Powdercoat Magnesium wheels?

#1

Burning Brakes

Thread Starter

There are threads out there saying powdercoating aluminum wheels can aneal the alloy. My question is has anyone heard if powdercoating magnesium is a not recomended ? My powdercoater said his oven has to get to 375*. Thanks!

#4

I don;t think there are any wheels that are actually made from all magnesium...its too brittle and not even a little bit maleable. Lightweight but brittle as a cracker.

Still not sure where the term "mag" wheels came from.....since 99% were made of aluminum or alum variant.

Still not sure where the term "mag" wheels came from.....since 99% were made of aluminum or alum variant.

#5

Safety Car

I don;t think there are any wheels that are actually made from all magnesium...its too brittle and not even a little bit maleable. Lightweight but brittle as a cracker.

Still not sure where the term "mag" wheels came from.....since 99% were made of aluminum or alum variant.

Still not sure where the term "mag" wheels came from.....since 99% were made of aluminum or alum variant.

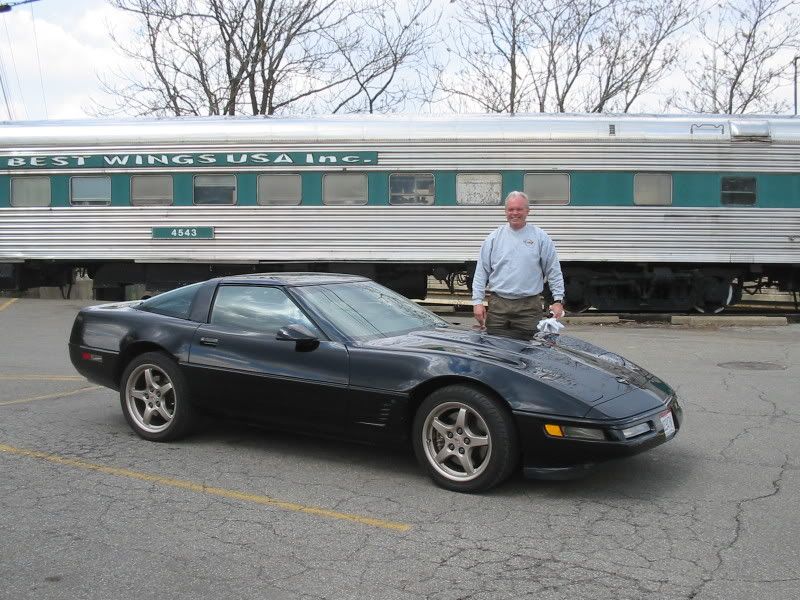

Here is photo of them on my 1996..

#6

Hi I used to powdercoat, we did aluminum wheels all the time. My own corvette has ZR1 A mold wheels that are powdercoated with a chrome look alike powder[I was to cheap to rechrome them]. The 375-400 degree heat needed for powdercoating will not hurt aluminum wheels in any way. I'm pretty sure you would have to heat aluminum way over 2000 degrees to do any real damage. Sometimes you get out gassing from the metal heating up that can effect the finish. for that reason and to make the wheels have a lot more gloss I tell people to ask that they preheat the parts so the parts have time to burn off anything that might be on them. That also lets the powder melt when it hits the part making the finish much smoother with much more gloss than if they are done cold and then put in the oven.

#7

interesting....magnesium is an interesting lt metal. Lite as a feather and pretty hard, just brittle like untempered glass. I suppose a good design can compensate for the metals inability to flex or absorb stress that could cause cracks.

My big complaint with magnesium is that it can;t be polished, hence the thousands upon thousands of brown C4 valve covers.....Even with the mag valve covers I remember how easy it was to break an edge off the cover when installing if it got banged around or hit something. Magnesium & water & fire are also interesting...old VW bugs would burn like a roman candle once the temp got high enough and water was added to the burning mag engine cases.

Anyone old enough to have seen that should be in bed by now...

#8

Safety Car

Hi I used to powdercoat, we did aluminum wheels all the time. My own corvette has ZR1 A mold wheels that are powdercoated with a chrome look alike powder[I was to cheap to rechrome them]. The 375-400 degree heat needed for powdercoating will not hurt aluminum wheels in any way. I'm pretty sure you would have to heat aluminum way over 2000 degrees to do any real damage. Sometimes you get out gassing from the metal heating up that can effect the finish. for that reason and to make the wheels have a lot more gloss I tell people to ask that they preheat the parts so the parts have time to burn off anything that might be on them. That also lets the powder melt when it hits the part making the finish much smoother with much more gloss than if they are done cold and then put in the oven.

Temps as low as 350°F start to deteriorate the strength of many aluminum alloys. Now if the piece was only held to the temp for a short period of time, then the strength degredation is reduced.

However, if an aluminum alloy is heated to the "plastic phase", all of the temper properties are long since gone. There are specific heat treat and age processes that various alloys go through to give them strength.

