1971 Reverse lock out - key removal

#1

I can't get the key out of the ignition of my 71 4 speed when I put it in reverse. It worked yesterday but now the ignition won't go the final click so I can remove the key. Any help is much appreciated.

#2

Le Mans Master

It sounds like your lock out cable is not pushing far enough . You will have to investigate to find out why. From my memory there is no adjustment on my 72. Maybe something worn or binding. Maybe just need a little more adjustment on your reverse rod.

#5

Team Owner

Member Since: Sep 2006

Location: Westminster Maryland

Posts: 30,173

Likes: 0

Received 2,878 Likes

on

2,515 Posts

Hi,

Check to make sure the cable is properly 'clipped' to the brackets at each end of the cable… at the steering column and the transmission.

There's no adjustment possible at the column lever, but….

Since the reverse rod on the shifter is moving the reverse lever on the transmission which moves the reverse lock cable, a SLIGHT adjustment of the rod to make it move the lever a tiny BIT further might help.

Don't move it far under any circumstance, since you don't wan't to goof up the reverse adjustment.

Regards,

Alan

Here's the connection at the reverse lever on the side of the transmission… you're looking at the very end of the reverse lever.

Check to make sure the cable is properly 'clipped' to the brackets at each end of the cable… at the steering column and the transmission.

There's no adjustment possible at the column lever, but….

Since the reverse rod on the shifter is moving the reverse lever on the transmission which moves the reverse lock cable, a SLIGHT adjustment of the rod to make it move the lever a tiny BIT further might help.

Don't move it far under any circumstance, since you don't wan't to goof up the reverse adjustment.

Regards,

Alan

Here's the connection at the reverse lever on the side of the transmission… you're looking at the very end of the reverse lever.

#6

Le Mans Master

Member Since: Jul 2000

Location: Saginaw Michigan

Posts: 6,001

Likes: 0

Received 98 Likes

on

81 Posts

Hi,

Check to make sure the cable is properly 'clipped' to the brackets at each end of the cable… at the steering column and the transmission.

There's no adjustment possible at the column lever, but….

Since the reverse rod on the shifter is moving the reverse lever on the transmission which moves the reverse lock cable, a SLIGHT adjustment of the rod to make it move the lever a tiny BIT further might help.

Don't move it far under any circumstance, since you don't wan't to goof up the reverse adjustment.

Regards,

Alan

Here's the connection at the reverse lever on the side of the transmission… you're looking at the very end of the reverse lever.

Check to make sure the cable is properly 'clipped' to the brackets at each end of the cable… at the steering column and the transmission.

There's no adjustment possible at the column lever, but….

Since the reverse rod on the shifter is moving the reverse lever on the transmission which moves the reverse lock cable, a SLIGHT adjustment of the rod to make it move the lever a tiny BIT further might help.

Don't move it far under any circumstance, since you don't wan't to goof up the reverse adjustment.

Regards,

Alan

Here's the connection at the reverse lever on the side of the transmission… you're looking at the very end of the reverse lever.

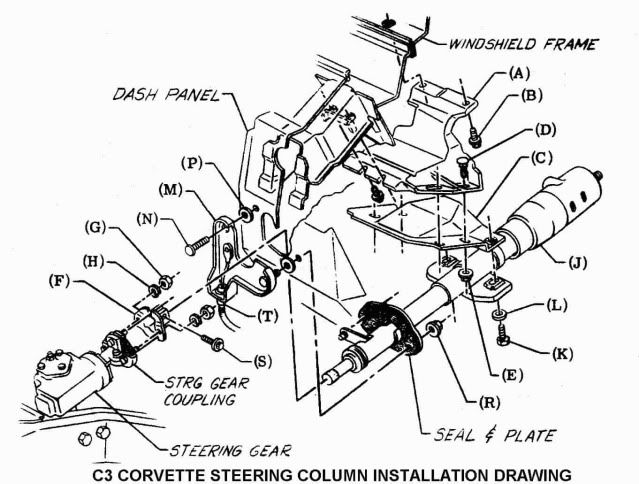

There is a slight amount of adjustment available where the cable sheath (T) attaches to the big plate (M) on the engine side of the dash panel.

