At Home Phosphate Coating?

#1

Burning Brakes

Thread Starter

I am at the point of sending off the major frame and suspension parts to the powder coater on my 73 restore/rebuild and need to get the numerous nuts, bolts and washers black phosphate coated. I have found a few shops in the So Cal area that can and will do the parts, but I would like to know if the phosphate coating can be done at home. Is home coating near the same quality as a commercial operation?

It would make my life more simple if I dont have to sort out a 5 gal bucket of parts, and do them a few at a time instead on my timetable.

Where would I find the materials? I have heard of folks using crock pots etc...

Thanks for the help.

It would make my life more simple if I dont have to sort out a 5 gal bucket of parts, and do them a few at a time instead on my timetable.

Where would I find the materials? I have heard of folks using crock pots etc...

Thanks for the help.

#2

Melting Slicks

I'm at work so I don't have a copy of my latest Eastwood catalog (it's probably listed online though)...I recall seeing a "black oxide " coating kit that they sold awhile back. Check them out- since I'm just down the road in temecula I might send you a bucket of my own bolts!!

#3

Team Owner

Member Since: Sep 2006

Location: Westminster Maryland

Posts: 30,173

Likes: 0

Received 2,878 Likes

on

2,515 Posts

Hi C....

Phosphating is really the easiest plating to do at home

The process is called 'Parkerizing' and apparently people who make firearms use it.

The supplies and instructions are readily available. Google... 'Parkerizing'.

I use both the manganese phosphate, (VERY dark gray, almost black), and zinc phosphate, (medium gray).

Here's a m & f hood latch with the zinc phosphate finish.

Regards,

Alan

Phosphating is really the easiest plating to do at home

The process is called 'Parkerizing' and apparently people who make firearms use it.

The supplies and instructions are readily available. Google... 'Parkerizing'.

I use both the manganese phosphate, (VERY dark gray, almost black), and zinc phosphate, (medium gray).

Here's a m & f hood latch with the zinc phosphate finish.

Regards,

Alan

#4

Burning Brakes

Thread Starter

Parkerizing? Well I would never have guessed that was the same thing!!!

Thanks Alan...Will look into that angle...BTW, is the hood latch spring the Zinc and the mount Manganese?

And Birdsmith, you can bring a 1/4 barrel of a fine microbrew for the kegerator up with your bolts !

Thanks Alan...Will look into that angle...BTW, is the hood latch spring the Zinc and the mount Manganese?

And Birdsmith, you can bring a 1/4 barrel of a fine microbrew for the kegerator up with your bolts !

Last edited by C2C6Z06; 02-01-2012 at 04:30 PM.

#5

Team Owner

Member Since: Sep 2006

Location: Westminster Maryland

Posts: 30,173

Likes: 0

Received 2,878 Likes

on

2,515 Posts

Hi C2,

The latches are the zinc phosphate.

