Help removing bolt for Crank Position Sensor - LT4

#1

Drifting

Thread Starter

Hi:

I bought a new o ring for the CPS. I can not get the bolt out that holds the CPS in place. A few questions for anyone who has done this:

1. Bolt size 8mm yes or no

2. Did you remove it from the top (sticking arm down passenger side next to power steering resevoir)?

or

3. Did you remove it with the car up on ramps from beneath the car?

4. If yes, did you have to remove crossmember?

5. Did you use an open end wrench or socket?

Any other tips greatly appreciated

trebor

I bought a new o ring for the CPS. I can not get the bolt out that holds the CPS in place. A few questions for anyone who has done this:

1. Bolt size 8mm yes or no

2. Did you remove it from the top (sticking arm down passenger side next to power steering resevoir)?

or

3. Did you remove it with the car up on ramps from beneath the car?

4. If yes, did you have to remove crossmember?

5. Did you use an open end wrench or socket?

Any other tips greatly appreciated

trebor

#2

Tech Contributor

The bolt is 8mm

You remove it from below

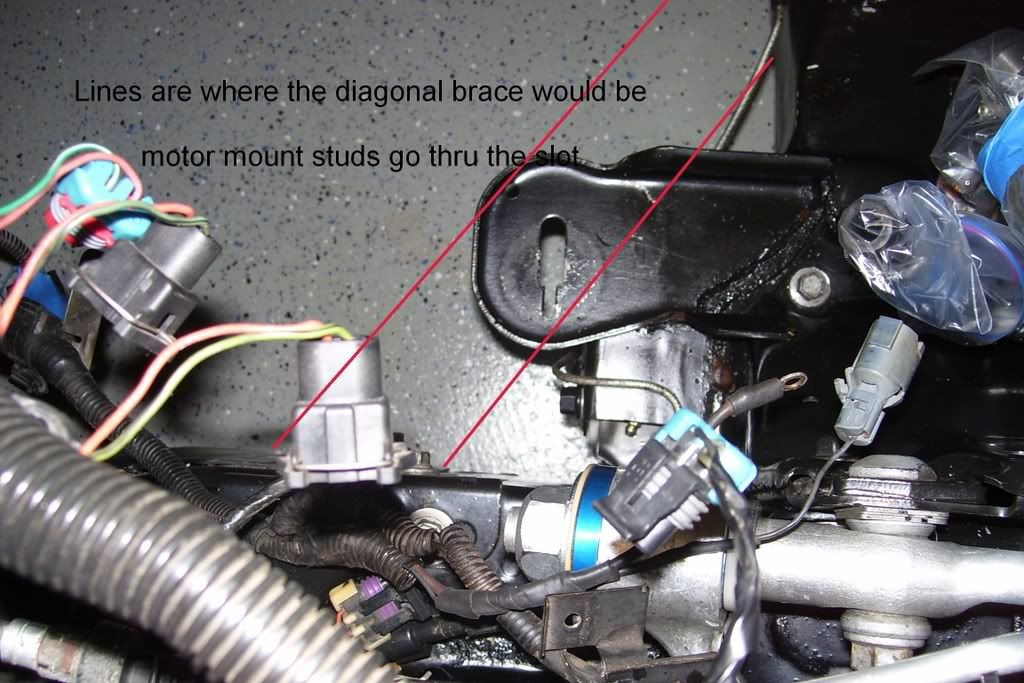

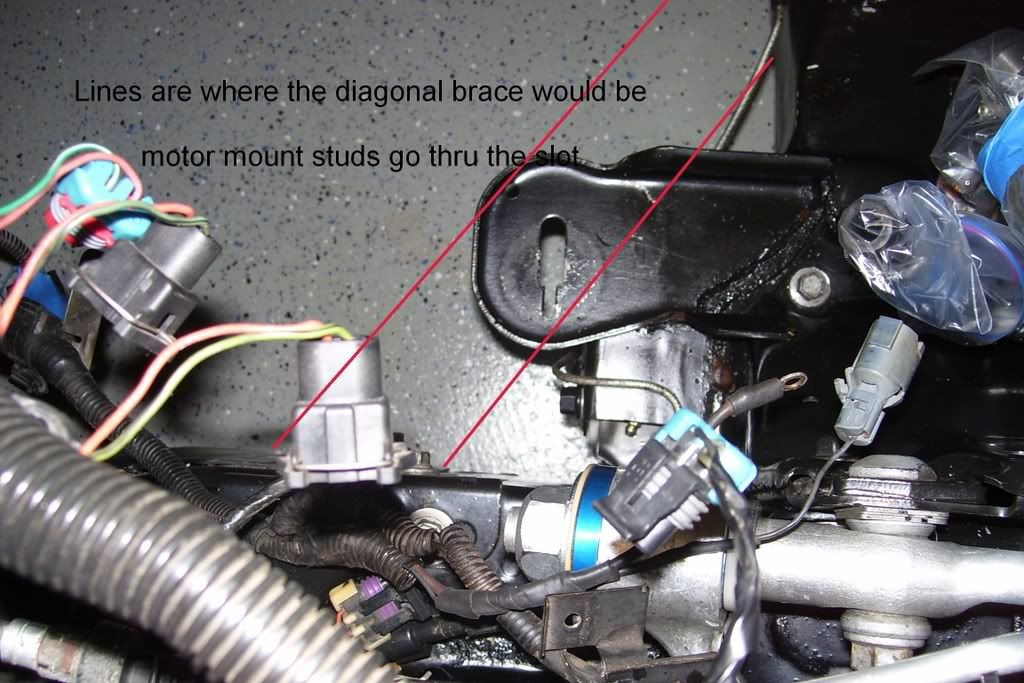

Remove the two (1/side) 18mm nuts that secure each motor mount stud to the diagonal cross brace.

Jack the engine up ~1"

You should now have enough room to remove the bolt using an open end wrench.

You remove it from below

Remove the two (1/side) 18mm nuts that secure each motor mount stud to the diagonal cross brace.

Jack the engine up ~1"

You should now have enough room to remove the bolt using an open end wrench.

#3

Melting Slicks

When you jack the engine, what do you use to "spread" the load, 2X4 or 4X8 piece of wood ?

