New 12 Bolt, Off Set T/As, & Suspension Upgrades

#1

Burning Brakes

Thread Starter

I thought I'd start a build thread for my latest round of resto-mods to my '70 vert. Some of you may remember last year I did a thread on the new 555 build & install, TKO 600, Steeriods, & 3" exhaust so this is the next build phase.

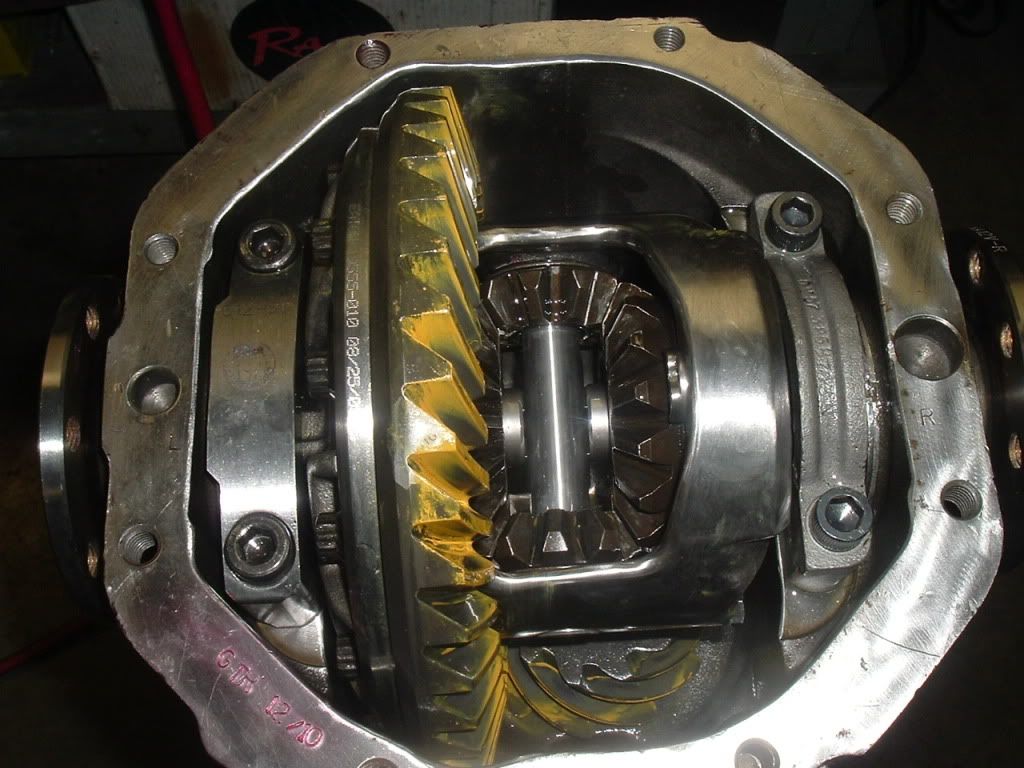

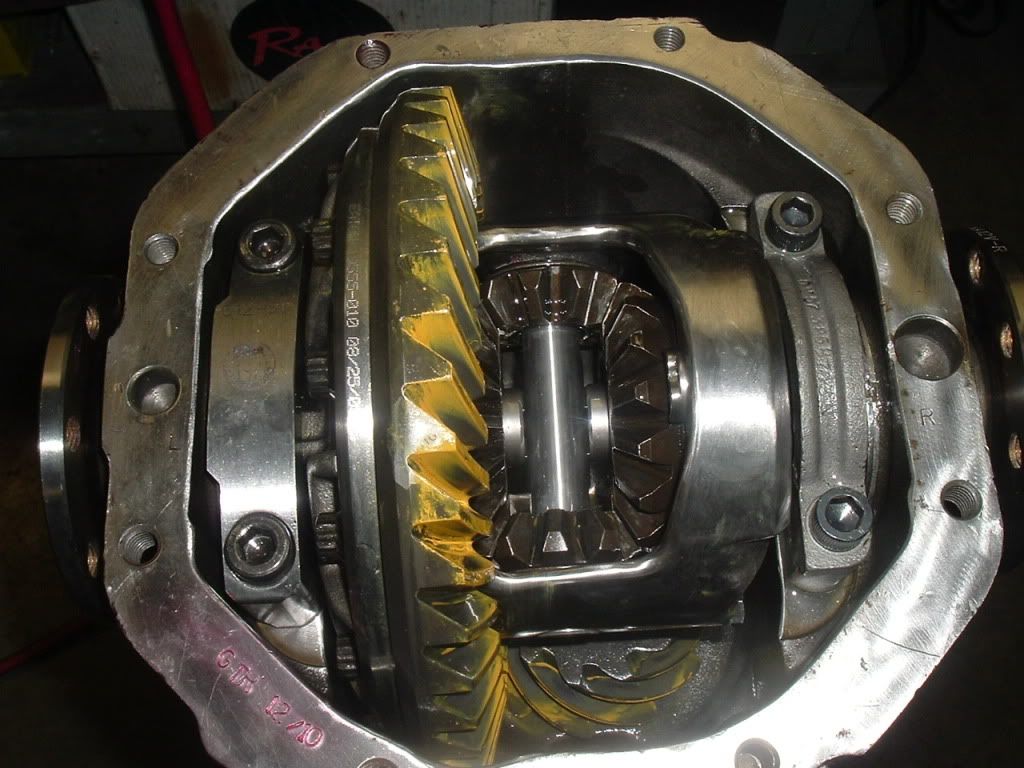

The rear end got disassembled over the past week and things are starting to go back together now. Back in December I received my new 12 Bolt rear end built by Gary Ramadei and it's been patiently sitting in it's crate waiting on the snow to melt so I could get the car over to the shop. If you are not familair with Gary's work on 12 Bolt conversions you should search some of his old posts, his work is top notch & he documented the build to me with over 100 photos. Here's a couple of teaser photos of the guts since you never get to see them:

I went with 3.73 gears, Series 4 Eaton Posi case, 10-17 Spiders, Tom's 1350 Axle kit w/ 30 spline heat treated inners, and a 1330 billet yoke.

A Tom's locator kit is used on the differential cross member and front snubber mounting points.

One minor modification was made to the stainless steel fill plug Gary installs, it was cut down and a 3/4" stainless nut was welded on top to make getting a wrench on it feasible while installed in the car.

Tom's also makes a frame gusset kit that welds on to strengthen the area near the crossmember. Those got welded in today and it looks plenty stout now. Interestingly the two sides are slightly different from the factory.

I chose the Van Steel Coil Over style Off Set Trailing Arms that use QA1's in place of a leaf spring. These things are so black it's hard to get a good photo of the drop leg that the shock mounts to. Upgraded to 1/2" ARP wheel studs that have been machined to length.

