Just picked up a T56 to swap into my '79

#21

Safety Car

Hey ATL

Some misinformation being passed onto you here.

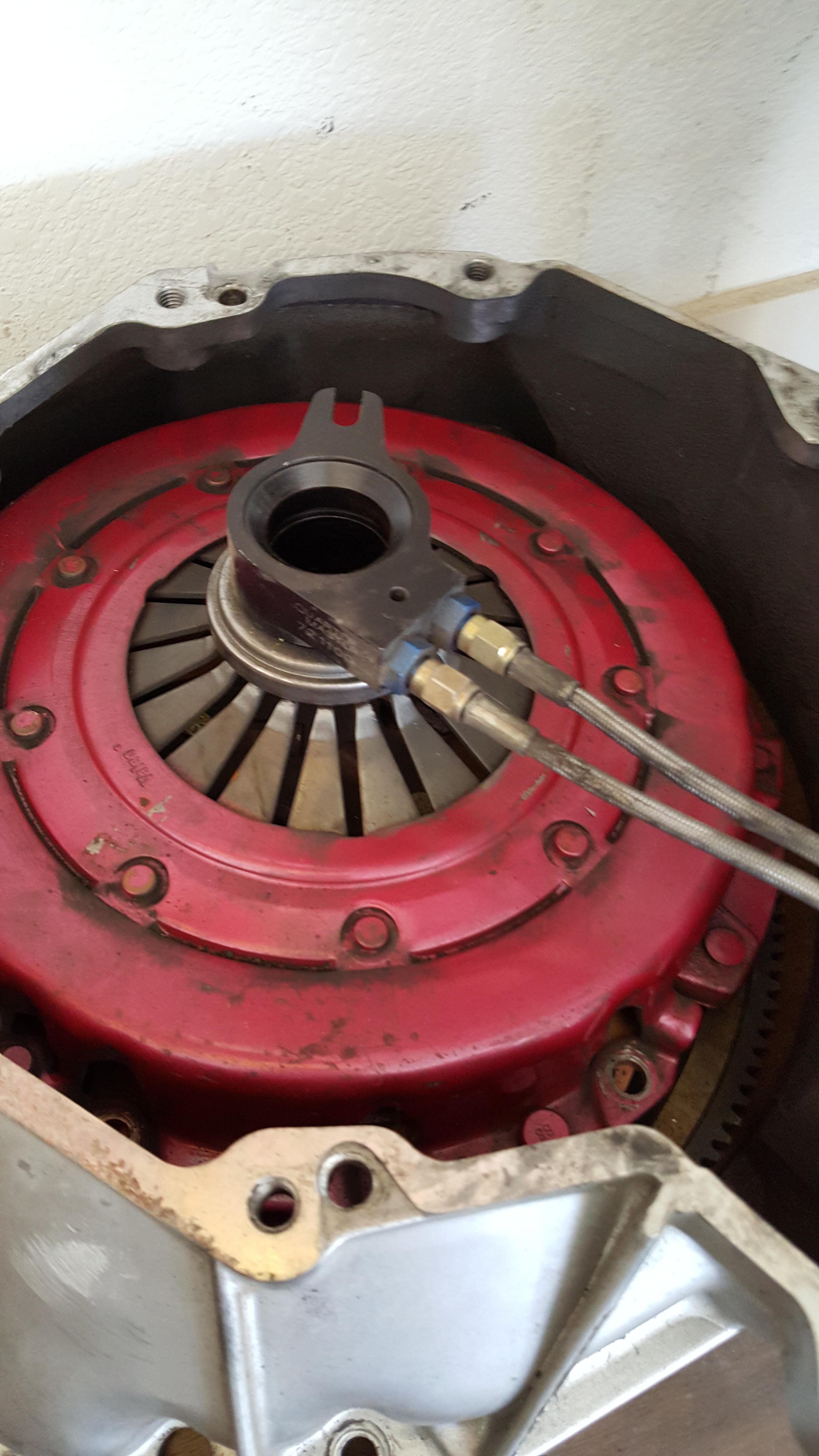

Take a real close look at that pin (3" rod) that is mounted next to the collar on the input shaft. It looks like someone modified the front of the transmission and bolted this pin in place. That pin is what steadies the hydraulic throwout bearing (TOB). See that? I have never seen that mod before.

Some misinformation being passed onto you here.

