Finally, an analysis of I-Beam rods vs H-Beam rods

#1

Pro

Thread Starter

Member Since: Apr 2006

Location: Southern California

Posts: 625

Likes: 0

Received 47 Likes

on

25 Posts

The discussion came up last week, here in another thread about I-Beam rods vs H-Beam rods, and which is better. So, I thought I'd post it as a stand alone discussion for those who may have missed it and may like to see it. This all came about after a 632 Mountain Motor coughed a Carillo H-Beam rod and EXPLODED on a chassis dyno. Though the owner Steve never gave out a dollar amount, others have estimated that when that motor exploded, it was like flushing $30,000.00 down the commode. So, the search was on to find an appropriate rod for the rebuild. But research had been inconclusive, because some claim that either one will do, but H-Beam makers and others say H-Beams are best, while I-Beam makers and others say I-Beams are best. They can't ALL be right.

Of course rods need to have enough absolute strength to not be snapped apart by the maximum tension forces at TDC exhaust, where the piston would like nothing better than to go right up through the head. Those tension forces are mitigated some during the opposing compression forces at TDC compression. Absolute strength is determined by the total cross-sectional area of the rod. The material being used has to have a low enough psi loading from the forces it sees, to have a positive margin of safety, if the rod is to survive a reasonable length of time. So, there is a minimum total area that will get the job done for any given rod material and engine combo.

Rods also have to be stiff enough to stand up to the enormous cylinder pressure forces it sees on the power stroke, which would like nothing better than to bend the rod into a C-shape, if the rod is to have an acceptable fatigue life (durability). If the rod bends/flexes on the power stroke, even a little, the fatigue life will be reduced by the pressure cycles causing that repeated bending/flexing, which will eventually lead to micro-cracks and ultimately total failure. And the rod does NOT have to be bent beyond it elastic limit for fatigue to take its toll, causing cracks and failure.

The bottom line is that we need an ideal rod to be both STRONG enough and STIFF enough, in order for it to last more or less indefinitely. If you don't have both things, then your rods will be a ticking time bomb and will give up the ghost sooner than you'd like, which will ruin your whole day. Aluminum rods that are used in really serious stuff, for reduced weight and for some cushioning, so to speak, are considered disposable items because of flexing reducing their fatigue life. So, for most gear heads and less than Pro Racers, the rod material of choice is a high quality steel with high quality bolts. So, from here on out, the discussion of I-Beams vs H-Beams will assume the same material and bolts are used for both types of rods, so that the only consideration between the two is strength and stiffness.

