Wiring Dual Spals--A New Way

#1

Safety Car

Thread Starter

I thought that I would design a fan control circuit that simulates the way a thermal fan clutch controls coolant temperature. I did this to attempt to get the most control, performance, and economy from the dual SPALS.

This is what I intend to try in my car as soon as the fans arrive. I would like to have you guys rip this idea apart before I go through all the trouble to install it!

It seemed to me that the way all other temperature controls are placed, it allows the fans to come on when not really necessary. They do not factor in engine speed, radiator effiency, temperature of the air passing through the radiator, flow rate of the coolant (water pump speed), air conditioner condenser outflow air temperature, etc.

A thermal fan clutch does this extremely well by measuring the temperature of the air leaving the radiator over the average of the radiator surface. Unless your thermal fan clutch has failed, I'll bet you've never seen it engage unless it was actually needed (except on engine startup).

Even new cars/vans/pickups, ones that don't use electric fans, still use the thermal fan clutch--unchanged from the form found in our C3's.

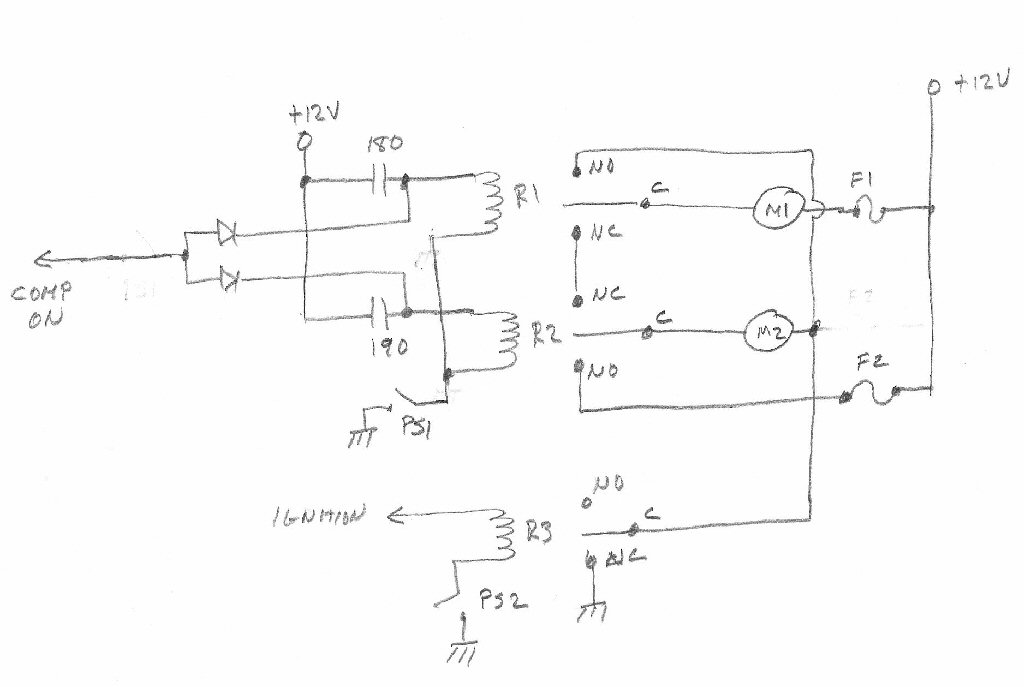

My circuit uses two Thermodisc airstream thermostats placed as shown in diagram. The drivers side fan controls from 180-190F, The passenger side fan controls from 190-200F. This gives a total range of 20F similar to a 185F thermal fan clutch. By the way, a no a/c C3 has a 170F fan clutch, while a a/c C3 has a 190F fan clutch as OEM.

The circuit also includes two vacuum switches. PSW1 is attached to the ported vacuum signal to the distributor. What this does is allows both fans to run at FAST speed when the throttle is closed and the a/c is on. This provides free fan energy when coasting--the extra drag on the alternator will just slow the car down a bit faster. It turns on fans to FAST speed when at idle--stopped--when the condenser coil needs more airflow.

This is backed up by another vacuum switch which turns off all fans and the a/c compressor when at WOT. There is a 0.5 second delay built into the vacuum switches to prevent short cycling.