Take a real close look at that pin (3" rod) that is mounted next to the collar on the input shaft. It looks like someone modified the front of the transmission and bolted this pin in place. That pin is what steadies the hydraulic throwout bearing (TOB). See that? I have never seen that mod before.

To use it with a 2pc RMS block you can adapt the existing bellhousing or go with an aftermarket bellhousing like I did. Quicktime makes a scattershield #6023 designed just for this modification. That way you can use a hydraulic TOB, and any flywheel/clutch setup that fits the original 2pc RMS engine.

-- Joe

#22

Race Director

Member Since: Nov 2006

Location: Athens GA

Posts: 19,446

Received 351 Likes

on

304 Posts

St. Jude Donor '12-'13, '15- '16-'17-'18-'19, '21

That is how you do it on a T56. It doesn't have a retainer in the front like a T5/T10, saginaw, etc.

True but only for the hydraulic TOB version not for the LT1 version that uses a clutch fork/ball setup.

It's an LT1 T56. The front plate is different on both i.e, the part that bracket is bolted to that holds the stud for the TOB, that is at a completely different angle and spot on the LS1 version. Also the input shaft is an LT1 style, you can tell by the nose for the pilot bearing.

But the LT1 does not use a hydraulic TOB like the one shown in the beginning pics. It uses an external slave cylinder that actuates the clutch fork. That is why I said someone modified an LT1 to work with an LS1 TOB setup.

Isn't that part# only for an LS1 version ? I assumed due to the length of the input shaft, you'd need a special stepped pilot bushing if you use it with a LT1 T56.

-- Joe

True but only for the hydraulic TOB version not for the LT1 version that uses a clutch fork/ball setup.

It's an LT1 T56. The front plate is different on both i.e, the part that bracket is bolted to that holds the stud for the TOB, that is at a completely different angle and spot on the LS1 version. Also the input shaft is an LT1 style, you can tell by the nose for the pilot bearing.

But the LT1 does not use a hydraulic TOB like the one shown in the beginning pics. It uses an external slave cylinder that actuates the clutch fork. That is why I said someone modified an LT1 to work with an LS1 TOB setup.

Isn't that part# only for an LS1 version ? I assumed due to the length of the input shaft, you'd need a special stepped pilot bushing if you use it with a LT1 T56.

-- Joe

Good questions/points.

And even more reason for the OP to do his homework as he progresses with this project.

Bman

#23

Safety Car

The QT # is for the LS1 version but mates up to a 2pc RMS SBC. It is a one use type scattershield which is why it sells for $500-600. I found one for $450 new. You do use a pilot bushing to match the LS1 input shaft.

Good questions/points.

And even more reason for the OP to do his homework as he progresses with this project.

Bman

Good questions/points.

And even more reason for the OP to do his homework as he progresses with this project.

Bman

My recommendation is to use ALL the parts he got (clutch, bellhousing, transmission) and get a new 153 tooth flywheel, and a master cylinder with mount bracket.

He's going to need to fabricate a mount/adapter, as well as driveshaft too.

-- Joe

#25

Team Owner

Member Since: Oct 2004

Location: altered state

Posts: 81,242

Received 3,043 Likes

on

2,602 Posts

St. Jude Donor '05

Gen 1 block F body T56 I used the GM fluted pilot bushing they are less than $10

Test fit it first on the shaft

Used a parts store bushing and boy was I sorry!

FWIW the fbody GM slave stinks theres such a fine line between disengaging and blowing the seal it isnt even funny. Dont trust mine, been through a few

Use a differrent one if you can

Test fit it first on the shaft

Used a parts store bushing and boy was I sorry!

FWIW the fbody GM slave stinks theres such a fine line between disengaging and blowing the seal it isnt even funny. Dont trust mine, been through a few

Use a differrent one if you can

#26

Burning Brakes

Thread Starter

Wow, OK, I was offline for a bit and got a lot of great replies. MIKE80 your threads are great, I'll give that one another read.

