Tach Drive Distributor Question

#21

Former Vendor

Member Since: Aug 2006

Location: Jeffersonville Indiana 812-288-7103

Posts: 76,656

Received 1,813 Likes

on

1,458 Posts

St. Jude Donor '08-'09-'10-'11-'12-'13-'14-'15

The brass (or steel) is normally used for 1969 and older cars. The 1969 and new cars had the plastic button inside and you can tell from the hole in the side of the housing. You can see in the picture below.

I wonder if the brass button failure is due to customers installing it themselves, not realizing that it's more than just drill a hole in the side of the distributor to install the wall button. We machine the housing wall so when the button is installed the wall is the thickness it was originally.

The bushings upper and lower... boy there is a topic. I posted above that the bushings in most cases have to be re-sized after installed. If the bushings are driven in the housing and the clearance isn't correct the bushings will cease up on the shaft. I have to say that you at home builders need to be on your game when your own distributor.

IMHO,

Willcox

I wonder if the brass button failure is due to customers installing it themselves, not realizing that it's more than just drill a hole in the side of the distributor to install the wall button. We machine the housing wall so when the button is installed the wall is the thickness it was originally.

The bushings upper and lower... boy there is a topic. I posted above that the bushings in most cases have to be re-sized after installed. If the bushings are driven in the housing and the clearance isn't correct the bushings will cease up on the shaft. I have to say that you at home builders need to be on your game when your own distributor.

IMHO,

Willcox

#23

Burning Brakes

I drilled and tapped mine and used a long 5/16" set screw with the tip ground flat and polished(overkill?)and a jamb nut. Gives the ability to fine tune end play and should be hard enough to not wear out. So far so good!

#24

Melting Slicks

Thread Starter

On my distributor, when I went to push out the button through the hole (from the exterior), all that came out was the button's stem, and all that was left of the button inside was a washer-like remanent. It was of a plastic material.

I threw it away before I took a photo, dammit.

Steve

I threw it away before I took a photo, dammit.

Steve

#25

Former Vendor

Member Since: Aug 2006

Location: Jeffersonville Indiana 812-288-7103

Posts: 76,656

Received 1,813 Likes

on

1,458 Posts

St. Jude Donor '08-'09-'10-'11-'12-'13-'14-'15

On my distributor, when I went to push out the button through the hole (from the exterior), all that came out was the button's stem, and all that was left of the button inside was a washer-like remanent. It was of a plastic material.

I threw it away before I took a photo, dammit.

Steve

I threw it away before I took a photo, dammit.

Steve

#26

Drifting

Member Since: Oct 2001

Location: Halifax, Nova Scotia, Canada

Posts: 1,865

Received 831 Likes

on

242 Posts

The brass (or steel) is normally used for 1969 and older cars. The 1969 and new cars had the plastic button inside and you can tell from the hole in the side of the housing. You can see in the picture below.

I wonder if the brass button failure is due to customers installing it themselves, not realizing that it's more than just drill a hole in the side of the distributor to install the wall button. We machine the housing wall so when the button is installed the wall is the thickness it was originally.

The bushings upper and lower... boy there is a topic. I posted above that the bushings in most cases have to be re-sized after installed. If the bushings are driven in the housing and the clearance isn't correct the bushings will cease up on the shaft. I have to say that you at home builders need to be on your game when your own distributor.

IMHO,

Willcox

I wonder if the brass button failure is due to customers installing it themselves, not realizing that it's more than just drill a hole in the side of the distributor to install the wall button. We machine the housing wall so when the button is installed the wall is the thickness it was originally.

The bushings upper and lower... boy there is a topic. I posted above that the bushings in most cases have to be re-sized after installed. If the bushings are driven in the housing and the clearance isn't correct the bushings will cease up on the shaft. I have to say that you at home builders need to be on your game when your own distributor.

IMHO,

Willcox

I purchased a new main shaft and cross gear (with brass button). There was minimal wear in the housing, I drilled a partial hole in the housing from the inside, for the "peg" on the brass button.

I machined the surface of the brass button to achieve the correct end play.

Greased it up and re assembled.

Last summer I read here about the early failure of the brass buttons. I removed the dist and had a look, the button had no wear, just a bit shinny from the rotation of the cross gear, end play was still within spec.

I don't know if I have a good brass button or just good grease. I'll check it again in a few years.

#27

Drifting

I'm starting to think the load on the cross gear has more to do with the gears and housings/buttons wearing out that anything else.

The assembly itself with nothing (cable / tach) attached would probably last quite a few years and many miles with normal maintenance.

I think where the huge disparity between totally trashed vs mildly worn distributors comes in has a lot to do with the condition of the tach drive cable and the tach itself.

If the cable is dry or kinked, it's going to place a much bigger load on that side gear- Same with if the tach doesn't spin freely.

I've seen many a C3 with the tach cable running at all sorts of awkward angles as it attempts to attach to the distributor and that can't be good.

It's just a theory but believe it's very plausible.

The assembly itself with nothing (cable / tach) attached would probably last quite a few years and many miles with normal maintenance.

