torquing the wheel bearings correctly? Also, any idea why the bearing may have failed? Thanks Joe

#2

Le Mans Master

According to Corvette Magazine torque spindle nut to 15 lb ft whole rotating assembly, then back off to first position that cotter key will go through.

IIRC I have seen and used the torque spec of 12 lb ft for this procedure.

IIRC I have seen and used the torque spec of 12 lb ft for this procedure.

#3

15 is probably about right. Snug the nut in tight enough to seat the bearing assembly while turning the roter then back the nut off as described.

#4

That could leave it too tight depending on how close the cotter pin hole is. I would tighten the nut to 10-15 ft lbs then back off on the nut between 1/8 to 1/4 turn...between 1/8 and 1/4, not one or the other. I do these all the time on the job and don't use a torque wrench, but if you do this it won't be a problem.

#5

Melting Slicks

Hello,

I have a '65 small block coupe. I had the front end rebuilt last year by a Chevy mechanic, who also replaced the wheel bearings, he used timkins. I've put around 500 miles on the car since. I noticed a popping sound/vibration last night when I turn left and right. Jacked the car up and the driver side wheel has about 1/2" play when rocked back and forth. I'm thinking the mechanic didn't torque the bearings correctly. I'm going to replace them this time. Anybody have a good method of torquing the wheel bearings correctly? Also, any idea why the bearing may have failed? Thanks Joe

I have a '65 small block coupe. I had the front end rebuilt last year by a Chevy mechanic, who also replaced the wheel bearings, he used timkins. I've put around 500 miles on the car since. I noticed a popping sound/vibration last night when I turn left and right. Jacked the car up and the driver side wheel has about 1/2" play when rocked back and forth. I'm thinking the mechanic didn't torque the bearings correctly. I'm going to replace them this time. Anybody have a good method of torquing the wheel bearings correctly? Also, any idea why the bearing may have failed? Thanks Joe

Joe,

You might check condition of the bearing race as it could have been damaged. Not that difficult to knock them out and replace with new.

Resto

#7

Race Director

Member Since: May 2000

Location: Redondo Beach USA

Posts: 12,487

Received 1,974 Likes

on

1,188 Posts

The front wheel bearings should have clearance, and I believe the spec is one to five thou. The purpose of initially torquing them is merely to ensure that the races are fully seated. Torque them, then back off and hand tighten the nut and feel for clearance. It takes a little practice to find the minimum clearance position.

The thread count is 24/inch, and with the castle nut and two perpendicular cotter pin holes you can adjust in 1/12th turn increments which is .0035". Once you hand tighten the nut, install the cotter pin and rotate the wheel a couple of times. Then try going one more 1/12th of a turn, and repeat until you find the minimum clearance. It takes a little practice if you haven't done it before.

The proper adjusting procedure as above is in any GM service manual of the era.

Duke

The thread count is 24/inch, and with the castle nut and two perpendicular cotter pin holes you can adjust in 1/12th turn increments which is .0035". Once you hand tighten the nut, install the cotter pin and rotate the wheel a couple of times. Then try going one more 1/12th of a turn, and repeat until you find the minimum clearance. It takes a little practice if you haven't done it before.

The proper adjusting procedure as above is in any GM service manual of the era.

Duke

Last edited by SWCDuke; 05-28-2016 at 10:59 AM.

The following users liked this post:

Dr L-88 (03-12-2017)

#8

Le Mans Master

Everything written above assumes perfect threads on your spindle. Since many of these cars are 50 years old threads are not always perfect making it hard to adjust by hand. Some hands are much stronger than others offering another variable.

Spin the nut down till you feel it take out the play while spinning the tire.

Take a screwdriver and see if you can make the washer behind the nut slip a little side to side. If the washer moves freely add a little tension till you feel drag on the washer but can still slip it side to side. A small adjustment tighter shows up in immediate drag increase.

An old mechanic taught me this method 30 years ago and it always works to get minimum play without ever causing a bearing failure from over or under tension.

Spin the nut down till you feel it take out the play while spinning the tire.