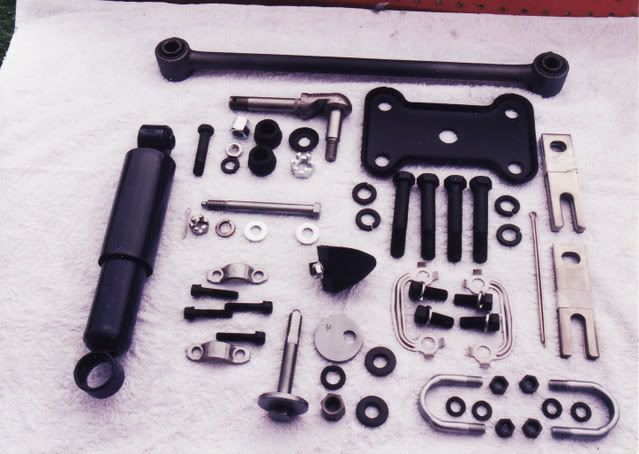

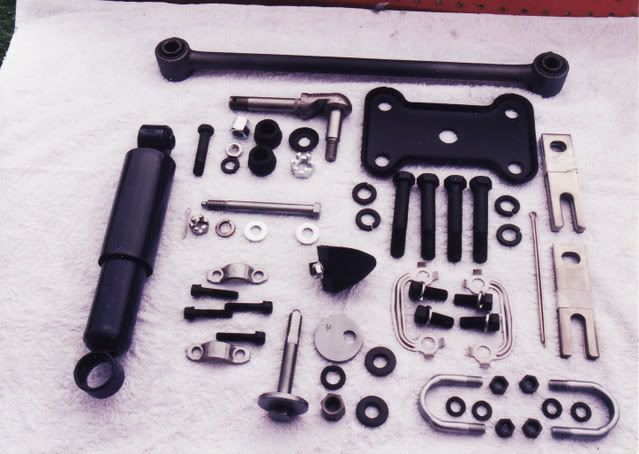

This isn't a great picture but the 4 bolts for the rear spring, the bolts for the top mounts of the shock absorbers, the drive shaft universal joint bolts, and some washers and nuts, are manganese phosphate. You can see they're almost as black as the painted spring mounting plate.

Regards,

Alan

The latches are the zinc phosphate.

This isn't a great picture but the 4 bolts for the rear spring, the bolts for the top mounts of the shock absorbers, the drive shaft universal joint bolts, and some washers and nuts, are manganese phosphate. You can see they're almost as black as the painted spring mounting plate.

Regards,

Alan

#6

Race Director

Member Since: Apr 2011

Location: North of Toronto - Ontario

Posts: 10,853

Received 3,138 Likes

on

2,069 Posts

Of the different plating/coating, one of the easiest to do at home.

(don't use you kitchen oven

)

)Also don't confuse it with black oxide, gun bluing or tool-black. Basically if there's no heat, it's not going to do a real good job.

The other thing to watch is for higher hardness steels, there is a possibility of hydrogen embrittlement, although there is some conflicting information out there, most if not all aerospace spec's for manganese coatings call for a 375/4 hydrogen bake afterwards...

From what I remember that kicked in at around 30Rc

Mooser

#7

Team Owner

Member Since: Feb 2003

Location: Sitting in his Nowhere land Hanover Pa

Posts: 49,006

Received 6,943 Likes

on

4,782 Posts

2015 C2 of Year Finalist

Allan where did you buy your stuff to do your work

#10

Melting Slicks

For fiddly small parts and hardware I like either Caswell Plating's Black Oxide finish or another gun related sprayable finish called DuraCoat from Lauer Custom Weaponry. Black Oxide is easy to use, contains no caustic chemicals, and requires no heat to apply... simply degrease, blast, dip and rinse. It is not as hard or durable as real phosphating but is much safer and simpler. DuraCoat is a two part sprayable coating available in any color you can imagine, and is both harder and more durable than cold oxides... it approaches the scuff resistance of real phosphated parts and offers the bonus of being "touch up" friendly if you have an issue with assembly. It does require a spray application, but is sprayable through airbrushes, "touch up" sprayguns or even Preval type self contained aerosol applicators. I use it often and think it's excellent bang for both the buck and effort expended to achieve a good looking and reasonably durable finish.

Last edited by markids77; 02-01-2012 at 10:01 PM. Reason: missed a letter!

#11

Drifting

I do gun parts with it. You can find your supplies on some gun sales places. I think I got some from Brownell's Or maybe Midway USA. There are some cheaper sources. Stainless bowl will work for small stuff. I use an old behind bar bottle holder for rifle barrels.

#12

Melting Slicks

Here's a Manganese Phosphate "how to" primmer... Degrease the part to be finished in either a suitable water based hot tank or use a degreaser like brake claner or acetone to clean thoroughly. Blast the entire surface clean using media which cuts fairly aggressively to expose max surface area for finishing. Set up three heaters and either stainless or Pyrex glass containers... one to contain boiling distilled water to preheat and final rinse your parts, one to contain the phosphating solution which must be maintained at somewhere near 190 degrees farenheit depending on who made the salts, and a third container which will contain a passivating solution of some sort. Preheat the clean part in boiling water until heated uniformly, then hang it in the phospating solution until it stops fizzing... 10 to 30 minutes. Transfer to the passivating bath for whatever time the destructions say you need, then back to the clean boiling water to rinse. Blow dry... then oil immediately to prevent "flash rust". Hope you performed all the steps correctly so your parts don't come out mottled or have a "salt bloom"... a white deposit formed from incomplete passivation. Whew! Now you know why I like "dip it and oil it", or sprayable finishes.

