LS3 into my 72

#361

Melting Slicks

Got the water pump back on today with some other things. The fittings clear everything just fine. I think I will go with straight fittings off the 45s I have coming out of the pump now. The 45s I have for the hose just don't want to cooperate very well. Straight seems to work better.

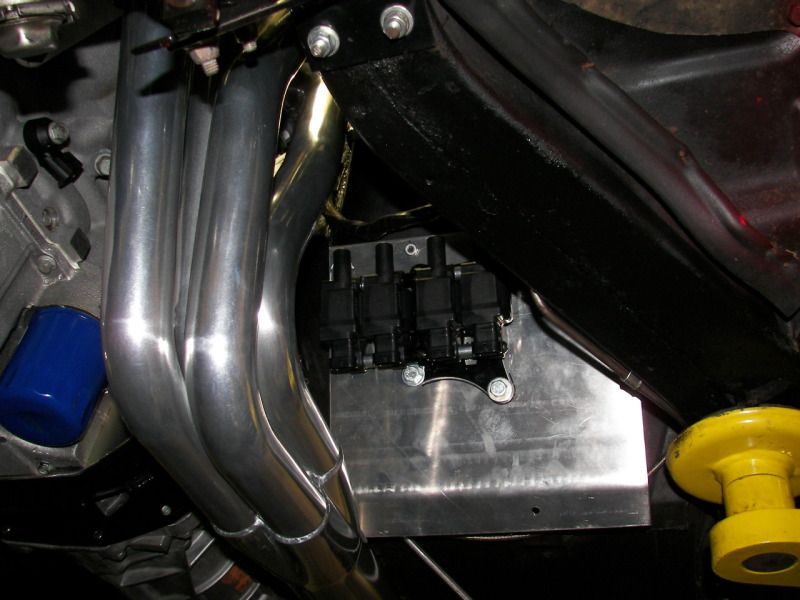

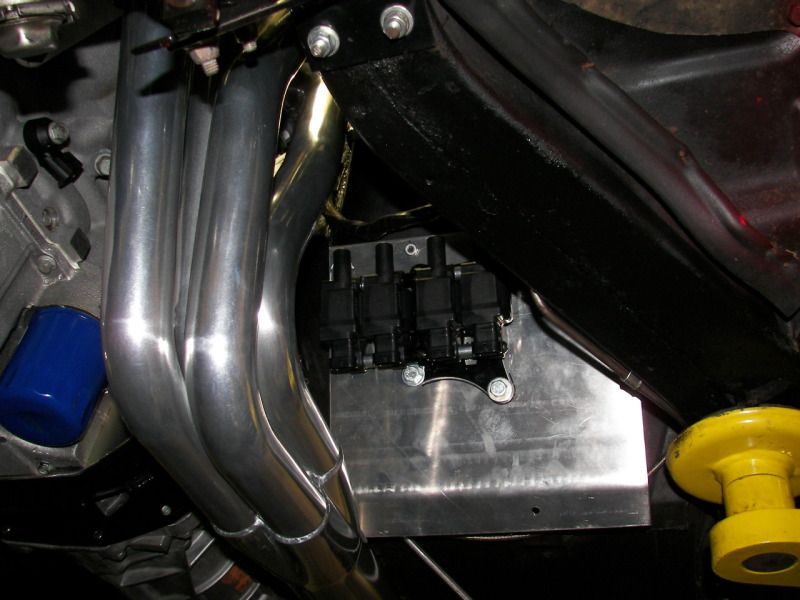

Also was working on reloacting the coils. The brackets I bought were for the back of the cylinder head. There is just not enough clearance to do this on my setup. So I made some plates. These are in the location of the stock plates I just made them bigger and out of aluminum stock. I drilled some holes for the brackets. I was able to route the wiring around some so it is out of the way and looks decent. I think I will paint these black also.