Take a screwdriver and see if you can make the washer behind the nut slip a little side to side. If the washer moves freely add a little tension till you feel drag on the washer but can still slip it side to side. A small adjustment tighter shows up in immediate drag increase.

An old mechanic taught me this method 30 years ago and it always works to get minimum play without ever causing a bearing failure from over or under tension.

#11

Team Owner

Everything written above assumes perfect threads on your spindle. Since many of these cars are 50 years old threads are not always perfect making it hard to adjust by hand. Some hands are much stronger than others offering another variable.

Spin the nut down till you feel it take out the play while spinning the tire.

Take a screwdriver and see if you can make the washer behind the nut slip a little side to side. If the washer moves freely add a little tension till you feel drag on the washer but can still slip it side to side. A small adjustment tighter shows up in immediate drag increase.

An old mechanic taught me this method 30 years ago and it always works to get minimum play without ever causing a bearing failure from over or under tension.

Spin the nut down till you feel it take out the play while spinning the tire.

Take a screwdriver and see if you can make the washer behind the nut slip a little side to side. If the washer moves freely add a little tension till you feel drag on the washer but can still slip it side to side. A small adjustment tighter shows up in immediate drag increase.

An old mechanic taught me this method 30 years ago and it always works to get minimum play without ever causing a bearing failure from over or under tension.

R&R'ed a dozen wheels a day and had the 'feel' down pat. We sure agonize over things now that weren't given a second thought when these cars were everyday drivers...

#12

I was unable to figure out how to start a new thread, so I'll ask here.

Does anyone know where I can find a front spindle washer with the little tab which prevents it from rotating for my 62 Corvette. Stupid (me) lost one while changing the wheel bearings.

I found that you have to buy the whole kit from Paragon, so I was hoping to find a used one somewhere.

Thanks,

Tcheairs

Does anyone know where I can find a front spindle washer with the little tab which prevents it from rotating for my 62 Corvette. Stupid (me) lost one while changing the wheel bearings.

I found that you have to buy the whole kit from Paragon, so I was hoping to find a used one somewhere.

Thanks,

Tcheairs

#13

Drifting

I was unable to figure out how to start a new thread, so I'll ask here.

Does anyone know where I can find a front spindle washer with the little tab which prevents it from rotating for my 62 Corvette. Stupid (me) lost one while changing the wheel bearings.

I found that you have to buy the whole kit from Paragon, so I was hoping to find a used one somewhere.

Thanks,

Tcheairs

Does anyone know where I can find a front spindle washer with the little tab which prevents it from rotating for my 62 Corvette. Stupid (me) lost one while changing the wheel bearings.

I found that you have to buy the whole kit from Paragon, so I was hoping to find a used one somewhere.

Thanks,

Tcheairs

#14

Burning Brakes

Member Since: Jun 2005

Location: Hinesville, GA & Oswego, NY

Posts: 793

Received 215 Likes

on

136 Posts

I was unable to figure out how to start a new thread, so I'll ask here.

Does anyone know where I can find a front spindle washer with the little tab which prevents it from rotating for my 62 Corvette. Stupid (me) lost one while changing the wheel bearings.

I found that you have to buy the whole kit from Paragon, so I was hoping to find a used one somewhere.

Thanks,

Tcheairs

Does anyone know where I can find a front spindle washer with the little tab which prevents it from rotating for my 62 Corvette. Stupid (me) lost one while changing the wheel bearings.

I found that you have to buy the whole kit from Paragon, so I was hoping to find a used one somewhere.

Thanks,

Tcheairs

Bill

#15

Drifting

As Duke said, the correct way to do it is set a clearance after torqueing. There are 2 cotter pin holes in the spindle so if one is too tight, rotate the nut to use the other one.