Looking at the plate from the engine side, you will see a welded stud on the right side of the plate. On the left side of the plate is a carriage bolt (N). The stud extends through the dash panel where there is just a clearance hole. The carriage bolt extends through the plate and into a slot in the dash panel. (In the picture above, it doesn't look like much of a slot but it is!)

If you go inside the car and loosen both nuts (R) on the driver side of the dash panel, you should be able to rotate the big plate around the welded stud (and clearance hole) within the limits of the carriage bolt and the slot on the left side of the dash panel.

Since the sheath of the backdrive cable (T) is attached to the plate any movement of the plate relative to the steering column lever will effectively shorten or lengthen the distance from the plate to the steering column lever and some adjustment is available.

Jim

Last edited by Jim Shea; 11-23-2014 at 11:23 AM.

#7

Team Owner

Member Since: Sep 2006

Location: Westminster Maryland

Posts: 30,173

Likes: 0

Received 2,878 Likes

on

2,515 Posts

Hi Jim,

You CERTAINLY know this area of our cars…..

Isn't that really just adjusting the position of the cable's sheath since 'm' is independent of the cable itself?

I thought because the cable is a fixed length you can just adjust how FAR it moves, not how long it's effective LENGTH is.

Regards,

Alan

You CERTAINLY know this area of our cars…..

Isn't that really just adjusting the position of the cable's sheath since 'm' is independent of the cable itself?

I thought because the cable is a fixed length you can just adjust how FAR it moves, not how long it's effective LENGTH is.

Regards,

Alan

Last edited by Alan 71; 11-23-2014 at 12:33 PM.

#8

Le Mans Master

Member Since: Jul 2000

Location: Saginaw Michigan

Posts: 6,001

Likes: 0

Received 98 Likes

on

81 Posts

Hi Jim,

You CERTAINLY know this area of our cars…..

Isn't that really just adjusting the position of the cable's sheath since 'm' is independent of the cable itself?

I thought because the cable is a fixed length you can just adjust how FAR it moves, not how long it's effective LENGTH is.

Regards,

Alan

You CERTAINLY know this area of our cars…..

Isn't that really just adjusting the position of the cable's sheath since 'm' is independent of the cable itself?

I thought because the cable is a fixed length you can just adjust how FAR it moves, not how long it's effective LENGTH is.

Regards,

Alan

When I graduated with my bachelor in mechanical engineering in 1966, I started at Saginaw Steering Gear Div, GMC in the Advanced Engineering Dept. One of the projects that I worked on was adjustable brake and accelerator pedals. One mechanism that we designed for the accelerator pedal was cable actuated. The moveable mechanism for the accelerator pedal had a fixed cable and the lever arm from the accelerator pedal pushed and pulled on the sheath. As I recall, the sheath and cable had to be in somewhat of an arc in order for it to work.

I have an artists conception of the adjustable pedals. It does show the pedal arm pushing and pulling on the sheath. I will post the pic in a day or two when I find it.

Jim

#9

Le Mans Master

Member Since: Jul 2000

Location: Saginaw Michigan

Posts: 6,001

Likes: 0

Received 98 Likes

on

81 Posts

Here is an artist rendering of one of our Advanced Engineering adjustable brake and accelerator pedal concepts. We actually built several prototypes and installed them in Chevrolets, Pontiacs, and Cadillacs.

If you look closely at the above picture, you can see where the sheath of the throttle cable is connected to the moveable arm that is part of the accelerator pedal. The actual cable is connected to the translating arm, (i.e. the translating arm is stationary relative to the movement of the pedal.) When you depress the accelerator pedal, the sheath is moved toward the driver and the cable extending from the sheath on the carburator end is shortened.

I had a hard time understanding the concept of moving the cable sheath but it was very successful when used in several adjustable pedal mockup and vehicle installations.

Jim

If you look closely at the above picture, you can see where the sheath of the throttle cable is connected to the moveable arm that is part of the accelerator pedal. The actual cable is connected to the translating arm, (i.e. the translating arm is stationary relative to the movement of the pedal.) When you depress the accelerator pedal, the sheath is moved toward the driver and the cable extending from the sheath on the carburator end is shortened.

I had a hard time understanding the concept of moving the cable sheath but it was very successful when used in several adjustable pedal mockup and vehicle installations.

