homemade tools part 2

#21

Race Director

Great ideas in this thread guys. I love the fold up table. That is an awesome idea. At my house, in my garage it would wind up with lots of stuff setting on top of it and never get folded back out of the way. I may try it anyway after I have my spring garage cleaning. Thanks for posting it.

The wheel studs are another great idea. Those would be nice for any chevy vehicle. If you have a truck, you know how heavy those wheels are when you pull them off. This should make it much easier to put them back on.

Here is my homemade pressure bleeder. It is made from a bug sprayer, pressure gauge, tygon tubing and a lexan cover with rubber gasket for the master cylinder cap.

The wheel studs are another great idea. Those would be nice for any chevy vehicle. If you have a truck, you know how heavy those wheels are when you pull them off. This should make it much easier to put them back on.

Here is my homemade pressure bleeder. It is made from a bug sprayer, pressure gauge, tygon tubing and a lexan cover with rubber gasket for the master cylinder cap.

#22

Melting Slicks

I'll leave that fancy CNC stuff to YOU guys with ALL the money!!

The fun part of making these guides the way I do is, I end up sharpening a skill that I have no formal training with. The lathe I have is pretty old and supposedly spent a bunch of it's life in a High School Trades Shop so you can imagine the "abuse" it saw during it's life there. There is damn little this thing will do for itself and 75% of the cuts I have to make for these guides are done with "hand power" feed. Here is a link to some pictures of my "manufacturing" process

. http://s126.photobucket.com/albums/p.../Handy%20tool/

. http://s126.photobucket.com/albums/p.../Handy%20tool/

Last edited by Jim Martley2; 02-17-2007 at 12:41 PM.

#23

Great ideas in this thread guys. I love the fold up table. That is an awesome idea. At my house, in my garage it would wind up with lots of stuff setting on top of it and never get folded back out of the way. I may try it anyway after I have my spring garage cleaning. Thanks for posting it.

The wheel studs are another great idea. Those would be nice for any chevy vehicle. If you have a truck, you know how heavy those wheels are when you pull them off. This should make it much easier to put them back on.

Here is my homemade pressure bleeder. It is made from a bug sprayer, pressure gauge, tygon tubing and a lexan cover with rubber gasket for the master cylinder cap.

The wheel studs are another great idea. Those would be nice for any chevy vehicle. If you have a truck, you know how heavy those wheels are when you pull them off. This should make it much easier to put them back on.

Here is my homemade pressure bleeder. It is made from a bug sprayer, pressure gauge, tygon tubing and a lexan cover with rubber gasket for the master cylinder cap.

#24

[QUOTE=bobs77vet;1558961828]

[IMG] [/IMG]

[/IMG]

A)Engine stand stress test.

B)Slacking off again

C)Carbon based block heater

D)World's most uncomfortable chair

E)Waiting for new shop heater to arrive

[IMG]

[/IMG]

[/IMG]A)Engine stand stress test.

B)Slacking off again

C)Carbon based block heater

D)World's most uncomfortable chair

E)Waiting for new shop heater to arrive

#25

Tech Contributor

Hey I'm a trade school grad('77) what do you mean the abuse- I used to take the machines apart ! Another kid used to ride the shaper- this was the pre-mechanical bull days too! LOL The best thing was the freshmen grinding the clutches in a J head Bridgeport!Hehehe

The surface grinder we have here came out of a public HS. They closed the shop down to make a daycare for all the 13-17 year old mothers attending school. Pretty sad times.

It doesn't look like you have a taper attachment on the lathe but does the tailstock offset? It may be easier to turn that way with the power feed. Looks like about a 13 or 14" lathe- good for general work and corvette related work as well.

Keep up the good work!

#26

Tech Contributor

Tools, well here's some of my stuff I posted on before.

Ring gear install bolts- cut from old RG bolts.

Posi case tools to install and to use 2 jaw puller to remove old bearings.

I beams to support jobs in a press

Not homemade but this sissors jack makes removing a diff with the car on jack stands very easy- even I could do it!!

Tranny cradle - made from an old desk

Tranny work stand- made from mostly black pipe and angel iron

Spicer Joint tool

Not Homemade but certainly needed to do differentials and steering boxes.

Rear bearing tools. I made the fixture plate, the setup tool is bought but could be made from a spindle.

EMT with the ID bored a little to clear spindle. Use balck pipe if you have a lathe to turn it to size.