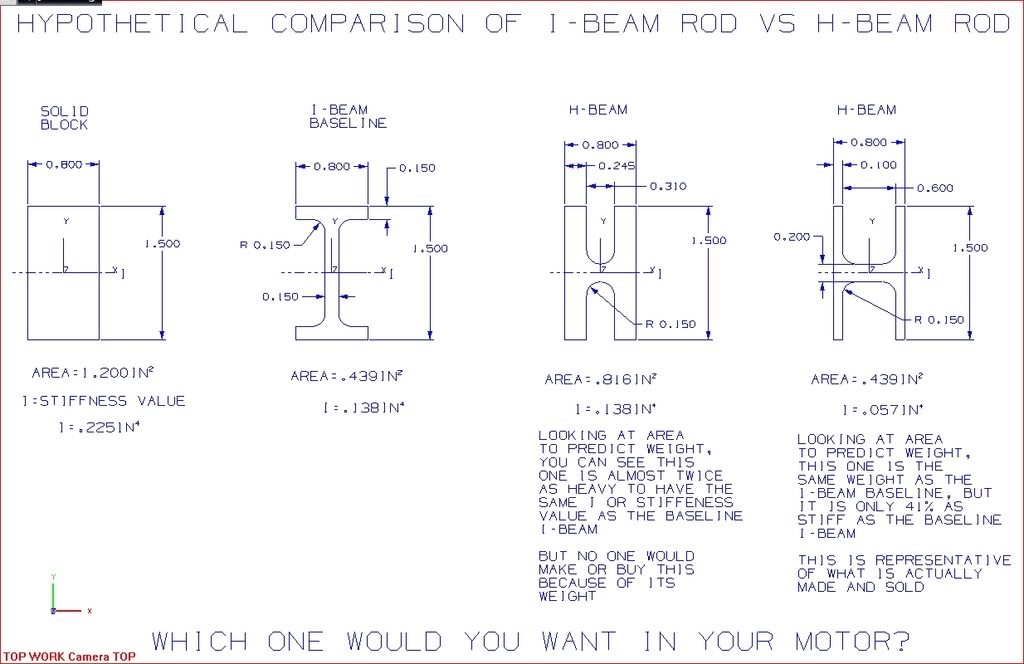

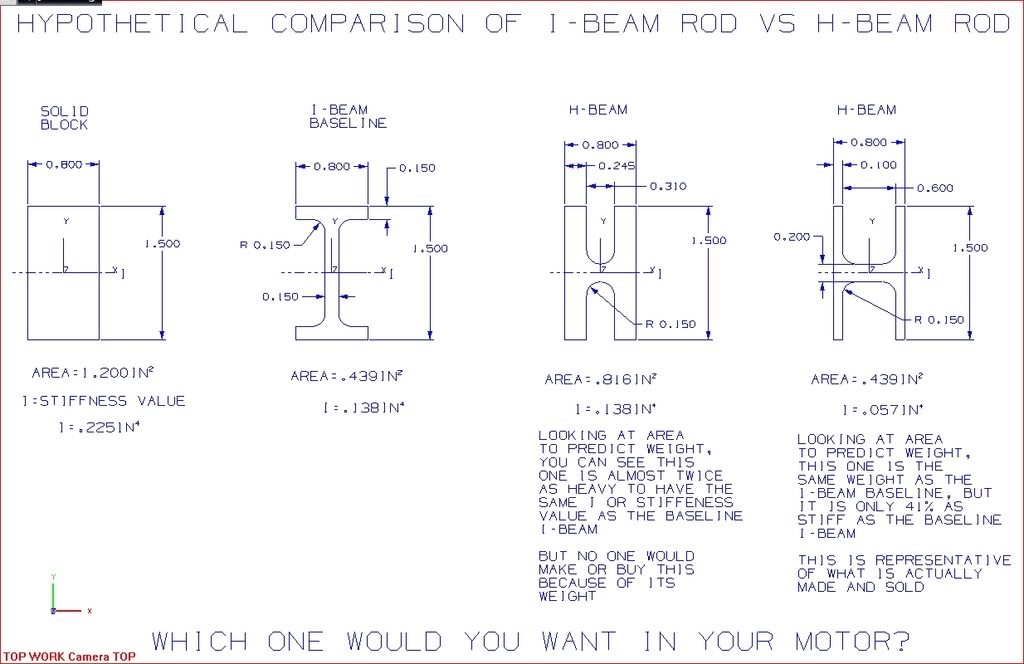

Personally, I hadn't come across any good factual analysis between both types of rods. Only opinions, personal preferences, and who's marketing what, seem to be plentiful. But nothing concrete is available to really help anyone make a good intelligent buying decision. And if that isn't bad enough, some tech info put out by certain manufacturers as well as some magazine articles coming from them, are filled with incorrect information. So much so, that it became quite apparent that most rod makers are not even engineers at all, they simply make stuff based on what's been done before. I've run across this issue countless times before with other aftermarket Hotrod/Race parts that don't fit or function as they should. That being the case, I decided it was time for me to do some analysis myself and see once and for all, where the chips fall. Keep in mind the important things here come down to AREA in square inches for absolute strength, and STIFFNESS value called "I", (and this has nothing to do with the shape of the rod, its just a name here), which is used in an equation to calculate the amount of bending/flexing. The higher the area number, the stronger the part. And the higher the stiffenss "I" value, the more durable the part, from extended faigue life. So, consider the following and decide for yourself:

But keep in mind, that even the best rod "design" could fail if it wasn't used in the right application. For example an I-Beam that is perfect for a stock 396 isn't going to live in a bad boy 572. It must be robust enough for the job at hand. Also material imperfections as well as surface nicks, can also derail your plans. So, all those things need to be kept in mind as well.

Of course rods need to have enough absolute strength to not be snapped apart by the maximum tension forces at TDC exhaust, where the piston would like nothing better than to go right up through the head. Those tension forces are mitigated some during the opposing compression forces at TDC compression. Absolute strength is determined by the total cross-sectional area of the rod. The material being used has to have a low enough psi loading from the forces it sees, to have a positive margin of safety, if the rod is to survive a reasonable length of time. So, there is a minimum total area that will get the job done for any given rod material and engine combo.

