Bad wheels studs?

#1

Melting Slicks

Thread Starter

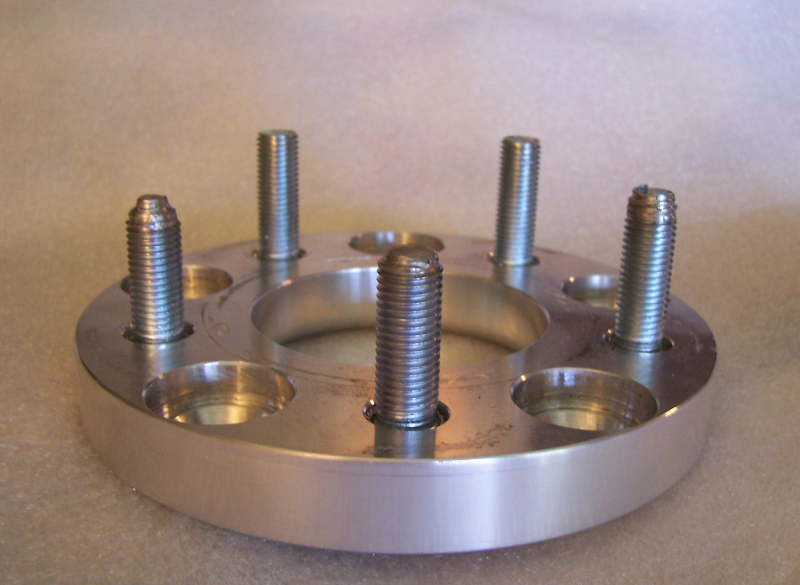

Ok bought some adapters from a decent adapter place(I thought) this last winter. Put them on and had an issue with them fitting kinda tight and figured it was prob the new wheels, last time I had new wheels of this brand they fit kinda snug until you put them on and torqued them down.

Anyways on my last wheel as I tighten the lugs down(all hand started on each wheel, tightened with a socket&ratchet and no air/power tools used) one of the lugs goes hard halfway on. So I pull that lug and it messed up the threads on the lug and tip of stud. Pull the wheel fix stud and use another lugnut and reinstall wheel. It happens again, lug is ruined and have too fix stud again. So I steal two same thread lugs diff brand from another project car and reinstall the wheel and torq per instructions. It goes on fine and I drive the car for 5 miles per adapter instructions and start too pull the wheels too retorq adapters. Figured I'd start with the problem wheel, just incase that stud goes bad, because it's a rear wheel and if it gives me a problem again I'll install it on the front for now. When I start pulling the lugs three lugs(two orig and one new brand) start to give me a problem halfway out. One of each brand pulls part of the stud with them and the 3rd just messes up the threads.

I checked the studs and they are the correct thread, same as the studs. I am going to call the adapter place Monday, but I'm sure he will claim user error. I haven't pulled the other three wheels I am sick(head cold) and too annoyed. At this point I'm sure I'll change all lugs, might be able to change the studs or just buy new diff brand adapters too be safe. The studs are china and I'm sure If I don't replace them it'll turn into an on going problem every time I pull a wheel.

Figured I'd post this in the tech section incase someone can think of anything I could have missed.

other details

-no oil or anti-seize was used and the directions call for none.

-all five lugs where hand started before any were tightened down

-the studs were flush with the wheel and not too long or too short

-the lugs where both the same style and correct for the wheel type

-all lugs were torqued 70ft-lb per adapter instructions for stud size and the nuts to hub 80ft-lb

Anyways on my last wheel as I tighten the lugs down(all hand started on each wheel, tightened with a socket&ratchet and no air/power tools used) one of the lugs goes hard halfway on. So I pull that lug and it messed up the threads on the lug and tip of stud. Pull the wheel fix stud and use another lugnut and reinstall wheel. It happens again, lug is ruined and have too fix stud again. So I steal two same thread lugs diff brand from another project car and reinstall the wheel and torq per instructions. It goes on fine and I drive the car for 5 miles per adapter instructions and start too pull the wheels too retorq adapters. Figured I'd start with the problem wheel, just incase that stud goes bad, because it's a rear wheel and if it gives me a problem again I'll install it on the front for now. When I start pulling the lugs three lugs(two orig and one new brand) start to give me a problem halfway out. One of each brand pulls part of the stud with them and the 3rd just messes up the threads.

I checked the studs and they are the correct thread, same as the studs. I am going to call the adapter place Monday, but I'm sure he will claim user error. I haven't pulled the other three wheels I am sick(head cold) and too annoyed. At this point I'm sure I'll change all lugs, might be able to change the studs or just buy new diff brand adapters too be safe. The studs are china and I'm sure If I don't replace them it'll turn into an on going problem every time I pull a wheel.

Figured I'd post this in the tech section incase someone can think of anything I could have missed.

other details

-no oil or anti-seize was used and the directions call for none.

-all five lugs where hand started before any were tightened down

-the studs were flush with the wheel and not too long or too short

-the lugs where both the same style and correct for the wheel type

-all lugs were torqued 70ft-lb per adapter instructions for stud size and the nuts to hub 80ft-lb

#3

Melting Slicks

Thread Starter

By part of stud I mean use a breaker bar with a few feet of pipe and twist off part of the stud.

