Kicking around idea for a mini project: alternator swap

#1

Le Mans Master

Thread Starter

I've hit a bit of a snag on my build thanks to a grinding clutch and a leak requiring the transmission to come out. Soooo, while SPEC has my clutch for inspection, the tinker bug bit after reviewing some C2 and C3 pictures of alternator swaps and some really clean engine bays of C4s that are running shorter belts and less accessories. I found a few guys using the Geo Metro mini alternator in their builds in the C2 section, with some positive reviews of the junkyard parts. I said what the hell and took a look at the local pick-a-part yard. A few Metros but most were picked over pretty good. The last Metro I checked on the way out of the place had an alternator still on the car. After some sweating and bug bites in the weeds, I got it off the car and for a pretty cheap price.

I figured if these guys running high performance big blocks are running these things with all lights intact, and electric water pumps, a little street mouse motor should be fine. To be honest, a prime reason I wanted to try this is to get rid of the bulky 120 amp alternator, gutted AIR pump (which acts as an extra pulley), associated brackets and AC eliminator pulley. The plan after eyeballing it was to relocate it on the passenger side where the AC compressor was. The AC bracket, with some mild massaging, looks like a great bracket that lines up fairly well with the bolt hole orientation of the Geo alt. Of course there are some issues:

1) I can remove the current 3 rib pulley on the Geo alternator and possibly swap the 120 amp 5 rib on to maintain a one belt system. Both alternators use the same size nut and thread to hold pulleys on.

2) Even if the pulley swap works, there's the matter of a belt sized to run just the mini alternator, belt tensioner, water pump, PS pump, and crank pulley.

3) The routing of a new belt would run the ribbed side against the smooth pulleys of the PS pump and water pump, instead of the back side of the belt as intended. Maybe there are ribbed versions of these two pulleys in the same diameter that I could swap in?

4) The Geo alternator has a three pronged male plug on the back unlike the two prong on my 120 amp. I'm guessing there isn't too much difference there and perhaps that third prong could be a ground?

This isn't anything I'm heavily invested in but if I can make this work, I think I'd enjoy putting it all together. The only power accessories inside the car would be the power windows.

I figured if these guys running high performance big blocks are running these things with all lights intact, and electric water pumps, a little street mouse motor should be fine. To be honest, a prime reason I wanted to try this is to get rid of the bulky 120 amp alternator, gutted AIR pump (which acts as an extra pulley), associated brackets and AC eliminator pulley. The plan after eyeballing it was to relocate it on the passenger side where the AC compressor was. The AC bracket, with some mild massaging, looks like a great bracket that lines up fairly well with the bolt hole orientation of the Geo alt. Of course there are some issues:

1) I can remove the current 3 rib pulley on the Geo alternator and possibly swap the 120 amp 5 rib on to maintain a one belt system. Both alternators use the same size nut and thread to hold pulleys on.

2) Even if the pulley swap works, there's the matter of a belt sized to run just the mini alternator, belt tensioner, water pump, PS pump, and crank pulley.

3) The routing of a new belt would run the ribbed side against the smooth pulleys of the PS pump and water pump, instead of the back side of the belt as intended. Maybe there are ribbed versions of these two pulleys in the same diameter that I could swap in?

4) The Geo alternator has a three pronged male plug on the back unlike the two prong on my 120 amp. I'm guessing there isn't too much difference there and perhaps that third prong could be a ground?

This isn't anything I'm heavily invested in but if I can make this work, I think I'd enjoy putting it all together. The only power accessories inside the car would be the power windows.

#2

Team Owner

Member Since: Oct 2004

Location: altered state

Posts: 81,242

Received 3,043 Likes

on

2,602 Posts

St. Jude Donor '05

Talk to Chris Jones at Jones racing products see if he can hook you up with a pulley that will work, charge right etc etc

#3

Melting Slicks

If it was me after what I learned rebuilding the alternator on my 1999 F150 last week Id use a ford 3G alternator. Thing puts out 14.4 volts at slow idle all the time. The cs140 swap I did on my 87 convertible works great compared to the original alternator and will keep it but the ford alternator actually puts out more volts and is more stable about keeping the voltage at the 14.4 it works at. Just something to think about. Its easy to wire up in any vehicle.

#4

Le Mans Master

Thread Starter

If it was me after what I learned rebuilding the alternator on my 1999 F150 last week Id use a ford 3G alternator. Thing puts out 14.4 volts at slow idle all the time. The cs140 swap I did on my 87 convertible works great compared to the original alternator and will keep it but the ford alternator actually puts out more volts and is more stable about keeping the voltage at the 14.4 it works at. Just something to think about. Its easy to wire up in any vehicle.