20 ton press- this is a HF special. I had to replace the cylinder but this could be fab's up if you have a welder(240 vac) and a mill to bore the holes.

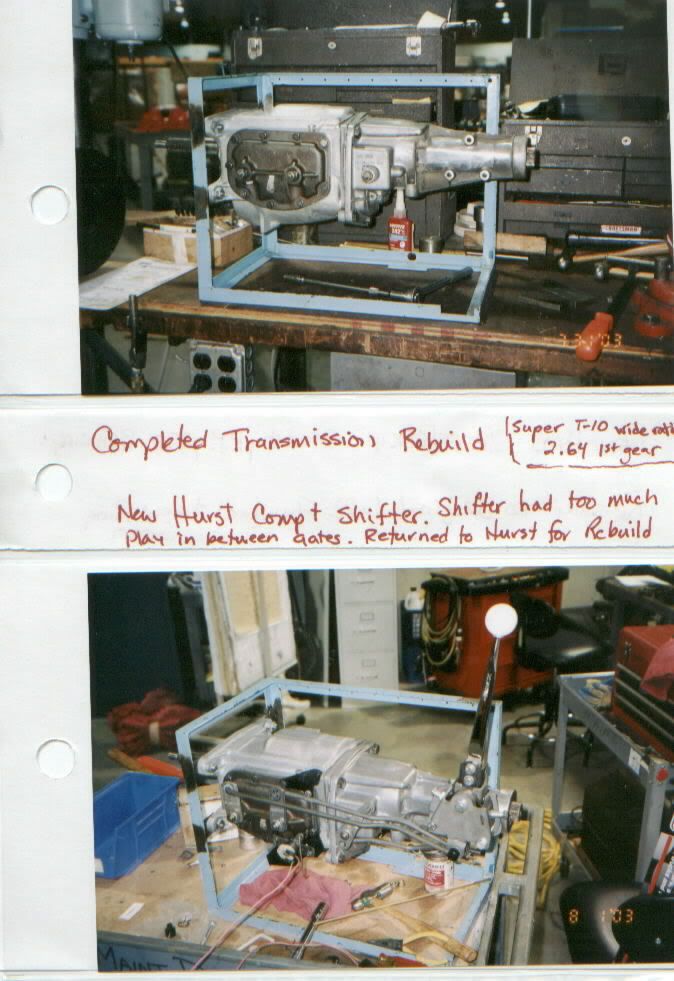

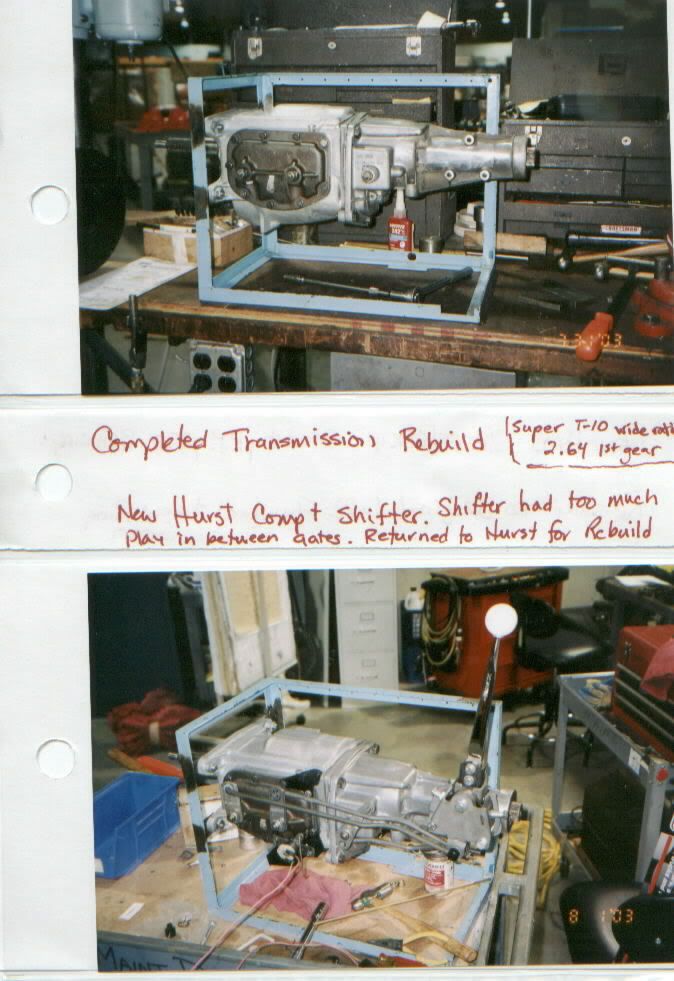

Muncie or ST-10 tranny stand. Makes rebuilding it much easier. 1" angle iron and a welder req'd.

