David and Goliath (a study of two cylinder heads)

#1

Former Vendor

Thread Starter

Well for me its been so long since I read or heard about the story I don't know or remember how the much smaller David slays the much larger Goliath but I think most people regardless of their religion understand the parallel when those two names are brought up discussing a particular situation....

But I'm probably already getting ahead of myself so let me back up and lay out a situation that's all too common on this board as well as a misconception I have been trying to address since I started spending more time here....

John Doe decides he wants to build more power and is going to spring for a big bucks stroker motor....he decides to build a 410 CID hydraulic roller small block (hypothetical situation) and is undecided whether to use a ported "Stg III" LT4 head with new aftermarket larger valves and all the trimmings (done by a well known porting shop alot of his piers recommend) that's claimed to be 220 cc's or so and flow over 300 CFM (Goliath for those who haven't figured it out yet....LOL)

OR, go with the smaller AFR 195 comp ported head that Tony Mamo and perhaps a few others have recommended (our smaller "David") but he's concerned the AFR's might just be hype due to some other recent posts he has read.

So I ask all of you....if a poll was taken considering the size of this shortblock how many people you think might casually dismiss the 195 AFR as "too small" and to go with the larger ported stock castings? If my time here has shown me anything my guess is that over 50% of the poll would be pushing John Doe to use the larger ported stocker....maybe I'm wrong and maybe (hopefully) this thread will be a wake up call for some of you because for the last few months I have been preaching that cylinder head efficiency is the key to making big power and the fact that pound for pound the new AFR Eliminator heads are the most efficient heads currently offered in a 23' bolt on situation and offer more airflow and more power than any other heads in their respective "cc" class. Most importantly, especially in regards to this particular exercise, that a ported stock head simply can't compete.

Why you ask?.....because your already starting with a compromised port shape that must be made alot bigger (and less efficient) to flow what a much smaller clean sheet of paper approach can accomplish if enough time is invested in the design (and we have invested an insane amount to bring you this new line up of castings).

Purely looking at peak flow numbers is not the answer folks.....sure you can get a ported stocker over or close to the benchmark 300 CFM figure but you must evaluate the entire flow curve (ALL the numbers from the crack of the valve to full lift) and also take into account how large the port shapes and cross section we are comparing, because a smaller port that flows the same will not only make a bunch more low and midrange power, it will also make more peak power as well (alot of people dont understand that). This is due to to the more efficient port's higher airspeed which will better pack the combustion chamber/cylinder before being lit off and also greatly reduce reversion which is a big negative trait when discussing aftermarket cams that have a fair amount of overlap. Part throttle between the two will be night and day btw....a point I have also beaten to death on this board over the last few months and that is a key feature when considering which cylinder head is the right choice for you....especially if the application is a street/strip car where the majority of the time driving it will be part throttle on the street.

Enough background and hypothetical situations....let's get to the meat and potato's of this thread.

The players....

Goliath.....a ported LT4 Stg III casting with aftermarket 2.08/1.6 valves and what is suppose to be a 220 ish cc port that "flows over 300 CFM" (which it does btw). Just gazing down the huge intake port had me intimidated for a moment but this isn't my first rodeo and I have seen big heads disappoint on the flowbench (and the dyno) before....especially big heads that were carved in stock OEM castings.

David.....a 195 Comp ported AFR Eliminator casting that pound for pound represents arguably the most efficient medium sized 23' casting on the planet that achieves 300 CFM with only an actual pour volume of 196 cc's, but most importantly reaches this milestone number for a 23' SBC head at a very usable .600 lift point and is flirting with 300 CFM as early as .550 lift! (that's an extremely powerful statement guys....and represents a huge accomplishment you would have to be cylinder head savvy to appreciate). While to the untrained eye this port may like small in the company we are comparing here, looks can be deceiving because one of the other points I have been trying to hammer home is that SHAPE is far more important than size.

The moment of truth.....how do these two heads compare on the flowbench and how does the comparison look when examining the entire curve. Before we go there however we need to see how big Goliath really is and how small David is in comparison.

As I mentioned earlier, just peaking down Goliath's huge intake port opening and looking at the critical cross section in the bowl where the air is forced to negotiate close to a 90' turn, I knew this Stg III stock head was BIG....my guess was 230 cc's but even that turned out to be conservative. The actual pour volume of this port was 241 cc's!.....Yikes that's a big port and I was so surprised at that figure I cleaned it up and poured it again (got 241.2 cc's that time). The exhaust was also noticeably big (just eyeballing it) ultimately coming in at a very generous 83.5 cc's (also very big for an SBC exhaust port). In comparison David's exhaust port (the AFR 195) is only 75 cc's.....some 10% smaller and in this comparison has the obvious huge handicap on the intake side only pouring an actual 196 cc's.....a whopping 45 cc's smaller than Goliath. Guys....that's a ridiculous disparity and while I should probably be comparing Goliath to one of our larger 210 or 227 cc Eliminators to keep things closer to being fair, I am comparing it to our smaller 195 program to make a point and I hope a glaring one at that.

Here are the numbers....I am going to use some actual flow figures from a few 195 Comp's I have had the opportunity to check lately and in fact will be averaging their numbers to make it even fairer (not picking the best number at each liftpoint).

Intake (with radiused entry)

Lift.....Goliath...David...Net CFM

.200.....138......154......+16

.300.....193......209......+16

.400.....244......257......+13

.500.....278......287......+9

.550.....286......298......+12

.600.....294......304......+10

.650.....300......300......Same

.700.....305......N/A

.750.....308......N/A

.800.....310......N/A

Guys, while anything over .600 lift is really meaningless for most of you reading this, I included the numbers to mainly show you that of course the huge port kept carrying and by exactly how much. Even if you were to run a .750 lift solid roller (that after lash and some defection in your pushrods and valvetrain would likely net you closer to .700), this head would never catch up even if we were discussing two heads that were similar in volume. The huge losses it sees at the lower and middle part of the curve would never be made up with a few more CFM past .650 lift....not enough time would be spent there. Not to mention if I really knew this customer was using a solid roller with .750 gross lift, I would of course had suggested our 227 heads on an engine that large (which flow over 320 CFM at .650 and almost clear 300 CFM as early as .500 lift!)

On to the exhaust side....

Exhaust (flow tested with a 1.75 pipe)

Lift.....Goliath...David...Net CFM

.200......112......130....+18

.300......153......170....+17

.400......179......206....+27

.500......199......229....+30

.600......214......237....+23

.700......225......242....+17

A huge disparity in flow across the entire curve in spite of the fact the AFR exhaust port is 10% smaller.....think about how much stronger a draw the exhaust port has on the intake in that scenario (aiding to help fill the cylinder on the next intake stroke)....not to mention how much more power could be made at higher RPM when there is soooo little time to evacuate the cylinder and make room for the next intake charge.

