Brake line fitting stuck in ABS/ASR pump!!!

#1

Le Mans Master

Thread Starter

Member Since: Feb 2003

Location: Chicago IL

Posts: 9,087

Likes: 0

Received 0 Likes

on

0 Posts

I am replacing the ABS/ASR pump on my '94. All the line fittings came off pretty easily until the last one. The fitting on the side closest to the driver seat will not budge at all!!!

The sides rounded off from the wrench and from trying to loosen it. I tried using a vice grip as a last resort because that is the only thing that could grab it and even that is not working. This bolt has limited space from the way the pump is designed. I tried unbolting the pump and moving it, but still won't budge.

This thing is practically welded in place and the fitting head is a bit chewed from the vise grip. The compartment took in water from the last owners unintentional off-road excursion, so that might be the reason it is stuck?

I am about ready to just cut the line and install a new one....

Any ideas???

The sides rounded off from the wrench and from trying to loosen it. I tried using a vice grip as a last resort because that is the only thing that could grab it and even that is not working. This bolt has limited space from the way the pump is designed. I tried unbolting the pump and moving it, but still won't budge.

This thing is practically welded in place and the fitting head is a bit chewed from the vise grip. The compartment took in water from the last owners unintentional off-road excursion, so that might be the reason it is stuck?

I am about ready to just cut the line and install a new one....

Any ideas???

Last edited by formul89; 09-09-2008 at 10:21 PM.

#3

Le Mans Master

Thread Starter

Member Since: Feb 2003

Location: Chicago IL

Posts: 9,087

Likes: 0

Received 0 Likes

on

0 Posts

I may just do that. Probably cheaper to buy the flare tools and fittings and do it myself than have a shop do it. There is enough line where I can shorten it a bit and install a new fitting.

Doesn't look too hard.

Doesn't look too hard.

#4

This was 9 years ago, so hopefully fixed by now. Just wanted to add to this for others who come across it. If you're going to bend your own lines you will need a really good tool. If you buy a cheap one, then you will find that the line just slides out the back instead of being bent. They just don't grip the line very well. The solution is unfortunately a VERY expensive tool. In case you're wondering what I mean by VERY expensive...basically you should be saying to yourself "holy ****!" when you see the price, and I don't mean the regular holy **** prices of the medium level ones. I really like the Master Cool MSC71475 which comes in at roughly a whopping $300. If you're not willing to spend the money, then I suggest you just have someone else do it. The others will scratch the hell out of the lines as they try & fail to grip the line while bending the ends. On the plus side, you get basically all of the dies you could ever need for all the different types and sizes of bends for your $300.

#5

Just cut it off as close as you can. You can even cut the nut with the pipe. Get a flare tool for free at most part stores with a deposit.

#6

I will say one thing about frozen fasteners though. I've dealt with enough in my time that I have very little patience for rusty fasteners. Particularly if you are trying to deal with it without a proper torch, and I don't mean some little propane torch. Maybe you don't own one, or maybe the fastener is in a location where a torch can't be used. There might be parts that can't handle the nearby heat, or maybe it's right near the fuel tank. Either way the one thing that might possibly make a frozen fastener a little easier is heat, and if you can't use it...you're out of luck. My policy has been for a long time to give them one chance, and if they don't loosen I just cut them off straight away. I've spent insane amounts of time in my younger & dumber mechanic days trying to get fasteners off. It is absolutely not worth it. Give it a go with your wrench after applying a 50/50 mix of ATF & Acetone, and if it doesn't go give it a little heat if you can. If it still doesn't go, then save yourself some time & just cut the damn thing.

#7

Safety Car

I realize this is an old thread but doing a postmortem on it, there's the obvious question: why didn't the original person use a flair nut wrench in the first place? Whether vice grips or regular wrenches, it's easy to take the shoulders of a nut on a brake line. Same thing as using a 12 point socket on a square or hex bolt head. Using the right tools in the first place is always easier and cheaper than fixing the resulting damage IMO.

My 2 cent.

My 2 cent.

#8

I realize this is an old thread but doing a postmortem on it, there's the obvious question: why didn't the original person use a flair nut wrench in the first place? Whether vice grips or regular wrenches, it's easy to take the shoulders of a nut on a brake line. Same thing as using a 12 point socket on a square or hex bolt head. Using the right tools in the first place is always easier and cheaper than fixing the resulting damage IMO.

My 2 cent.

My 2 cent.

#9

Team Owner

Pro Mechanic

The real question is...why didn't the OP use HEAT? HEAT it. HEAT works. When it's stuck...get a torch and use HEAT....it'll come right out.