Trailing arm bushing stake tool

Old rotor cut with a flat to torque the rear spindle nut to 100+ ft/lbs

Ring gear install bolts- cut from old RG bolts.

Posi case tools to install and to use 2 jaw puller to remove old bearings.

I beams to support jobs in a press

Not homemade but this sissors jack makes removing a diff with the car on jack stands very easy- even I could do it!!

Tranny cradle - made from an old desk

Tranny work stand- made from mostly black pipe and angel iron

Spicer Joint tool

Not Homemade but certainly needed to do differentials and steering boxes.

Rear bearing tools. I made the fixture plate, the setup tool is bought but could be made from a spindle.

EMT with the ID bored a little to clear spindle. Use balck pipe if you have a lathe to turn it to size.

20 ton press- this is a HF special. I had to replace the cylinder but this could be fab's up if you have a welder(240 vac) and a mill to bore the holes.

Muncie or ST-10 tranny stand. Makes rebuilding it much easier. 1" angle iron and a welder req'd.

Trailing arm bushing stake tool

Old rotor cut with a flat to torque the rear spindle nut to 100+ ft/lbs

#27

Race Director

Thread Starter

#28

Hello everyone, new guy here. I like the thread! I've got a pretty neat

homemade tool, well, home shop made anyway. The picture below is the

real deal, perhaps the most versatile engine test stand on the planet. And,

this one is built out of 304 stainless steel with aluminum radiator, gauge

panel, fuel cell, battery tray. These actually came about almost 3 years

ago when I was helping a buddy build a 496 ci stroker for his drag 'Vette.

Seemed like every car guy that saw it wanted one, so now I build these things

full time. My wife and I finally got a website, http://www.metalmassfab.com

up and running where you can see a few more pictures, and read more

about these units. I am not trying to make a sale here, but I would

appreciate suggestions on the website and the test stands. These things

have evolved into their current state due to excellent customer feedback,

suggestions, comments, etc. Thank you for your time!

homemade tool, well, home shop made anyway. The picture below is the

real deal, perhaps the most versatile engine test stand on the planet. And,

this one is built out of 304 stainless steel with aluminum radiator, gauge

panel, fuel cell, battery tray. These actually came about almost 3 years

ago when I was helping a buddy build a 496 ci stroker for his drag 'Vette.

Seemed like every car guy that saw it wanted one, so now I build these things

full time. My wife and I finally got a website, http://www.metalmassfab.com

up and running where you can see a few more pictures, and read more

about these units. I am not trying to make a sale here, but I would

appreciate suggestions on the website and the test stands. These things

have evolved into their current state due to excellent customer feedback,

suggestions, comments, etc. Thank you for your time!

#30

Hello, thank you for your interest. The steel ones, stage 1, is $595. this

includes the stand, casters, all hardware, and the stainles rear hanger

engine mounts. A stage 2 unit is the same, plus an aluminum tig welded

fuel cell, battery tray, and gauge panel for $780. Stage 3 is a complete

unit at $1325, with 26" x 19" tig welded aluminum 2 row radiator, electric

fan,Autometer Sport Comp 3 3/8" tach, 2 5/8" oil pressure and water

temp withelectric senders. A keyed ignition switch, 2 cole hersee 25 amp

toggle switches, 6 circuit fuse block. All required holes are drilled and or

tapped. Assembly is very simple and straight forward. Stainless steel units

are $240 additional due to the much higher price in materials. The 4-port

radiator option is $220 additional to a stage 3 stand. The 4-port radiator

option is mainly for those who run all sorts of engines, Ford, Chevy, Mopar

etc. Some say the price is too high on these test stands, but the

design requires well over twice the work compared to other stands.

Sorry for the long winded reply!