So, normal operation:

Engine starts: both fans in SLOW speed. Average radiator temperature being sensed by the tstats.

Temperature above 180F but below 190F: DS fan goes to FAST speed. PS fan switches OFF.

Temperature above 190F: both fans in FAST speed.

Car coasts greater that 0.5 seconds: If a/c on, both fans go to FAST speed.

Car goes to WOT: After 0.5 seconds, the a/c compressor and both fans go to OFF.

This is what I intend to try in my car as soon as the fans arrive. I would like to have you guys rip this idea apart before I go through all the trouble to install it!

It seemed to me that the way all other temperature controls are placed, it allows the fans to come on when not really necessary. They do not factor in engine speed, radiator effiency, temperature of the air passing through the radiator, flow rate of the coolant (water pump speed), air conditioner condenser outflow air temperature, etc.

A thermal fan clutch does this extremely well by measuring the temperature of the air leaving the radiator over the average of the radiator surface. Unless your thermal fan clutch has failed, I'll bet you've never seen it engage unless it was actually needed (except on engine startup).

Even new cars/vans/pickups, ones that don't use electric fans, still use the thermal fan clutch--unchanged from the form found in our C3's.

My circuit uses two Thermodisc airstream thermostats placed as shown in diagram. The drivers side fan controls from 180-190F, The passenger side fan controls from 190-200F. This gives a total range of 20F similar to a 185F thermal fan clutch. By the way, a no a/c C3 has a 170F fan clutch, while a a/c C3 has a 190F fan clutch as OEM.

The circuit also includes two vacuum switches. PSW1 is attached to the ported vacuum signal to the distributor. What this does is allows both fans to run at FAST speed when the throttle is closed and the a/c is on. This provides free fan energy when coasting--the extra drag on the alternator will just slow the car down a bit faster. It turns on fans to FAST speed when at idle--stopped--when the condenser coil needs more airflow.

This is backed up by another vacuum switch which turns off all fans and the a/c compressor when at WOT. There is a 0.5 second delay built into the vacuum switches to prevent short cycling.

So, normal operation:

Engine starts: both fans in SLOW speed. Average radiator temperature being sensed by the tstats.

Temperature above 180F but below 190F: DS fan goes to FAST speed. PS fan switches OFF.

Temperature above 190F: both fans in FAST speed.

Car coasts greater that 0.5 seconds: If a/c on, both fans go to FAST speed.

Car goes to WOT: After 0.5 seconds, the a/c compressor and both fans go to OFF.

Last edited by PhotoVette1; 07-06-2006 at 08:31 AM.

#3

Le Mans Master

Member Since: Jan 2006

Location: Boca Raton Florida

Posts: 9,192

Likes: 0

Received 24 Likes

on

23 Posts

Looks pretty good. Couple of questions;

1. what is PSW2 to do?

2. Why have the fans on at all at startup engine cold?

so far I like it, but I think I would first turn the fans on low when that first blast of hot water gets to the radiator as soon as the motor heats up

1. what is PSW2 to do?

2. Why have the fans on at all at startup engine cold?

so far I like it, but I think I would first turn the fans on low when that first blast of hot water gets to the radiator as soon as the motor heats up

#4

Hmm, you must be in the HVAC field! Looks like some Honeywell HVAC parts to me.

I think the concept is good, if not a little overly complex for the task.

Where are you going to put all those relays?

Any idea what the temperature differential is between the actual coolant temperature and the air where you plan on putting your sensors? I'm thinking it will be substantially different.

Where are you getting your .5S delay? Is that built into the limit switches?

The only real drawback that I see with your setup is that it lacks adjustability. That may or may not be a problem, but I like to have my fans come on relative to the thermostat opening and closing.

I have dual flex-a-lites and an adjustable controller that uses a direct coolant reading via a bulb in the coolant flow. I have it set so that the fans come on come on a little after the thermostat opens up.

Actually, now that I'm thinking about it, maybe adding a some sort of sail switch would be nice. It would sense air flow through the radiator, and at higher speeds (dunno, maybe 35mph or higher), it would disable the fans.

