About to ready to call it quits: $&@! Clutch bogging engine idle

#41

Le Mans Master

Thread Starter

Looks like the pivot stud type checks out for this type of application. You can see the wear pattern on it though. Not sure if this contributed to the contact:

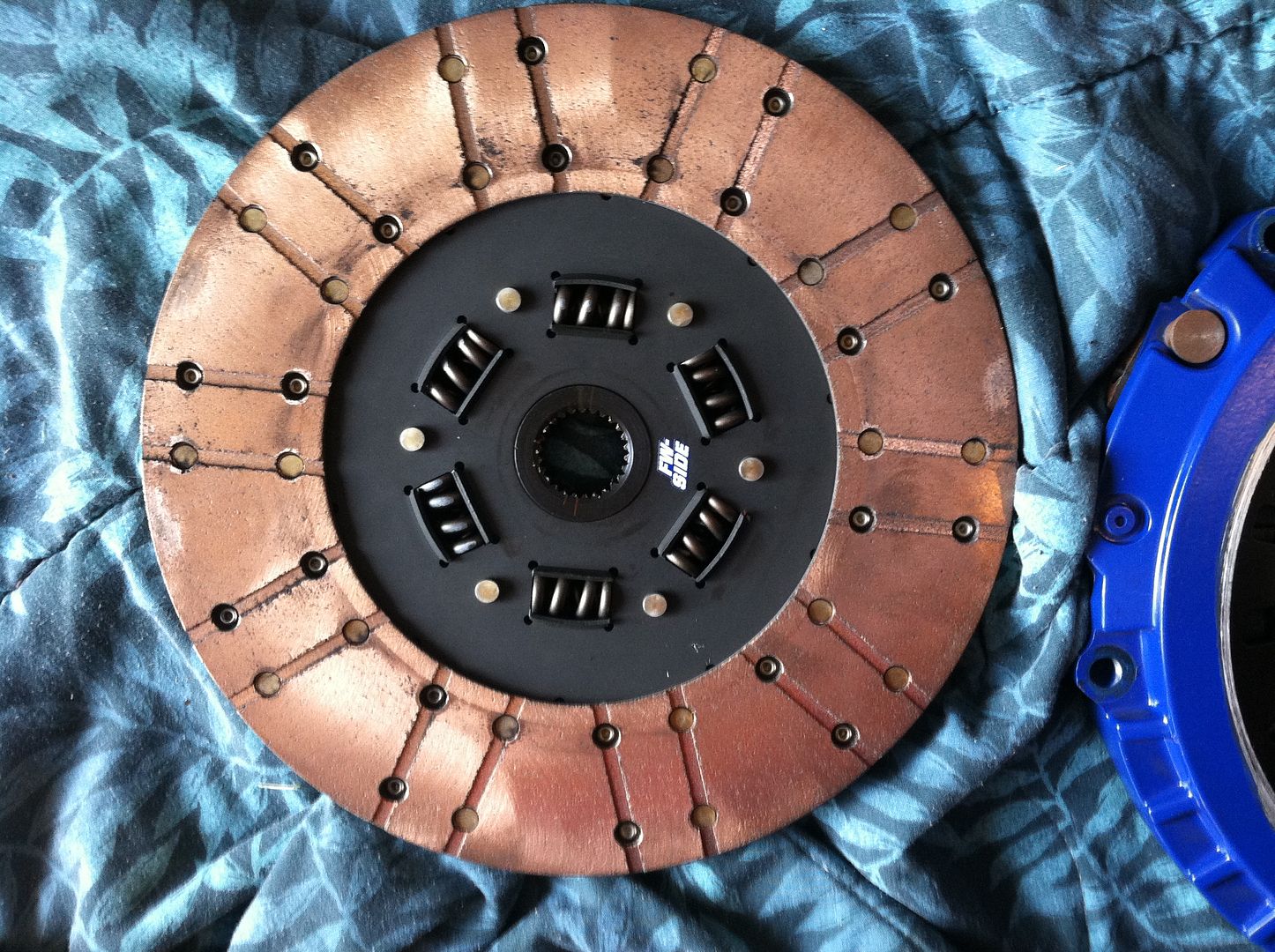

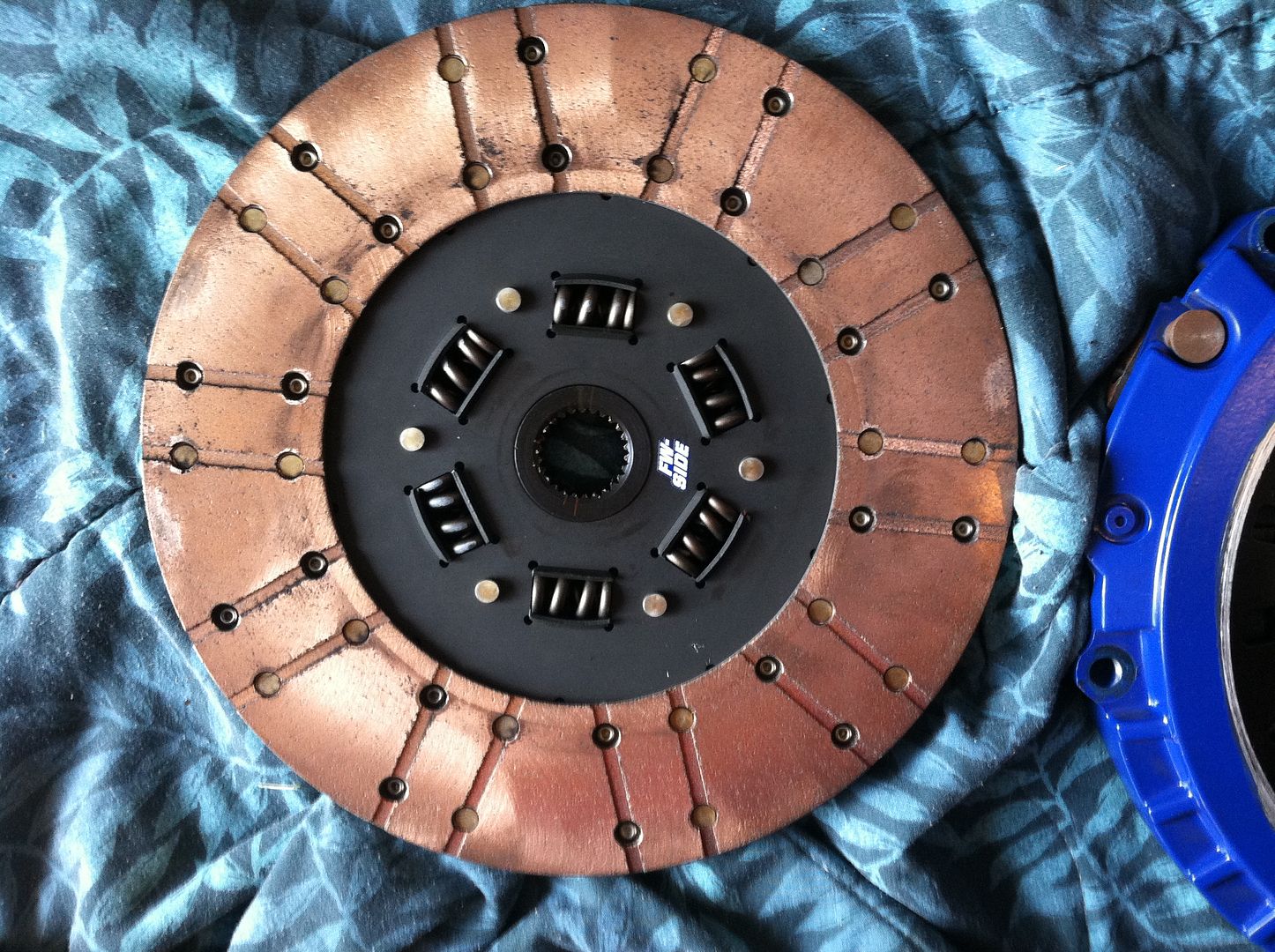

Pictures of the disc with stickers still attached

And a not so great shot of the flywheel

And unfortunately, once the pressure plate and disc were off, I reached into the hole where the pilot bearing resides and found this

So looks like messed up the roller bearing on install. Totally my fault when I was dropping the engine in last year, it mated up to the bellhousing and trans great until the last 1/4". I tightened the bellhousing bolts to draw both together that last little bit and that's probably why I found these. Lesson learned.. I have a pilot bushing that came with the spec kit that I'll press in.

That being said, I took a good look at the tip of input shaft but I don't have an eye for damage. It looks just like it did when I originally put it in.

Pictures of the disc with stickers still attached

And a not so great shot of the flywheel

And unfortunately, once the pressure plate and disc were off, I reached into the hole where the pilot bearing resides and found this

So looks like messed up the roller bearing on install. Totally my fault when I was dropping the engine in last year, it mated up to the bellhousing and trans great until the last 1/4". I tightened the bellhousing bolts to draw both together that last little bit and that's probably why I found these. Lesson learned.. I have a pilot bushing that came with the spec kit that I'll press in.

