c3 road race build

#23

#25

Race Director

Interesting project! I have to agree with gkull though, 2000 lb is going to be a tough number to reach!

The Trans-Am Camaro we ran in the 80's, had a frame built completely from square tube, a Kevlar body and a 4.3 liter Chevy V6. If I remember correctly, we were allowed a minimum weight of 2,250 lbs, and had a tough time getting there. That was with a purpose built silhouette type race car, and we had some development help from the Chevrolet factory backed Protofab team!

What do you plan to use for a trans and rear end?

The Trans-Am Camaro we ran in the 80's, had a frame built completely from square tube, a Kevlar body and a 4.3 liter Chevy V6. If I remember correctly, we were allowed a minimum weight of 2,250 lbs, and had a tough time getting there. That was with a purpose built silhouette type race car, and we had some development help from the Chevrolet factory backed Protofab team!

What do you plan to use for a trans and rear end?

#27

Drifting

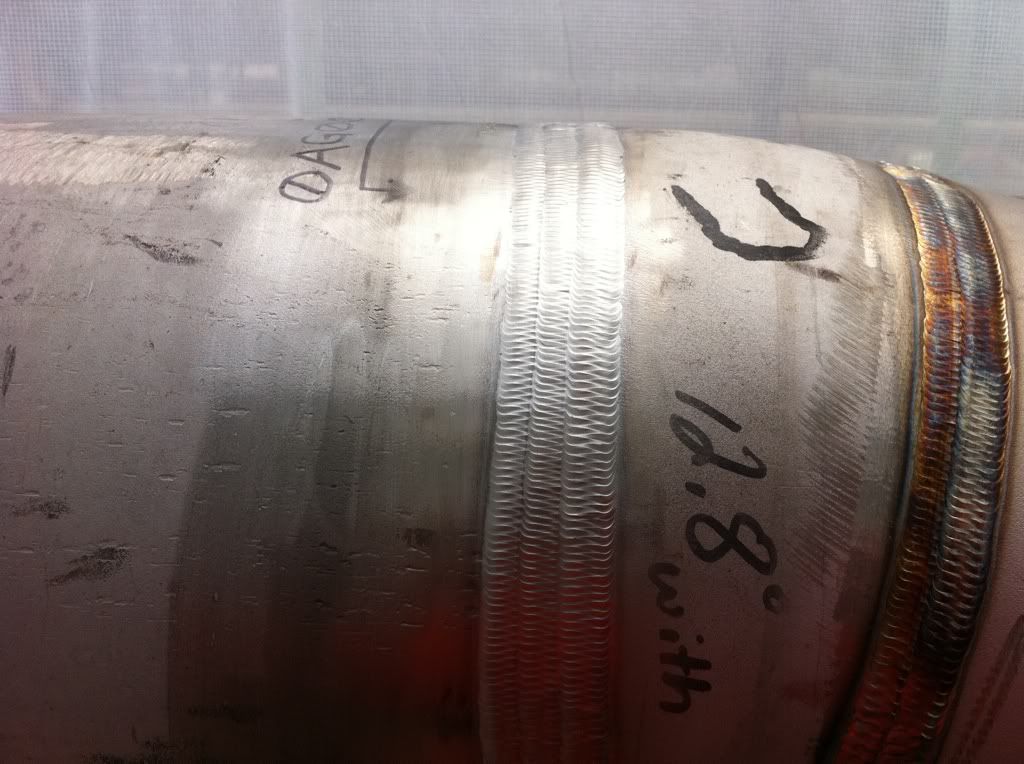

Very nice welds and fab work,but I do have a problem with what you are welding it to! You better take care of that rusty POS frame before moving any further,with it that rusty who knows how square,and how close to spec it may be,issues that will cause some major grief down the road...

#29

Team Owner

IMO - No matter how bad a V-6 you build they just don't sound right! Back in around 1980 I bought a Chevy Monza Spyder which came with a 262 ci V-8 and 5 speed. Very few hop up parts for the smog mini wonder. i had big heads and crane mech cam single plane and headers. So I came across a chevy 231 ci Odd fire that had been used in an alki injected sprint car class.

The class I was in was your lower end 911's and Your Datsun 240/260/280/300ZX's So it was a battle of 6 cylinders and my 4.3 bored out was one of the bigger N/A motors in the field. This was in a something like 2250 pound class min. It was kind of a battle of midgets. It was kind of fun when you were young

The class I was in was your lower end 911's and Your Datsun 240/260/280/300ZX's So it was a battle of 6 cylinders and my 4.3 bored out was one of the bigger N/A motors in the field. This was in a something like 2250 pound class min. It was kind of a battle of midgets. It was kind of fun when you were young

#30

Interesting project! I have to agree with gkull though, 2000 lb is going to be a tough number to reach!