Rods also have to be stiff enough to stand up to the enormous cylinder pressure forces it sees on the power stroke, which would like nothing better than to bend the rod into a C-shape, if the rod is to have an acceptable fatigue life (durability). If the rod bends/flexes on the power stroke, even a little, the fatigue life will be reduced by the pressure cycles causing that repeated bending/flexing, which will eventually lead to micro-cracks and ultimately total failure. And the rod does NOT have to be bent beyond it elastic limit for fatigue to take its toll, causing cracks and failure.

The bottom line is that we need an ideal rod to be both STRONG enough and STIFF enough, in order for it to last more or less indefinitely. If you don't have both things, then your rods will be a ticking time bomb and will give up the ghost sooner than you'd like, which will ruin your whole day. Aluminum rods that are used in really serious stuff, for reduced weight and for some cushioning, so to speak, are considered disposable items because of flexing reducing their fatigue life. So, for most gear heads and less than Pro Racers, the rod material of choice is a high quality steel with high quality bolts. So, from here on out, the discussion of I-Beams vs H-Beams will assume the same material and bolts are used for both types of rods, so that the only consideration between the two is strength and stiffness.

Personally, I hadn't come across any good factual analysis between both types of rods. Only opinions, personal preferences, and who's marketing what, seem to be plentiful. But nothing concrete is available to really help anyone make a good intelligent buying decision. And if that isn't bad enough, some tech info put out by certain manufacturers as well as some magazine articles coming from them, are filled with incorrect information. So much so, that it became quite apparent that most rod makers are not even engineers at all, they simply make stuff based on what's been done before. I've run across this issue countless times before with other aftermarket Hotrod/Race parts that don't fit or function as they should. That being the case, I decided it was time for me to do some analysis myself and see once and for all, where the chips fall. Keep in mind the important things here come down to AREA in square inches for absolute strength, and STIFFNESS value called "I", (and this has nothing to do with the shape of the rod, its just a name here), which is used in an equation to calculate the amount of bending/flexing. The higher the area number, the stronger the part. And the higher the stiffenss "I" value, the more durable the part, from extended faigue life. So, consider the following and decide for yourself:

But keep in mind, that even the best rod "design" could fail if it wasn't used in the right application. For example an I-Beam that is perfect for a stock 396 isn't going to live in a bad boy 572. It must be robust enough for the job at hand. Also material imperfections as well as surface nicks, can also derail your plans. So, all those things need to be kept in mind as well.

#2

Tech Contributor

Member Since: Jun 2004

Location: I tend to be leery of any guy who doesn't own a chainsaw or a handgun.

Posts: 18,343

Received 767 Likes

on

549 Posts

Excellent write up! As a design engineer by training, I always like to see the actual data behind someone's comments and recommendations. Looking forward to additional postings on this subject.

#3

Race Director

If you rotate the H beam rod 90 degrees what type of rod is it ?

Very good analysis

My take on the H vs I beam is this, many of us don't have the money to buy top notch I beam rods so the compromise is to use a cheaper and heavier H beam to get the same strength

Very good analysis

My take on the H vs I beam is this, many of us don't have the money to buy top notch I beam rods so the compromise is to use a cheaper and heavier H beam to get the same strength

#4

Team Owner

Very true on an engineering design level. I use Manley rods and they are rated in HP and gram weights. Page 11 shows Big block Chevy 6.385 inch rods. H-beam 900 HP weigh 810 grams. The I-beam 900 HP weigh only 736 grams.

But as Motor Head mentioned price is a factor. I personally have the heavier H beams in both of my motors.

http://www.manleyperformance.com/dl/2008/rods.pdf

But as Motor Head mentioned price is a factor. I personally have the heavier H beams in both of my motors.

http://www.manleyperformance.com/dl/2008/rods.pdf

#5

Le Mans Master

Yeah! those Carrillio rods are PURE JUNK that is why none of the Cup tems run them. I don't know what happened to the guy's rod but, I would guess it is a application or assembly error by someone. Oliver, Pankl or Arrow make rods of good quality in Carrillio's area of inspection and metalurgical expirience but, not many others

#6

Le Mans Master

First off, I want to establish that I'm only posting this as much to foster a healthy debate from which to learn as for any other reason, but FWIW to anyone wondering where I'm coming from, over the years I've used everything from standard factory rods to blueprinted L88s, to I-beams, to H-beams, to aluminum; so at least some of what I have to offer comes out of what might be called "field experience".