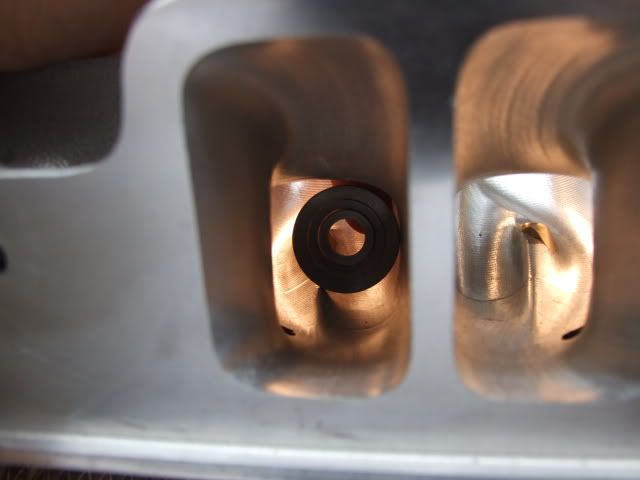

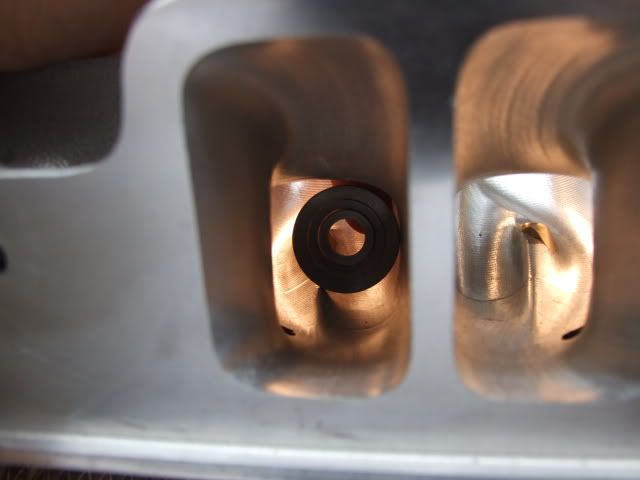

Lastly.....for the guys that are more visual, I have also decided to post some pictures of our little comparison here from the actual heads we have discussed in this thread. While nothing is as good as standing right in front of them, I think its pretty obvious to see the size disparity and to better help out I placed a titanium retainer in each port for some "scale" to better convey the difference in cross section.

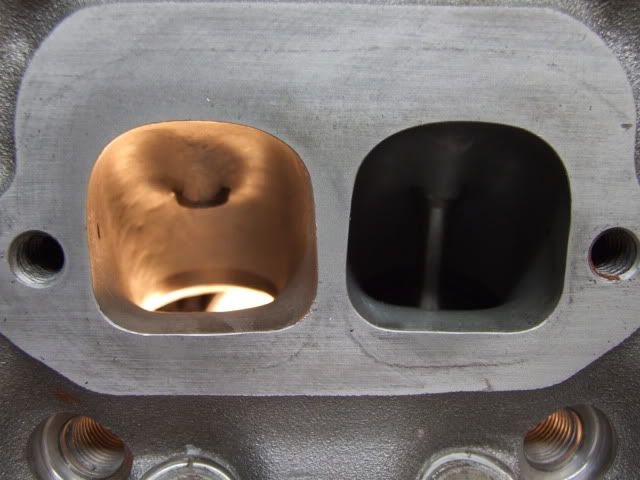

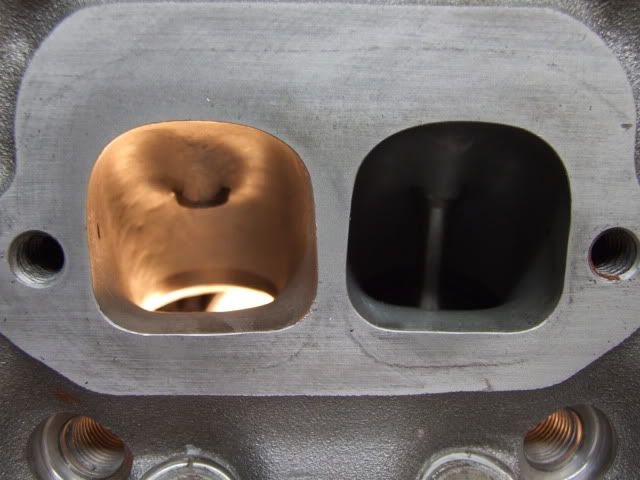

And here is a comparison shot of the exhaust ports.....

So now I ask you.....given John Doe's hypothetical 410 CID stroker engine with a hydraulic roller cam that lifts the valve to say .600 lift with a 1.6 rocker arm.....which head do you think will perform the best?? Do you choose a head based on how large the runner is (conventional "wisdom") and when building stroker engines subscribe to bigger is always better? (answer....NO).

Seriously, the power delivery between these two proposed combinations would be retarded with David slaying Goliath as soon as they rang the bell. The part throttle and low RPM torque and power curve would be even more ridiculous than comparing peak data with the AFR combo feeling like a bigblock in comparison to the sluggish response the larger head would provide down low.

Now if this customer was more aggressive in nature and was more concerned with big peak numbers than explosive part throttle response would I recommend a 210 AFR Eliminator instead?.....Actually yes I would and of course had I posted our 210 Eliminator numbers the difference between the two heads would have looked even greater comparing flow data while the AFR's would still have been 30 cc's smaller than Goliath (still a huge disparity in cross sectional area and volume) so they would have still offered the end user a big power advantage while still providing gobs of low/midrange torque and alot of snappy throttle response as well (slightly less than the 195's though).

That's about it for now....its 8 AM in the morning and I couldn't sleep well last night and started typing this at 6AM. I'm hoping more than just a few of you benefited from the time I have spent and hopefully this little exercise will further aid your understanding in the "WHY" our product should be given strong consideration....not just because it appears we have a handful of "cheerleaders". We have the cheerleaders because our product works so well....dont let comformity discourage you from getting the most efficient 23' SBC heads on the planet right now....sometimes its OK to be conforming and join the crowd....they just might be on to something

Cheers,

Tony Mamo

AFR R&D / Product Design Mgr.

(661)257-8124 Ext. 109

But I'm probably already getting ahead of myself so let me back up and lay out a situation that's all too common on this board as well as a misconception I have been trying to address since I started spending more time here....

John Doe decides he wants to build more power and is going to spring for a big bucks stroker motor....he decides to build a 410 CID hydraulic roller small block (hypothetical situation) and is undecided whether to use a ported "Stg III" LT4 head with new aftermarket larger valves and all the trimmings (done by a well known porting shop alot of his piers recommend) that's claimed to be 220 cc's or so and flow over 300 CFM (Goliath for those who haven't figured it out yet....LOL)

OR, go with the smaller AFR 195 comp ported head that Tony Mamo and perhaps a few others have recommended (our smaller "David") but he's concerned the AFR's might just be hype due to some other recent posts he has read.

So I ask all of you....if a poll was taken considering the size of this shortblock how many people you think might casually dismiss the 195 AFR as "too small" and to go with the larger ported stock castings? If my time here has shown me anything my guess is that over 50% of the poll would be pushing John Doe to use the larger ported stocker....maybe I'm wrong and maybe (hopefully) this thread will be a wake up call for some of you because for the last few months I have been preaching that cylinder head efficiency is the key to making big power and the fact that pound for pound the new AFR Eliminator heads are the most efficient heads currently offered in a 23' bolt on situation and offer more airflow and more power than any other heads in their respective "cc" class. Most importantly, especially in regards to this particular exercise, that a ported stock head simply can't compete.