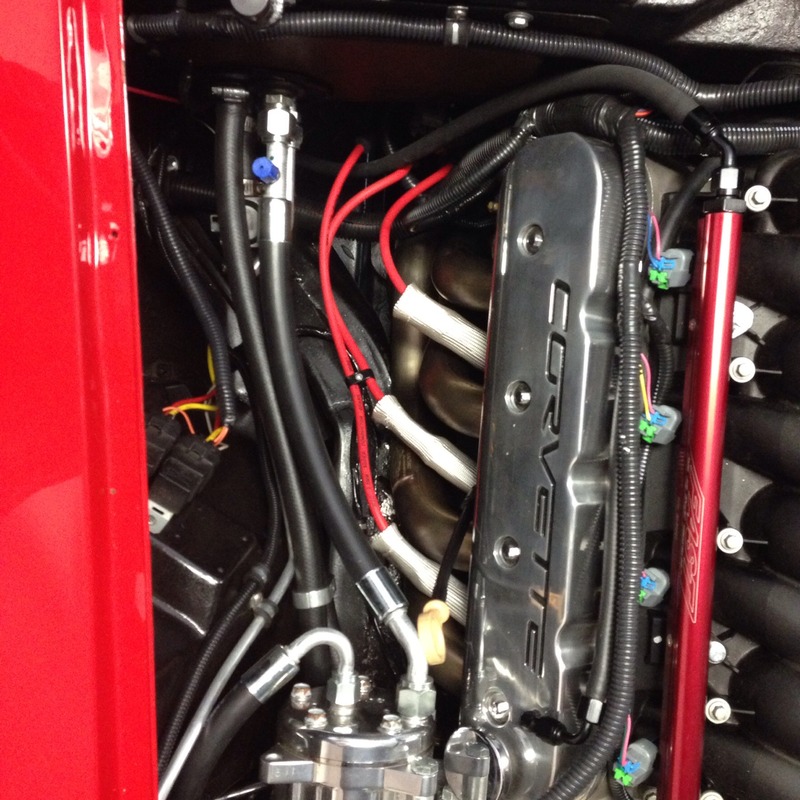

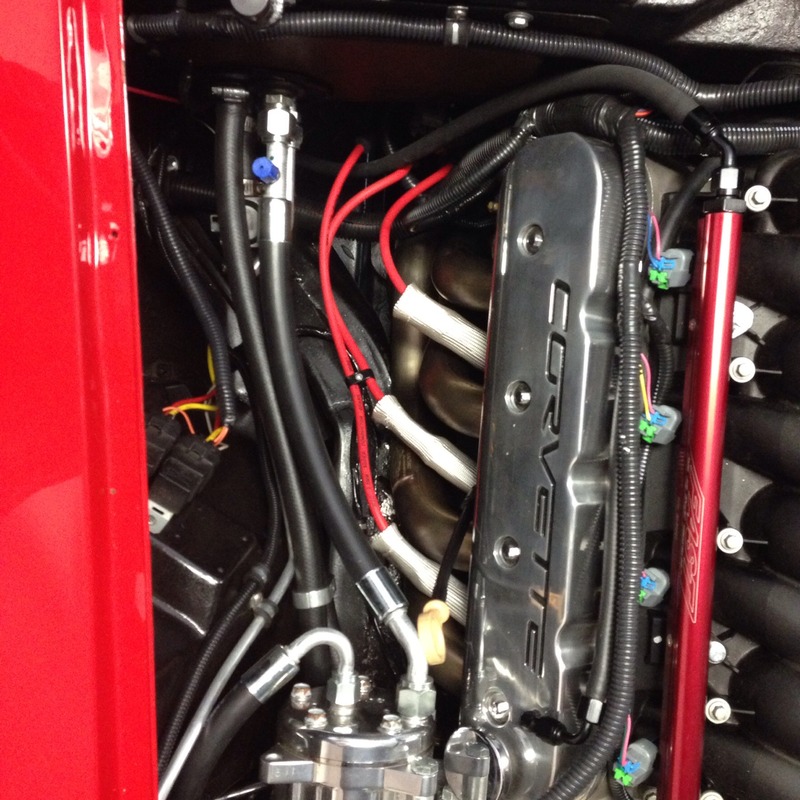

Finally just insatlled the valve covers and running some vacuum lines for trial fit.

Also was working on reloacting the coils. The brackets I bought were for the back of the cylinder head. There is just not enough clearance to do this on my setup. So I made some plates. These are in the location of the stock plates I just made them bigger and out of aluminum stock. I drilled some holes for the brackets. I was able to route the wiring around some so it is out of the way and looks decent. I think I will paint these black also.

Finally just insatlled the valve covers and running some vacuum lines for trial fit.

