rear spindles with grease fittings

#41

Melting Slicks

Thread Starter

Billysvette,

What's the cost difference between these and standard units? That right there should be all you need to make the decision.

I think it's been clearly pointed out that adding grease zerks opens up the possibility of user error in overapplying grease and blowing out the seals. That said, if you think you've got the skills to avoid said rear bearing seal catastrophe, then this would be a non-issue for you. So then it comes back down to cost.

There are a lot of aftermarket parts available for our cars. Some more popular than others. Asking about a specific aftermarket part will usually get you at least some response from the forum. However, not everyone checks this forum on a daily basis. So don't be surprised if you don't get an immediate answer to your question.

Ultimately, though, the only person who can decide whether or not you need a specific part for your vehicle... is you.

the blonde weasel

What's the cost difference between these and standard units? That right there should be all you need to make the decision.

I think it's been clearly pointed out that adding grease zerks opens up the possibility of user error in overapplying grease and blowing out the seals. That said, if you think you've got the skills to avoid said rear bearing seal catastrophe, then this would be a non-issue for you. So then it comes back down to cost.

There are a lot of aftermarket parts available for our cars. Some more popular than others. Asking about a specific aftermarket part will usually get you at least some response from the forum. However, not everyone checks this forum on a daily basis. So don't be surprised if you don't get an immediate answer to your question.

Ultimately, though, the only person who can decide whether or not you need a specific part for your vehicle... is you.

the blonde weasel

Blonde weasel,the cost of the units are comparable to the non grease spindles,and everybody that gave their opinion,the opinion was a personal feeling about them ,they had no experience with the spindles,so they cant give a good product evaluation,i cant go with a personal opinion right off,i usually go with factual information.I think everybody would do the same,dont you think?I dont want to spend that much money just to experiment with the product,i dont think many people would either.everybody has to understand what im saying,its just common sense

#42

Melting Slicks

Thread Starter

I think you've got your expectations too high.

Standard bearing assemblies have a greasing interval of 40K miles. Greasing them more often than that will not yield positive results until both the test sample(s) and the control sample(s) have exceeded that interval.

Being that most owners don't have a clue about the last time their bearings were replaced/greased, you cannot establish the credibility of the control group. Part of the cause is the low annual mileage put on these cars compounded by the frequency of purchase and sale. In other words, mtce. history is lost at time of transfer.

Another contributor is the fact that the 40K interval is not the finite life of all bearings- it's simply a recommended 'low ball' mtce interval which presumes that the majority of average bearings subjected to poor or reasonable conditions will survive the interval. There's many examples of high mileage cars (some getting close to 70K miles and up) where the bearings are still fine despite never having been serviced. This variation in field experience makes it difficult to see any trend in a slightly modified product.

The combined scatter in field life, low utilization and lack of mtce traceability to accreditate any sample means that you would spend a lifetime trying to collect enough data to see if there's a difference.

My guess is that a carefully cared for semi retired C3 used for only a few thousand miles a year would go for three human lifetimes of ownership before anything showed up.

Standard bearing assemblies have a greasing interval of 40K miles. Greasing them more often than that will not yield positive results until both the test sample(s) and the control sample(s) have exceeded that interval.

Being that most owners don't have a clue about the last time their bearings were replaced/greased, you cannot establish the credibility of the control group. Part of the cause is the low annual mileage put on these cars compounded by the frequency of purchase and sale. In other words, mtce. history is lost at time of transfer.

Another contributor is the fact that the 40K interval is not the finite life of all bearings- it's simply a recommended 'low ball' mtce interval which presumes that the majority of average bearings subjected to poor or reasonable conditions will survive the interval. There's many examples of high mileage cars (some getting close to 70K miles and up) where the bearings are still fine despite never having been serviced. This variation in field experience makes it difficult to see any trend in a slightly modified product.

The combined scatter in field life, low utilization and lack of mtce traceability to accreditate any sample means that you would spend a lifetime trying to collect enough data to see if there's a difference.

My guess is that a carefully cared for semi retired C3 used for only a few thousand miles a year would go for three human lifetimes of ownership before anything showed up.

I also figured that more people would have bought them since the company has been in business for a long time.

#43

Advanced

Member Since: Jan 2002

Location: Stillman Valey Illinois

Posts: 77

Likes: 0

Received 1 Like

on

1 Post

Does anybody here have these rear spindles that have grease fittings in them,from THE SPINDLE PEOPLE company? Are they any good,or not worth messing with ? Seems to me they would be great if they work.It would be good if you could grease it yourself and not have to take things apart to do it.what do you guys think?Ive been meaning to ask this for a while now and keep forgetting about it.