#4

Melting Slicks

Thread Starter

All lugs say 12mm 1.5 and the studs are WS-327B. My adapter invoice says 12mm 1.5 studs and I figured the wrong stud where installed when it gave me problems and it's was the 1st thing I checked when I pulled the adapter.

Unless the studs were stamped with the wrong part number.

Unless the studs were stamped with the wrong part number.

#5

Press one or two of the studs from the spacer and see what the spline dimensions are on the stud. If you can fit new off the shelf studs to the spacers then it might be considered OK to use what you've got but maybe replace any that have similar issues. Maybe chase all of the studs with a die or chaser to correct them. You might have some poorly constructed studs and some real good wheel nuts and the "pitch" is certainly susceptible to error. They might be 1.5 but major and minor diameters aren't done to spec.

#6

Melting Slicks

Thread Starter

Press one or two of the studs from the spacer and see what the spline dimensions are on the stud. If you can fit new off the shelf studs to the spacers then it might be considered OK to use what you've got but maybe replace any that have similar issues. Maybe chase all of the studs with a die or chaser to correct them. You might have some poorly constructed studs and some real good wheel nuts and the "pitch" is certainly susceptible to error. They might be 1.5 but major and minor diameters aren't done to spec.

Still hope the vendor does the right thing.

Last edited by BOOT77; 05-11-2014 at 10:23 PM. Reason: dirrrrrrrr

#7

Melting Slicks

I agree with the other posts regarding different threads, i have adapters on my 85 for more than ten years. They have only had one issue with some idiot using a rattle gun and not starting the nuts by hand and stuffed one stud/wheel nut, the wheel nuts should go on easy by hand till they touch the wheel. Then torque them.

#8

Melting Slicks

Thread Starter

The lug nuts thread on fine by hand and even the adapter nuts for the hub 12mm 1.5 as well. Each time I fixed the stud I ran the lug down to the end by hand and back off. Gotta be poor china metal.

All lugs are clearly marked 12mm 1.5

All lugs are clearly marked 12mm 1.5

#9

Melting Slicks

And yes they use some very poor quality metal in Asia, profit not quality is obviously their number one goal.

#10

Melting Slicks

Thread Starter

Will compare a adapter nut, new wheel style lug and oem lug to the gm studs and two good adapter studs tomorrow before I call.

#11

Dorman has some studs that have 16mm + dimension for the knurl.

#12

Melting Slicks

Thread Starter

Called earlier today and talked to a guy who sounded promising and told me I'd have too talk to the boss. Boss sounds like some punk kid(same guy who took my order). Wants me too pay too ship them in so they can look at them and maybe replace them. Didn't say he'd replace my lugs. Complained I bought them almost 6 months ago, like it's my fault he had a sale in December and I just got around too installing them because of the winter that wouldn't die. At one point he giggled and I had too call him on it and he still didn't seem to care. He even tried too tell me these aren't cheap studs and I told him I looked them up they are china studs.

I'm leaning towards disputing the charge and cutting my losses and ordering from another place that says they use USA studs.

I'm leaning towards disputing the charge and cutting my losses and ordering from another place that says they use USA studs.

#13

Melting Slicks

Thread Starter

Maybe Dorman 610-449 .627 knurl

#14

That looks to be a 1/2"-20 thread. Is that the way the knurl is done? Is that length correct?

I believe these are the larger knurl dimensioned in M12X1.5

http://www.dormanproducts.com/catalo...ec10_Part7.pdf

I believe these are the larger knurl dimensioned in M12X1.5

http://www.dormanproducts.com/catalo...ec10_Part7.pdf

Last edited by WVZR-1; 05-12-2014 at 11:52 PM.

#15

Melting Slicks

Thread Starter

I thought the knurl was the splines near the head. Thread doesn't matter, replace studs gonna replace the lugs too. The stud in the adapters are 15.9mm/.6259 knurl, not sure if I can get away with a slight undersize like the Moser .625 or how much over I can go and not run into press in problems. I'd prefer a quick-start tip.

#16

I thought the knurl was the splines near the head. Thread doesn't matter, replace studs gonna replace the lugs too. The stud in the adapters are 15.9mm/.6259 knurl, not sure if I can get away with a slight undersize like the Moser .625 or how much over I can go and not run into press in problems. I'd prefer a quick-start tip.

#17

Melting Slicks

Thread Starter

I would think you'd like to stay with the 12 X 1.5 just so that you could use the same wheel wrench on both the "Welds and the car to adapter to change a flat if needed. I can't imagine not attempting to keep that one hex dimension. Most everything else I understand but mixing those I don't quite get. Specialty nuts maybe? Yes there are such things but I'd think a "long way to get there". Just take an adapter to the local NAPA and check for a stud fit.

#18

Melting Slicks

Thread Starter

#20

Melting Slicks

Thread Starter

edit: I meant lugnut washer not spacer.

Last edited by BOOT77; 05-13-2014 at 06:31 PM. Reason: dirrrrrrrr