#5

Race Director

Good idea! I have thought of doing something similar. I think Matt (mrc24x) has a small alt on the pass side. On my combo I have the water pump (smooth pulley) being turned by the ribbed side of the belt and it has been fine. Some day I've thought of grooving it on a lathe.

I made a thread awhile back with some pulley sizes that might help:

https://www.corvetteforum.com/forums...ley-ratio.html

I made a thread awhile back with some pulley sizes that might help:

https://www.corvetteforum.com/forums...ley-ratio.html

#6

Le Mans Master

Thread Starter

Good idea! I have thought of doing something similar. I think Matt (mrc24x) has a small alt on the pass side. On my combo I have the water pump (smooth pulley) being turned by the ribbed side of the belt and it has been fine. Some day I've thought of grooving it on a lathe.

I made a thread awhile back with some pulley sizes that might help:

https://www.corvetteforum.com/forums...ley-ratio.html

I made a thread awhile back with some pulley sizes that might help:

https://www.corvetteforum.com/forums...ley-ratio.html

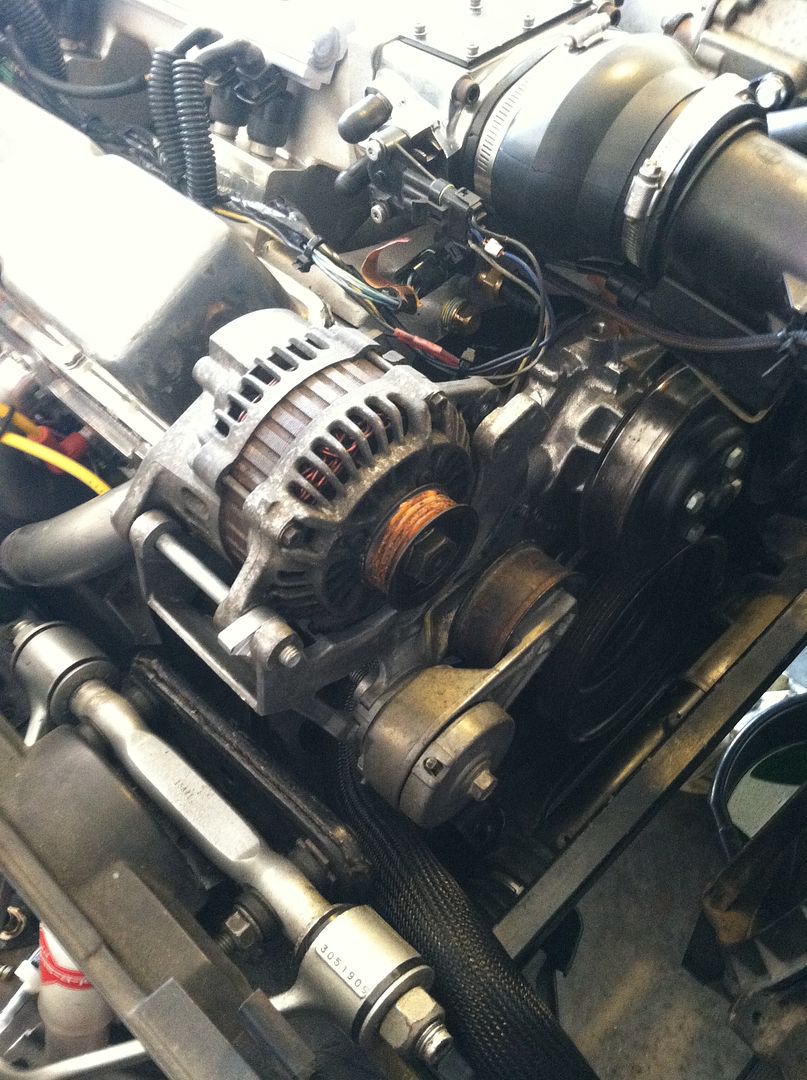

I have a few more pics to load but the last photo here while not great shows the alignment looks pretty good on just an eyeball.

Last edited by 1985 Corvette; 08-09-2015 at 08:33 PM.

#7

Le Mans Master

Thread Starter

Hey guys, I just wanted to do a little follow up that I got the old pulley off but am still searching for the best pulley to work with a five rib belt. I found a place that rebuilds alternators and other electrical equipment so I'm going to see if they have a spare pulley or two that they won't miss. I'm also wondering about this alternator. If I read the sticker on the back of it, it's 55 amp output unit. After a little research it seems the amp output at idle is important more than overall max amp output. So at idle this thing may run the exterior lights and engine but may not provide enough juice to charge.