#9

[QUOTE=AKS Racing;1578985521]Completely inaccurate.

Temps as low as 350°F start to deteriorate the strength of many aluminum alloys. Now if the piece was only held to the temp for a short period of time, then the strength degredation is reduced.

However, if an aluminum alloy is heated to the "plastic phase", all of the temper properties are long since gone. There are specific heat treat and age processes that various alloys go through to give them strength.[/QUOTE]

>>>>>>>>>>>>>>>>>>>>>><<<<<<<<<<<<<<<<<< <<<<<<<

Thats exactly what I understood of the annealing process....

annealing is heat and controlled cooling to REMOVE strength and make the metal soft and maleable. This is done to repair, modify or shape some aluminum and steel parts. Wheels are common. The cooling of some metals can be done by water quench..instantly, while others require hours if not days of slow cooling to prevent crystalization. There is lots more to it than heat it and beat it...

Once the work is finished, then the part/wheel has to be heat treated again to restore its strength.

This is where some of these wheel repair places do more harm than good. They will press the bends and dents out of cold aluminum and create micro fractures that can end up coming apart..somewhere down the road. The right way to do the repair is to anneal it, repair it, then heat treat. But that cost money and makes the process impractical for most.

Temps as low as 350°F start to deteriorate the strength of many aluminum alloys. Now if the piece was only held to the temp for a short period of time, then the strength degredation is reduced.

However, if an aluminum alloy is heated to the "plastic phase", all of the temper properties are long since gone. There are specific heat treat and age processes that various alloys go through to give them strength.[/QUOTE]

>>>>>>>>>>>>>>>>>>>>>><<<<<<<<<<<<<<<<<< <<<<<<<

Thats exactly what I understood of the annealing process....

annealing is heat and controlled cooling to REMOVE strength and make the metal soft and maleable. This is done to repair, modify or shape some aluminum and steel parts. Wheels are common. The cooling of some metals can be done by water quench..instantly, while others require hours if not days of slow cooling to prevent crystalization. There is lots more to it than heat it and beat it...

Once the work is finished, then the part/wheel has to be heat treated again to restore its strength.

This is where some of these wheel repair places do more harm than good. They will press the bends and dents out of cold aluminum and create micro fractures that can end up coming apart..somewhere down the road. The right way to do the repair is to anneal it, repair it, then heat treat. But that cost money and makes the process impractical for most.

#11

Team Owner

Member Since: Oct 2004

Location: altered state

Posts: 81,242

Received 3,043 Likes

on

2,602 Posts

St. Jude Donor '05

The real problem is, mag can catch fire in the oven when powder coating

#13

I don;t think there are any wheels that are actually made from all magnesium...its too brittle and not even a little bit maleable. Lightweight but brittle as a cracker.

Still not sure where the term "mag" wheels came from.....since 99% were made of aluminum or alum variant.

Still not sure where the term "mag" wheels came from.....since 99% were made of aluminum or alum variant.

#14

Team Owner

Member Since: Sep 2003

Location: Freedom is never more than one generation away from extinction.

Posts: 20,161

Received 640 Likes

on

444 Posts

St. Jude '03-'04-'05-'06-'07-'08-'09-'10-'11-'12-'13-'14-'15-'16-'17-'18-‘19-'20-'21-'22-'23-'24

The auto-ignition temp of Magnesium is: 473 °C (883 °F)

Figure it out.

BTW magnesium wheels were the mainstay in racing during the fifties and sixties until aluminum became its replacement.

Figure it out.

BTW magnesium wheels were the mainstay in racing during the fifties and sixties until aluminum became its replacement.

#15

Race Director

My powder coater told me they take the paint off by immersing in molten salt. When I told him my valve covers are magnesium he freaked out. He told me they did a Ducati motorcycle engine that was magnesium and it caught fire in the salt bath. He charged me extra to send them out to a paint removal service.

One tip: they have standard colors in stock. If you want a custom color then they have to buy a minimum quantity. You might have to pay extra to cover their cost because the leftover powder is essentially worthless to them.

I went to a beach party once where a few fire pits down from us there suddenly appeared REALLY bright flames. I went down there to see what was happening. They said they worked at a VW dealership and grabbed a few scrapped engine cases from VW bugs. The lifeguards came by and told them to put out the fire. They just laughed.

One tip: they have standard colors in stock. If you want a custom color then they have to buy a minimum quantity. You might have to pay extra to cover their cost because the leftover powder is essentially worthless to them.

I went to a beach party once where a few fire pits down from us there suddenly appeared REALLY bright flames. I went down there to see what was happening. They said they worked at a VW dealership and grabbed a few scrapped engine cases from VW bugs. The lifeguards came by and told them to put out the fire. They just laughed.