Right, here is another photo of that part:

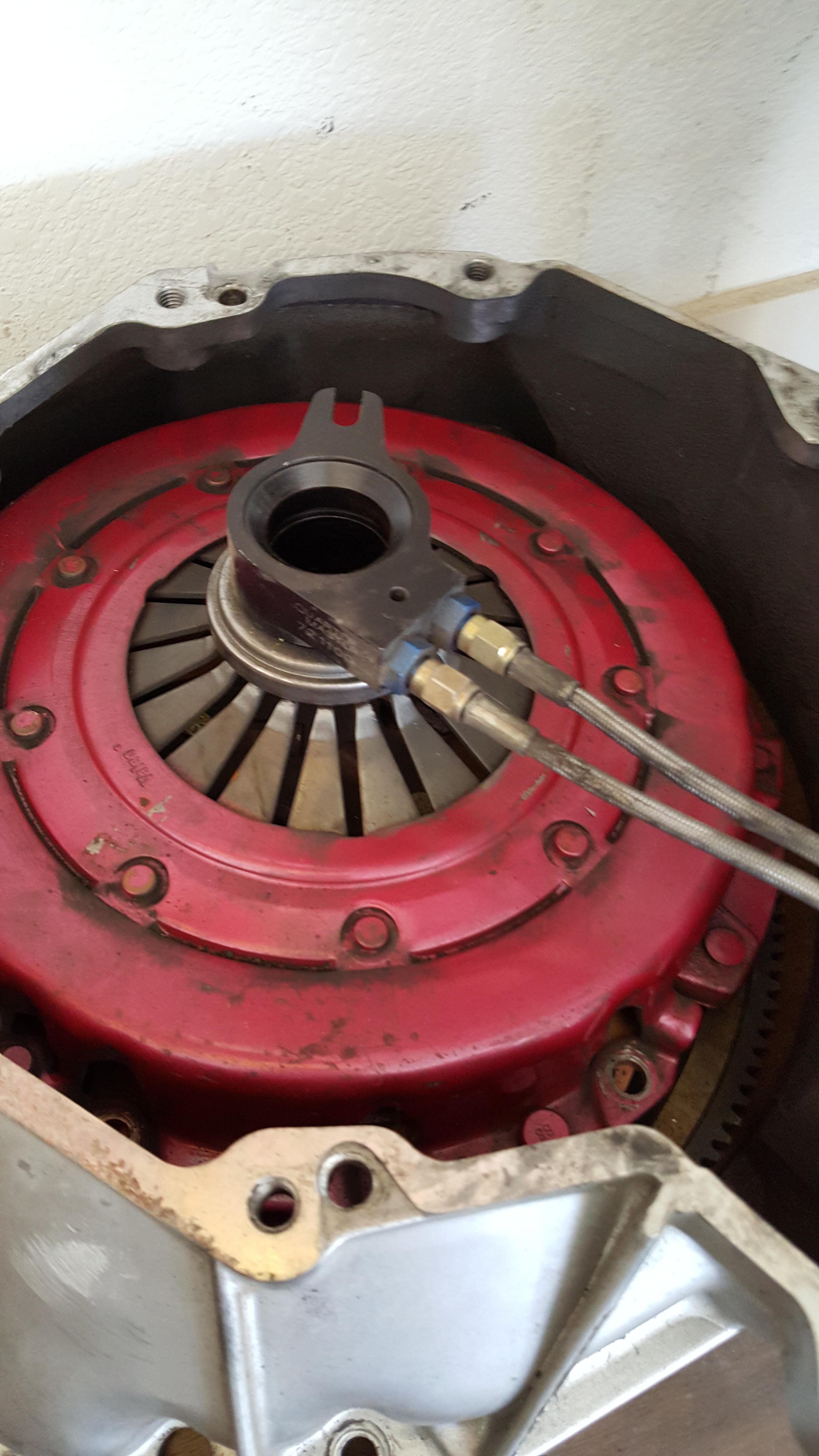

Here's a better photo of the slave. Its a quarter master 721100, a part which sells for $200+ new.

Next to the pressure plate:

This confuses me. I don't know if I need any special bushings but I'm thinking that since this all came out of a working vehicle, I could put it all together with the custom flywheel and it should function with no other modifications between the trans and engine.

Considering the depth of the LT1 bellhousing vs. the super 10 bellhousing, I'm leaning towards using the LT1 housing and converting the car to hydraulic simply so avoid shortening the driveshaft more than necessary since I heard there may be some angle issues.

I'm not terribly worried about the crossmember and driveshaft piece. Its the hydraulic conversion that concerns me.

You guys said it, I need to do my homework more.

I drove the car again today... feels like a blown bearing in the super 10. Noisy but driveable, just a matter of time before it fails.

Take a real close look at that pin (3" rod) that is mounted next to the collar on the input shaft. It looks like someone modified the front of the transmission and bolted this pin in place. That pin is what steadies the hydraulic throwout bearing (TOB). See that? I have never seen that mod before.

Here's a better photo of the slave. Its a quarter master 721100, a part which sells for $200+ new.