Gary Ramadei also built the T/As up for me and set them up with Wilwood 13" big brake 2-piece rotors. In the previous photo you can just make out the billet brake bracket. They have Tom's heat treated 31 spline outter axles installed and will get 3 1/2" half shafts with 1350 solid Spicer joints.

Both T/As are now in place and now waiting on a couple of parts to arrive tomorrow to get moving again.

I'll post an update after we make a little more progress. I hope you will enjoy the photos and the info.

The rear end got disassembled over the past week and things are starting to go back together now. Back in December I received my new 12 Bolt rear end built by Gary Ramadei and it's been patiently sitting in it's crate waiting on the snow to melt so I could get the car over to the shop. If you are not familair with Gary's work on 12 Bolt conversions you should search some of his old posts, his work is top notch & he documented the build to me with over 100 photos. Here's a couple of teaser photos of the guts since you never get to see them:

I went with 3.73 gears, Series 4 Eaton Posi case, 10-17 Spiders, Tom's 1350 Axle kit w/ 30 spline heat treated inners, and a 1330 billet yoke.

A Tom's locator kit is used on the differential cross member and front snubber mounting points.

One minor modification was made to the stainless steel fill plug Gary installs, it was cut down and a 3/4" stainless nut was welded on top to make getting a wrench on it feasible while installed in the car.

Tom's also makes a frame gusset kit that welds on to strengthen the area near the crossmember. Those got welded in today and it looks plenty stout now. Interestingly the two sides are slightly different from the factory.