Why you ask?.....because your already starting with a compromised port shape that must be made alot bigger (and less efficient) to flow what a much smaller clean sheet of paper approach can accomplish if enough time is invested in the design (and we have invested an insane amount to bring you this new line up of castings).

Purely looking at peak flow numbers is not the answer folks.....sure you can get a ported stocker over or close to the benchmark 300 CFM figure but you must evaluate the entire flow curve (ALL the numbers from the crack of the valve to full lift) and also take into account how large the port shapes and cross section we are comparing, because a smaller port that flows the same will not only make a bunch more low and midrange power, it will also make more peak power as well (alot of people dont understand that). This is due to to the more efficient port's higher airspeed which will better pack the combustion chamber/cylinder before being lit off and also greatly reduce reversion which is a big negative trait when discussing aftermarket cams that have a fair amount of overlap. Part throttle between the two will be night and day btw....a point I have also beaten to death on this board over the last few months and that is a key feature when considering which cylinder head is the right choice for you....especially if the application is a street/strip car where the majority of the time driving it will be part throttle on the street.

Enough background and hypothetical situations....let's get to the meat and potato's of this thread.

The players....

Goliath.....a ported LT4 Stg III casting with aftermarket 2.08/1.6 valves and what is suppose to be a 220 ish cc port that "flows over 300 CFM" (which it does btw). Just gazing down the huge intake port had me intimidated for a moment but this isn't my first rodeo and I have seen big heads disappoint on the flowbench (and the dyno) before....especially big heads that were carved in stock OEM castings.

David.....a 195 Comp ported AFR Eliminator casting that pound for pound represents arguably the most efficient medium sized 23' casting on the planet that achieves 300 CFM with only an actual pour volume of 196 cc's, but most importantly reaches this milestone number for a 23' SBC head at a very usable .600 lift point and is flirting with 300 CFM as early as .550 lift! (that's an extremely powerful statement guys....and represents a huge accomplishment you would have to be cylinder head savvy to appreciate). While to the untrained eye this port may like small in the company we are comparing here, looks can be deceiving because one of the other points I have been trying to hammer home is that SHAPE is far more important than size.

The moment of truth.....how do these two heads compare on the flowbench and how does the comparison look when examining the entire curve. Before we go there however we need to see how big Goliath really is and how small David is in comparison.

As I mentioned earlier, just peaking down Goliath's huge intake port opening and looking at the critical cross section in the bowl where the air is forced to negotiate close to a 90' turn, I knew this Stg III stock head was BIG....my guess was 230 cc's but even that turned out to be conservative. The actual pour volume of this port was 241 cc's!.....Yikes that's a big port and I was so surprised at that figure I cleaned it up and poured it again (got 241.2 cc's that time). The exhaust was also noticeably big (just eyeballing it) ultimately coming in at a very generous 83.5 cc's (also very big for an SBC exhaust port). In comparison David's exhaust port (the AFR 195) is only 75 cc's.....some 10% smaller and in this comparison has the obvious huge handicap on the intake side only pouring an actual 196 cc's.....a whopping 45 cc's smaller than Goliath. Guys....that's a ridiculous disparity and while I should probably be comparing Goliath to one of our larger 210 or 227 cc Eliminators to keep things closer to being fair, I am comparing it to our smaller 195 program to make a point and I hope a glaring one at that.

Here are the numbers....I am going to use some actual flow figures from a few 195 Comp's I have had the opportunity to check lately and in fact will be averaging their numbers to make it even fairer (not picking the best number at each liftpoint).

Intake (with radiused entry)

Lift.....Goliath...David...Net CFM

.200.....138......154......+16

.300.....193......209......+16

.400.....244......257......+13

.500.....278......287......+9

.550.....286......298......+12

.600.....294......304......+10

.650.....300......300......Same

.700.....305......N/A

.750.....308......N/A

.800.....310......N/A

Guys, while anything over .600 lift is really meaningless for most of you reading this, I included the numbers to mainly show you that of course the huge port kept carrying and by exactly how much. Even if you were to run a .750 lift solid roller (that after lash and some defection in your pushrods and valvetrain would likely net you closer to .700), this head would never catch up even if we were discussing two heads that were similar in volume. The huge losses it sees at the lower and middle part of the curve would never be made up with a few more CFM past .650 lift....not enough time would be spent there. Not to mention if I really knew this customer was using a solid roller with .750 gross lift, I would of course had suggested our 227 heads on an engine that large (which flow over 320 CFM at .650 and almost clear 300 CFM as early as .500 lift!)

On to the exhaust side....

Exhaust (flow tested with a 1.75 pipe)

Lift.....Goliath...David...Net CFM

.200......112......130....+18

.300......153......170....+17

.400......179......206....+27

.500......199......229....+30

.600......214......237....+23

.700......225......242....+17

A huge disparity in flow across the entire curve in spite of the fact the AFR exhaust port is 10% smaller.....think about how much stronger a draw the exhaust port has on the intake in that scenario (aiding to help fill the cylinder on the next intake stroke)....not to mention how much more power could be made at higher RPM when there is soooo little time to evacuate the cylinder and make room for the next intake charge.

Lastly.....for the guys that are more visual, I have also decided to post some pictures of our little comparison here from the actual heads we have discussed in this thread. While nothing is as good as standing right in front of them, I think its pretty obvious to see the size disparity and to better help out I placed a titanium retainer in each port for some "scale" to better convey the difference in cross section.

And here is a comparison shot of the exhaust ports.....

So now I ask you.....given John Doe's hypothetical 410 CID stroker engine with a hydraulic roller cam that lifts the valve to say .600 lift with a 1.6 rocker arm.....which head do you think will perform the best?? Do you choose a head based on how large the runner is (conventional "wisdom") and when building stroker engines subscribe to bigger is always better? (answer....NO).

Seriously, the power delivery between these two proposed combinations would be retarded with David slaying Goliath as soon as they rang the bell. The part throttle and low RPM torque and power curve would be even more ridiculous than comparing peak data with the AFR combo feeling like a bigblock in comparison to the sluggish response the larger head would provide down low.

Now if this customer was more aggressive in nature and was more concerned with big peak numbers than explosive part throttle response would I recommend a 210 AFR Eliminator instead?.....Actually yes I would and of course had I posted our 210 Eliminator numbers the difference between the two heads would have looked even greater comparing flow data while the AFR's would still have been 30 cc's smaller than Goliath (still a huge disparity in cross sectional area and volume) so they would have still offered the end user a big power advantage while still providing gobs of low/midrange torque and alot of snappy throttle response as well (slightly less than the 195's though).

That's about it for now....its 8 AM in the morning and I couldn't sleep well last night and started typing this at 6AM. I'm hoping more than just a few of you benefited from the time I have spent and hopefully this little exercise will further aid your understanding in the "WHY" our product should be given strong consideration....not just because it appears we have a handful of "cheerleaders". We have the cheerleaders because our product works so well....dont let comformity discourage you from getting the most efficient 23' SBC heads on the planet right now....sometimes its OK to be conforming and join the crowd....they just might be on to something

Cheers,

Tony Mamo

AFR R&D / Product Design Mgr.

(661)257-8124 Ext. 109

Last edited by Tony Mamo @ AFR; 10-18-2008 at 11:46 AM.

