starting the rebuild...383 on its way

#3

Racer

Thread Starter

Member Since: Aug 2010

Location: bethpage NY

Posts: 263

Likes: 0

Received 0 Likes

on

0 Posts

#4

Racer

Thread Starter

Member Since: Aug 2010

Location: bethpage NY

Posts: 263

Likes: 0

Received 0 Likes

on

0 Posts

out with the old turbo 350 700 r4 on its way should be here by monday

a press i made to press the new bushings in its not pretty but does the trick

i took the heater core out and fabricated a piece to cover the hole

#7

Drifting

yeah, it sure does. I'd be leery of using a 2-bolt block for a stroker motor. If that block is original and stamped, I'd store it in favor of an early 70's 4-bolt block, preferrably one with 2482 caps.

#8

Drifting

If a guy wants to use a 2 bolt block we will put some splayed caps on and so far no problems.

Its the extra stroke that kills the 2 bolt caps as it does put more side load on them.

#9

Le Mans Master

How much power are you planning to make? Many, many well-done 383's our there running on 2-bolt mains (w/studs)...but over 5,500 RPM or about 400 HP or so...and you're rolling the dice for sure.

Unless it's an absolute requirement to keep the block, aftermarket steel caps are false economy - better off at that point to get a roller-capable 4-bolt block.

I agree that if it's numbers-matching, the best approach is to set it aside.

Unless it's an absolute requirement to keep the block, aftermarket steel caps are false economy - better off at that point to get a roller-capable 4-bolt block.

I agree that if it's numbers-matching, the best approach is to set it aside.

#10

Racer

Thread Starter

Member Since: Aug 2010

Location: bethpage NY

Posts: 263

Likes: 0

Received 0 Likes

on

0 Posts

How much power are you planning to make? Many, many well-done 383's our there running on 2-bolt mains (w/studs)...but over 5,500 RPM or about 400 HP or so...and you're rolling the dice for sure.

Unless it's an absolute requirement to keep the block, aftermarket steel caps are false economy - better off at that point to get a roller-capable 4-bolt block.

I agree that if it's numbers-matching, the best approach is to set it aside.

Unless it's an absolute requirement to keep the block, aftermarket steel caps are false economy - better off at that point to get a roller-capable 4-bolt block.

I agree that if it's numbers-matching, the best approach is to set it aside.

#11

Le Mans Master

I know when I had the same shop that Billa uses in Seattle (Action Machine) quote me the cost of installing splayed center caps and a billet front cap, the cost of caps and machining was $800. You are better off picking up a late '80s roller block for a few hundred bucks or buy a Dart high performance block.

Last edited by Scott Marzahl; 08-26-2010 at 06:40 PM.

#12

Drifting

We have installed a lot of splayed caps over the years, But first the block should be sonic tested before its even cleaned to make sure the cylinder wall thickness is good enough!!

Since Dart has come out with the SHP blocks we don't put that many spalyed caps on any more.

Like was posted its about an 7 or 800 dollar job then you still have decking, boring, plate honing, stroker clearance ETC.

Since Dart has come out with the SHP blocks we don't put that many spalyed caps on any more.

Like was posted its about an 7 or 800 dollar job then you still have decking, boring, plate honing, stroker clearance ETC.

#13

Le Mans Master

IMHO if you're building to a power level where splayed caps would make a difference...you should be using an aftermarket block.

It's always a tough call - sometimes we look at the block we have and get kind of attached. But the amount of money you'll have in that chunk of iron by the time it's square to the world in all respects - especially for a high-power build - you have to take a very close look at what the best choice is.

It all starts with the power levels - figure out what you want to make for power and work backwards from there.

It's always a tough call - sometimes we look at the block we have and get kind of attached. But the amount of money you'll have in that chunk of iron by the time it's square to the world in all respects - especially for a high-power build - you have to take a very close look at what the best choice is.

It all starts with the power levels - figure out what you want to make for power and work backwards from there.