The Trans-Am Camaro we ran in the 80's, had a frame built completely from square tube, a Kevlar body and a 4.3 liter Chevy V6. If I remember correctly, we were allowed a minimum weight of 2,250 lbs, and had a tough time getting there. That was with a purpose built silhouette type race car, and we had some development help from the Chevrolet factory backed Protofab team!

What do you plan to use for a trans and rear end?

The Trans-Am Camaro we ran in the 80's, had a frame built completely from square tube, a Kevlar body and a 4.3 liter Chevy V6. If I remember correctly, we were allowed a minimum weight of 2,250 lbs, and had a tough time getting there. That was with a purpose built silhouette type race car, and we had some development help from the Chevrolet factory backed Protofab team!

What do you plan to use for a trans and rear end?

Very nice welds and fab work,but I do have a problem with what you are welding it to! You better take care of that rusty POS frame before moving any further,with it that rusty who knows how square,and how close to spec it may be,issues that will cause some major grief down the road...

thank you all for your kind words

#31

IMO - No matter how bad a V-6 you build they just don't sound right! Back in around 1980 I bought a Chevy Monza Spyder which came with a 262 ci V-8 and 5 speed. Very few hop up parts for the smog mini wonder. i had big heads and crane mech cam single plane and headers. So I came across a chevy 231 ci Odd fire that had been used in an alki injected sprint car class.

The class I was in was your lower end 911's and Your Datsun 240/260/280/300ZX's So it was a battle of 6 cylinders and my 4.3 bored out was one of the bigger N/A motors in the field. This was in a something like 2250 pound class min. It was kind of a battle of midgets. It was kind of fun when you were young

The class I was in was your lower end 911's and Your Datsun 240/260/280/300ZX's So it was a battle of 6 cylinders and my 4.3 bored out was one of the bigger N/A motors in the field. This was in a something like 2250 pound class min. It was kind of a battle of midgets. It was kind of fun when you were young

http://youtu.be/KkglxJH6jGE

and this sounds pretty good to me it's ok if you don't like it it's not your car

#33

Melting Slicks

I realise You say the Frame is Ok but looking at this picture it sure looks like somebody has welded a Flat Bar over a large Hole in the frame just before the Rear Wheels wich is where they always rust out first.

I have been doing a lot of Tig Welding Pipe at my Job and after looking at Your Welds I'm ready to just stop and tell everybody I can't weld anymore.

I have been doing a lot of Tig Welding Pipe at my Job and after looking at Your Welds I'm ready to just stop and tell everybody I can't weld anymore.

#34

I realise You say the Frame is Ok but looking at this picture it sure looks like somebody has welded a Flat Bar over a large Hole in the frame just before the Rear Wheels wich is where they always rust out first.

I have been doing a lot of Tig Welding Pipe at my Job and after looking at Your Welds I'm ready to just stop and tell everybody I can't weld anymore.

I have been doing a lot of Tig Welding Pipe at my Job and after looking at Your Welds I'm ready to just stop and tell everybody I can't weld anymore.

Last edited by powersauto; 05-27-2012 at 01:04 AM.

#36

Team Owner

if... and a big IF my v6 isnt up to the task then I'll just do this to it

http://youtu.be/KkglxJH6jGE

and this sounds pretty good to me

http://youtu.be/KkglxJH6jGE

and this sounds pretty good to me

As for your projects weight. To get my weight down I put in the 81 twin turbo front end. It was good for 150 weight lose over my stock 79 thick fiber glass. IMO the way to really lose weight would be to get a removable front end held on with Zues slotted fastners. Of course lexan windows

#37

Melting Slicks

Why Tig Weld something so Thick? I generaly work with Hyd Pipe and we will Tig weld the 1st pass so that there isn't any Slag or leaks and then we just fill in the ditch with a Wire Feed. You must be welding this Pipe to some sort of spec's, glad I'm not paying for it....

#38

Why Tig Weld something so Thick? I generaly work with Hyd Pipe and we will Tig weld the 1st pass so that there isn't any Slag or leaks and then we just fill in the ditch with a Wire Feed. You must be welding this Pipe to some sort of spec's, glad I'm not paying for it....

did you go too a tech school or did the union teach you those skills?

did you go too a tech school or did the union teach you those skills?