#3

Safety Car

Thanks for sharing.

I think to complete your test, the next step needs to be taken, which is running both cylinder heads on that 410 motor on the dyno and/or track..... this will tell us what we need to know.

As it is contended on this forum by several, "Airflow does not matter"..... thus your post is irrelevant to a few others here.

Which leads me to my question to you.... do you believe cylinder head airflow is important ?

I think to complete your test, the next step needs to be taken, which is running both cylinder heads on that 410 motor on the dyno and/or track..... this will tell us what we need to know.

As it is contended on this forum by several, "Airflow does not matter"..... thus your post is irrelevant to a few others here.

Which leads me to my question to you.... do you believe cylinder head airflow is important ?

#5

Melting Slicks

Member Since: Jun 2007

Location: Poocakes loves teh sausage! N.E. Ohio

Posts: 3,389

Likes: 0

Received 0 Likes

on

0 Posts

Great post  I am glad we have knowledgeable people like you on this forum. Sometimes when I read these threads my head hurts(Pun intended)

I am glad we have knowledgeable people like you on this forum. Sometimes when I read these threads my head hurts(Pun intended) Because of the way most of these threads go(south) I would never post a question or debate in them. I would prefer to PM someone or call them as I have in the past. Thanks again and someday when I can save the money I will be calling you.

Because of the way most of these threads go(south) I would never post a question or debate in them. I would prefer to PM someone or call them as I have in the past. Thanks again and someday when I can save the money I will be calling you.

Regards, Larry

I am glad we have knowledgeable people like you on this forum. Sometimes when I read these threads my head hurts(Pun intended)

I am glad we have knowledgeable people like you on this forum. Sometimes when I read these threads my head hurts(Pun intended) Because of the way most of these threads go(south) I would never post a question or debate in them. I would prefer to PM someone or call them as I have in the past. Thanks again and someday when I can save the money I will be calling you.

Because of the way most of these threads go(south) I would never post a question or debate in them. I would prefer to PM someone or call them as I have in the past. Thanks again and someday when I can save the money I will be calling you.Regards, Larry

#7

Tony,

It is unfortunate that this topic keeps coming back from the dead. I like to think that I am very objective person and like to keep an open mind when it comes to performance; so I am not here to bash you or anybody else. I believe that you get what you pay for and if anything else; happy to hear your responses.

Not that I am saying everything you say is gospel but for the fact that you are a vendor and part of this forum. I may be wrong; but I don't see too many other manufacturers in here participating in this conversation.

The fact is; too many brain cells have been killed on this subject already and I usually refrain from these type of posts.

Here is my 0.02 cents:

I am a completely satisfied customer and a repeat customer at that!

I don't regret one bit for the price that I paid for my cylinder heads nor do I stay awake at night thinking that I left horsepower on the table. That is one of the reasons why I went with AFR. Quality of the product and Customer satisfaction.

Could I have gotten the same results with a lesser expensive head or could I have gotten more with a total custom job; maybe, but I don't need to worry about that versus going with a lesser expensive head and wonder "gee" did I get what I paid for or did that shop really know what they were doing?

Either way; if you really read into the posts, it's not "gee" AFR hasn't lived up to their claims, or you will get crappy performance, or the company doesn't stand behind their products.

It's "gee"; AFR is more expensive than the others; are they worth it?

My answer is "yes" but everyone will have their 0.02 cents.....and that was mine...

don't let this get to you and hope you stay on the board....

glenn

It is unfortunate that this topic keeps coming back from the dead. I like to think that I am very objective person and like to keep an open mind when it comes to performance; so I am not here to bash you or anybody else. I believe that you get what you pay for and if anything else; happy to hear your responses.

Not that I am saying everything you say is gospel but for the fact that you are a vendor and part of this forum. I may be wrong; but I don't see too many other manufacturers in here participating in this conversation.

The fact is; too many brain cells have been killed on this subject already and I usually refrain from these type of posts.

Here is my 0.02 cents:

I am a completely satisfied customer and a repeat customer at that!

I don't regret one bit for the price that I paid for my cylinder heads nor do I stay awake at night thinking that I left horsepower on the table. That is one of the reasons why I went with AFR. Quality of the product and Customer satisfaction.

Could I have gotten the same results with a lesser expensive head or could I have gotten more with a total custom job; maybe, but I don't need to worry about that versus going with a lesser expensive head and wonder "gee" did I get what I paid for or did that shop really know what they were doing?

Either way; if you really read into the posts, it's not "gee" AFR hasn't lived up to their claims, or you will get crappy performance, or the company doesn't stand behind their products.

It's "gee"; AFR is more expensive than the others; are they worth it?

My answer is "yes" but everyone will have their 0.02 cents.....and that was mine...

don't let this get to you and hope you stay on the board....

glenn

Last edited by GM_96LT4; 10-18-2008 at 02:10 PM.

#8

Drifting

Thanks for the write up Tony, but when you stated that the heads were Stock Re-worked castings it was very evident that it was going to be an unfair fight from the get-go. Still, it brings to light that if a person, such as I was during construction of my build, were considering the stock casting re-work approach. My personal goal of MAXIMIZING my bang for the buck when it came to performance, made the choice to go with the clean sheet castings clear.

I also agree with Glenn, you are one of the few vendors that actively support OUR cause and provide insight on your current offerings. If there were a new need, I feel confident that you are poised to support that need faster than anyone else in the market. NOW, There's always the Jeg's and Summit guys out there racing everyday, but that's not the majority in THIS crowd. AND there is ALWAYS someone out here that just goes in a different direction and reputes it all, because they are made that way, so let's NOT focus on them!.....LOL

Either way, I am extremely happy with my Comp Ported 195's and thanks again for all of your help! I truly made the best decision for MY build!

R/Noland Smith, Jr.

STSC(SS) USN Ret.

I also agree with Glenn, you are one of the few vendors that actively support OUR cause and provide insight on your current offerings. If there were a new need, I feel confident that you are poised to support that need faster than anyone else in the market. NOW, There's always the Jeg's and Summit guys out there racing everyday, but that's not the majority in THIS crowd. AND there is ALWAYS someone out here that just goes in a different direction and reputes it all, because they are made that way, so let's NOT focus on them!.....LOL

Either way, I am extremely happy with my Comp Ported 195's and thanks again for all of your help! I truly made the best decision for MY build!

R/Noland Smith, Jr.

STSC(SS) USN Ret.

#9

Drifting

Member Since: Mar 2008

Location: Wichita KS

Posts: 1,756

Likes: 0

Received 0 Likes

on

0 Posts

I think it's epidemic these days on forums that people come on here with little or no knowledge and hack away at the top people in an industry. This borders on defamation of character. I don't see the comedy in these opposing posts that are supposedly meant to spur independent thinking. What I see here is Tony put on the defensive because a number of members being taken in by a speculative member out to cause hate & discontent with nothing to loose but an argument. AFR cylinder heads are out there in the real World performing in all levels of automotive racing. If a person wants other facts besides advertised numbers. Simply walk away from your PC and visit your local sanctioned racing event. Talk with some real people face-to-face. See whom is going fast. Get the facts on their build or facts behind whom built the engine, machine work etc. Perhaps even visit your local top engine builders. We have Saum Engineering here along with Patterson Racing and Darryl Palmer. All these guys are friendly and enjoy speaking with customers.