#14

Racer

Thread Starter

Member Since: Aug 2010

Location: bethpage NY

Posts: 263

Likes: 0

Received 0 Likes

on

0 Posts

soooo... i actually forgot i started this post  but ive been wrenching away little by little. i did decide to keep the block switched to studs and the guy at my local engine shop seemed pretty confident that i would be ok with it as ill be right around 400 425 hp max. so that being said nthey bored it .030 over boiled it honed it and all that good stuff and i picked it up last monday

but ive been wrenching away little by little. i did decide to keep the block switched to studs and the guy at my local engine shop seemed pretty confident that i would be ok with it as ill be right around 400 425 hp max. so that being said nthey bored it .030 over boiled it honed it and all that good stuff and i picked it up last monday

... nice and clean

plasti-guaged the bearings

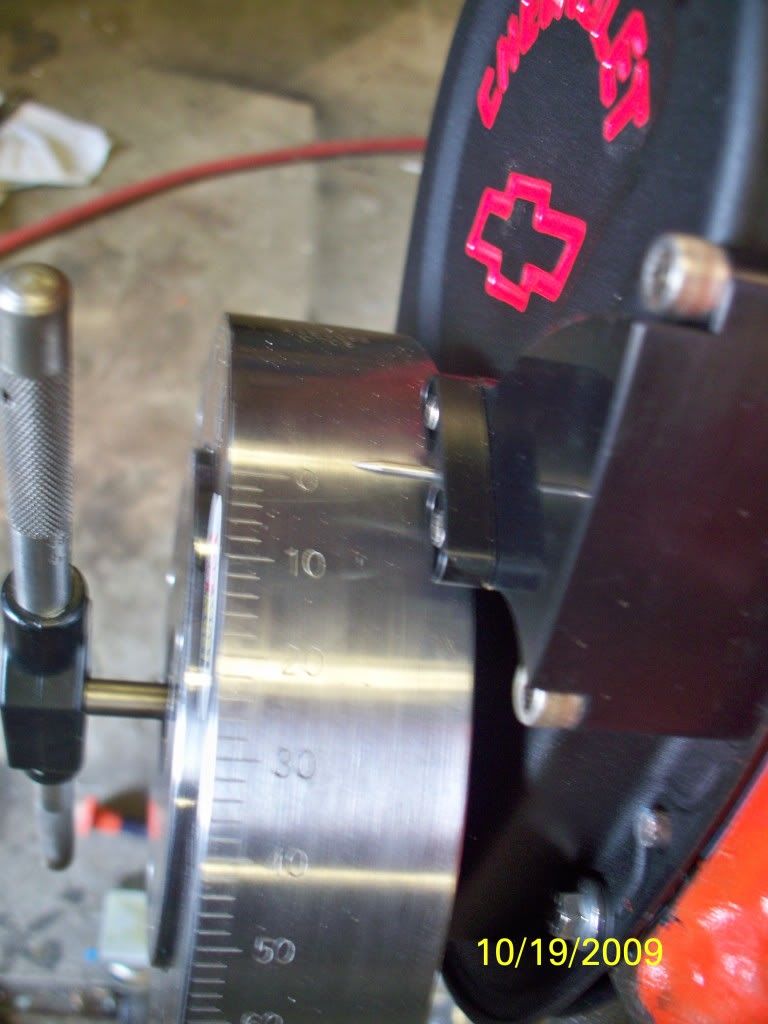

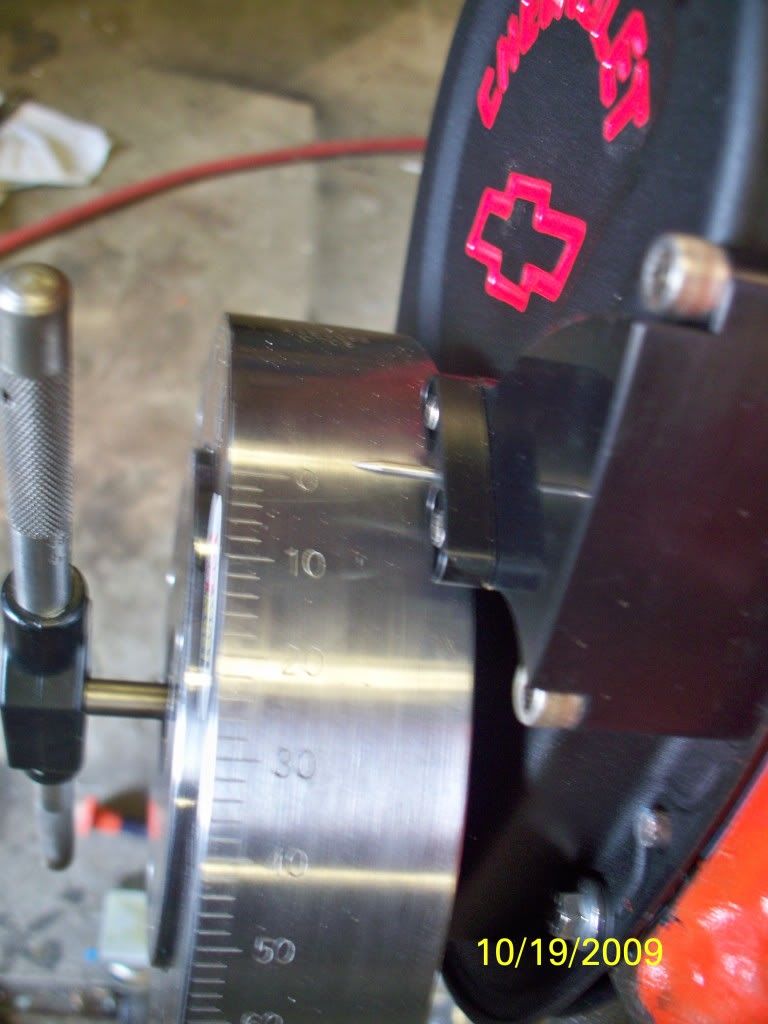

installed the eagle crank

setting piston/ oil rings were a PITA and very time consuming... i messed up the first set... i guess a noob mistake but it happens

then i threw in the cam and gears

http://www.jegs.com/i/Comp+Cams/249/12-246-3/10002/-1

and onto the tc cover and prosport sfi dampener

head gaskets and edelbrock performer rpm heads

crane lifters, comp cam 7.800 pushrods, scorpion 1.6 roller rockers

threw on the intake manifold also a edelbrock performer rpm, valve covers, holley fuel pump, stewart water pump

i filled it with oil double checked everything and a few more bolt ons and as it turns out i missed an oil hole made a mess while priming

made a mess while priming

threw on the flex plate and bolted it up to the new 700 r4 i decided to swap "while the motor was out" along with all new urethane front end suspension kit from energy suspensions... another one of the "well while i got it open" and that lies goes on and on $$$$

dropped them in with almost no problems i also took the liberty while it was out to clean up the whole compartment and paint it flat black it looks pretty good

and i havent taken any pics since but i got the headers, carb, mounted the msd 6al box and blaster,distributor, and the rad support. now all the fun begins with the wiring i have to do for the dual elec fans im installing and plumbing for a 2nd tranny cooler