Now, on the one hand, while an I-beam may well be "stronger" than an H-beam of equal weight for a given application, when considering strength-to-weight ratio and cycle-life most of us simply cannot dismiss the cost factor associated with overkill. For that reason, I submit that a set of H-beams remains a viable choice for many an engine as long as the rod's basic design limitations are not exceeded (an important qualification, that).

But on the other hand, hypothetically (I'm not looking to point any fingers here), when a rod fails in an application where it is likely to have been subjected to excessive abuse well beyond its basic design limitations, is it not the build's "engineer" who ought best to be questioned for his component selection rather than the component itself?

As for aluminum rods, given their relatively short fatigue life (I'm not kidding when I suggest buying and machining them in bulk sets for anyone remotely thinking about them), cushioning is the overriding reason I've ever gone with them. Perhaps, what with the way he tends to push things, Steve might be a candidate for a case of BMEs instead of the I-beams. Just a thought... (BTW, anyone who hasn't seen the carnage from his catastrophic failure owes it to themselves to check it out. )

)

Bottom line for me; I'm plenty comfortable with putting Eagle H-beams in the ~500HP 427 BB on which I'm working. (Say what you will about Eagle, my being so nearby I can get them for a song and I always check everything, besides.) IMHO, the Crower I-beams (first used them ~30 years ago ) are best left to more serious builds.

) are best left to more serious builds.

One last thing; hasn't a case been made recently for H-beams being more resistant to twisting??

Thoughts, pro and con alike, are most welcome...

Now, on the one hand, while an I-beam may well be "stronger" than an H-beam of equal weight for a given application, when considering strength-to-weight ratio and cycle-life most of us simply cannot dismiss the cost factor associated with overkill. For that reason, I submit that a set of H-beams remains a viable choice for many an engine as long as the rod's basic design limitations are not exceeded (an important qualification, that).

But on the other hand, hypothetically (I'm not looking to point any fingers here), when a rod fails in an application where it is likely to have been subjected to excessive abuse well beyond its basic design limitations, is it not the build's "engineer" who ought best to be questioned for his component selection rather than the component itself?

As for aluminum rods, given their relatively short fatigue life (I'm not kidding when I suggest buying and machining them in bulk sets for anyone remotely thinking about them), cushioning is the overriding reason I've ever gone with them. Perhaps, what with the way he tends to push things, Steve might be a candidate for a case of BMEs instead of the I-beams. Just a thought... (BTW, anyone who hasn't seen the carnage from his catastrophic failure owes it to themselves to check it out.

)

) Bottom line for me; I'm plenty comfortable with putting Eagle H-beams in the ~500HP 427 BB on which I'm working. (Say what you will about Eagle, my being so nearby I can get them for a song and I always check everything, besides.) IMHO, the Crower I-beams (first used them ~30 years ago

) are best left to more serious builds.

) are best left to more serious builds.One last thing; hasn't a case been made recently for H-beams being more resistant to twisting??

Thoughts, pro and con alike, are most welcome...

#7

Race Director

"Actually according to the desktop dyno it says you are hitting 840 ft lbs at 1500 rpms if you are hitting the Nitrous already. It drops from there progressively to 560 ft lbs at 6500 rpms. "

Here are the numbers with no nitrous.

"10.4:1 is 535hp @ 6000 rpm & 485 ft lbs @ 4500 rpm."

Here are numbers with the same 150 shot at higher RPM

"I just put the 150 lbs nitrous shot on you figures at 10.4 straight up and here, WOW!:

693HP @ 6500 Rpm @ 656 ft lbs @ 4500, 679 ft lbs @ 3000 rpm.

I khow the desktop dyno is theoretical but so is this discussion. As you can see with the above numbers the increase in torque is higher the lower rpm the nitrous is engaged. The 679 ft lbs is a 150 shot @ 3000 RPM. That is where the nitrous engagement happened in the motor that blew. Without nitrous the same 3000 rpm is under 450 ft lbs.

So a 150 shot @ 3000 rpm gives you over 225 Ft Lbs @ 3000 RPM.

Theoreticaly, 900 Ft Lbs of additional torque instantaniously applied to the rod that already has a heavy load on it.

I don't think the Carrillo H beam rod was at fault here. It was just the part that had been repeatedly stressed and finally failed. I don't know that any 6 year old rod with that many hard runs would have withstood that much shock.