I think where the huge disparity between totally trashed vs mildly worn distributors comes in has a lot to do with the condition of the tach drive cable and the tach itself.

If the cable is dry or kinked, it's going to place a much bigger load on that side gear- Same with if the tach doesn't spin freely.

I've seen many a C3 with the tach cable running at all sorts of awkward angles as it attempts to attach to the distributor and that can't be good.

It's just a theory but believe it's very plausible.

#28

Melting Slicks

Thread Starter

I'm starting to think the load on the cross gear has more to do with the gears and housings/buttons wearing out that anything else.

The assembly itself with nothing (cable / tach) attached would probably last quite a few years and many miles with normal maintenance.

I think where the huge disparity between totally trashed vs mildly worn distributors comes in has a lot to do with the condition of the tach drive cable and the tach itself.

If the cable is dry or kinked, it's going to place a much bigger load on that side gear- Same with if the tach doesn't spin freely.

I've seen many a C3 with the tach cable running at all sorts of awkward angles as it attempts to attach to the distributor and that can't be good.

It's just a theory but believe it's very plausible.

The assembly itself with nothing (cable / tach) attached would probably last quite a few years and many miles with normal maintenance.

I think where the huge disparity between totally trashed vs mildly worn distributors comes in has a lot to do with the condition of the tach drive cable and the tach itself.

If the cable is dry or kinked, it's going to place a much bigger load on that side gear- Same with if the tach doesn't spin freely.

I've seen many a C3 with the tach cable running at all sorts of awkward angles as it attempts to attach to the distributor and that can't be good.

It's just a theory but believe it's very plausible.

Steve

#29

Team Owner

I'm starting to think the load on the cross gear has more to do with the gears and housings/buttons wearing out that anything else.

The assembly itself with nothing (cable / tach) attached would probably last quite a few years and many miles with normal maintenance.

I think where the huge disparity between totally trashed vs mildly worn distributors comes in has a lot to do with the condition of the tach drive cable and the tach itself.

If the cable is dry or kinked, it's going to place a much bigger load on that side gear- Same with if the tach doesn't spin freely.

I've seen many a C3 with the tach cable running at all sorts of awkward angles as it attempts to attach to the distributor and that can't be good.

It's just a theory but believe it's very plausible.

The assembly itself with nothing (cable / tach) attached would probably last quite a few years and many miles with normal maintenance.

I think where the huge disparity between totally trashed vs mildly worn distributors comes in has a lot to do with the condition of the tach drive cable and the tach itself.

If the cable is dry or kinked, it's going to place a much bigger load on that side gear- Same with if the tach doesn't spin freely.

I've seen many a C3 with the tach cable running at all sorts of awkward angles as it attempts to attach to the distributor and that can't be good.

It's just a theory but believe it's very plausible.

Last edited by Paul L; 02-28-2015 at 08:24 AM.

#31

Drifting

Exactly!

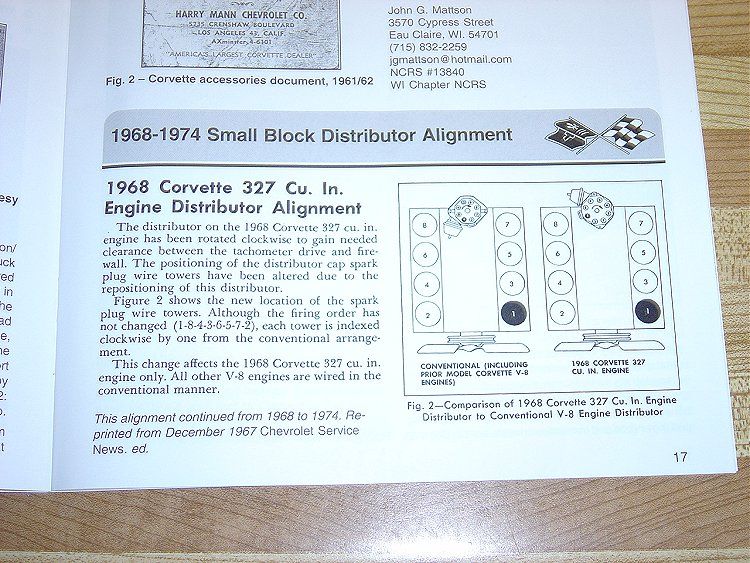

I've even gone as far as rotating the position of the plug wires in relation to the cap just to ensure the tach cable is not unnecessarily bent when I set the advance where it needs to be on my 409 SBC.

I've even gone as far as rotating the position of the plug wires in relation to the cap just to ensure the tach cable is not unnecessarily bent when I set the advance where it needs to be on my 409 SBC.