I chose the Van Steel Coil Over style Off Set Trailing Arms that use QA1's in place of a leaf spring. These things are so black it's hard to get a good photo of the drop leg that the shock mounts to. Upgraded to 1/2" ARP wheel studs that have been machined to length.

Gary Ramadei also built the T/As up for me and set them up with Wilwood 13" big brake 2-piece rotors. In the previous photo you can just make out the billet brake bracket. They have Tom's heat treated 31 spline outter axles installed and will get 3 1/2" half shafts with 1350 solid Spicer joints.

Both T/As are now in place and now waiting on a couple of parts to arrive tomorrow to get moving again.

I'll post an update after we make a little more progress. I hope you will enjoy the photos and the info.

#4

Le Mans Master

Very nice. I'm going to have to do something similar to mine. With the 540, my diff won't be long for this world. Thinking of going with a Ford 9" instead b/c of cost.

#6

Burning Brakes

Thread Starter

Well most of the week was spent waiting on parts that were late coming in, or didn't ship with the right quantity of items, or need powder coating....you know how it goes. We got enough stuff finished or mocked up to get a wheel & tire on to check fit and I'm happy to report that they will fit fine and I could most likely go wider still. Rear wheels are AR TTII w/ 5/5" BS with Nitto NT05R tires in 285/40ZR/18.

The QA1 coil over kit comes with beefer upper shock mounts that weld on over the stock ones. The new holes are 1/2" so the old mounts get enlarged. Mike did a great job blending them in. I picked the 600# Hyperco springs for the rears.

The Wilwood 4 piston calipers are now installed BUT I need to get a new brake line to them made. The Wilwood braided lines that come with the kit are ~7/8" too short for the routing. I don't know if this due to the offset T/A brake tab location, or possibly the billet aluminum brake bracket having the caliper bracket mounting holes rotated back a couple of degress, or maybe the lines were just cut too short (which I doubt). Anyway I need to call Wilwood on Monday and see if I can get some custom ones made up since nobody up here makes them over the counter. The 13" rotors and 4 piston calipers look great!!

I forgot to shoot a photo after we got the new shortened sway bar attached to the T/As and the frame mounts installed, but it's almost done. Looks like the spare tire tub will have to be modified slightly but noting drastic (it just hides the fuel pump & filter anyway). The half shaft loops (ordered from Van Steet but they are made by DragVette) will come off for powder coating on Monday along with the lower camber rod bushings that finally arrived. I used a lot of Tom's stuff in this build because it's strong, but I can not recommend using his lower camber rod kit. Nothing is powder coated, the tapered shims had to be machined to the correct length, the grade 8 hardware is not plated, and it took multiple shipments to get all of the parts.

More to come next weekend....

The QA1 coil over kit comes with beefer upper shock mounts that weld on over the stock ones. The new holes are 1/2" so the old mounts get enlarged. Mike did a great job blending them in. I picked the 600# Hyperco springs for the rears.

The Wilwood 4 piston calipers are now installed BUT I need to get a new brake line to them made. The Wilwood braided lines that come with the kit are ~7/8" too short for the routing. I don't know if this due to the offset T/A brake tab location, or possibly the billet aluminum brake bracket having the caliper bracket mounting holes rotated back a couple of degress, or maybe the lines were just cut too short (which I doubt). Anyway I need to call Wilwood on Monday and see if I can get some custom ones made up since nobody up here makes them over the counter. The 13" rotors and 4 piston calipers look great!!

I forgot to shoot a photo after we got the new shortened sway bar attached to the T/As and the frame mounts installed, but it's almost done. Looks like the spare tire tub will have to be modified slightly but noting drastic (it just hides the fuel pump & filter anyway). The half shaft loops (ordered from Van Steet but they are made by DragVette) will come off for powder coating on Monday along with the lower camber rod bushings that finally arrived. I used a lot of Tom's stuff in this build because it's strong, but I can not recommend using his lower camber rod kit. Nothing is powder coated, the tapered shims had to be machined to the correct length, the grade 8 hardware is not plated, and it took multiple shipments to get all of the parts.

More to come next weekend....

#7

Melting Slicks

Nice!

Any fiberglass modification to the battery compartments with the coilovers or half shafts?

Are those tom's half shaft kits? what size ujoint kit?

I have the Tom's half shaft loops which weld to the xmember but only go midway down the half shaft. The drag vette ones are nice too but i wanted some safety further up the half shaft.