but ive been wrenching away little by little. i did decide to keep the block switched to studs and the guy at my local engine shop seemed pretty confident that i would be ok with it as ill be right around 400 425 hp max. so that being said nthey bored it .030 over boiled it honed it and all that good stuff and i picked it up last monday

but ive been wrenching away little by little. i did decide to keep the block switched to studs and the guy at my local engine shop seemed pretty confident that i would be ok with it as ill be right around 400 425 hp max. so that being said nthey bored it .030 over boiled it honed it and all that good stuff and i picked it up last monday ... nice and clean

plasti-guaged the bearings

installed the eagle crank

setting piston/ oil rings were a PITA and very time consuming... i messed up the first set... i guess a noob mistake but it happens

then i threw in the cam and gears

http://www.jegs.com/i/Comp+Cams/249/12-246-3/10002/-1

and onto the tc cover and prosport sfi dampener

head gaskets and edelbrock performer rpm heads

crane lifters, comp cam 7.800 pushrods, scorpion 1.6 roller rockers

threw on the intake manifold also a edelbrock performer rpm, valve covers, holley fuel pump, stewart water pump

i filled it with oil double checked everything and a few more bolt ons and as it turns out i missed an oil hole

made a mess while priming

made a mess while priming

threw on the flex plate and bolted it up to the new 700 r4 i decided to swap "while the motor was out" along with all new urethane front end suspension kit from energy suspensions... another one of the "well while i got it open" and that lies goes on and on $$$$

dropped them in with almost no problems i also took the liberty while it was out to clean up the whole compartment and paint it flat black it looks pretty good

and i havent taken any pics since but i got the headers, carb, mounted the msd 6al box and blaster,distributor, and the rad support. now all the fun begins with the wiring i have to do for the dual elec fans im installing and plumbing for a 2nd tranny cooler

. Good luck

. Good luck .

.