Next to the pressure plate:

Considering the depth of the LT1 bellhousing vs. the super 10 bellhousing, I'm leaning towards using the LT1 housing and converting the car to hydraulic simply so avoid shortening the driveshaft more than necessary since I heard there may be some angle issues.

I'm not terribly worried about the crossmember and driveshaft piece. Its the hydraulic conversion that concerns me.

You guys said it, I need to do my homework more.

I drove the car again today... feels like a blown bearing in the super 10. Noisy but driveable, just a matter of time before it fails.

Last edited by AboveTheLogic; 10-12-2015 at 12:21 AM.

The following users liked this post:

MIKE80 (10-12-2015)

#27

Safety Car

YOU have a working transmission and clutch setup. Just buy a bell housing, and a master cylinder with the vette firewall mount. Many threads on it.

Shortening the driveshaft and making a mount is a bit more interesting.

I'd probably cut the old crossmember out, and make a new one out of DOM tubing and some 3/16" plate. Kinda sucks that manual cars had welded in crossmembers.

Then figure $100-200 to have the driveshaft shortened. I think I paid about $125 last time I had it done.

-- Joe

#28

Burning Brakes

Thread Starter

If you're saying that the hydraulic conversion stuff is bolt-on, that's not what I'm seeing. In my searches, I'm finding custom bracketry and trimmed pedal rods with concern of pushing the master cylinder's piston beyond its designed stopping point.

#29

Race Director

Member Since: Nov 2006

Location: Athens GA

Posts: 19,446

Received 351 Likes

on

304 Posts

St. Jude Donor '12-'13, '15- '16-'17-'18-'19, '21

I converted my LT1 T56 to a hydraulic throw out bearing.

https://www.corvetteforum.com/forums...-s-list-8.html

https://www.corvetteforum.com/forums...-s-list-8.html

Gen 1 block F body T56 I used the GM fluted pilot bushing they are less than $10

Test fit it first on the shaft

Used a parts store bushing and boy was I sorry!

FWIW the fbody GM slave stinks theres such a fine line between disengaging and blowing the seal it isnt even funny. Dont trust mine, been through a few

Use a differrent one if you can

Test fit it first on the shaft

Used a parts store bushing and boy was I sorry!

FWIW the fbody GM slave stinks theres such a fine line between disengaging and blowing the seal it isnt even funny. Dont trust mine, been through a few

Use a differrent one if you can

Both of these guys' projects are good examples of what can be done with an LT1 T56.

Some of us started with just the trans and went all out on beefing it up and using a scattershield as opposed to an aluminum bellhousing.

Again...it all depends upon your choice of direction and budget.

Good luck with your project.

Keep posting as you progress.

Btw...many guys have cut out the fixed crossmember and just made adapter plates to make it into a bolt-in type. Or.... You can also buy an aftermarket one from some of the suppliers that make the T56 conversion kit.

Bman

#30

Burning Brakes

Thread Starter

Response from Rockland Standard Gear when I asked about their LT1/LS1 kit that converts the LT1 T56 to the LS1 style:

I contacted Bowtie regarding their custom crossmember that MIKE80 has, here is the conversation:

My email:

His response:

I'm leaning heavily towards using the custom flywheel and bowtie's crossmember. I just need to figure out my parts and everything for the hydraulic conversion. I'll read up on that some more and eventually post back here with my shopping list. I'll have to make sure I include a starter in that shopping list. Bummer since I just put a new starter on this car.

Pricing for the LT1/LS1 kit is $498.95 plus an additional $50.00 deposit until we get your old adapter plate back. The kit will include everything but a bellhousing.

If need you one we do stock an alum bell for $286.47

This kit will only work for a 2.66 first gear ratio option trans.

Shipping ground to you would be $ 27.50 for the kit, if you also need the bell the total freight would be $52.50 plus a COD fee if paying by check.

We send a prepaid return label to pick up the old adapter.

Let me know

Thanks

Cindy ext. 113

Rockland Standard Gear

If need you one we do stock an alum bell for $286.47

This kit will only work for a 2.66 first gear ratio option trans.

Shipping ground to you would be $ 27.50 for the kit, if you also need the bell the total freight would be $52.50 plus a COD fee if paying by check.

We send a prepaid return label to pick up the old adapter.