That being said, I took a good look at the tip of input shaft but I don't have an eye for damage. It looks just like it did when I originally put it in.

#42

Le Mans Master

Thread Starter

#44

Le Mans Master

Thread Starter

If the transmission is bolted up completely to the bellhousing, and the bolts are torqued down all the way, how would the damaged pilot bearing cause the clutch fork to contact the pressure plate? I'm picturing the input shaft in as far as it's supposed to go if the transmission is fully seated onto the bellhousing, even with a compromised pilot bearing.

#46

Le Mans Master

Thread Starter

So if the flywheel is the correct one, is there a specific thickness the pressure plate should be? Just trying to touch bases on everything before it goes back together. I only want to do this one more time.

#47

Race Director

Your input on it has been greatly appreciated. I hate to hang my hat on just the pilot bearing failure, due to error on my part, being the only thing that was causing the fork to contact the plate. At this point, I am set on getting a new clutch pivot stud from powertorque and using a specified pilot bushing by ZF Doc. I just hate the thought of putting it all together only to get grinding....then it's all gotta come right back out.

So if the flywheel is the correct one, is there a specific thickness the pressure plate should be? Just trying to touch bases on everything before it goes back together. I only want to do this one more time.

So if the flywheel is the correct one, is there a specific thickness the pressure plate should be? Just trying to touch bases on everything before it goes back together. I only want to do this one more time.

There are 2 different pressure plate thicknesses.. LT1/L98 and LT5. I don't have or remember the measurements off hand though

I would say it is a smart choice to replace the Pivot stud just by the wear shown.. are you doing a new fork too?

#48

Burning Brakes

Do you have a spacer between the firewall, and the clutch master?

Last edited by aDigitalPhantom; 07-10-2015 at 12:34 PM. Reason: spelling

#49

Team Owner

Pro Mechanic

It wouldn't. You're thinking is correct here. The pilot bearing could bind, dragging on the input shaft and cause the input to not want to slow when you depress the clutch, but it has nothing to do w/the relationship between the fork and the pressure plate.

#50

Le Mans Master

Thread Starter

The spacer is the 4+3 piece, the clutch master mated right up.

That's why I enjoy multiple forms of input. We will keep pecking away at it until we find the main cause, though I know a smashed pilot bearing compliments of me isn't helping.

#51

Race Director

So thinking about the wear on the pressure plate lead me to believe that on the section of wear, the plate sat higher which caused it to rub that spot on another part. only piece I think it could rub was the clutch fork (or another protrusion in the BH)

Have you looked for signs of wear on the Clutch fork or the bellhousing that would coincide with the markings on the pressure plate?

#52

Team Owner

Pro Mechanic

So thinking about the wear on the pressure plate lead me to believe that on the section of wear, the plate sat higher which caused it to rub that spot on another part. only piece I think it could rub was the clutch fork (or another protrusion in the BH)

Have you looked for signs of wear on the Clutch fork or the bellhousing that would coincide with the markings on the pressure plate?

Have you looked for signs of wear on the Clutch fork or the bellhousing that would coincide with the markings on the pressure plate?

I didn't mean to dismiss the wear markings on the PP...just didn't want the OP to think that the pilot bearing was the cause.

I didn't mean to dismiss the wear markings on the PP...just didn't want the OP to think that the pilot bearing was the cause. I too, would be scrutinizing the fork and inside of the bell housing. Something made those marks and the fork seems like the most likely culprit to me, too.

#53

Le Mans Master

Thread Starter

I didn't mean to dismiss the wear markings on the PP...just didn't want the OP to think that the pilot bearing was the cause.

I didn't mean to dismiss the wear markings on the PP...just didn't want the OP to think that the pilot bearing was the cause. I too, would be scrutinizing the fork and inside of the bell housing. Something made those marks and the fork seems like the most likely culprit to me, too.

#54

Burning Brakes

Do you know how thick it is? I cant find mine right now, but IIRC it about 1/2".

It sounds very similar to the LT1 Camaro T56 Clutch. On those the sprung hub faces the flywheel.

It sounds very similar to the LT1 Camaro T56 Clutch. On those the sprung hub faces the flywheel.