I'm having a hard time believing it can't charge given the Geo at one point could have had lights and wipers on in the rain, with the radio and AC on, while sitting in traffic. It should make it on my no frills car...wishful thinking probably. The only things drawing power would be the engine and related electronics, exterior lights, horns, power windows and that's it. Everything else is gone. Thoughts?

I'm having a hard time believing it can't charge given the Geo at one point could have had lights and wipers on in the rain, with the radio and AC on, while sitting in traffic. It should make it on my no frills car...wishful thinking probably. The only things drawing power would be the engine and related electronics, exterior lights, horns, power windows and that's it. Everything else is gone. Thoughts?

#8

Team Owner

Member Since: Oct 2004

Location: altered state

Posts: 81,242

Received 3,043 Likes

on

2,602 Posts

St. Jude Donor '05

Try it and monitor is all you can do. If its putting 55a out at idle you may be just fine. There are shops that can upgrade it if need be

#9

Le Mans Master

Thread Starter

That is true, I do have a ton of shops in Jacksonville for automotive electrical. I guess I forgot the fuel pump amp draw as well. That junkyard is full of tons of GM vehicles with higher amp rated alternators that may have the same bolt hole orientation. I may visit again and see what they have. If I find something in the 105 amp area, I'd probably sleep better on it.

#10

Team Owner

Member Since: Oct 2004

Location: altered state

Posts: 81,242

Received 3,043 Likes

on

2,602 Posts

St. Jude Donor '05

Theres a manual (bet someone wil know the name of it) that shows all the interchange/cross reference type of stuff so if you find one you like it will show all the cars its available on.

#11

Le Mans Master

Thread Starter

Found a pulley that works with the alternator but it's a seven groove pulley. I'm guessing with the tensioner doing its job, the five rib belt won't walk. This may actually give me a few extra grooves to move the belt forward or back to make sure the belt is as straight as possible. A few pics.

Going to go through the alternator this weekend for a cleanup and inspection of the bearings. The guy that worked with me on getting this pulley had a ton of these and this was the only one with a groove count close to five and also had a neck slim enough to fit into the alternator housing as the original three groove pulley did. He also said everything should be good to go if I'm not running an AC clutch, blower motor or big stereo. This is getting more and more interesting to see through. Next step will probably be finding a drive belt the closest size possible for the possible new accessory layout.

Going to go through the alternator this weekend for a cleanup and inspection of the bearings. The guy that worked with me on getting this pulley had a ton of these and this was the only one with a groove count close to five and also had a neck slim enough to fit into the alternator housing as the original three groove pulley did. He also said everything should be good to go if I'm not running an AC clutch, blower motor or big stereo. This is getting more and more interesting to see through. Next step will probably be finding a drive belt the closest size possible for the possible new accessory layout.

Last edited by 1985 Corvette; 08-13-2015 at 04:38 PM.

#12

Le Mans Master

Thread Starter

The idea I was kicking around has turned into a full blown engineering dedication now. Big thanks to Aardwolf, Cuisinart and Crowz on the knowledge like the belt ribs running against the smooth PS pulley. No downsides whatsoever and this setup is snug all around with the tensioner doing its thing. Actually Aardwolf posting "good idea!" was the final step to go forward. I usually kick these ideas around and run it by the seasoned posters on here but I was half expecting a, "what the hell made you try this?" Actually when I read, "Good idea!", I said to myself, "That's it, going to the parts store now", so you guys have more influence on me than you might think. I didn't get as much done today as I wanted to due to running back and forth to the auto parts store for the right belt. I did get everything in place and everything looks great with the exception of shortening the positive terminal stud so it doesn't touch the passenger side cylinder head.

I didn't get as much done today as I wanted to due to running back and forth to the auto parts store for the right belt. I did get everything in place and everything looks great with the exception of shortening the positive terminal stud so it doesn't touch the passenger side cylinder head.

Measured and drilled a hole in the AC bracket to hold the other end of the alternator and that was pretty much it. Not that I would imagine anyone would want to go this same route but the belt I used is a 63 inch circumference belt.....just a Duralast model. Overall, I dropped 30 pounds worth of pulleys and accessories off the car doing this. I just stared at the AC delete pulley and thought, "What if I could swap an alternator to this side and ditch that pulley and the AIR pump?"....and it just went from there. A few pics.