Last edited by 63mako; 02-04-2009 at 09:29 AM.

#8

That was a really good write-up! Thanks for the info and time you took to create it.

I went with the Eagle H beams as well in my 434sbc. The same reason as Skunkworks, I have seen them do very well in my applications and they are close by and I can get a great deal on them. I think it depends on your build and picking the correct rod for your application. A 300 hp 5500 rpm motor wouldn't know the difference betweent the two types of rods. So, you could run a stock rod and be fine. A 750 hp 7500rpm motor you would would have to pick the best rod for the application regarless of cost effectiveness if want it to live. This is great info for those who are planning a build, since we have everyone from car show cars to full on race cars on here.

I went with the Eagle H beams as well in my 434sbc. The same reason as Skunkworks, I have seen them do very well in my applications and they are close by and I can get a great deal on them. I think it depends on your build and picking the correct rod for your application. A 300 hp 5500 rpm motor wouldn't know the difference betweent the two types of rods. So, you could run a stock rod and be fine. A 750 hp 7500rpm motor you would would have to pick the best rod for the application regarless of cost effectiveness if want it to live. This is great info for those who are planning a build, since we have everyone from car show cars to full on race cars on here.

#9

Melting Slicks

Nice write up

Semi related:

I tried to build my engine using American parts. I went with Oliver I beams, Crower cam, roller lifters and shaft rockers - Callies Magnum crank that I later found out was a forging from China , the block was an aluminum SBC from Bill Mitchell. My point is that if people keep buying the foreign stuff, US manufacturers won't be around, they're already offshoring some things just to compete. Callies offered me CompStar rods (foreign), I wanted American. Sure I could have built the motor for a lot less using offshore components but eventually that'll be the only place to buy engine components....it's short sighted IMO to do what's best for the pocket book instead of the good ol' USA. I spent a bunch of coin but I have confidence that this engine will stay together at red line whereas I'd be puckering with a block full of China cheepo stuff. You get what you pay for....

, the block was an aluminum SBC from Bill Mitchell. My point is that if people keep buying the foreign stuff, US manufacturers won't be around, they're already offshoring some things just to compete. Callies offered me CompStar rods (foreign), I wanted American. Sure I could have built the motor for a lot less using offshore components but eventually that'll be the only place to buy engine components....it's short sighted IMO to do what's best for the pocket book instead of the good ol' USA. I spent a bunch of coin but I have confidence that this engine will stay together at red line whereas I'd be puckering with a block full of China cheepo stuff. You get what you pay for....

Semi related:

I tried to build my engine using American parts. I went with Oliver I beams, Crower cam, roller lifters and shaft rockers - Callies Magnum crank that I later found out was a forging from China

, the block was an aluminum SBC from Bill Mitchell. My point is that if people keep buying the foreign stuff, US manufacturers won't be around, they're already offshoring some things just to compete. Callies offered me CompStar rods (foreign), I wanted American. Sure I could have built the motor for a lot less using offshore components but eventually that'll be the only place to buy engine components....it's short sighted IMO to do what's best for the pocket book instead of the good ol' USA. I spent a bunch of coin but I have confidence that this engine will stay together at red line whereas I'd be puckering with a block full of China cheepo stuff. You get what you pay for....

, the block was an aluminum SBC from Bill Mitchell. My point is that if people keep buying the foreign stuff, US manufacturers won't be around, they're already offshoring some things just to compete. Callies offered me CompStar rods (foreign), I wanted American. Sure I could have built the motor for a lot less using offshore components but eventually that'll be the only place to buy engine components....it's short sighted IMO to do what's best for the pocket book instead of the good ol' USA. I spent a bunch of coin but I have confidence that this engine will stay together at red line whereas I'd be puckering with a block full of China cheepo stuff. You get what you pay for....

#10

That was a really good write-up! Thanks for the info and time you took to create it.

I went with the Eagle H beams as well in my 434sbc. The same reason as Skunkworks, I have seen them do very well in my applications and they are close by and I can get a great deal on them. I think it depends on your build and picking the correct rod for your application. A 300 hp 5500 rpm motor wouldn't know the difference betweent the two types of rods. So, you could run a stock rod and be fine. A 750 hp 7500rpm motor you would would have to pick the best rod for the application regarless of cost effectiveness if want it to live. This is great info for those who are planning a build, since we have everyone from car show cars to full on race cars on here.