We have taken several trailing arms off cars with zerks that have come through our shop over the years and have always found loads of bearing grease flung every where , even up on the rotors from over greasing and pushing out of the seals.

There is no way for the person using the grease gun to tell how much extra grease is going in. The spindle housing cavity is larger on the c2 and earlier c3 and may take up to a 1/3 tube of grease each.

We plug the grease zerk holes and pack the bearings with Mobil 1.

#44

Tech Contributor

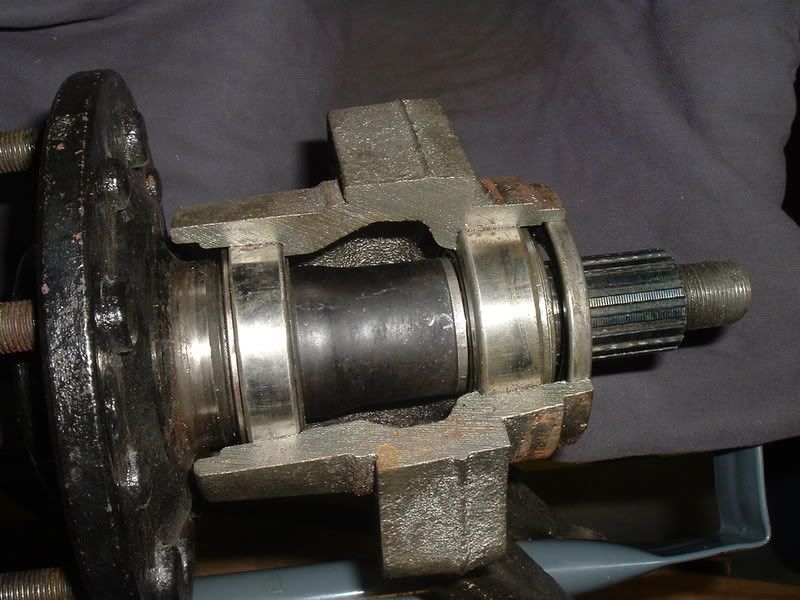

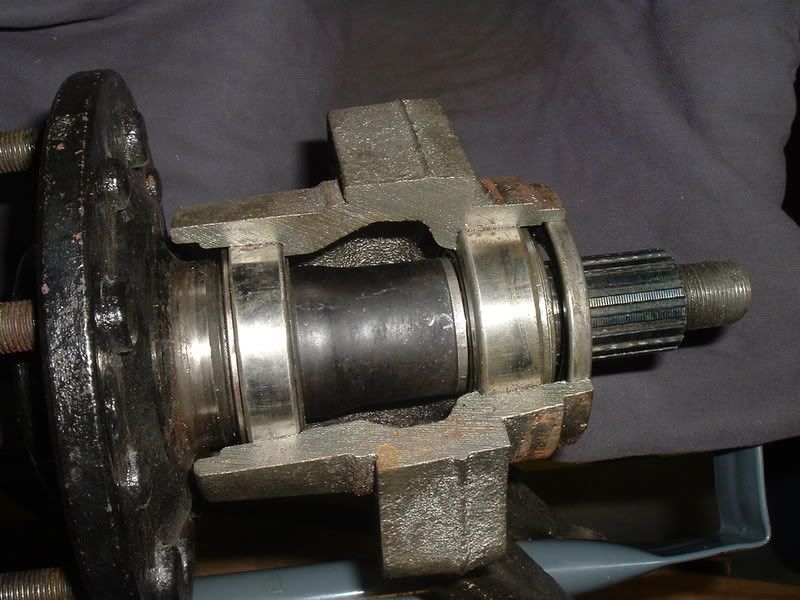

I should walk away from this thread but I'm going to break my own rule again and post a picture here.

Here is a support I did a year or so ago. It had a zerk fitting to grease it. You can see where the grease enters- just below the race and bearing.

Here is a cut away of a support, spindle, spacer, shim and bearings. Pumping in grease it will go in the path of least resistance so I think if you pump in grease it will fill the well first, before it goes into the bearings. There will be way too much grease in it then and most likely blow out the seals. A lot depends on the grease used as well. I no longer use Mobil 1 in rear bearings.The later supports have no well, just a bore for less grease.