.

Last edited by Tom400CFI; 03-21-2017 at 04:25 PM.

#10

Because often, the thin wall of a flare nut wrench allows it to spread, and effectively grab worse than a good quality open end wrench. I had a set of MAC Tools flare wrenches that would round the nut nearly every time. AFTER the MAC wrenches rounded the nut, I'd put a Snap-On open end on it and break the nut free. I could apply more torque to the nut w/a basic good quality open end wrench. The MAC wrench set ended up in the trash, I've never replaced them. A GOOD open end wrench works, and a flare wrench is most definitely NOT the same as a 12 point socket. Not at all.

The real question is...why didn't the OP use HEAT? HEAT it. HEAT works. When it's stuck...get a torch and use HEAT....it'll come right out.

.

The real question is...why didn't the OP use HEAT? HEAT it. HEAT works. When it's stuck...get a torch and use HEAT....it'll come right out.

.

As for heat...heat is definitely the best way to remove a stuck bolt, but not everyone has an oxy-acetylene torch. Propane torches don't do a damn thing. Also, heat and brake lines don't necessarily go together all that well. Nor does heat and the rubber seals or bushings near those lines. I've definitely had cars where it was pretty damn difficult to get a torch in there without roasting something else in the process. My order of operation for stuck bolts is spray it with a 50/50 mix of acetone & ATF; if that doesn't work I hit it with a little heat if possible; if that doesn't work I cut or drill the damn thing. I move pretty quickly to just cutting them off. It's not worth my time most of the time messing around with stuff like that. The acetone/ATF mix works incredibly well though. I rarely need to move to heat or cutting since I started using that stuff. Beats any commercially available product I've ever tried. Also, be careful applying heat to brake areas...Chlorinated brake cleaner & heat = Phosgene gas. Google WWI Phosgene gas if you don't know what Phosgene is.

#11

Team Owner

Pro Mechanic

Personally, I really don't like 12 point sockets unless it's an actual 12 point fastener. As for the flare nut wrenches I've found that if you grind the edge flat that they work much better. The top and bottom tend to be rounded which puts less meat on the fastener. Grinding it flat gives you more contact area. If you have a fastener where you can actually get a socket around it, then you should obviously use one; but I'd still recommend a 6 point for 6 points and a 12 point for 12 points.

Obviously one should use their brain and eye ***** to avoid burning surrounding items.

Last edited by Tom400CFI; 03-21-2017 at 06:30 PM.

#12

Race Director

Ahhh....how does that work? The ID of the wrench is tapered "down" to the bolt interface surface...you grind the top and bottom down..you haven't increased the contact area. All you've done is weaken an already weak wrench.

None of that is true. A propane torch CAN work great...MAP gas, even better. We use MAP all the time on stuck hardware here in our fleet shop. It works. Even on brake parts.

Obviously one should use their brain and eye ***** to avoid burning surrounding items.

None of that is true. A propane torch CAN work great...MAP gas, even better. We use MAP all the time on stuck hardware here in our fleet shop. It works. Even on brake parts.

Obviously one should use their brain and eye ***** to avoid burning surrounding items.

Propane and/or map gas do work.

Propane and/or map gas do work.

#13

Ahhh....how does that work? The ID of the wrench is tapered "down" to the bolt interface surface...you grind the top and bottom down..you haven't increased the contact area. All you've done is weaken an already weak wrench.

None of that is true. A propane torch CAN work great...MAP gas, even better. We use MAP all the time on stuck hardware here in our fleet shop. It works. Even on brake parts.

Obviously one should use their brain and eye ***** to avoid burning surrounding items.

None of that is true. A propane torch CAN work great...MAP gas, even better. We use MAP all the time on stuck hardware here in our fleet shop. It works. Even on brake parts.

Obviously one should use their brain and eye ***** to avoid burning surrounding items.

As for grinding the wrench. I'm not talking about grinding the ID. You grind the wrench so that it lays flat against the fastener. You have just increased the surface area in contact with the fastener. If you don't get how this works...think about it real hard until you do.

#14

Team Owner

Pro Mechanic

5 posts in...and you start w/the attitude, huh?

Ayuh. Earlier, you said: "Propane torches don't do a damn thing."...but they do. So that was bad advice. Now you're agreeing that they do work. That is good...since they do work.

We are talking about flare nuts....right? With a flare nut, the hexagonal part of the nut where you apply the torque, isn't flush against the surface it's bolted into. it stands out, typically 1/4" or so from the surface it's threaded into. Sooooo, you can get any flare wrench fully engaged to the hexagonal part of the nut quite easily. If you don't get how this works...think about it real hard until you do.