Anyway, not trying to snipe.....your concept looks workable to me

I think the concept is good, if not a little overly complex for the task.

Where are you going to put all those relays?

Any idea what the temperature differential is between the actual coolant temperature and the air where you plan on putting your sensors? I'm thinking it will be substantially different.

Where are you getting your .5S delay? Is that built into the limit switches?

The only real drawback that I see with your setup is that it lacks adjustability. That may or may not be a problem, but I like to have my fans come on relative to the thermostat opening and closing.

I have dual flex-a-lites and an adjustable controller that uses a direct coolant reading via a bulb in the coolant flow. I have it set so that the fans come on come on a little after the thermostat opens up.

Actually, now that I'm thinking about it, maybe adding a some sort of sail switch would be nice. It would sense air flow through the radiator, and at higher speeds (dunno, maybe 35mph or higher), it would disable the fans.

Anyway, not trying to snipe.....your concept looks workable to me

#5

just trying to think of anything to contribute:

not sure that i'd want the fans to cut off when WOT unless maybe drag racing all the time; but if i did, i think i'd rather have a swith sensing throttle position (could be anywhere in the linkage) as opposed to a pressure sensing switch. just seems like it would be more consistant (move throttle, check switch with meter), and no delay.

ok, < 0.02

not sure that i'd want the fans to cut off when WOT unless maybe drag racing all the time; but if i did, i think i'd rather have a swith sensing throttle position (could be anywhere in the linkage) as opposed to a pressure sensing switch. just seems like it would be more consistant (move throttle, check switch with meter), and no delay.

ok, < 0.02

#6

Race Director

Member Since: Nov 1999

Location: Foxfield CO 1970 Convertible

Posts: 10,642

Likes: 0

Received 5 Likes

on

4 Posts

A few devils advocate questions:

When the temperature of the air across the radiator fins is 190F, what do you think the coolant temperature is in the heads? 225? 250? something higher? I think many radiator designs are such that the radiator inlet *coolant* temp is assumed to be between 180-190 degrees. With 100 degree air flowing through the radiator (summertime), you might consider lowering the sensor temp to account for the temp differential from the air through the radiator fins to the coolant...

I'm running an electric fan, and I am using 180 as my fan on temp, but I'm using sensors in the heads - one for the computer and one for the dashboard gauge. That way I'm actually monitoring and controlling the fan based on the actual engine coolant temperature, not the radiator temperature. Call me old fashioned, but I like to take measurements as close to the source as possible...

When the temperature of the air across the radiator fins is 190F, what do you think the coolant temperature is in the heads? 225? 250? something higher? I think many radiator designs are such that the radiator inlet *coolant* temp is assumed to be between 180-190 degrees. With 100 degree air flowing through the radiator (summertime), you might consider lowering the sensor temp to account for the temp differential from the air through the radiator fins to the coolant...

I'm running an electric fan, and I am using 180 as my fan on temp, but I'm using sensors in the heads - one for the computer and one for the dashboard gauge. That way I'm actually monitoring and controlling the fan based on the actual engine coolant temperature, not the radiator temperature. Call me old fashioned, but I like to take measurements as close to the source as possible...

#9

Advanced

When you release from WOT and the A/C was previously on, the compressor might engage at a high rpm - seems like it would be hard on compressor clutch. On a manual transmission, it could happen multiple times on one hard acceleration. If you are going to accelerate at a rate at which having the A/C on or off matters - one would know it with enough warning to shut off A/C. Good idea though - I had contemplated something similar as well.

#10

Hey, that saves $75 bucks if buying the weather pack type relays, or about $15 if going the cheapo route. The fewer relays, the better! I've been working on the wiring in my car the last week and it's not easy mounting a bunch of relays out of sight. BTW, i'm assuming you've seen the SPAL controller. You could add the cut off features to that or a competitive controller. The SPAL is supposed to vary the speed of the first fan beginning at half speed to full speed as more cooling is needed, bringing in the second fan at full speed (can also be connected to A/C for full on with A/C). That setup is supposed to eliminate the cooling system always "hunting" between the low and high set points (supposed to; assuming enough system capacity).