Last edited by Cliff Harris; 10-18-2011 at 03:02 AM.

#16

Safety Car

This has been discussed before......no real resolution that I can find......but mag wheels have been powder coated..

http://forums.corvetteforum.com/c5-g...sium-rims.html

http://forums.corvetteforum.com/c5-g...sium-rims.html

#17

Instructor

When I was in the Navy we were taught that if a helicopter caught fire on the flight deck, it had a lot of magnesium in it which when on fire could not be put out. We were told to try to cool it with a water mist to slow it down up on deck but we had buckets of sand in the compartment below the flight deck. We were supposed to wait down there for the magnesium to burn through the steel flight deck and catch the burning pieces in the buckets of sand then take them up on deck and dump them in the water.

Knowing about that was almost as interesting as knowing how to fix a hole in the side of the ship with a mattress..........

Knowing about that was almost as interesting as knowing how to fix a hole in the side of the ship with a mattress..........

Last edited by ProjectC4; 10-18-2011 at 09:19 PM.

#18

Team Owner

Member Since: Sep 2003

Location: Freedom is never more than one generation away from extinction.

Posts: 20,161

Received 640 Likes

on

444 Posts

St. Jude '03-'04-'05-'06-'07-'08-'09-'10-'11-'12-'13-'14-'15-'16-'17-'18-‘19-'20-'21-'22-'23-'24

DC plugs, mattresses, block & tackle...... Oh does that bring back memories at the San Diego DC training center. We did put out a mag wheel fire with the fog nozzles. It was easier than I imagined. But also in a controlled environment.

But removing paint with molten salt, thats gotta be hot!

And not good for temperature sensitive parts like wheels and other structural components.

But removing paint with molten salt, thats gotta be hot!

And not good for temperature sensitive parts like wheels and other structural components.

#19

Burning Brakes

DC plugs, mattresses, block & tackle...... Oh does that bring back memories at the San Diego DC training center. We did put out a mag wheel fire with the fog nozzles. It was easier than I imagined. But also in a controlled environment.

But removing paint with molten salt, thats gotta be hot!

And not good for temperature sensitive parts like wheels and other structural components.

But removing paint with molten salt, thats gotta be hot!

And not good for temperature sensitive parts like wheels and other structural components.

A street car will probably never use a pure Mag wheel. They are all composite. It's the aluminum that you have to worry about. Aluminum is refined at 2000 degrees Celsius. However, it reaches "thermal expansion" at around 25 degrees Celsius. That's only 77 degrees F!!!! this means that the particles of aluminum actually begin to drift away from each other due to heat. At 350, a solid block of aluminum would be very malleable. However, that is why they use composite materials. Aluminum is cheap and heavy, mag is light and strong. I don't see much of an issue with powder coating stock rims. The composite material will keep the rim strong enough to support its own weight. However, I wouldn't go much higher and not for very long. Once the composite material begins to hit the plastic phase, the different materials seperate from each other. Even though the molecules start to drift away from eachother, molecules want to be with their own molecules. It is no longer a composite. You will have strips of mag and strips of alum. This means a weaker rim.

With full Magnesium rims, there is the problem with breaking. Less aluminum means it is stronger but brittle. You can go ahead and throw the in the oven as long as you want. Magnesium will ignite itself, but you will never get it up to this point on convection air by itself. It takes a mass amount of jet fuel burning to set of the Mag and titanium parts in an aircraft off.

If you have a metal fire, you are screwed. You can't put it out with a hose. It's so hot, the water evaporates before it hits the metal. The Navy jettison's a metal fire into the ocean. It continues to burn. So hot in fact, that the vaporized water is actually split into H and O2 and creates a bomb under the surface of the water. It's pretty horrifying...

#20

Safety Car

Aluminum is not refined at 2000°C. Refineries operate at under 300°F (many sections under 180°F) except the high temp digester section which will go over 500°F.

Aluminum is smelted (conversion of Al2O3 to Al metal) at ~950°C (~1750°F). However, the plastic phase (where the aluminum begins to deform or flow like plastic) is much lower and all heat treat properties are lost.

Safe temps for aluminum tend to be ~275-350°F depending on alloy.

Magnesium is ~35% lighter than aluminum, but much more difficult to machine, more brittle, and certainly more costly. Aluminum is malleable, magnesium is not.

There is a lot of misinformation in this thread.

Aluminum is smelted (conversion of Al2O3 to Al metal) at ~950°C (~1750°F). However, the plastic phase (where the aluminum begins to deform or flow like plastic) is much lower and all heat treat properties are lost.

Safe temps for aluminum tend to be ~275-350°F depending on alloy.

Magnesium is ~35% lighter than aluminum, but much more difficult to machine, more brittle, and certainly more costly. Aluminum is malleable, magnesium is not.

There is a lot of misinformation in this thread.

[/IMG]

[/IMG]