Last edited by markids77; 02-01-2012 at 10:28 PM. Reason: I need a new keyboard

#13

Race Director

I've cheated on creating a black phosphate finish, by using paint.

By spraying parts with flat black paint, and then giving them a very light dusting with silver paint, I've been able get a fair representation of black phosphate. I dust with the silver from about a foot above the part, and do it while the black is still damp.

With a little experimentation, you can get a credible looking finish on many parts. Don't laugh, I've fooled a few people (including judges), by doing this.

By spraying parts with flat black paint, and then giving them a very light dusting with silver paint, I've been able get a fair representation of black phosphate. I dust with the silver from about a foot above the part, and do it while the black is still damp.

With a little experimentation, you can get a credible looking finish on many parts. Don't laugh, I've fooled a few people (including judges), by doing this.

#14

Safety Car

I've worked with both black oxide (via Eastwood) and the manganese phosphate and have gotten nice results with either. The challenge with manganese phosphate for me has been maintaining the temperature for the heat required with the phosphate plating.

These are the steps I've used but curious what others have used to maintain the 190 degrees? I used a cheap crock pot but took forever to get to 190 and than sustain even tho I preboiled the water before putting into the crock and cooking metal before dipping into the plating solution.

one to contain the phosphating solution which must be maintained at somewhere near 190 degrees farenheit depending on who made the salts, and a third container which will contain a passivating solution of some sort. Preheat the clean part in boiling water until heated uniformly, then hang it in the phospating solution until it stops fizzing... 10 to 30 minutes.

#15

Team Owner

Member Since: Sep 2006

Location: Westminster Maryland

Posts: 30,173

Likes: 0

Received 2,878 Likes

on

2,515 Posts

Hi,

I'll only add that I've used 'PreLube 6', which comes in a spray can, to protect the parts after parkerizing.

I buy it from Quanta the gas tank people. It protects the finish of natural parts too, and doesn't get sticky or attract dust.

Regards,

Alan

I'll only add that I've used 'PreLube 6', which comes in a spray can, to protect the parts after parkerizing.

I buy it from Quanta the gas tank people. It protects the finish of natural parts too, and doesn't get sticky or attract dust.

Regards,

Alan

#16

Team Owner

Member Since: Sep 2006

Location: Westminster Maryland

Posts: 30,173

Likes: 0

Received 2,878 Likes

on

2,515 Posts

Hi Keith,

Good to talk to you!

I bought my supplies from Palmetto Enterprises.

Google 'phosphate Palmetto Enterprises'; you see info and phone #.

Can you believe THIS WINTER!?!?

Regards,

Alan

Good to talk to you!

I bought my supplies from Palmetto Enterprises.

Google 'phosphate Palmetto Enterprises'; you see info and phone #.

Can you believe THIS WINTER!?!?

Regards,

Alan

#18

Burning Brakes

Thread Starter

#20

Hi Alan - Sorry for dragging up an old thread. Very nice work shown here! Was curious if you have a current source for manganese phosphate available to the home guy? Or what other guys are using. I'm finding that there seem to be a couple of military grades available, one used for guns, not sure what the other one is. Thank you, Jim

Hi C....

Phosphating is really the easiest plating to do at home

The process is called 'Parkerizing' and apparently people who make firearms use it.

The supplies and instructions are readily available. Google... 'Parkerizing'.

I use both the manganese phosphate, (VERY dark gray, almost black), and zinc phosphate, (medium gray).

Here's a m & f hood latch with the zinc phosphate finish.

Regards,

Alan

Phosphating is really the easiest plating to do at home

The process is called 'Parkerizing' and apparently people who make firearms use it.

The supplies and instructions are readily available. Google... 'Parkerizing'.

I use both the manganese phosphate, (VERY dark gray, almost black), and zinc phosphate, (medium gray).

Here's a m & f hood latch with the zinc phosphate finish.

Regards,

Alan