#11

Jcmayerimc: When you release from WOT and the A/C was previously on, the compressor might engage at a high rpm - seems like it would be hard on compressor clutch. On a manual transmission, it could happen multiple times on one hard acceleration. If you are going to accelerate at a rate at which having the A/C on or off matters - one would know it with enough warning to shut off A/C. Good idea though - I had contemplated something similar as well.

#12

Le Mans Master

Member Since: Jan 2006

Location: Boca Raton Florida

Posts: 9,192

Likes: 0

Received 24 Likes

on

23 Posts

Originally Posted by Z-man

A few devils advocate questions:

When the temperature of the air across the radiator fins is 190F, what do you think the coolant temperature is in the heads? 225? 250? something higher? I think many radiator designs are such that the radiator inlet *coolant* temp is assumed to be between 180-190 degrees. With 100 degree air flowing through the radiator (summertime), you might consider lowering the sensor temp to account for the temp differential from the air through the radiator fins to the coolant...

I'm running an electric fan, and I am using 180 as my fan on temp, but I'm using sensors in the heads - one for the computer and one for the dashboard gauge. That way I'm actually monitoring and controlling the fan based on the actual engine coolant temperature, not the radiator temperature. Call me old fashioned, but I like to take measurements as close to the source as possible...

When the temperature of the air across the radiator fins is 190F, what do you think the coolant temperature is in the heads? 225? 250? something higher? I think many radiator designs are such that the radiator inlet *coolant* temp is assumed to be between 180-190 degrees. With 100 degree air flowing through the radiator (summertime), you might consider lowering the sensor temp to account for the temp differential from the air through the radiator fins to the coolant...

I'm running an electric fan, and I am using 180 as my fan on temp, but I'm using sensors in the heads - one for the computer and one for the dashboard gauge. That way I'm actually monitoring and controlling the fan based on the actual engine coolant temperature, not the radiator temperature. Call me old fashioned, but I like to take measurements as close to the source as possible...

#13

Melting Slicks

Member Since: Nov 2003

Location: St. Charles Mo

Posts: 2,655

Likes: 0

Received 104 Likes

on

49 Posts

CI 5 & 8 Veteran

I think of it this way. The whole purpose of the cooling system is to keep the engine running at its optimum thermal operating condition for best performance. Performance across a wide range of expectations i.e. gas mileage, power, reliability, emmisions, etc. For my RamJet engine, the engine temp sensor is located in the intake manifold water channel. That is probably the best place to sense, since it serves as a good average of all engine cylinder temps with a known temp delta and very short temp lag. (i.e. quick temp sense response.) I think, at least for RamJet, that desired temp is somewhere ~ 200-210deg F. That is the point you want the cooling system to control. That being said, The fastest reacting controller with minimum lag is best. To my way of thinking, there is nothing wrong with a bang bang system turning the fan or fans full off/on as required to maintain that temp as constant as you can....as long as the electrical system can handle it. Engine temperature change is relatively slow, so having a cooling system capacity large enough to handle the operational extremes and maintain a quick response time is what is required, and then you are in good shape. For me, sensing the radiator output air temp would only be of value for those extremes when the ambient air is very hot and/or when the A/C is on. I would use an air temp switch to sense when to engage the secound fan operation in parallel with the primary fan. And incorportate a simple bang-bang control system. Who cares if the fan or fans are running 50% of the time, or 50% of the speed???

ok, I am ready......what's wrong with my thinking

Turning off the fans at WOT makes some sense for very short durations if the engine temp is below some pre determined level.

Bullshark

ok, I am ready......what's wrong with my thinking

Turning off the fans at WOT makes some sense for very short durations if the engine temp is below some pre determined level.

Bullshark

Last edited by Bullshark; 07-07-2006 at 10:38 PM.

#14

Melting Slicks

Member Since: Nov 2003

Location: St. Charles Mo

Posts: 2,655

Likes: 0

Received 104 Likes

on

49 Posts

CI 5 & 8 Veteran

Just had another thought.......Maybe some sort of mode control would be desireable to change the engine operating temp base on what is needed. Fuel economy mode requires one temp while performance mode might require a different engine temp.