The only way I can see grease getting into the bearings would be to have a hole in the hardened race. I don't think its a good idea, does "sound" good though. Also I do not know if the above zerk job is from this company. Again I have never had a contact with them other then looking over their site today.

Bearings will wear out, regardless if they're in a corvette, S10, machine-tool. As Mike stated, with the low miles put on most corvettes these days does it really matter? The endplay spec and assembly procedures are more important, believe me.

Here is a support I did a year or so ago. It had a zerk fitting to grease it. You can see where the grease enters- just below the race and bearing.

Here is a cut away of a support, spindle, spacer, shim and bearings. Pumping in grease it will go in the path of least resistance so I think if you pump in grease it will fill the well first, before it goes into the bearings. There will be way too much grease in it then and most likely blow out the seals. A lot depends on the grease used as well. I no longer use Mobil 1 in rear bearings.The later supports have no well, just a bore for less grease.

The only way I can see grease getting into the bearings would be to have a hole in the hardened race. I don't think its a good idea, does "sound" good though. Also I do not know if the above zerk job is from this company. Again I have never had a contact with them other then looking over their site today.

Bearings will wear out, regardless if they're in a corvette, S10, machine-tool. As Mike stated, with the low miles put on most corvettes these days does it really matter? The endplay spec and assembly procedures are more important, believe me.

Last edited by GTR1999; 02-27-2009 at 12:25 PM.

#47

Le Mans Master

I've had them for 10 years. If I remember correctly, the instructions says to grease them every 50,000 miles. I probably will not have to worry about greasing them in my life time.

Larry

Larry

#48

Le Mans Master

I understand what you guys are saying and i search this subject also,there is no real evidence about these spindles,theres just people saying the grease fitting spindle is no good and wont work ,but no body has any experience with the product talked about.do you know what im tring to say,i dont mean to make anybody mad,but does anybody have evidence to support what they believe.then you can make a good judgement on whether to buy them or not.I respect everybody on here so please tell me why ,ive heard the theories that some have but there is no concrete evidence about the spindles, just what they think.I would not want anybody on here to do what i said unless i had experience with what im telling you.Again im not tring to cause any trouble ,just want to understand why with real world evidence. What makes me think is that the company is still selling them,for years now and they have not stop making them because of nobody buying them ,because of being a bad product.

The first set of IRS spindles that I rebuilt in 1974 was on my own 1966 Roadster. When I re-assembled the supports, bearings and spindles, I packed the spindle support completely full of grease.

The first time I drove the car long enough to heat up the bearings, the grease expanded, blew out the seals, and ruined my brand new parking brake shoes. It was a huge mess, and I had to re-do the entire job.

Since the grease fitting is installed between the two bearings, it works by forcing grease outward toward both bearings. So... the grease will not reach the bearings until the entire cavity is filled and grease pushes its way outward to the bearings. You cannot effectively "re-grease" a bearing unless you force/remove the old grease. Ergo, using the grease fitting, you would technically have to force old grease out past the seals to actually achieve a re-grease.

Do the math.

#49

Melting Slicks

Thread Starter

gtr1999,did you take a spindle and cut it up like that just for me i am touched:o, Im just kidding with ya. i can see what you are saying,seeing it does put perspctive to it.and it does help me out ,thank you.my decision is on hold now.I didnot mean to upset anybody,i just wanted some facts about a certain product,you can understand if i dont take somebodies thoughts about something without any facts to back it up.you must research it for a while

i am touched:o, Im just kidding with ya. i can see what you are saying,seeing it does put perspctive to it.and it does help me out ,thank you.my decision is on hold now.I didnot mean to upset anybody,i just wanted some facts about a certain product,you can understand if i dont take somebodies thoughts about something without any facts to back it up.you must research it for a while  Bill. by the way i appreciated what you did.

Bill. by the way i appreciated what you did.

i am touched:o, Im just kidding with ya. i can see what you are saying,seeing it does put perspctive to it.and it does help me out ,thank you.my decision is on hold now.I didnot mean to upset anybody,i just wanted some facts about a certain product,you can understand if i dont take somebodies thoughts about something without any facts to back it up.you must research it for a while

i am touched:o, Im just kidding with ya. i can see what you are saying,seeing it does put perspctive to it.and it does help me out ,thank you.my decision is on hold now.I didnot mean to upset anybody,i just wanted some facts about a certain product,you can understand if i dont take somebodies thoughts about something without any facts to back it up.you must research it for a while  Bill. by the way i appreciated what you did.