Do you have the part number for the straight thermostat inlet, thanks Kevin

#363

Intermediate

GordonM,

Thank you for this thread. Very informative and well documented. It will come in very handy as I am doing a 1980 Corvette with a DR525 engine (sealed crate LS3 setup) for NMCA this season. Nick at ARH and I go way back so I was thankful you went to him for your setup. Now we can work with your template on my race car!

Thank you for this thread. Very informative and well documented. It will come in very handy as I am doing a 1980 Corvette with a DR525 engine (sealed crate LS3 setup) for NMCA this season. Nick at ARH and I go way back so I was thankful you went to him for your setup. Now we can work with your template on my race car!

#364

Pro

Great thread GordonM,

Any new updated progress on your car? Is it complete and running without further issues? I have a line on a used LS7 and am seriously considering the swap from SBC to LS7.

Any estimate on what this swap has cost? I am asking from a parts perspective only because I know the labor is out of this world and cannot be included in the overall cost. Your thread shows many dedicated hours spent on custom modifications in this build. Very nice work.

Would you recommend the LS upgrade if you had to do it all over again?

Thanks

Don

Any new updated progress on your car? Is it complete and running without further issues? I have a line on a used LS7 and am seriously considering the swap from SBC to LS7.

Any estimate on what this swap has cost? I am asking from a parts perspective only because I know the labor is out of this world and cannot be included in the overall cost. Your thread shows many dedicated hours spent on custom modifications in this build. Very nice work.

Would you recommend the LS upgrade if you had to do it all over again?

Thanks

Don

#365

Gordon, here is some interesting reading for you when installing a Vintage Air setup with a LS motor. Start at post #91. http://www.ffcars.com/forums/42-fact...ntation-3.html

The problem of overheating occurs when the Vintage Air is left in MAX AIR position. This position closes the water valve to the heater core. A LS engines water heater outlets on the side of the water pump are designed to always have a flow of coolant going thru them. There are two different valves that can be installed in place of the one supplied by Vintage Air. One of them is vacuum operated and the other is electronic. They both have an additional port to allow the coolant to return to the water heater outlet on the waterpump when in MAX AIR position. I can give you a link to both of them if you think this is needed for you.

The problem of overheating occurs when the Vintage Air is left in MAX AIR position. This position closes the water valve to the heater core. A LS engines water heater outlets on the side of the water pump are designed to always have a flow of coolant going thru them. There are two different valves that can be installed in place of the one supplied by Vintage Air. One of them is vacuum operated and the other is electronic. They both have an additional port to allow the coolant to return to the water heater outlet on the waterpump when in MAX AIR position. I can give you a link to both of them if you think this is needed for you.

The following users liked this post:

donnie1956 (09-19-2015)

#366

Race Director

Thread Starter

Great thread GordonM,

Any new updated progress on your car? Is it complete and running without further issues? I have a line on a used LS7 and am seriously considering the swap from SBC to LS7.

Any estimate on what this swap has cost? I am asking from a parts perspective only because I know the labor is out of this world and cannot be included in the overall cost. Your thread shows many dedicated hours spent on custom modifications in this build. Very nice work.

Would you recommend the LS upgrade if you had to do it all over again?

Thanks

Don

Any new updated progress on your car? Is it complete and running without further issues? I have a line on a used LS7 and am seriously considering the swap from SBC to LS7.

Any estimate on what this swap has cost? I am asking from a parts perspective only because I know the labor is out of this world and cannot be included in the overall cost. Your thread shows many dedicated hours spent on custom modifications in this build. Very nice work.

Would you recommend the LS upgrade if you had to do it all over again?

Thanks

Don

#367

Pro

Yes I would do it again. The LS motor makes so much power and the torque curve is flat so driveabilty is great. Mine is running but not totally complete due to some life issues. I have driven it and even with a bad tune it is so much nicer than a Gen 1 SB. The cost, ahh that is a bad word I guess. You can do it on the cheap but I did not go that way and have done a lot of extras. How much is in it. A freakin LOT! Could have done it cheaper but it's only money. I had to put a limit on some things but I wanted it to look like it was supposed to be there. An LS7 is great. The dry sump can be challenging though as not much room in a C3 to put things. The computer and stuff is tricky enough.

I would probably contact Custom Image Corvettes and purchase the body panels to flare the front and rear fenders to add wider wheels and tires.

Would also replace the rear bumper panel to remove the ugly 77 unit.

A L-88 hood would be added to complete the exterior transformation.