We all know pistons go up & down. It's how an engine breathes that produces power. Some people are just learning this secret. But going about it in a totally wrong manner. If you want to learn about a subject. Don't log onto a public forum and throw a bunch of BS out there and see what comes back. This isn't how parents teach their young. It's not how teachers teach in school. Why would you expect forum members to react any different then your parents or teachers would react to you coming onto a forum and posting fiction like it's real just to see what kind of shock you get back? Making a fool out of yourself can be achieved by dropping your pants in the Mall. Posting on a forum is the lazy way....

We all know pistons go up & down. It's how an engine breathes that produces power. Some people are just learning this secret. But going about it in a totally wrong manner. If you want to learn about a subject. Don't log onto a public forum and throw a bunch of BS out there and see what comes back. This isn't how parents teach their young. It's not how teachers teach in school. Why would you expect forum members to react any different then your parents or teachers would react to you coming onto a forum and posting fiction like it's real just to see what kind of shock you get back? Making a fool out of yourself can be achieved by dropping your pants in the Mall. Posting on a forum is the lazy way....

#10

Le Mans Master

Thanks for taking your time to educate us. Since its been yrs. ago on my last build I don't get involved with these type of discussions often, because things have changed so much. But the one thing I can attest to is bigger is not always better. I put alot of money into a sbc 332 (327, 30 over) the heads I used were bought from the dealership, chevy called them "strickly off the road heads) can't remember all the details, and the cam wasn't wild, but that little David slew alot of Goliaths including some pumped up BBs. I've always felt that if you had max. low end thru mid range power that peak power would loose in the short end. Of course I'm talking about what we used to get away with and the strip.

#11

Melting Slicks

I dunno, what's the only negative thing you hear about AFR heads? They're expensive. I've never heard of anyone buying AFR heads and regretting it later.

As far as the 196 AFR eliminators VS the LT4 heads, regardless of flow numbers I think the AFR heads will make the car faster at the track. I'm sure we'll see as time goes on.

I do agree that a flow bench is a pretty flawed way to measure a head, but at the moment it's the best we have (other than real world, on engine testing.).

As far as the 196 AFR eliminators VS the LT4 heads, regardless of flow numbers I think the AFR heads will make the car faster at the track. I'm sure we'll see as time goes on.

I do agree that a flow bench is a pretty flawed way to measure a head, but at the moment it's the best we have (other than real world, on engine testing.).

#12

Le Mans Master

I had sort of assumed there would be actual tests at the end. So I was sort of surprised to read the post and not see them.

I had sort of assumed there would be actual tests at the end. So I was sort of surprised to read the post and not see them.Reading it, I thought your contention you were trying to prove was that more flow from less volume was better. But in the end you say one head is better than the other because it has more flow from less volume.

Anyway, not that you have to prove anything to me, just that that isn't what I was expecting.

#13

Team Owner

Awesome read Tony!!!!

Anybody want to trade my ported Brodix Track 1's for a pair of 195's?

Anybody want to trade my ported Brodix Track 1's for a pair of 195's?

#14

Le Mans Master

This post really hits home with me. I have a set of "Stage IV" ported LT4 heads from one of the best porters in the business (Gary Grimes). My heads probably have around 230cc intake ports and flow right about what the AFRs do up at .500+ lift but I can almost guarantee that the AFRs flow better in the low-lift area. I wish I had the flow sheet but I lost it years ago.

Just for reference here's a pic of my heads next to stock LT4 heads;

If I ever get the chance to take the heads off I'd like to get them flowed, but this is my daily driver right now so I just don't have the time. However, the car performs great, and the heads do what I want them to, make power high in the rev-range. Here's the dyno;

I wonder what a set of AFR 210's might be able to do for me though...

If the Eliminator series head was available when I was putting this engine together I would have went that route in a heartbeat. My heads cost me about $3500 in machining a parts alone, I already had the heads themselves!!

Just for reference here's a pic of my heads next to stock LT4 heads;

If I ever get the chance to take the heads off I'd like to get them flowed, but this is my daily driver right now so I just don't have the time. However, the car performs great, and the heads do what I want them to, make power high in the rev-range. Here's the dyno;

I wonder what a set of AFR 210's might be able to do for me though...

If the Eliminator series head was available when I was putting this engine together I would have went that route in a heartbeat. My heads cost me about $3500 in machining a parts alone, I already had the heads themselves!!

#16

Former Vendor

Thread Starter

How many head swaps have you done bolting on a higher flowing head and made less power.....because I have done more than I can possibly remember and count with the results being the exact opposite of the crap your trying to shovel down every one's throat. Call your engineers and PHD's and masters of fluid dynamics and have them bring us REAL WORLD EXAMPLES to prove your point because obviously you have no real world experience to draw from yourself (no dyno yet?) but that doesn't stop you from being the loudest on this board jumping up and down on your soap box about stuff your not even remotely experienced enough to comment on..

A flowbench is a very instrumental tool in the development and design of a cylinder head (and a great way to compare cylinder heads as well)....it simulates EXACTLY what is going on in an internal combustion engine....air moving thru the ports due to a pressure differential (vacuum on the intake side....pressure on the exhaust). Sure there are other design facets that come into play such as the size of the runner and the shape of the entire curve which I have also been trying to drive home, but a flowbench creates a pressure differential no different than an engine....the only difference is it provides you with the ability to actually quantify how much air a port is capable of moving.

Let me break it down for you JSUP.....Engine 101

An engine is an air pump and the more air (and fuel) it can process, the more power it will make. It's a very simple device actually (when you break it down to the basics) that has been around for 100 years. Take any combination you like and with no other changes swap to a more efficient higher DRY FLOWING head and as long as that head flows more air at liftpoints the cam in that particular combination can take advantage of, you will make more power....peroid....END OF STORY

If that head flows more air and has a smaller runner (as in the case I laid out in my first post), due to an increase in AIRSPEED and cylinder packing ability you will see even more power from the swap with a large increase in low and midrange power output as well as a jump in the peak numbers as well...double bonus. The kicker is part throttle however, and that will be especially enhanced with the high flow/high velocity efficient design and the fun factor in a street car goes up dramatically.