Jim

#10

Team Owner

Member Since: Sep 2006

Location: Westminster Maryland

Posts: 30,173

Likes: 0

Received 2,878 Likes

on

2,515 Posts

Hi Jim,

I think I'm seeing that the end of the cable is fixed and the arm is sliding the sheath along the length of the cable. (The opposite concept of our interlock cable…. fixed sheath/movable cable.)

Since we can't see it in this drawing…. what's going on at the other end of this cable…. is that end of the cable fixed too, and the sliding sheath is accomplishing the work by being attached to something that moves... (a throttle lever)?

Regards,

Alan

I think I'm seeing that the end of the cable is fixed and the arm is sliding the sheath along the length of the cable. (The opposite concept of our interlock cable…. fixed sheath/movable cable.)

Since we can't see it in this drawing…. what's going on at the other end of this cable…. is that end of the cable fixed too, and the sliding sheath is accomplishing the work by being attached to something that moves... (a throttle lever)?

Regards,

Alan

#11

Le Mans Master

Member Since: Jul 2000

Location: Saginaw Michigan

Posts: 6,001

Likes: 0

Received 98 Likes

on

81 Posts

Hi Jim,

I think I'm seeing that the end of the cable is fixed and the arm is sliding the sheath along the length of the cable. (The opposite concept of our interlock cable…. fixed sheath/movable cable.)

Since we can't see it in this drawing…. what's going on at the other end of this cable…. is that end of the cable fixed too, and the sliding sheath is accomplishing the work by being attached to something that moves... (a throttle lever)?

Regards,

Alan

I think I'm seeing that the end of the cable is fixed and the arm is sliding the sheath along the length of the cable. (The opposite concept of our interlock cable…. fixed sheath/movable cable.)

Since we can't see it in this drawing…. what's going on at the other end of this cable…. is that end of the cable fixed too, and the sliding sheath is accomplishing the work by being attached to something that moves... (a throttle lever)?

Regards,

Alan

The other end (at the carburator) has the sheath fixed and the cable pulls on the carburator arm to open the primary blade as conventional.

It is not usual for a cable to be used in the "push" mode (such as the case with the Corvette steering column/transmission shift interlock system.) Note nearly all of the other GM vehicles used a lever/rod/bell crank type linkage rather than a cable to operate their interlock systems.

Now when it comes to the big plate on the front of dash. We are rotating the plate and moving the sheath attachment relative to the point where the cable attaches to the steering column lower lever (adjusting the cable assembly.)

Jim

Last edited by Jim Shea; 11-24-2014 at 09:59 AM.

#12

Team Owner

So long since I had a muncie in my car, I almost forget, but I popped the cable off the old '72 steering column, and wired the lever up high as it would go, fixed that puppy, course when changing it out for a last shark TT column, I didn't even put that entire lever assy in the rebuild....

#13

Team Owner

Member Since: Sep 2006

Location: Westminster Maryland

Posts: 30,173

Likes: 0

Received 2,878 Likes

on

2,515 Posts

Hi Jim,

I don't understand.

If the sheath is moved by the lever in your drawing, but is fixed at it's other end at the carb….. doesn't the sheath just 'buckle' and want to 'whip' around when the lever is moved? The lever is trying to move something that's fixed in place.

I don't understand what moves the cable at the carb end.

Regards,

Alan

The accelerator cable…

The sheath is fixed at both ends.

When the accelerator is depressed it pulls the cable into the interior moving the carb linkage and loading the throttle spring on the carb linkage. The foot over comes that load until the foot is removed and the spring load pulls the cable back toward the carb 'automatically'.

Isn't the interlock the same principle except that's there's no spring to load so the lever at the transmission moves the cable in both directions manually controlled by the driver.

I don't understand.

If the sheath is moved by the lever in your drawing, but is fixed at it's other end at the carb….. doesn't the sheath just 'buckle' and want to 'whip' around when the lever is moved? The lever is trying to move something that's fixed in place.

I don't understand what moves the cable at the carb end.

Regards,

Alan

The accelerator cable…

The sheath is fixed at both ends.

When the accelerator is depressed it pulls the cable into the interior moving the carb linkage and loading the throttle spring on the carb linkage. The foot over comes that load until the foot is removed and the spring load pulls the cable back toward the carb 'automatically'.

Isn't the interlock the same principle except that's there's no spring to load so the lever at the transmission moves the cable in both directions manually controlled by the driver.