So the road to the LS7 would not be short or inexpensive. But, I suppose if one is going to the trouble of swapping in a LS7 then the rest of the changes should also be part of the project.

Not sure if the investment is worth the dollars spent, but it would be one very bad azz rare custom 77 C3 if I decided to go down the LS7 path.

Regards,

Don

#368

Melting Slicks

I was on this site to see where you mounted the ECM and fuse panel and it was good to see its where I plan to mount as well.

https://www.corvetteforum.com/forums...ica-kinda.html

https://www.corvetteforum.com/forums...ica-kinda.html

#369

Race Director

Thread Starter

I'll bring this back up to the top as I have done a little work to it recently. I bought some different fittings for the Vintage AC unit so the install is much cleaner. Summit has all VA fittings so I ordered them. I will post a picture of the setup. I have it all mocked up I just have to mark the fittings and the hose so they go in the proper oreintation. I will then take it to a hydraulic shop and have them crimp the fittings.

I also got some better HVAC hose from Summit. It is much sturdier and should work better. I will try that very shortly.

I need to bring the car to the tuner so the air fuel ratios are better so it can be driven.

Front AC line

Rear AC line

Engine as it sits now. Waiting for a good tune

I also got some better HVAC hose from Summit. It is much sturdier and should work better. I will try that very shortly.

I need to bring the car to the tuner so the air fuel ratios are better so it can be driven.

Front AC line

Rear AC line

Engine as it sits now. Waiting for a good tune

Last edited by Gordonm; 09-17-2015 at 04:23 PM.

#372

Race Director

Thread Starter

I used one of the VA fittings that came in the kit. That was for the pressure line and it was the straight fitting with the bleeder on it. On the other end I used a 135 degree fitting coming off the back of the compressor. The other side which is #10 they supply a straight. That would have worked but was right at the dipstick and close to the motor. I figured a 45 would be better. On the firewall side I used a straight with the bleeder on it. I did use their tubing but not much of it. It all fits nice and tight and clean looking.

#373

Race Director

Thread Starter

My stumbling block right now is my sppedo. It is electronic and worked fine before with the T56 using the line coming off the trans. It is now for the VSS for the computer. They do provide a lead off the ecm for the speedo but I cannot get an answer if it is a square wave 5 volt signal. Nobody seems to know. Asked over at LS1tech nobody can answer. Whatever it is it is not working. Glad yours is running well.

#374

Melting Slicks

Member Since: Jan 2014

Location: Downers Grove Illinois

Posts: 2,474

Received 250 Likes

on

239 Posts

My stumbling block right now is my sppedo. It is electronic and worked fine before with the T56 using the line coming off the trans. It is now for the VSS for the computer. They do provide a lead off the ecm for the speedo but I cannot get an answer if it is a square wave 5 volt signal. Nobody seems to know. Asked over at LS1tech nobody can answer. Whatever it is it is not working. Glad yours is running well.

#376

Melting Slicks

I used one of the VA fittings that came in the kit. That was for the pressure line and it was the straight fitting with the bleeder on it. On the other end I used a 135 degree fitting coming off the back of the compressor. The other side which is #10 they supply a straight. That would have worked but was right at the dipstick and close to the motor. I figured a 45 would be better. On the firewall side I used a straight with the bleeder on it. I did use their tubing but not much of it. It all fits nice and tight and clean looking.

#377

Instructor

My stumbling block right now is my sppedo. It is electronic and worked fine before with the T56 using the line coming off the trans. It is now for the VSS for the computer. They do provide a lead off the ecm for the speedo but I cannot get an answer if it is a square wave 5 volt signal. Nobody seems to know. Asked over at LS1tech nobody can answer. Whatever it is it is not working. Glad yours is running well.

http://www.trifive.com/forums/archiv.../t-103955.html

Mike

#378

Race Director

Thread Starter

I don't know a whole lot about this end of it , but I did a little digging and found this link to a forum dealing with this exact subject. Maybe this will help a little.

http://www.trifive.com/forums/archiv.../t-103955.html

Mike

http://www.trifive.com/forums/archiv.../t-103955.html

Mike

#379

#380

Race Director

Thread Starter

One of the main reasons I did this was I had already run the fans with my previous fuel injected 383 this was. So the setup was already there and wired in and it worked just fine. If I was starting from scratch yes I would let the PCM handle that chore.