Bullshark

This is one reason I like Fuel injection with ECU's

Bullshark

This is one reason I like Fuel injection with ECU's

#15

Safety Car

Thread Starter

Originally Posted by Bullshark

Just had another thought.......Maybe some sort of mode control would be desireable to change the engine operating temp base on what is needed. Fuel economy mode requires one temp while performance mode might require a different engine temp.

Bullshark

This is one reason I like Fuel injection with ECU's

Bullshark

This is one reason I like Fuel injection with ECU's

#16

Safety Car

Thread Starter

I have been following this discussion along and there's a lot to think about.

Such as, does the thermostat control coolant temperature or does the fan? Us C3ers usually say the tstat gives a minimum temperature, but what if your Vette has a high performing cooling system--one that can handle 120F with the a/c on--how does that system control temps when its 60F? With the fan or thermostat?

There are as many places to put temperature sensors as there places to mount them--heads, before the tstat, on the tstat water outlet, one the radiator inlet, through the radiator fins, and on the radiator outlet. Which is best? There are any number of opinions.

I have noticed that thermal fan clutches do an excellant job maintaining coolant temperatures--that's why I want to try simulating how they operate.

Then why switch to electric fans?

First, I have had them before and I know there is a real mpg gain to be had from them. Second, fan clutches don't work over 3000 rpm--that is my highway cruising speed--I'm overheating. Third, all that blessed room they free up in the engine compartment.

So, I'm going to try this just to see what happens.

Such as, does the thermostat control coolant temperature or does the fan? Us C3ers usually say the tstat gives a minimum temperature, but what if your Vette has a high performing cooling system--one that can handle 120F with the a/c on--how does that system control temps when its 60F? With the fan or thermostat?

There are as many places to put temperature sensors as there places to mount them--heads, before the tstat, on the tstat water outlet, one the radiator inlet, through the radiator fins, and on the radiator outlet. Which is best? There are any number of opinions.

I have noticed that thermal fan clutches do an excellant job maintaining coolant temperatures--that's why I want to try simulating how they operate.

Then why switch to electric fans?

First, I have had them before and I know there is a real mpg gain to be had from them. Second, fan clutches don't work over 3000 rpm--that is my highway cruising speed--I'm overheating. Third, all that blessed room they free up in the engine compartment.

So, I'm going to try this just to see what happens.

Last edited by PhotoVette1; 07-07-2006 at 08:54 PM.

#17

Race Director

Originally Posted by Jcmayerimc

When you release from WOT and the A/C was previously on, the compressor might engage at a high rpm - seems like it would be hard on compressor clutch. On a manual transmission, it could happen multiple times on one hard acceleration. If you are going to accelerate at a rate at which having the A/C on or off matters - one would know it with enough warning to shut off A/C. Good idea though - I had contemplated something similar as well.

Here is a quote I had saved you may find interesting concerning temperatures:

"As a retired GM Engineer responsible for among other things engine cooling, your system is set up to kick the fan in about 210-220... the engine system is pressurized so the engine will not boil until 249-253... we run these vehicles at 100 +++degrees up a 7% grade with full passenger load, fuel and 500-1000 lbs of additioanl load for hours in death valley...then idle for hours.... the temps you see do absolutely no harm to the engine and are completely normal................ when the temp hits 240+ then you worry... remember you can always reduce the temp by putting on the heater to pull heat..(not too comfortable in 110 heat but it works....)"

#18

Safety Car

Thread Starter

Originally Posted by noonie

When engines started to be computer controlled, the ecm would shut of the a/c clutch at around 99% wot, and there is also a delay of anywhere from 10 seconds to as long as a minute on some models before re-engagement. The newer trend is to manage the a/c clutch from engine load instead, so a smaller engine can make it up a long hill at speed. For pre computer cars there was a crude vacumn switch available the cut off the a/c.