Any fiberglass modification to the battery compartments with the coilovers or half shafts?

Are those tom's half shaft kits? what size ujoint kit?

I have the Tom's half shaft loops which weld to the xmember but only go midway down the half shaft. The drag vette ones are nice too but i wanted some safety further up the half shaft.

#8

Burning Brakes

Thread Starter

Nice!

Any fiberglass modification to the battery compartments with the coilovers or half shafts?

Are those tom's half shaft kits? what size ujoint kit?

I have the Tom's half shaft loops which weld to the xmember but only go midway down the half shaft. The drag vette ones are nice too but i wanted some safety further up the half shaft.

Any fiberglass modification to the battery compartments with the coilovers or half shafts?

Are those tom's half shaft kits? what size ujoint kit?

I have the Tom's half shaft loops which weld to the xmember but only go midway down the half shaft. The drag vette ones are nice too but i wanted some safety further up the half shaft.

No fiberglass work was required on the storage compartments for either pieces of hardware. The half shafts are 3 1/2" Tom's with 1350 solid Spicer joints at each end. If you jump up to the 1480 joints I hear you have to modify the box and I can see where you would looking at the 1350 fit. I used a 1330 solid Spicer with a billet yoke on the differential input shaft, also no clearance issues there either.

I bought a set of the Tom's half shaft loops first but decided to order the DragVette ones too, the primary reason was not having to remove the crossmember & diff again to coat the crossmember with weld on loops in place.

I talked with Dan @ Van Steel today about the rear brake line being too short, he called Wilwood and hopefully tomorrow I will know which of them is making new rear braided lines for me and when I can have them. Not huge timing issue since we haven't even started on the front A-Arms yet.

#12

Team Owner

I was going ask why you decided on 600# rear springs............... but with 555 ci you might be up on just the rear tires and then you would need them

#13

#14

Burning Brakes

Thread Starter

I know the Ford 9" is stout, and it costs less up front, but aren't you just swapping $ for $ in the added installation\\fabrication costs to make it fit & work?

My 12 bolt conversion is a direct fit bolt in (the differential guts of course are not). It took less than a half hour to bolt in the diff & hook up the drive line. I'm guessing you can't say the same.

My 12 bolt conversion is a direct fit bolt in (the differential guts of course are not). It took less than a half hour to bolt in the diff & hook up the drive line. I'm guessing you can't say the same.

#15

Melting Slicks

I know the Ford 9" is stout, and it costs less up front, but aren't you just swapping $ for $ in the added installation\\fabrication costs to make it fit & work?

My 12 bolt conversion is a direct fit bolt in (the differential guts of course are not). It took less than a half hour to bolt in the diff & hook up the drive line. I'm guessing you can't say the same.

My 12 bolt conversion is a direct fit bolt in (the differential guts of course are not). It took less than a half hour to bolt in the diff & hook up the drive line. I'm guessing you can't say the same.

12 bolt has a large of upfront cost for the conversion and a good chance you'll need someone with Gary's skill level to perform a repair/gear change in the future. Hopefully you won't need to touch this thing ever again unless you need a gear change. Is the 12 bolt ring gear only available from Tom's?

9inch is cheaper and is much more readily available, now and in the future. Can be sourced from anywhere...however you have large upfront labor/difficulty to adapt it to the vette. Should the actual 3rd member break you can replace rather cheaply and the aftermarket supports it. Should the adapter break then you'll need to find someone capable to fix it.

There's pro's and con's to both setups.

#16

I know the Ford 9" is stout, and it costs less up front, but aren't you just swapping $ for $ in the added installation\\fabrication costs to make it fit & work?

My 12 bolt conversion is a direct fit bolt in (the differential guts of course are not). It took less than a half hour to bolt in the diff & hook up the drive line. I'm guessing you can't say the same.

My 12 bolt conversion is a direct fit bolt in (the differential guts of course are not). It took less than a half hour to bolt in the diff & hook up the drive line. I'm guessing you can't say the same.

I am doing the nine inch set up right now.

The 12 bolt converted differential, served me just fine for my hp addiction and drag racing needs. I finally ended up going 8.32 at 172 mph on my 12 bolt set up. never broke it or had any trouble with it.