Bill. by the way i appreciated what you did.

Last edited by Billysvette; 02-27-2009 at 04:13 PM.

#50

Melting Slicks

Thread Starter

I don't have any experience with a spindle support with a grease fitting, but I do have relevant experience.

The first set of IRS spindles that I rebuilt in 1974 was on my own 1966 Roadster. When I re-assembled the supports, bearings and spindles, I packed the spindle support completely full of grease.

The first time I drove the car long enough to heat up the bearings, the grease expanded, blew out the seals, and ruined my brand new parking brake shoes. It was a huge mess, and I had to re-do the entire job.

Since the grease fitting is installed between the two bearings, it works by forcing grease outward toward both bearings. So... the grease will not reach the bearings until the entire cavity is filled and grease pushes its way outward to the bearings. You cannot effectively "re-grease" a bearing unless you force/remove the old grease. Ergo, using the grease fitting, you would technically have to force old grease out past the seals to actually achieve a re-grease.

Do the math.

The first set of IRS spindles that I rebuilt in 1974 was on my own 1966 Roadster. When I re-assembled the supports, bearings and spindles, I packed the spindle support completely full of grease.

The first time I drove the car long enough to heat up the bearings, the grease expanded, blew out the seals, and ruined my brand new parking brake shoes. It was a huge mess, and I had to re-do the entire job.

Since the grease fitting is installed between the two bearings, it works by forcing grease outward toward both bearings. So... the grease will not reach the bearings until the entire cavity is filled and grease pushes its way outward to the bearings. You cannot effectively "re-grease" a bearing unless you force/remove the old grease. Ergo, using the grease fitting, you would technically have to force old grease out past the seals to actually achieve a re-grease.

Do the math.

#51

Le Mans Master

Member Since: May 2003

Location: Fernandina Beach FL

Posts: 8,481

Received 3,220 Likes

on

1,732 Posts

2023 Restomod of the Year finalist

2020 C3 of the Year Winner - Modified

Geeze......Why don't you just send your trailing arms to Gary and be done w/ it!!!!

Richard

Richard

#52

Melting Slicks

Thread Starter

Geeze,what is Geeze for,am i upsetting you for some reason? get a grip and just walk away,that was uncalled for.you azz ,i just wanted help with something and theres always somebody like you that has to ruin a forum.

#53

Tech Contributor

Billy,

No I didn't cut that support up for you, sorry buddy. I used to teach tech classes and used this as an aid. I even offered to do classes at Carlisle last year to Lance Miller.

Listen to Tom, he's a wise old guy or is that a wise guy!

#54

Race Director

Here is a different method from another forum

toobroketoretire

Back in the 40's and 50's it was very common back then to repack throwout bearings by submerging them in a pan of boiling #2 grease for a while, then putting the whole pan (with the bearing) into a freezer overnight. The next morning, you would remove the pan from the freezer, remove the throwout bearing from the pan, wipe off the excess solidified grease, then reuse it.

Corvette rear wheel bearings can be greased in much the same way; flooding them with boiling liquid grease, then letting the liquid grease cool and solidify back into #2 grease. I'll explain how:

Start off by removing the spindle yoke, then using compressed air, blow all around the small gap between the seal and the bearing. Once the gap is well blown out, you need to make the bearing liquid greasing tool:

Buy a 12" long piece of 1-1/4" (1.660" OD) schedule 120 PVC thin wall pipe, and a 1-1/4" pipe cap. Glue the cap onto one end, then saw the pipe down the middle lengthwise up TO the cap. Now from the top, cut down half way alongside the cap until you reach the long lengthwise sawed split. Remove the upper piece and you now have a 12" long "liquid grease funnel".

Heat a pound of #2 grease in a pan on a hot plate (outside) until it is completely liquid. Continue heating (and stirring) until the liquid grease begins to boil, then remove from the heat.

Place the end of your PVC funnel very lightly up against the face of the inner bearing, and slightly elevate the cap end of the funnel. Slowly pour the boiling liquid grease into the top of the funnel at the cap end. The boiling grease will flow down the length of the funnel, under the spindle, down through the small gap between the seal and the bearing, between the rollers of the inner bearing, and then between the rollers of the outer bearing; finally stopping when it reaches the outer seal. In a short time, the boiling grease in the bearings and hub will cool and re-solidify back into #2 grease.