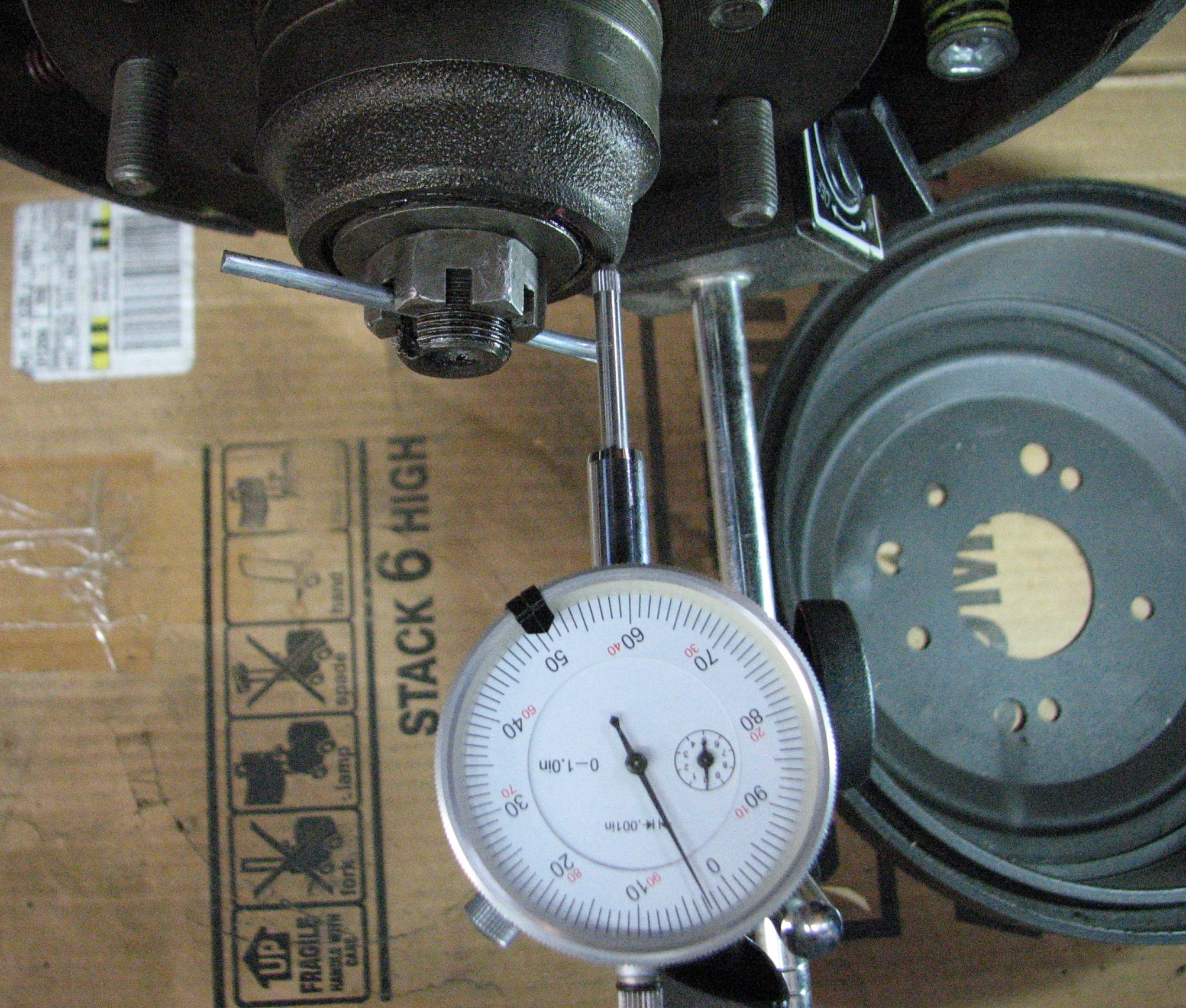

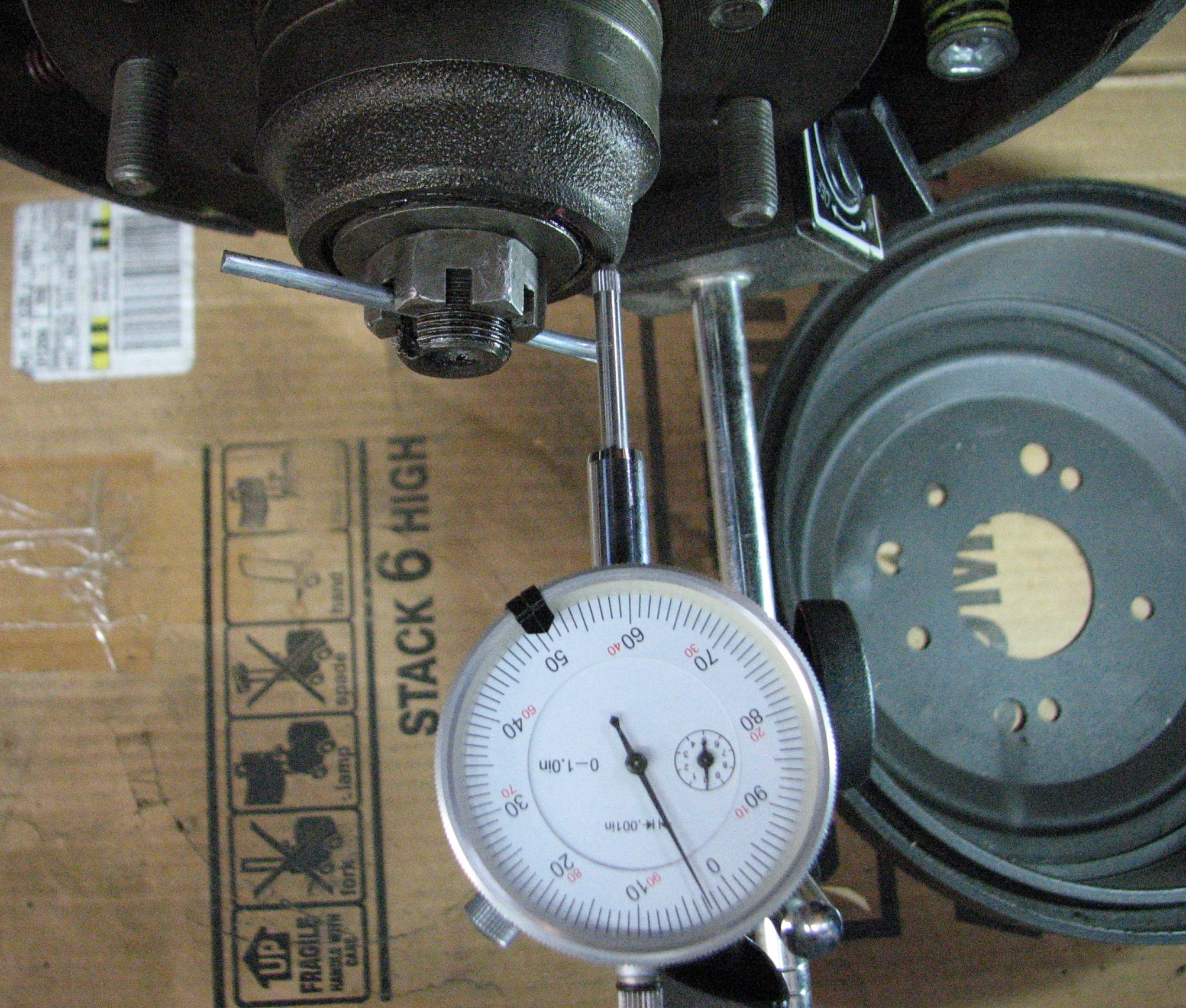

I use the method shown below. Make sure to put the dial indicator on the face of the hub closest to the spindle so your measurements aren't influenced by the tilt of the hub due to a clearance.

Verne

I use the method shown below. Make sure to put the dial indicator on the face of the hub closest to the spindle so your measurements aren't influenced by the tilt of the hub due to a clearance.

Verne

The following users liked this post:

Dr L-88 (03-12-2017)

#16

Drifting

It would be interesting to see what a dial indicator might reveal about the relative accuracy of the many 'old school' methods that seem to have worked successfully for so many years.