The reason I am now going to a ford nine inch set up is because of gear ratio choices, 35 spline axles, aftermarket support, easy set up.

With my old 12 bolt differential, I was stuck at 3.73 gear as my lowest numeric option. I am running a 28 inch tire with a th400 trans and I am now building a turbo big block that will produce over 2000 hp. My goal is to take the overall IRS record by beating a 7.52 E/T held by a turbo viper. I intend on surpassing that record by quite a margin. I designed my combo to not spin over 7200 rpm for reliability purposes, so by the math I would need a 3.00 ratio gear to go through the traps at over 200 mph, if you account for converter slippage. As you can tell The 12 bolt set up can not meet this demand. So I decided to fab up the nine inch set up. I dont claim it to be easy or cheap, It has most definitly NOT been easy or cheap to accomplish. You need quite an amount of fab skills and tools to do it yourself. I have them so I did it.

The 12 bolt is definitly a fine set up to have and should meet 99.9% of everyones needs to handle the power of there combos. As you can tell, I am a special case, but I wanted to show you fellow vette guys how it can be done.

#18

Terrorizing Orange Cones

Ray Y,

Your setup looks awesome. I like the 12-bolt idea and each of you have engineered strong axles. His 9" will be great for the focused application he seeks and I wish him excellent results in his quest.

Yours, on the other hand, will be a strong street driven 12-bolt application and suspect it will handle anything you dish out from the 555 and TKO. An equally well thought out project.

Thanks for posting your guts photos too; lots of blueprinted hand work to make that carrier and gear sets to be so smooth.

Good luck to both of you and thanks for the nice write ups. Keep us posted and Good Luck.

Your setup looks awesome. I like the 12-bolt idea and each of you have engineered strong axles. His 9" will be great for the focused application he seeks and I wish him excellent results in his quest.

Yours, on the other hand, will be a strong street driven 12-bolt application and suspect it will handle anything you dish out from the 555 and TKO. An equally well thought out project.

Thanks for posting your guts photos too; lots of blueprinted hand work to make that carrier and gear sets to be so smooth.

Good luck to both of you and thanks for the nice write ups. Keep us posted and Good Luck.

#19

Burning Brakes

Thread Starter

Its a tough choice.

12 bolt has a large of upfront cost for the conversion and a good chance you'll need someone with Gary's skill level to perform a repair/gear change in the future. Hopefully you won't need to touch this thing ever again unless you need a gear change. Is the 12 bolt ring gear only available from Tom's?

9inch is cheaper and is much more readily available, now and in the future. Can be sourced from anywhere...however you have large upfront labor/difficulty to adapt it to the vette. Should the actual 3rd member break you can replace rather cheaply and the aftermarket supports it. Should the adapter break then you'll need to find someone capable to fix it.

There's pro's and con's to both setups.

12 bolt has a large of upfront cost for the conversion and a good chance you'll need someone with Gary's skill level to perform a repair/gear change in the future. Hopefully you won't need to touch this thing ever again unless you need a gear change. Is the 12 bolt ring gear only available from Tom's?

9inch is cheaper and is much more readily available, now and in the future. Can be sourced from anywhere...however you have large upfront labor/difficulty to adapt it to the vette. Should the actual 3rd member break you can replace rather cheaply and the aftermarket supports it. Should the adapter break then you'll need to find someone capable to fix it.

There's pro's and con's to both setups.

The gears are Richmond's so no you are not reliant on Tom's. Gary documents all of the set up details to you so that if you had to make changes in the future it could be done elsewhere if you wanted/needed to. The work Gary performs for the critical fit/clearancing work for the parts selected is key, the detail work for set up could be done by other shops IF you can get them to pay attention to the details and some probably will not. Gary uses absolutely the best & strongest parts available from ARP bolts, billet yoke, fitted steel cap, larger bolts, heat treated axles, solid sleeve,....

For my plans this is the best choice.

Ever driven a spool on the street? I like the posi.

Last edited by Ray Y; 04-20-2011 at 11:31 PM.

#20

Burning Brakes

Thread Starter

These are dual adjust QA1s, where should you start with the settings? The QA1 data sheet has some suggestions but its for their springs and not the Hyperco heavier ones.