When I first bought my '82 in 1988 (and having no access to a spindle press) I began experimenting with different ways to grease my bearings without removing them. Of the several things I tried, this PVC funnel and boiling liquid grease idea worked like a charm.

Since it worked so well for me during these past 20 years, I thought I'd pass the idea on to you. Just remember boiling grease WILL burn you, so please be real careful in how you handle it.

Back in the 40's and 50's it was very common back then to repack throwout bearings by submerging them in a pan of boiling #2 grease for a while, then putting the whole pan (with the bearing) into a freezer overnight. The next morning, you would remove the pan from the freezer, remove the throwout bearing from the pan, wipe off the excess solidified grease, then reuse it.

Corvette rear wheel bearings can be greased in much the same way; flooding them with boiling liquid grease, then letting the liquid grease cool and solidify back into #2 grease. I'll explain how:

Start off by removing the spindle yoke, then using compressed air, blow all around the small gap between the seal and the bearing. Once the gap is well blown out, you need to make the bearing liquid greasing tool:

Buy a 12" long piece of 1-1/4" (1.660" OD) schedule 120 PVC thin wall pipe, and a 1-1/4" pipe cap. Glue the cap onto one end, then saw the pipe down the middle lengthwise up TO the cap. Now from the top, cut down half way alongside the cap until you reach the long lengthwise sawed split. Remove the upper piece and you now have a 12" long "liquid grease funnel".

Heat a pound of #2 grease in a pan on a hot plate (outside) until it is completely liquid. Continue heating (and stirring) until the liquid grease begins to boil, then remove from the heat.

Place the end of your PVC funnel very lightly up against the face of the inner bearing, and slightly elevate the cap end of the funnel. Slowly pour the boiling liquid grease into the top of the funnel at the cap end. The boiling grease will flow down the length of the funnel, under the spindle, down through the small gap between the seal and the bearing, between the rollers of the inner bearing, and then between the rollers of the outer bearing; finally stopping when it reaches the outer seal. In a short time, the boiling grease in the bearings and hub will cool and re-solidify back into #2 grease.

When I first bought my '82 in 1988 (and having no access to a spindle press) I began experimenting with different ways to grease my bearings without removing them. Of the several things I tried, this PVC funnel and boiling liquid grease idea worked like a charm.

Since it worked so well for me during these past 20 years, I thought I'd pass the idea on to you. Just remember boiling grease WILL burn you, so please be real careful in how you handle it.

#55

Melting Slicks

Thread Starter

#56

Melting Slicks

Member Since: Feb 2001

Location: Europe , Luxembourg

Posts: 3,304

Likes: 0

Received 3 Likes

on

3 Posts

Hi

Thanks GTR1999 so much for this pics.

I really was wondering about how to get the grease past the race on the outher bearing not to speak about the inner one.

Your pics should well proof the ineffectiveness of this idea.

I guess, nobody ever pumps grease in there until it squeaks out front and back side , so will not produce any harm which might give a falsified impression to the owner of doing something worth while using this grease system.

Brgds. Günther

Thanks GTR1999 so much for this pics.

I really was wondering about how to get the grease past the race on the outher bearing not to speak about the inner one.

Your pics should well proof the ineffectiveness of this idea.

I guess, nobody ever pumps grease in there until it squeaks out front and back side , so will not produce any harm which might give a falsified impression to the owner of doing something worth while using this grease system.

Brgds. Günther

#58

Pro

Member Since: Sep 2002

Location: Melbourne, Fla. 6 months- New Middletown, Ohio 6 months

Posts: 624

Likes: 0

Received 1 Like

on

1 Post

Since I may be in the market for some bearing work in the near future I decided to contact the "Spindle People" and ask a few questions about their product. According to the reply the grease is injected directly into the bearing cage.

Since they are not supporting vendors I think it would be in violation to post the info here but if anyone is interested in the reply I received PM me and I will send it to you.

Since they are not supporting vendors I think it would be in violation to post the info here but if anyone is interested in the reply I received PM me and I will send it to you.

#60

Le Mans Master

Since I may be in the market for some bearing work in the near future I decided to contact the "Spindle People" and ask a few questions about their product. According to the reply the grease is injected directly into the bearing cage.

Since they are not supporting vendors I think it would be in violation to post the info here but if anyone is interested in the reply I received PM me and I will send it to you.

Since they are not supporting vendors I think it would be in violation to post the info here but if anyone is interested in the reply I received PM me and I will send it to you.