Let me know

Thanks

Cindy ext. 113

Rockland Standard Gear

My email:

I have a T56 from an LT1 F-body that I'm looking to swap into my '79. It is an original 4-speed car with the solid crossmember. It has 3.36 gears now but will be changed to 4.11 or higher. I saw on a corvette forum that you made a crossmember to bolt a T56 into an '80-'82 vette. Looks great. Do you make a crossmember that I can use to bolt this T56 into my '79?

Yes we do make that cross member. It sells for $ 225.00 and comes powder coated black with a bolt and mount kit.

Thank You;

Rich Weller

Bowtie Overdrives

760-947-5240

Thank You;

Rich Weller

Bowtie Overdrives

760-947-5240

Last edited by AboveTheLogic; 10-12-2015 at 06:35 PM.

#31

Safety Car

I'm leaning towards using the LT1 bell housing/clutch/cylinder with a custom flywheel. What are you suggesting with buying a bell housing?

If you're saying that the hydraulic conversion stuff is bolt-on, that's not what I'm seeing. In my searches, I'm finding custom bracketry and trimmed pedal rods with concern of pushing the master cylinder's piston beyond its designed stopping point.

If you're saying that the hydraulic conversion stuff is bolt-on, that's not what I'm seeing. In my searches, I'm finding custom bracketry and trimmed pedal rods with concern of pushing the master cylinder's piston beyond its designed stopping point.

You use an adjustable rod to the master..

#32

Burning Brakes

Thread Starter

Regarding the gearing in the rear end, the local driveline shop here that I like and trust quoted me about $775 to regear if I bring in the third member and drop it off. It would be another $280 in labor if I bring in the whole car to have it done.

I was hoping the cost to regear would be under $500 because I thought I saw some gear sets for around $200 but I guess I was wrong.

This same shop did a complete rebuild of that rear end with a refurbished case last year for $1300. They do really good work but are not cheap.

$775 plus some of my time to change from 3.36 to 4.10. I have to think about it a bit. I definitely will want to change that gearing. At least I don't need to worry about it until the trans is in.

I was hoping the cost to regear would be under $500 because I thought I saw some gear sets for around $200 but I guess I was wrong.

This same shop did a complete rebuild of that rear end with a refurbished case last year for $1300. They do really good work but are not cheap.

$775 plus some of my time to change from 3.36 to 4.10. I have to think about it a bit. I definitely will want to change that gearing. At least I don't need to worry about it until the trans is in.

#33

Burning Brakes

Thread Starter

It has been a couple of months and I haven't ordered any parts. I decided to pull the engine and trans out entirely and work out the mating of the T56 out of the car. It'll be some extra work but I think if I do it in the car it will be too frustrating.

This weekend I cleared out a spot in the garage for the job. I'll put it up on stands and begin the project during my holiday break. I might have the drivetrain out by new years:

I might end up doing some engine work while I have it all out. A head/cam swap is mighty tempting, although it already makes pretty good power.

This weekend I cleared out a spot in the garage for the job. I'll put it up on stands and begin the project during my holiday break. I might have the drivetrain out by new years:

I might end up doing some engine work while I have it all out. A head/cam swap is mighty tempting, although it already makes pretty good power.

#34

Burning Brakes

Thread Starter

If you use the FACTORY LT1 pull style clutch you need a conversion flywheel as the flywheel distance/depth is different.

If you use a PUSH STYLE clutch you can use any 153 tooth flywheel for a 2pc RMS.

If your block however is not tapped for both starters, that will be your next hurdle.

You already have a push style clutch, and hydraulic throwout bearing. so all you need is the correct flywheel for your engine.

Pioneer 153 Tooth Internal Balance Chevy V8 Clutch Flywheel P N FW 147 | eBay

-- Joe

If you use a PUSH STYLE clutch you can use any 153 tooth flywheel for a 2pc RMS.

If your block however is not tapped for both starters, that will be your next hurdle.

You already have a push style clutch, and hydraulic throwout bearing. so all you need is the correct flywheel for your engine.

Pioneer 153 Tooth Internal Balance Chevy V8 Clutch Flywheel P N FW 147 | eBay

-- Joe

Last edited by AboveTheLogic; 01-11-2016 at 12:36 AM.

#35

Burning Brakes

Thread Starter

Some progress pics:

Everything disconnected:

Cherry picker from the side because of the long nose

Something is missing

My buddy pulling the bellhousing off. We decided against pulling the engine and trans as a unit, so glad for that.

Out with the old. That old 4-speed is tiny!

Everything disconnected:

Cherry picker from the side because of the long nose

Something is missing

My buddy pulling the bellhousing off. We decided against pulling the engine and trans as a unit, so glad for that.