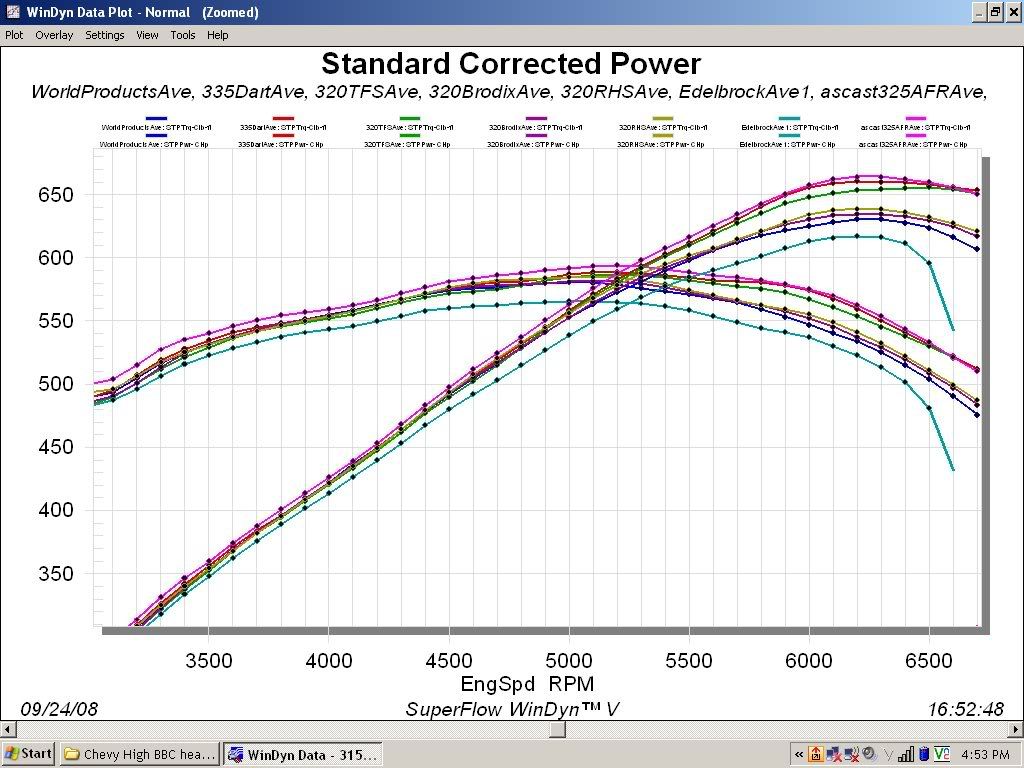

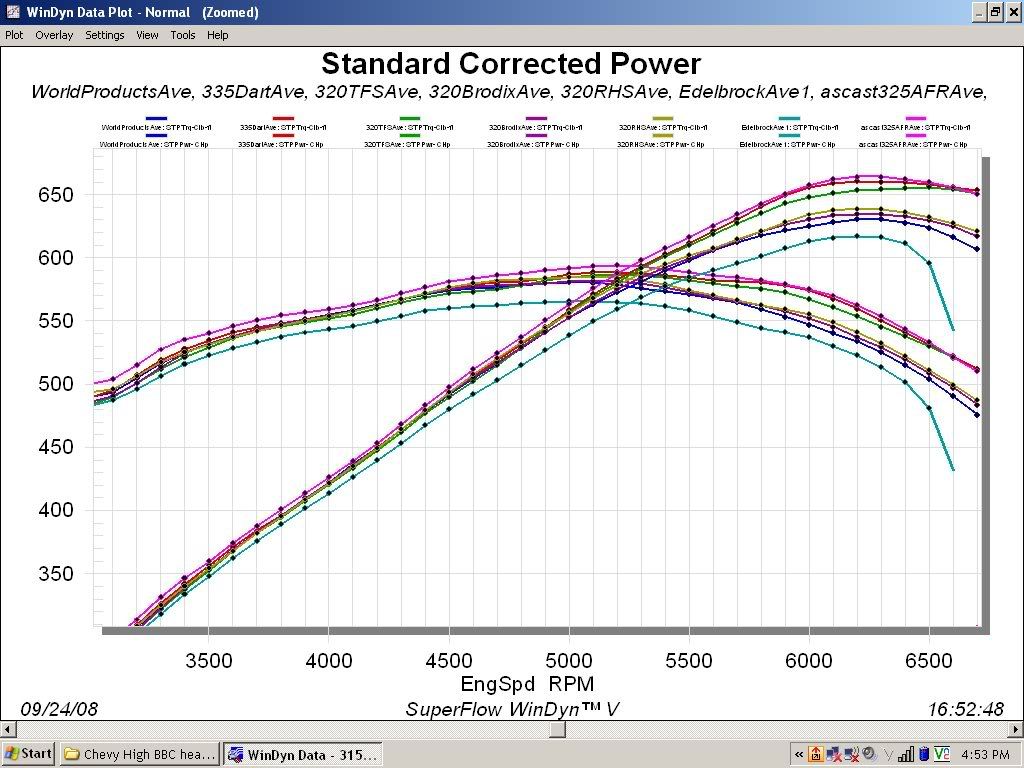

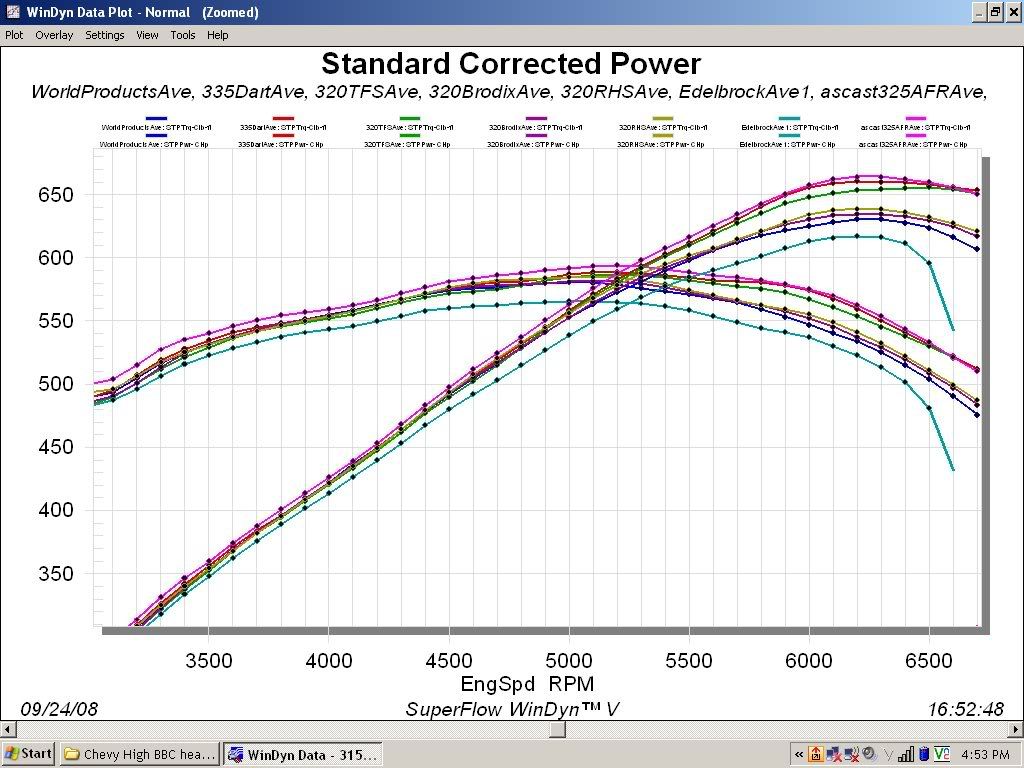

Here is a test that comes to mind that proves out my theory that a head with more dry flow will generate more power. It was done independently by Chevy High Performance Magazine (CHP) about six months ago....it happens to be a bigblock comparison but the theory and everything we are discussing still holds true.

The test starts with a bonestock GM 502 low compression crate engine (8.5 to one) and then CHP proceed to swap in a medium sized solid roller cam, a Vic Jr single plane, and a 950 HP carb. After that they proceeded to swap nothing else but cylinder heads....and in fact they flow tested all of these heads and verified the combustion chambers were the same volume so no one had an advantage in compression ratio. An enormous amount of time and energy went into this test as gathering all these heads, flowtesting and cc'ing all of them, and then finally swapping and testing them all on the dyno took over three straight days by two of their staff.