I went with the Eagle H beams as well in my 434sbc. The same reason as Skunkworks, I have seen them do very well in my applications and they are close by and I can get a great deal on them. I think it depends on your build and picking the correct rod for your application. A 300 hp 5500 rpm motor wouldn't know the difference betweent the two types of rods. So, you could run a stock rod and be fine. A 750 hp 7500rpm motor you would would have to pick the best rod for the application regarless of cost effectiveness if want it to live. This is great info for those who are planning a build, since we have everyone from car show cars to full on race cars on here.

#11

Le Mans Master

Member Since: Sep 2001

Location: Unreconstructed, South Carolina

Posts: 7,739

Received 628 Likes

on

556 Posts

reference MTBF (mean time between failure). Also, reference FEA (finite element analysis) ... a coupla years back there were interesting FEA reports published on web of various rod designs.

FYI ... both Eagle & Scat offer some affordable asian I-beams that're pretty good for semi-pro circle trackers. Also, take a look at some of the rods that Howard's Cams are having manufactured by GKN. Regardless, I prefer USA.

#12

Race Director

Nice write up

Semi related:

I tried to build my engine using American parts. I went with Oliver I beams, Crower cam, roller lifters and shaft rockers - Callies Magnum crank that I later found out was a forging from China , the block was an aluminum SBC from Bill Mitchell. My point is that if people keep buying the foreign stuff, US manufacturers won't be around, they're already offshoring some things just to compete. Callies offered me CompStar rods (foreign), I wanted American. Sure I could have built the motor for a lot less using offshore components but eventually that'll be the only place to buy engine components....it's short sighted IMO to do what's best for the pocket book instead of the good ol' USA. I spent a bunch of coin but I have confidence that this engine will stay together at red line whereas I'd be puckering with a block full of China cheepo stuff. You get what you pay for....

, the block was an aluminum SBC from Bill Mitchell. My point is that if people keep buying the foreign stuff, US manufacturers won't be around, they're already offshoring some things just to compete. Callies offered me CompStar rods (foreign), I wanted American. Sure I could have built the motor for a lot less using offshore components but eventually that'll be the only place to buy engine components....it's short sighted IMO to do what's best for the pocket book instead of the good ol' USA. I spent a bunch of coin but I have confidence that this engine will stay together at red line whereas I'd be puckering with a block full of China cheepo stuff. You get what you pay for....

Semi related:

I tried to build my engine using American parts. I went with Oliver I beams, Crower cam, roller lifters and shaft rockers - Callies Magnum crank that I later found out was a forging from China

, the block was an aluminum SBC from Bill Mitchell. My point is that if people keep buying the foreign stuff, US manufacturers won't be around, they're already offshoring some things just to compete. Callies offered me CompStar rods (foreign), I wanted American. Sure I could have built the motor for a lot less using offshore components but eventually that'll be the only place to buy engine components....it's short sighted IMO to do what's best for the pocket book instead of the good ol' USA. I spent a bunch of coin but I have confidence that this engine will stay together at red line whereas I'd be puckering with a block full of China cheepo stuff. You get what you pay for....

, the block was an aluminum SBC from Bill Mitchell. My point is that if people keep buying the foreign stuff, US manufacturers won't be around, they're already offshoring some things just to compete. Callies offered me CompStar rods (foreign), I wanted American. Sure I could have built the motor for a lot less using offshore components but eventually that'll be the only place to buy engine components....it's short sighted IMO to do what's best for the pocket book instead of the good ol' USA. I spent a bunch of coin but I have confidence that this engine will stay together at red line whereas I'd be puckering with a block full of China cheepo stuff. You get what you pay for....

#13

Le Mans Master

I don't know what "level" you race at but my good friend who is a noted USAC engine builder has a good relationship with Carrillio and Jack Sparks (you win a prize if you can tell me who Jack's father was.) Carrillio is well aware of the Asian competition and has done numerous testing on Scat, Eagle, Manley and other "copy cats" of their H-beam design. The comments I heard from my friend were yes it appears to be a Chrome Molly Steel BUT! the heat treatment is soo bad that these rods can be weaker that a 1038 mild steel American rod. Your cross section of the H-beam rod dosen't match the profile of a Carrillio beam cross section either. I would like you to tell me the method used when the bolts were torqued during assembly of the motor, I think we can find some issues there and hitting a motor with a BIG SHOT of N2O and then blaming the rod manufacturer for the failure? N2O is for people who don't have the God Given talent to build a proper motor in the first place. If I were hitting a motor with big shots of N20, I would have used a PWM progressive controller (dumping 200+HP shots into a engine is just BEGGING for a failure.) Running any race motor for over 6 years is asking for CATASTROPHIC FAILURE in my book. The reason you see parts on Flea-Bay from the Cup Teams is they know the failure cycles of their various parts and sell them to the lemmings who think they are getting a great deal on something the teams would otherwise be throwing out (I guess their gabage bills are reduced too, Flea Bay what a GREAT PLACE!)