Last edited by Alan 71; 11-24-2014 at 12:08 PM.

#14

Le Mans Master

Member Since: Jul 2000

Location: Saginaw Michigan

Posts: 6,001

Likes: 0

Received 98 Likes

on

81 Posts

Alan,

Think of it this way. When I press on the accelerator pedal the upper end of the accelerator rod moves and pushes on the cable sheath.

Note, the cable assembly routes into a 180 degree arc and then heads back toward the engine. This is the secret as to how it works. The cable assembly is fixed as it passes through a hole in the dash panel and is fixed as it attaches to the engine intake manifold.

The accelerator rod pushes on the sheath. This forces the cable assembly under the dash to route into a larger diameter arc. The sheath is fixed at the hole in the dash as well as fixed at the intake manifold. So the cable assembly is forced into that larger diameter arc. But the cable (inside the sheath) is fixed on the accelerator translating arm. The only way it can follow the sheath into the larger arc is for it to pull additional cable from the carburator end. Since the end of the cable is attached to an arm on the carburator, this causes the throttle plate to open.

Jim

Think of it this way. When I press on the accelerator pedal the upper end of the accelerator rod moves and pushes on the cable sheath.

Note, the cable assembly routes into a 180 degree arc and then heads back toward the engine. This is the secret as to how it works. The cable assembly is fixed as it passes through a hole in the dash panel and is fixed as it attaches to the engine intake manifold.

The accelerator rod pushes on the sheath. This forces the cable assembly under the dash to route into a larger diameter arc. The sheath is fixed at the hole in the dash as well as fixed at the intake manifold. So the cable assembly is forced into that larger diameter arc. But the cable (inside the sheath) is fixed on the accelerator translating arm. The only way it can follow the sheath into the larger arc is for it to pull additional cable from the carburator end. Since the end of the cable is attached to an arm on the carburator, this causes the throttle plate to open.

Jim

#15

Team Owner

Member Since: Sep 2006

Location: Westminster Maryland

Posts: 30,173

Likes: 0

Received 2,878 Likes

on

2,515 Posts

Hi Jim,

Now I get it.

The cable moves only because of what's happening to the sheath!

Thanks very much for taking the time to explain that for me.!

Regards,

Alan

Now I get it.

The cable moves only because of what's happening to the sheath!

Thanks very much for taking the time to explain that for me.!

Regards,

Alan

#16

Le Mans Master

Member Since: Jul 2000

Location: Saginaw Michigan

Posts: 6,001

Likes: 0

Received 98 Likes

on

81 Posts

Glad that you found my explanation clear enough. We had actual parts to play with and it still was difficult to understand. The sheath doesn't has to decribe much of a larger arc in order to reach wide open throttle.

Those were back in the glory days when GM had nearly 66% of the U.S. market. Saginaw was part of GM and our Advanced Engineering Department could work on virtually anything that COULD POSSIBLY bring new business to Saginaw. We actually did sell an adjustable foot pedal module to Pontiac for the 1972? model year. We were 30 years ahead of the market and Pontiac didn't really advertise the option and it died after only one or two model years.

We got into the exhaust emissions air pump business when our chief engineer went down to Corporate Headquarters with a machined block of wood and told top GM management that Saginaw would produce a belt driven air pump that would take up no more space than his block of wood. He guaranteed that it would pump X volume of air; would cost Y dollars to produce; and Saginaw would deliver production parts in 18 months.

Today you go running to purchasing with a computer chip with different programing.

Jim

Those were back in the glory days when GM had nearly 66% of the U.S. market. Saginaw was part of GM and our Advanced Engineering Department could work on virtually anything that COULD POSSIBLY bring new business to Saginaw. We actually did sell an adjustable foot pedal module to Pontiac for the 1972? model year. We were 30 years ahead of the market and Pontiac didn't really advertise the option and it died after only one or two model years.

We got into the exhaust emissions air pump business when our chief engineer went down to Corporate Headquarters with a machined block of wood and told top GM management that Saginaw would produce a belt driven air pump that would take up no more space than his block of wood. He guaranteed that it would pump X volume of air; would cost Y dollars to produce; and Saginaw would deliver production parts in 18 months.

Today you go running to purchasing with a computer chip with different programing.

Jim

Last edited by Jim Shea; 11-25-2014 at 11:03 AM.