Out with the old. That old 4-speed is tiny!

#36

Safety Car

-- Joe

#37

Burning Brakes

Thread Starter

Yes, it was converted to a hydraulic throwout bearing and is a push style. The conversion flywheels are $400+, a standard 153 tooth flywheel is under $200, so if I can use the standard non-conversion flywheel I'm all over it. I just don't understand why. It seems like I'm missing something. Using a non-conversion flywheel (I think) moves the entire clutch assembly further back towards the transmission, so there may be clearance issues with the bearing?

Maybe I need to get it all mocked up and do some measurements so I can understand it better... but if you or anyone can help explain it I'm all ears and very much appreciate it.

I may be confusing what I read about the LS1 vs LT1 engines. Something I read said that the flywheel mounting point protrudes further towards the rear of the car on the original SBC than it does on the newer engine, that might have been LS, though. I'll have to find that reference again.

Maybe I need to get it all mocked up and do some measurements so I can understand it better... but if you or anyone can help explain it I'm all ears and very much appreciate it.

I may be confusing what I read about the LS1 vs LT1 engines. Something I read said that the flywheel mounting point protrudes further towards the rear of the car on the original SBC than it does on the newer engine, that might have been LS, though. I'll have to find that reference again.

Last edited by AboveTheLogic; 01-11-2016 at 12:02 PM.

#38

Safety Car

Yes, it was converted to a hydraulic throwout bearing and is a push style. The conversion flywheels are $400+, a standard 153 tooth flywheel is under $200, so if I can use the standard non-conversion flywheel I'm all over it. I just don't understand why. It seems like I'm missing something. Using a non-conversion flywheel (I think) moves the entire clutch assembly further back towards the transmission, so there may be clearance issues with the bearing?

Maybe I need to get it all mocked up and do some measurements so I can understand it better... but if you or anyone can help explain it I'm all ears and very much appreciate it.

I may be confusing what I read about the LS1 vs LT1 engines. Something I read said that the flywheel mounting point protrudes further towards the rear of the car on the original SBC than it does on the newer engine, that might have been LS, though. I'll have to find that reference again.

Maybe I need to get it all mocked up and do some measurements so I can understand it better... but if you or anyone can help explain it I'm all ears and very much appreciate it.

I may be confusing what I read about the LS1 vs LT1 engines. Something I read said that the flywheel mounting point protrudes further towards the rear of the car on the original SBC than it does on the newer engine, that might have been LS, though. I'll have to find that reference again.

You have an LT1 trans and bellhousing.

The LT1 flywheel has a larger pocket where the bolts are, since the clutch disc mounts with with the spring sin the pocket.

That being said, I'd expect the LT1 flywheel to be thicker and closer to the transmission. So, I'd guess you need to add some shims to get your stackup distance to your pressure plate correct.

I'd buy the cheapest SFI approved 153 tooth flywheel you can afford. I like the SFI flywheels because they don't remove your feet when they get too hot.

-- Joe

#39

Burning Brakes

Thread Starter

The SFI flywheels on summit are all in the $230-$260 range depending on the weight. They range from 9lb to 30lb.

That's not bad. I need to decide on flywheel weight.

If I'm understanding this correctly, going to a push style throwout allows me to solve clearance issues with shims, which makes perfect sense. I was afraid that using a standard flywheel with the short LT1 bell housing would give me too little room, hence the need for the conversion flywheel.

I'm not finding much during my searches to illustrate the real difference between the conversion 153 tooth flywheel and a standard 153 tooth flywheel so that I can see it for myself.

Summit has a pretty good return policy and I can see if I can find it locally as well. I'll shop around for a flywheel and then measure up what I have.

Thanks again for all the replies, very helpful.

That's not bad. I need to decide on flywheel weight.

If I'm understanding this correctly, going to a push style throwout allows me to solve clearance issues with shims, which makes perfect sense. I was afraid that using a standard flywheel with the short LT1 bell housing would give me too little room, hence the need for the conversion flywheel.

I'm not finding much during my searches to illustrate the real difference between the conversion 153 tooth flywheel and a standard 153 tooth flywheel so that I can see it for myself.

Summit has a pretty good return policy and I can see if I can find it locally as well. I'll shop around for a flywheel and then measure up what I have.

Thanks again for all the replies, very helpful.

Last edited by AboveTheLogic; 01-11-2016 at 01:22 PM.