PS...free shipping on these units until 3/01/07

includes the stand, casters, all hardware, and the stainles rear hanger

engine mounts. A stage 2 unit is the same, plus an aluminum tig welded

fuel cell, battery tray, and gauge panel for $780. Stage 3 is a complete

unit at $1325, with 26" x 19" tig welded aluminum 2 row radiator, electric

fan,Autometer Sport Comp 3 3/8" tach, 2 5/8" oil pressure and water

temp withelectric senders. A keyed ignition switch, 2 cole hersee 25 amp

toggle switches, 6 circuit fuse block. All required holes are drilled and or

tapped. Assembly is very simple and straight forward. Stainless steel units

are $240 additional due to the much higher price in materials. The 4-port

radiator option is $220 additional to a stage 3 stand. The 4-port radiator

option is mainly for those who run all sorts of engines, Ford, Chevy, Mopar

etc. Some say the price is too high on these test stands, but the

design requires well over twice the work compared to other stands.

Sorry for the long winded reply!

PS...free shipping on these units until 3/01/07

Last edited by metalmassfab; 02-23-2007 at 09:33 PM.

#32

Drifting

We've built a CNC plasma cutter, and a 2 axis CNC mill...

ABP (Already Been Posted)

now for some bigger Iron...

2500 lbs and 3HP of 3 axis CNC Fun is getting started.... (CNC retrofit will be homemade)

ABP (Already Been Posted)

now for some bigger Iron...

2500 lbs and 3HP of 3 axis CNC Fun is getting started.... (CNC retrofit will be homemade)

#33

Tech Contributor

That is very nice engine stand!! If I did engines as much as I do diff, rear bearings, or boxes I'd get one.

Maybe you should offer a budget DIY kit out of steel so guys don't have to measure and cut up steel all they would need would be a welder or better yet a bolt together stand that can be broken down and stored. I like the fact you're here in the USA, I sometimes feel like we have the "wagons in a circle" waiting for the attack!

Nice job!

Maybe you should offer a budget DIY kit out of steel so guys don't have to measure and cut up steel all they would need would be a welder or better yet a bolt together stand that can be broken down and stored. I like the fact you're here in the USA, I sometimes feel like we have the "wagons in a circle" waiting for the attack!

Nice job!

Last edited by GTR1999; 02-24-2007 at 12:23 PM.

#34

Tech Contributor

Which one? The 4 spd one is just 1" angel iron welded up.

The rolling cradle is made from chrome office desk legs! Just 1" sq tubing

The rebuild stand is angle iron and black pipe that is U shaped to fit around the tranny. It's butt ugly but it worked pretty good doing my TH400.

The rolling cradle is made from chrome office desk legs! Just 1" sq tubing

The rebuild stand is angle iron and black pipe that is U shaped to fit around the tranny. It's butt ugly but it worked pretty good doing my TH400.

#35

That is very nice engine stand!! If I did engines as much as I do diff, rear bearings, or boxes I'd get one.

Maybe you should offer a budget DIY kit out of steel so guys don't have to measure and cut up steel all they would need would be a welder or better yet a bolt together stand that can be broken down and stored. I like the fact you're here in the USA, I sometimes feel like we have the "wagons in a circle" waiting for the attack!

Nice job!

Maybe you should offer a budget DIY kit out of steel so guys don't have to measure and cut up steel all they would need would be a welder or better yet a bolt together stand that can be broken down and stored. I like the fact you're here in the USA, I sometimes feel like we have the "wagons in a circle" waiting for the attack!

Nice job!

#36

Tech Contributor

#37

Race Director

Thread Starter

global economies and reverse engineering are really tough to deal with......i don't know what the answer to that is......unless its as simple as we need to start think globally as we make things. i think about these issues all the time. i recently made an engine stand adapter for for ford flat heads ..the problem is i can't make it cheap enough her inthe US to make it profitable to sell.....

[IMG] [/IMG]

[/IMG]

[IMG]

[/IMG]

[/IMG]

#38

A buddy of mine put it well: China takes all our scrap metal (i.e. all our old cars that get crushed) home on 1200-foot ships. They melt down all of the scrap, and pour it into new material. They load it back on the 1200-foot ships, and head for the land of riches; America. On their journey across the high seas, they've got thousands of 2-rice-grain-a-week workers in the ships hold, building the rip-off engine test stands and everything else. My buddy says that must be why Chinese welds are so nasty, 'cause they weld with the ships 'rolling around' in the sea, in the dark confines of ships belly! Of course, once the ships reach America all the workers are allowed to come ashore, take our jobs, and live off our tax dollars for long-time....Sorry, couldn't help it....

#40

Race Director

Thread Starter

glad to see it the post got resurrected...any body have any new home made tools?