Is it pure coincidence that if you basically looked at all the USABLE flow numbers (up to .650 or so in this test) that based on the DRY FLOW NUMBERS, (especially looking at the entire curves), that you could have picked the winner, the loser, and every one in between (now's the time to put your hands more tightly over your ears JSUP and close your eyes soon as well). An AFR "as cast" 320 cc BBC head was proud to be the top dog in this test even though it went up against a larger, much more expensive, fully CNC ported 335 Dart ($3600 for the Darts versus $2500 for the AFR's in this comparison). The thing was the larger fully ported Dart had an advantage in flow higher in the curve (+ .650 lift) where any gains seen there on the flowbench were not taken advantage of (these are critical things to consider when designing one's combination). And when you evaluate the usable curve, the AFR's had a smaller port that outflowed the larger DART at all the liftpoints that mattered in this test (note the AFR head with a pronounced increase in low RPM torque from the start of the dyno pull). I bring this particular example to light (AFR versus the DART), because purely looking at the peak numbers of all the head testing would not clearly show the winner here....you would have had to dig deeper.

Note the Edelbrock head which was by far the worst on a DRY FLOWBENCH, also had the most abysmal power curve making 50 less HP than the AFR.....that's a big difference when the only thing changed was a cylinder head and the compression, cam, displacement, and EVERYTHING else remained a constant.

Here is the graph showing all the curves from that head shoot-out test....

Alright....this post was suppose to be a quick one and as usual I got a bit long winded, but I think I bring some important things to consider here in addition to what I discussed previously as well as sharing real world examples of why dry flowbench numbers are still credible and extemely useful if analyzed properly, especially if your considering the size and cross sectional area of the parts being tested and taking the time to evaluate the entire usable curve (very important).

I leave the rest to you guys....hey would it be legal to temporarily ban JSUP from cylinder head threads until he at the very least got his car dyno'ed??

JSUP....word of advice, you need to get to the dyno to be taken more seriously. If you're going to continue your current course (and something tells me you are), actually checking your own combination would be helpful....Maybe you will be enlightened by the experience.

JSUP....word of advice, you need to get to the dyno to be taken more seriously. If you're going to continue your current course (and something tells me you are), actually checking your own combination would be helpful....Maybe you will be enlightened by the experience. Regards,

Tony

PS....Ron (Cuisinart), don't know how you manage to find some of the clips you post....Is there a special website you hit?!....LOL

Last edited by Tony Mamo @ AFR; 10-18-2008 at 07:34 PM.

#17

#18

Safety Car

This post really hits home with me. I have a set of "Stage IV" ported LT4 heads from one of the best porters in the business (Gary Grimes). My heads probably have around 230cc intake ports and flow right about what the AFRs do up at .500+ lift but I can almost guarantee that the AFRs flow better in the low-lift area. I wish I had the flow sheet but I lost it years ago.

Just for reference here's a pic of my heads next to stock LT4 heads;

If I ever get the chance to take the heads off I'd like to get them flowed, but this is my daily driver right now so I just don't have the time. However, the car performs great, and the heads do what I want them to, make power high in the rev-range. Here's the dyno;

I wonder what a set of AFR 210's might be able to do for me though...

If the Eliminator series head was available when I was putting this engine together I would have went that route in a heartbeat. My heads cost me about $3500 in machining a parts alone, I already had the heads themselves!!

Just for reference here's a pic of my heads next to stock LT4 heads;

If I ever get the chance to take the heads off I'd like to get them flowed, but this is my daily driver right now so I just don't have the time. However, the car performs great, and the heads do what I want them to, make power high in the rev-range. Here's the dyno;

I wonder what a set of AFR 210's might be able to do for me though...

If the Eliminator series head was available when I was putting this engine together I would have went that route in a heartbeat. My heads cost me about $3500 in machining a parts alone, I already had the heads themselves!!

Can I ask, what cam are you running ?

#19

Safety Car

Are you seriously trying to argue this....or are you the type that is so stubborn they will argue a point to the death when everything tells them inside they are wrong and your simply not man enough to admit it. You want to talk about getting sucked in by marketing....DART should post your picture on their website. You are literally blinded by your childish needs to be right and no matter how much sense and proof any of us bring to the table you have your hands over your ears going LAAHH LAAAAH LAAAH....but I do appreciate the entertainment value and the opportunity you enable me in helping to perhaps enlighten others reading this that have an open mind.

How many head swaps have you done bolting on a higher flowing head and made less power.....because I have done more than I can possibly remember and count with the results being the exact opposite of the crap your trying to shovel down every one's throat. Call your engineers and PHD's and masters of fluid dynamics and have them bring us REAL WORLD EXAMPLES to prove your point because obviously you have no real world experience to draw from yourself (no dyno yet?) but that doesn't stop you from being the loudest on this board jumping up and down on your soap box about stuff your not even remotely experienced enough to comment on..

A flowbench is a very instrumental tool in the development and design of a cylinder head (and a great way to compare cylinder heads as well)....it simulates EXACTLY what is going on in an internal combustion engine....air moving thru the ports due to a pressure differential (vacuum on the intake side....pressure on the exhaust). Sure there are other design facets that come into play such as the size of the runner and the shape of the entire curve which I have also been trying to drive home, but a flowbench creates a pressure differential no different than an engine....the only difference is it provides you with the ability to actually quantify how much air a port is capable of moving.

Let me break it down for you JSUP.....Engine 101

An engine is an air pump and the more air (and fuel) it can process, the more power it will make. It's a very simple device actually (when you break it down to the basics) that has been around for 100 years. Take any combination you like and with no other changes swap to a more efficient higher DRY FLOWING head and as long as that head flows more air at liftpoints the cam in that particular combination can take advantage of, you will make more power....peroid....END OF STORY

If that head flows more air and has a smaller runner (as in the case I laid out in my first post), due to an increase in AIRSPEED and cylinder packing ability you will see even more power from the swap with a large increase in low and midrange power output as well as a jump in the peak numbers as well...double bonus. The kicker is part throttle however, and that will be especially enhanced with the high flow/high velocity efficient design and the fun factor in a street car goes up dramatically.

Here is a test that comes to mind that proves out my theory that a head with more dry flow will generate more power. It was done independently by Chevy High Performance Magazine (CHP) about six months ago....it happens to be a bigblock comparison but the theory and everything we are discussing still holds true.

The test starts with a bonestock GM 502 low compression crate engine (8.5 to one) and then CHP proceed to swap in a medium sized solid roller cam, a Vic Jr single plane, and a 950 HP carb. After that they proceeded to swap nothing else but cylinder heads....and in fact they flow tested all of these heads and verified the combustion chambers were the same volume so no one had an advantage in compression ratio. An enormous amount of time and energy went into this test as gathering all these heads, flowtesting and cc'ing all of them, and then finally swapping and testing them all on the dyno took over three straight days by two of their staff.