#55

Team Owner

Pro Mechanic

You may want to measure the entire, assembled distance from the rear/top of the pressure plate to the block flange then see if you can find a spec for that...either from someone here, or ZF Doc or elsewhere.

You may want to measure the entire, assembled distance from the rear/top of the pressure plate to the block flange then see if you can find a spec for that...either from someone here, or ZF Doc or elsewhere. I don't know that the thickness of the friction disk matters. Only way it could is if it requires the throw range of the fork to be different than stock.

Can you assemble the FW, clutch, fork/TOB and bell housing w/no trans and play w/it while looking inside to see what's happening?

#56

Le Mans Master

Thread Starter

You may want to measure the entire, assembled distance from the rear/top of the pressure plate to the block flange then see if you can find a spec for that...either from someone here, or ZF Doc or elsewhere.

You may want to measure the entire, assembled distance from the rear/top of the pressure plate to the block flange then see if you can find a spec for that...either from someone here, or ZF Doc or elsewhere. I don't know that the thickness of the friction disk matters. Only way it could is if it requires the throw range of the fork to be different than stock.

Can you assemble the FW, clutch, fork/TOB and bell housing w/no trans and play w/it while looking inside to see what's happening?

#57

Advanced

Member Since: Aug 2007

Location: Hood River OR

Posts: 60

Likes: 0

Received 0 Likes

on

0 Posts

It kinda looks kind half of the pressure plate is lifting off the flywheel when you push the clutch down all the way. Having just fought clutch issues with my 86, one think I check now is to make sure the pressure plate is being fully tightened to the flywheel. It may feel fully tight but the bolt shanks can bottom on the flywheel if the shank is too long, washers are not used or the counterbores in the fw are not deep enough.

If you find you are over travelling just due to the particular mix of parts you have, a pedal stop between the pedal and floor works just fine. I welded a nut to the backside of the clutch foot pedal in my racecar and found a bolt with the right length to bottom in the nut and against the floor. I had to do this because of an oversized master cylinder and we didn't need all that travel. No amount of shimming or spacing master or slave or changing pushrod length will change the travel because the hydraulics are self adjusting (within their limits).

If you find you are over travelling just due to the particular mix of parts you have, a pedal stop between the pedal and floor works just fine. I welded a nut to the backside of the clutch foot pedal in my racecar and found a bolt with the right length to bottom in the nut and against the floor. I had to do this because of an oversized master cylinder and we didn't need all that travel. No amount of shimming or spacing master or slave or changing pushrod length will change the travel because the hydraulics are self adjusting (within their limits).

#58

Le Mans Master

Thread Starter

It kinda looks kind half of the pressure plate is lifting off the flywheel when you push the clutch down all the way. Having just fought clutch issues with my 86, one think I check now is to make sure the pressure plate is being fully tightened to the flywheel. It may feel fully tight but the bolt shanks can bottom on the flywheel if the shank is too long, washers are not used or the counterbores in the fw are not deep enough.

If you find you are over travelling just due to the particular mix of parts you have, a pedal stop between the pedal and floor works just fine. I welded a nut to the backside of the clutch foot pedal in my racecar and found a bolt with the right length to bottom in the nut and against the floor. I had to do this because of an oversized master cylinder and we didn't need all that travel. No amount of shimming or spacing master or slave or changing pushrod length will change the travel because the hydraulics are self adjusting (within their limits).

If you find you are over travelling just due to the particular mix of parts you have, a pedal stop between the pedal and floor works just fine. I welded a nut to the backside of the clutch foot pedal in my racecar and found a bolt with the right length to bottom in the nut and against the floor. I had to do this because of an oversized master cylinder and we didn't need all that travel. No amount of shimming or spacing master or slave or changing pushrod length will change the travel because the hydraulics are self adjusting (within their limits).

I'll check the hydraulics for any stampings this weekend that might tell me I've got a mismatch. Like I said, it's all new stuff. After I replace the ball stud, the only things that will be used are the fork, transmission and magnesium bellhousing.

#59

Race Director

What flywheel bolts did you use. I assume you know there are 2 sizes?

LT5 and then LT1/LT4/L98

LT5 ones are about 1/4 longer and will bottom out leaving space for an LT1 pressure plate to move

LT5 and then LT1/LT4/L98

LT5 ones are about 1/4 longer and will bottom out leaving space for an LT1 pressure plate to move

#60

Le Mans Master

Thread Starter

Hi Jeff, I will grab some measurements. The bolts were pretty short, they came with the steel flywheel. I've got to replace the rear seal on the crank, so I'm just piddling away on inspecting parts.