Also, do you Jack at the oil pan or some other location. I want to replace my son's balancer/pully, and, on an LT4 it I cannot get the balancer/pully out without raising the engine somewhat. LT1's don't have this problem, as I think the balancer/pully is a bit smaller so it doesn't have the intereference problem with the front crossmember like the LT4....

Thanks !

MikeC4

#4

Tech Contributor

Jim,

When you jack the engine, what do you use to "spread" the load, 2X4 or 4X8 piece of wood ?

Also, do you Jack at the oil pan or some other location. I want to replace my son's balancer/pully, and, on an LT4 it I cannot get the balancer/pully out without raising the engine somewhat. LT1's don't have this problem, as I think the balancer/pully is a bit smaller so it doesn't have the intereference problem with the front crossmember like the LT4....

Thanks !

MikeC4

When you jack the engine, what do you use to "spread" the load, 2X4 or 4X8 piece of wood ?

Also, do you Jack at the oil pan or some other location. I want to replace my son's balancer/pully, and, on an LT4 it I cannot get the balancer/pully out without raising the engine somewhat. LT1's don't have this problem, as I think the balancer/pully is a bit smaller so it doesn't have the intereference problem with the front crossmember like the LT4....

Thanks !

MikeC4

#6

Drifting

Thread Starter

What type of wrench did you use?? Any tips appreciated.

thanks,

trebor

#7

Melting Slicks

I believe I can remove it from above too. I can reach and pull the plug off the CPS from above with no problem. I can feel the top of the 8mm bolt with my fingers. I bent the shaft of a socket driver to 45 degrees and put the 8mm socket on it. I hooked up a couple of times with the top of the bolt head but could not generate enough torque to break the bolt loose. I am thinking of buying a flex driver.