Here is a quote I had saved you may find interesting concerning temperatures:

"As a retired GM Engineer responsible for among other things engine cooling, your system is set up to kick the fan in about 210-220... the engine system is pressurized so the engine will not boil until 249-253... we run these vehicles at 100 +++degrees up a 7% grade with full passenger load, fuel and 500-1000 lbs of additioanl load for hours in death valley...then idle for hours.... the temps you see do absolutely no harm to the engine and are completely normal................ when the temp hits 240+ then you worry... remember you can always reduce the temp by putting on the heater to pull heat..(not too comfortable in 110 heat but it works....)"

Here is a quote I had saved you may find interesting concerning temperatures:

"As a retired GM Engineer responsible for among other things engine cooling, your system is set up to kick the fan in about 210-220... the engine system is pressurized so the engine will not boil until 249-253... we run these vehicles at 100 +++degrees up a 7% grade with full passenger load, fuel and 500-1000 lbs of additioanl load for hours in death valley...then idle for hours.... the temps you see do absolutely no harm to the engine and are completely normal................ when the temp hits 240+ then you worry... remember you can always reduce the temp by putting on the heater to pull heat..(not too comfortable in 110 heat but it works....)"

Running at that high a temperature also increases cabin heat greatly in a C3.

#19

Safety Car

Thread Starter

After reading the suggestions (thanks, very helpful!), I have come up with this revised circuit.

Once again:

Ignition off/motor off: No fans

Ignition on/motor off: No fans--with no engine vacuum signal, fans are de-energized.

Ignition on/motor on: Both fans in slow speed.

Ignition on/motor on/temp 170-180F: DS fan in fast speed, PS fan off.

Ignition on/motor on/temp 180-190F: Both fans in fast speed.

Throttle at WOT: No fans--with no engine vacuum signal, fans are de-energized.

In the spirit of attempting to emulate a thermal fan clutch, I am ignoring the a/c heat load and maintaining at least 20% fan speed at all times.

I could, however, add a 130F switch to keep fans from going to slow speed before engine warms up--hmmm....

Once again:

Ignition off/motor off: No fans

Ignition on/motor off: No fans--with no engine vacuum signal, fans are de-energized.

Ignition on/motor on: Both fans in slow speed.

Ignition on/motor on/temp 170-180F: DS fan in fast speed, PS fan off.

Ignition on/motor on/temp 180-190F: Both fans in fast speed.

Throttle at WOT: No fans--with no engine vacuum signal, fans are de-energized.

In the spirit of attempting to emulate a thermal fan clutch, I am ignoring the a/c heat load and maintaining at least 20% fan speed at all times.

I could, however, add a 130F switch to keep fans from going to slow speed before engine warms up--hmmm....

Last edited by PhotoVette1; 07-07-2006 at 11:06 PM.

#20

Melting Slicks

Member Since: Nov 2003

Location: St. Charles Mo

Posts: 2,655

Likes: 0

Received 104 Likes

on

49 Posts

CI 5 & 8 Veteran

Originally Posted by PhotoVette1

I could, however, add a 130F switch to keep fans from going to slow speed before engine warms up--hmmm....

So, in my case, no fans until RamJet get's it's temperature (measured at the intake manifold water channel) to at least ~200 deg F. That would suggest a 190 or 195 deg thermostate. Then its time for the fans to step in and do thier job. Lets say for the sake of example, they kick in with minimum flow at 205 deg. Step up to full speed at 210. Now, if one fan can't maintain control keeping the system at the desired temp, it's time to kick the secound fan into operation. In my case with RamJet and a Be-Cool aluminum radiator, one fan seems to be capable of control up to ~95 deg ambient air....even in what I call normal city suburb traffic. That is why I was thinking a temp sensor sensing radiator output air temp might be a reasonable way to determine when its time to put the second fan into operation. That may work for A/C mode also??????

Bullshark

My dual Spal fans do not have two speeds, so in my case, I would not be able to incorporate a min speed at 205 and a full speed at 210. I would just pick a temp and bang-bang the fan something around 210 on and 205 off. Also, the cooling system's time constant plays a role. ( i.e. the lag time it takes to react). That may be why, with your system, you would turn on the the slow speed fan early and turn it off late to minimize overshoot and short cycling when little or no ambient air is flowing thru the radiator......stopped in traffic. This is probably pole vaulting over mouse turds now

Last edited by Bullshark; 07-08-2006 at 09:34 AM.