Is it pure coincidence that if you basically looked at all the USABLE flow numbers (up to .650 or so in this test) that based on the DRY FLOW NUMBERS, (especially looking at the entire curves), that you could have picked the winner, the loser, and every one in between (now's the time to put your hands more tightly over your ears JSUP and close your eyes soon as well). An AFR "as cast" 320 cc BBC head was proud to be the top dog in this test even though it went up against a larger, much more expensive, fully CNC ported 335 Dart ($3600 for the Darts versus $2500 for the AFR's in this comparison). The thing was the larger fully ported Dart had an advantage in flow higher in the curve (+ .650 lift) where any gains seen there on the flowbench were not taken advantage of (these are critical things to consider when designing one's combination). And when you evaluate the usable curve, the AFR's had a smaller port that outflowed the larger DART at all the liftpoints that mattered in this test (note the AFR head with a pronounced increase in low RPM torque from the start of the dyno pull). I bring this particular example to light (AFR versus the DART), because purely looking at the peak numbers of all the head testing would not clearly show the winner here....you would have had to dig deeper.

Note the Edelbrock head which was by far the worst on a DRY FLOWBENCH, also had the most abysmal power curve making 50 less HP than the AFR.....that's a big difference when the only thing changed was a cylinder head and the compression, cam, displacement, and EVERYTHING else remained a constant.

Here is the graph showing all the curves from that head shoot-out test....

Alright....this post was suppose to be a quick one and as usual I got a bit long winded, but I think I bring some important things to consider here in addition to what I discussed previously as well as sharing real world examples of why dry flowbench numbers are still credible and extemely useful if analyzed properly, especially if your considering the size and cross sectional area of the parts being tested and taking the time to evaluate the entire usable curve (very important).

I leave the rest to you guys....hey would it be legal to temporarily ban JSUP from cylinder head threads until he at the very least got his car dyno'ed?? JSUP....word of advice, you need to get to the dyno to be taken more seriously. If you're going to continue your current course (and something tells me you are), actually checking your own combination would be helpful....Maybe you will be enlightened by the experience.

JSUP....word of advice, you need to get to the dyno to be taken more seriously. If you're going to continue your current course (and something tells me you are), actually checking your own combination would be helpful....Maybe you will be enlightened by the experience.

Regards,

Tony

PS....Ron (Cuisinart), don't know how you manage to find some of the clips you post....Is there a special website you hit?!....LOL

How many head swaps have you done bolting on a higher flowing head and made less power.....because I have done more than I can possibly remember and count with the results being the exact opposite of the crap your trying to shovel down every one's throat. Call your engineers and PHD's and masters of fluid dynamics and have them bring us REAL WORLD EXAMPLES to prove your point because obviously you have no real world experience to draw from yourself (no dyno yet?) but that doesn't stop you from being the loudest on this board jumping up and down on your soap box about stuff your not even remotely experienced enough to comment on..

A flowbench is a very instrumental tool in the development and design of a cylinder head (and a great way to compare cylinder heads as well)....it simulates EXACTLY what is going on in an internal combustion engine....air moving thru the ports due to a pressure differential (vacuum on the intake side....pressure on the exhaust). Sure there are other design facets that come into play such as the size of the runner and the shape of the entire curve which I have also been trying to drive home, but a flowbench creates a pressure differential no different than an engine....the only difference is it provides you with the ability to actually quantify how much air a port is capable of moving.

Let me break it down for you JSUP.....Engine 101

An engine is an air pump and the more air (and fuel) it can process, the more power it will make. It's a very simple device actually (when you break it down to the basics) that has been around for 100 years. Take any combination you like and with no other changes swap to a more efficient higher DRY FLOWING head and as long as that head flows more air at liftpoints the cam in that particular combination can take advantage of, you will make more power....peroid....END OF STORY

If that head flows more air and has a smaller runner (as in the case I laid out in my first post), due to an increase in AIRSPEED and cylinder packing ability you will see even more power from the swap with a large increase in low and midrange power output as well as a jump in the peak numbers as well...double bonus. The kicker is part throttle however, and that will be especially enhanced with the high flow/high velocity efficient design and the fun factor in a street car goes up dramatically.

Here is a test that comes to mind that proves out my theory that a head with more dry flow will generate more power. It was done independently by Chevy High Performance Magazine (CHP) about six months ago....it happens to be a bigblock comparison but the theory and everything we are discussing still holds true.

The test starts with a bonestock GM 502 low compression crate engine (8.5 to one) and then CHP proceed to swap in a medium sized solid roller cam, a Vic Jr single plane, and a 950 HP carb. After that they proceeded to swap nothing else but cylinder heads....and in fact they flow tested all of these heads and verified the combustion chambers were the same volume so no one had an advantage in compression ratio. An enormous amount of time and energy went into this test as gathering all these heads, flowtesting and cc'ing all of them, and then finally swapping and testing them all on the dyno took over three straight days by two of their staff.

Is it pure coincidence that if you basically looked at all the USABLE flow numbers (up to .650 or so in this test) that based on the DRY FLOW NUMBERS, (especially looking at the entire curves), that you could have picked the winner, the loser, and every one in between (now's the time to put your hands more tightly over your ears JSUP and close your eyes soon as well). An AFR "as cast" 320 cc BBC head was proud to be the top dog in this test even though it went up against a larger, much more expensive, fully CNC ported 335 Dart ($3600 for the Darts versus $2500 for the AFR's in this comparison). The thing was the larger fully ported Dart had an advantage in flow higher in the curve (+ .650 lift) where any gains seen there on the flowbench were not taken advantage of (these are critical things to consider when designing one's combination). And when you evaluate the usable curve, the AFR's had a smaller port that outflowed the larger DART at all the liftpoints that mattered in this test (note the AFR head with a pronounced increase in low RPM torque from the start of the dyno pull). I bring this particular example to light (AFR versus the DART), because purely looking at the peak numbers of all the head testing would not clearly show the winner here....you would have had to dig deeper.

Note the Edelbrock head which was by far the worst on a DRY FLOWBENCH, also had the most abysmal power curve making 50 less HP than the AFR.....that's a big difference when the only thing changed was a cylinder head and the compression, cam, displacement, and EVERYTHING else remained a constant.

Here is the graph showing all the curves from that head shoot-out test....

Alright....this post was suppose to be a quick one and as usual I got a bit long winded, but I think I bring some important things to consider here in addition to what I discussed previously as well as sharing real world examples of why dry flowbench numbers are still credible and extemely useful if analyzed properly, especially if your considering the size and cross sectional area of the parts being tested and taking the time to evaluate the entire usable curve (very important).

I leave the rest to you guys....hey would it be legal to temporarily ban JSUP from cylinder head threads until he at the very least got his car dyno'ed??

JSUP....word of advice, you need to get to the dyno to be taken more seriously. If you're going to continue your current course (and something tells me you are), actually checking your own combination would be helpful....Maybe you will be enlightened by the experience.

JSUP....word of advice, you need to get to the dyno to be taken more seriously. If you're going to continue your current course (and something tells me you are), actually checking your own combination would be helpful....Maybe you will be enlightened by the experience. Regards,

Tony

PS....Ron (Cuisinart), don't know how you manage to find some of the clips you post....Is there a special website you hit?!....LOL

#20

Le Mans Master

Here are the specs;

242/252* duration @.050

.55x/.56x lift with 1.6 rockers

110 LSA