Just need to go through it now and inspect the bearings and clean it up but it works. This is the 55 amp version, so if I want more "cushion" I can do the 75 amp model with the exact same dimensions that will drop right in. I also didn't like the idea of potentially hacking up a new unit that wouldn't work when I can use junkyard piece for a mock up but the mock up is actually a good piece.

The alternator man I got the acceptable pulley from said no worries on power supply if I wasn't running AC or a blower motor of any kind. Of course, I gotta figure out the three pronged plug on the back of the alternator. But that's pretty much it. Maybe I'll post a few pics of the teardown and how I end up wiring it.

I didn't get as much done today as I wanted to due to running back and forth to the auto parts store for the right belt. I did get everything in place and everything looks great with the exception of shortening the positive terminal stud so it doesn't touch the passenger side cylinder head.

I didn't get as much done today as I wanted to due to running back and forth to the auto parts store for the right belt. I did get everything in place and everything looks great with the exception of shortening the positive terminal stud so it doesn't touch the passenger side cylinder head. Measured and drilled a hole in the AC bracket to hold the other end of the alternator and that was pretty much it. Not that I would imagine anyone would want to go this same route but the belt I used is a 63 inch circumference belt.....just a Duralast model. Overall, I dropped 30 pounds worth of pulleys and accessories off the car doing this. I just stared at the AC delete pulley and thought, "What if I could swap an alternator to this side and ditch that pulley and the AIR pump?"....and it just went from there. A few pics.

Just need to go through it now and inspect the bearings and clean it up but it works. This is the 55 amp version, so if I want more "cushion" I can do the 75 amp model with the exact same dimensions that will drop right in. I also didn't like the idea of potentially hacking up a new unit that wouldn't work when I can use junkyard piece for a mock up but the mock up is actually a good piece.

The alternator man I got the acceptable pulley from said no worries on power supply if I wasn't running AC or a blower motor of any kind. Of course, I gotta figure out the three pronged plug on the back of the alternator. But that's pretty much it. Maybe I'll post a few pics of the teardown and how I end up wiring it.

Last edited by 1985 Corvette; 08-15-2015 at 07:18 PM.

#14

Le Mans Master

Thread Starter

I can give another one a try. I had one that I hit with the heat gun to get over the 58 TB but ended up melting it. Yes, I'd love the OEM look over the temp setup I got in place just to get the air pumping through the motor.

#17

Le Mans Master

Thread Starter

That's a good question! The PS pump would now turn clockwise with the current belt routing. I checked a few diagrams of the internals of the PS pump and the vanes in the pump rotor stick straight out, and appear to be able to flow in any direction. Also seen a variety of Chevys, TPI and LT1/4, that have the belt routed on the outside of the PS pulley. Although it does show the belt routed on the inside of the pulley on Corvette TPI diagrams, I don't think it should be too much of an issue, unless someone wants to burst my bubble on this little project.

#18

Le Mans Master

Thread Starter

Wanted to do a little follow up on this project that sounded good on paper but probably may have hit a rough patch. The car has sat for a bit due to some clutch issues and has been run much so the battery was a little worn down. But wanted to test out my half assed wiring job to see if I had successfully "energized" the alt on startup.

Dash voltage was reading 11.7 volts before I started it up. While idling, voltage went to 12.7. Ran it for a minute or so and checked again and dash readout was displaying 13.4 volts. Turned on the cooling fan and the engine stumbled briefly but ran normally after. Dash kept showing over 13 volts. Then I tried the headlights in combination with the fan running....and that was the deal breaker it seems. Headlight doors flipped over no problem but with the lights on, the engine idle started slowing and the voltage readout went to 12.4 or so promptly.

Turned the lights off and as soon as the doors flipped back close, the engine was happy again and the voltage got back above 13. 55 amp alt...aside from the extra 5 cylinders it has to light up, everything else on that little economy car is similar in power demands with exception of the headlight motors and maybe the high volume fuel pump.

A little bummed.

Dash voltage was reading 11.7 volts before I started it up. While idling, voltage went to 12.7. Ran it for a minute or so and checked again and dash readout was displaying 13.4 volts. Turned on the cooling fan and the engine stumbled briefly but ran normally after. Dash kept showing over 13 volts. Then I tried the headlights in combination with the fan running....and that was the deal breaker it seems. Headlight doors flipped over no problem but with the lights on, the engine idle started slowing and the voltage readout went to 12.4 or so promptly.

Turned the lights off and as soon as the doors flipped back close, the engine was happy again and the voltage got back above 13. 55 amp alt...aside from the extra 5 cylinders it has to light up, everything else on that little economy car is similar in power demands with exception of the headlight motors and maybe the high volume fuel pump.

A little bummed.