#32

Team Owner

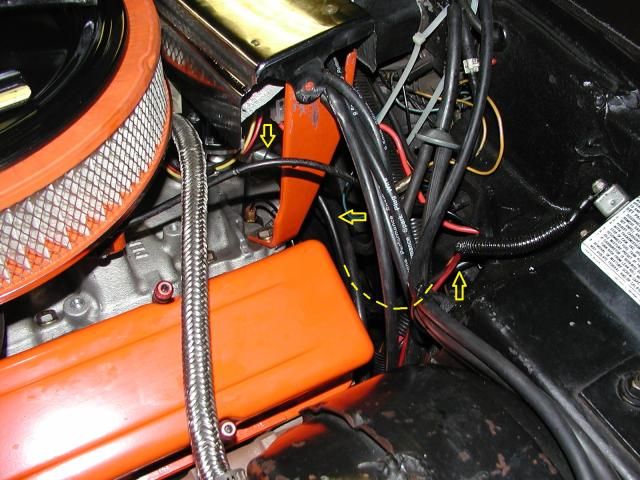

The Bubbafied intake vacuum fitting and hoses have since been cleaned up. You gotta love these cars to drive them. The vacuum feed back to the TH400 was entirely rubber and rotted near the vacuum modulator. Some funny shifts at times! I replaced the modulator and installed a proper steel vacuum line last year.

Last edited by Paul L; 02-28-2015 at 04:50 PM.

#33

Drifting

I had lunch today with a good engineer friend of mine that's worked on distributors for decades and pointed out another detail that is often overlooked-

The length of the tach cable itself.

With cars that are 45+ years old, there is a good chance that someone has replace the tach cable at one time or another.

How many people verify the length when replacing the cable to make sure that the cable isn't just a bit too long and bottoms out on the side gear, which in turn pre-loads the gear when you crank down the collar nut to the tach drive coupling?

You can ensure all day long that the gear has the appropriate clearance but if the cable is too long, it doesn't matter because the gear is forced to the bottom (back) of the housing.

Folks rebuilding these distributors would normally never see or know there was an issue because all they get is the distributor with munched gears.

I venture to guess that a majority of premature wear and destruction of cross gears and housings has more to do with binding/non-lubricated, too long cables than any manufacturing or design "defect" from Delco.

Just my .02, your mileage may vary.

The length of the tach cable itself.

With cars that are 45+ years old, there is a good chance that someone has replace the tach cable at one time or another.

How many people verify the length when replacing the cable to make sure that the cable isn't just a bit too long and bottoms out on the side gear, which in turn pre-loads the gear when you crank down the collar nut to the tach drive coupling?

You can ensure all day long that the gear has the appropriate clearance but if the cable is too long, it doesn't matter because the gear is forced to the bottom (back) of the housing.

Folks rebuilding these distributors would normally never see or know there was an issue because all they get is the distributor with munched gears.

I venture to guess that a majority of premature wear and destruction of cross gears and housings has more to do with binding/non-lubricated, too long cables than any manufacturing or design "defect" from Delco.

Just my .02, your mileage may vary.

#34

Melting Slicks

Thread Starter

I had lunch today with a good engineer friend of mine that's worked on distributors for decades and pointed out another detail that is often overlooked-

The length of the tach cable itself.

With cars that are 45+ years old, there is a good chance that someone has replace the tach cable at one time or another.

How many people verify the length when replacing the cable to make sure that the cable isn't just a bit too long and bottoms out on the side gear, which in turn pre-loads the gear when you crank down the collar nut to the tach drive coupling?

You can ensure all day long that the gear has the appropriate clearance but if the cable is too long, it doesn't matter because the gear is forced to the bottom (back) of the housing.

Folks rebuilding these distributors would normally never see or know there was an issue because all they get is the distributor with munched gears.

I venture to guess that a majority of premature wear and destruction of cross gears and housings has more to do with binding/non-lubricated, too long cables than any manufacturing or design "defect" from Delco.

Just my .02, your mileage may vary.

The length of the tach cable itself.

With cars that are 45+ years old, there is a good chance that someone has replace the tach cable at one time or another.

How many people verify the length when replacing the cable to make sure that the cable isn't just a bit too long and bottoms out on the side gear, which in turn pre-loads the gear when you crank down the collar nut to the tach drive coupling?

You can ensure all day long that the gear has the appropriate clearance but if the cable is too long, it doesn't matter because the gear is forced to the bottom (back) of the housing.

Folks rebuilding these distributors would normally never see or know there was an issue because all they get is the distributor with munched gears.

I venture to guess that a majority of premature wear and destruction of cross gears and housings has more to do with binding/non-lubricated, too long cables than any manufacturing or design "defect" from Delco.

Just my .02, your mileage may vary.

My problem: This car/project came to me without a distributor or cable. I have no idea what a proper length a factory cable should be. I do have a significant "wow" in my aftermarket cable/distributor.

Steve

#36

Melting Slicks

Thread Starter

Steve

#37

Team Owner

Not sure where Paul. This one came from Corvette Central, and others I've seen advertised never mentioned their length. It does have about 4" too many. Or, I could change the #1 cap tower to another and have the Vacuum Advance positioned behind the Shield Strut. But I don't think that would help "shorten" it that much, and it might just strain the cable near the Distributor more with a bend there.

Steve

Steve

#39

Drifting

Member Since: Oct 2001

Location: Halifax, Nova Scotia, Canada

Posts: 1,865

Received 831 Likes

on

242 Posts

I still have the original cable, and the dist is "clocked" the same as Paul's.

It lasted 100,000 mi, and likely would have lasted longer if I had greased it every 10 years or so.