#15

Team Owner

I don't know what "level" you race at but my good friend who is a noted USAC engine builder has a good relationship with Carrillio and Jack Sparks (you win a prize if you can tell me who Jack's father was.) Carrillio is well aware of the Asian competition and has done numerous testing on Scat, Eagle, Manley and other "copy cats" of their H-beam design. The comments I heard from my friend were yes it appears to be a Chrome Molly Steel BUT! the heat treatment is soo bad that these rods can be weaker that a 1038 mild steel American rod. Your cross section of the H-beam rod dosen't match the profile of a Carrillio beam cross section either. I would like you to tell me the method used when the bolts were torqued during assembly of the motor, I think we can find some issues there and hitting a motor with a BIG SHOT of N2O and then blaming the rod manufacturer for the failure? N2O is for people who don't have the God Given talent to build a proper motor in the first place. If I were hitting a motor with big shots of N20, I would have used a PWM progressive controller (dumping 200+HP shots into a engine is just BEGGING for a failure.) Running any race motor for over 6 years is asking for CATASTROPHIC FAILURE in my book. The reason you see parts on Flea-Bay from the Cup Teams is they know the failure cycles of their various parts and sell them to the lemmings who think they are getting a great deal on something the teams would otherwise be throwing out (I guess their gabage bills are reduced too, Flea Bay what a GREAT PLACE!)

I used to work on sprint car motors that used light weight Oliver I beam rods. Lots of them sheared half way up the beam in just 700HP 360 motors turning 8500 rpm. The fix was to go to the heavier weight I beams

#17

Melting Slicks

That's also what I thought. Bad thing was that when I was dealing with the sales guy, Arnold, he knew I was after American made only and didn't tell me the Magnum was a foreign forging, I guess all their cranks are and he couldn't say so without losing a sale. I would have gone with a Crower crank if I knew it was Chinese.

#18

Drifting

I find it interesting to read people's opinions on what happened. Some are intelligent, others aren't. The "experts" just seem to come out of the woodwork.

While I many never know the exact cause I will try to analyze the other 7 rods to see if I can get some kind of idea based on their condition.

I seem to be far less worked up about this rod failure than some of the responders. Would I have preferred if it wouldn't have happened - sure. But it is by no means the end of the world. Not even close.

Steve

While I many never know the exact cause I will try to analyze the other 7 rods to see if I can get some kind of idea based on their condition.

I seem to be far less worked up about this rod failure than some of the responders. Would I have preferred if it wouldn't have happened - sure. But it is by no means the end of the world. Not even close.

Steve

#19

Pro

Thread Starter

Member Since: Apr 2006

Location: Southern California

Posts: 625

Likes: 0

Received 47 Likes

on

25 Posts

I find it interesting to read people's opinions on what happened. Some are intelligent, others aren't. The "experts" just seem to come out of the woodwork.

While I many never know the exact cause I will try to analyze the other 7 rods to see if I can get some kind of idea based on their condition.

I seem to be far less worked up about this rod failure than some of the responders. Would I have preferred if it wouldn't have happened - sure. But it is by no means the end of the world. Not even close.

Steve

While I many never know the exact cause I will try to analyze the other 7 rods to see if I can get some kind of idea based on their condition.

I seem to be far less worked up about this rod failure than some of the responders. Would I have preferred if it wouldn't have happened - sure. But it is by no means the end of the world. Not even close.

Steve

#20

Pro

Thread Starter

Member Since: Apr 2006

Location: Southern California

Posts: 625

Likes: 0

Received 47 Likes

on

25 Posts

Steve is a good guy, and did not deserve the Bad-Mouthing you gave him above. You came across as an a**hole. He did not use Nitrous because he can't build a motor. He used Nitrous because he WANTED too. And that's good enough.