What type of wrench did you use?? Any tips appreciated.

thanks,

trebor

What type of wrench did you use?? Any tips appreciated.

thanks,

trebor

Trebor, are you saying that you can do this without raising the engine from the motor mounts ??

-Mike

#8

Tech Contributor

I believe I can remove it from above too. I can reach and pull the plug off the CPS from above with no problem. I can feel the top of the 8mm bolt with my fingers. I bent the shaft of a socket driver to 45 degrees and put the 8mm socket on it. I hooked up a couple of times with the top of the bolt head but could not generate enough torque to break the bolt loose. I am thinking of buying a flex driver.

What type of wrench did you use?? Any tips appreciated.

thanks,

trebor

What type of wrench did you use?? Any tips appreciated.

thanks,

trebor

#9

Drifting

Thread Starter

trebor

#10

Tech Contributor

Yes...using an led flash light I can see the CPS at the bottom of the timing cover. I can easily reach in and unplug the wire from the sensor. And as I mentioned, I can touch the 8mm bolt (can't see it) and I was able to get the 8mm socket over the head of the bolt but it was too tight a space to maintain enough torque to spin the bolt out and kept slipping off with the tool I was using. WIth a long thin flexible socket driver, I believe it's do-able without lifting the motor. I will let you know once I find he right tool.

trebor

trebor

If you took the car to the dealer, to a shop, or even a half-a$$ed shade tree mechanic, they'd have it done exactly as I've spelled out in 5 minutes.

But hey, whatever....

#11

Melting Slicks

Jim,

I will be lifting the motor. I think you just pointed out a critical step in your last post, which is to "loosen" the 18mm motor mount nut and not remove it. I was concerned that if I removed the nut and raised the engine to high, the motor mount bolts would go through the mounting hole completely and then get mis-aligned upon lowering the engine. This was my big worry. I messed with C3 motor mounts in the past, and I always had problems getting good clean alignment.

EDIT:

Jim, I just re-read your earlier posts and you said "remove" the motor mount nuts ???

Remove or Lossen ????????

Thanks for the great advice!

Mike

I will be lifting the motor. I think you just pointed out a critical step in your last post, which is to "loosen" the 18mm motor mount nut and not remove it. I was concerned that if I removed the nut and raised the engine to high, the motor mount bolts would go through the mounting hole completely and then get mis-aligned upon lowering the engine. This was my big worry. I messed with C3 motor mounts in the past, and I always had problems getting good clean alignment.

EDIT:

Jim, I just re-read your earlier posts and you said "remove" the motor mount nuts ???

Remove or Lossen ????????

Thanks for the great advice!

Mike

Last edited by MikeC4; 11-16-2008 at 08:22 PM.

#12

Tech Contributor

Jim,

I will be lifting the motor. I think you just pointed out a critical step in your last post, which is to "loosen" the 18mm motor mount nut and not remove it. I was concerned that if I removed the nut and raised the engine to high, the motor mount bolts would go through the mounting hole completely and then get mis-aligned upon lowering the engine. This was my big worry. I messed with C3 motor mounts in the past, and I always had problems getting good clean alignment.

EDIT:

Jim, I just re-read your earlier posts and you said "remove" the motor mount nuts ???

Remove or Lossen ????????

Thanks for the great advice!

Mike

I will be lifting the motor. I think you just pointed out a critical step in your last post, which is to "loosen" the 18mm motor mount nut and not remove it. I was concerned that if I removed the nut and raised the engine to high, the motor mount bolts would go through the mounting hole completely and then get mis-aligned upon lowering the engine. This was my big worry. I messed with C3 motor mounts in the past, and I always had problems getting good clean alignment.

EDIT:

Jim, I just re-read your earlier posts and you said "remove" the motor mount nuts ???

Remove or Lossen ????????

Thanks for the great advice!

Mike

#13

Tech Contributor

Here are some pics....

Motor mount stud and 18mm nut...

Motor mount stud and 18mm nut...