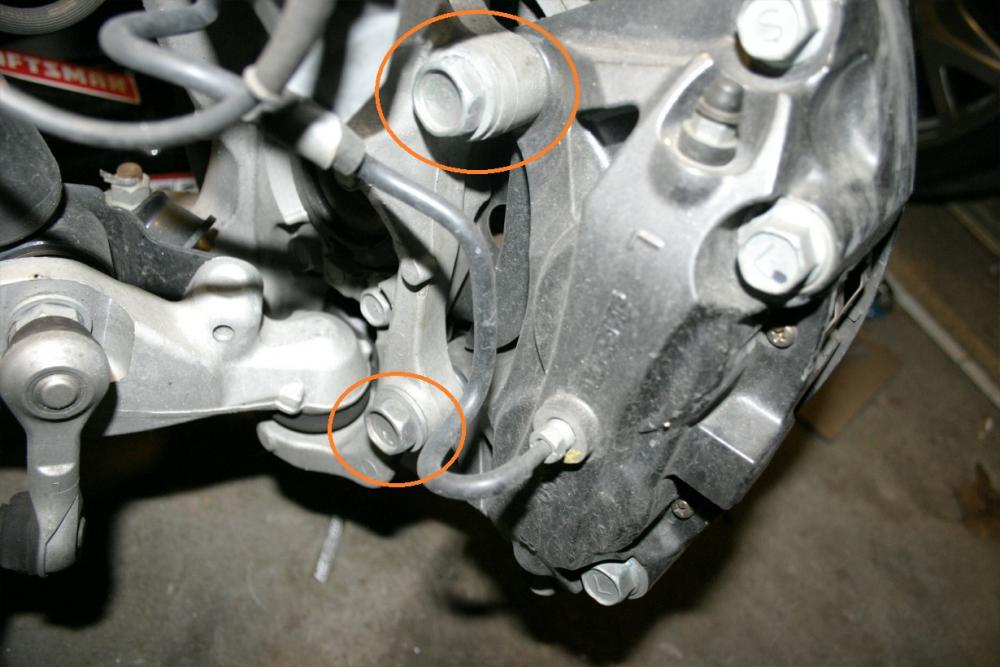

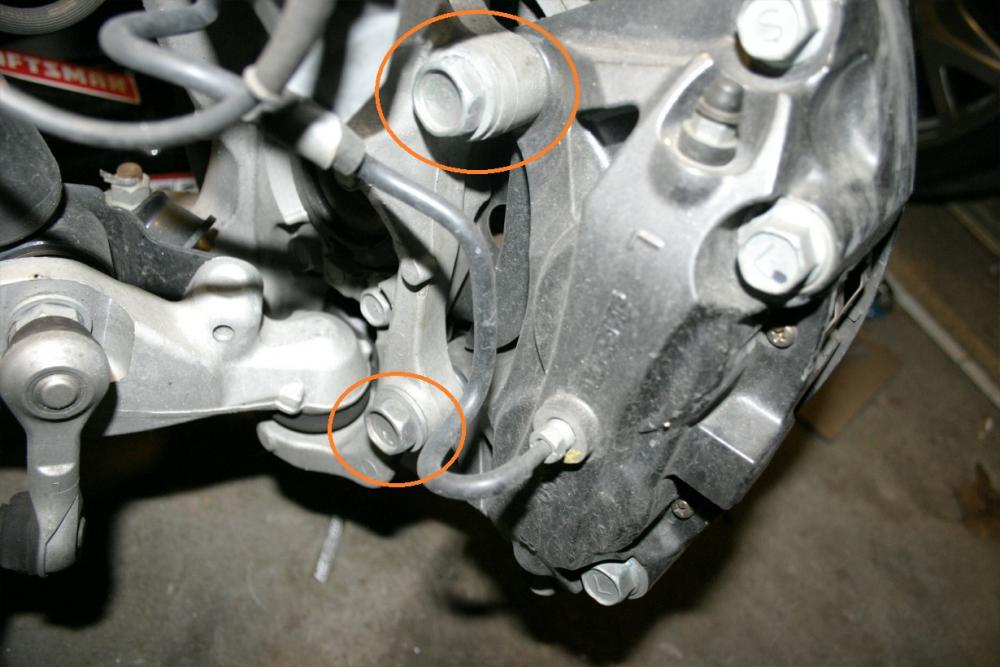

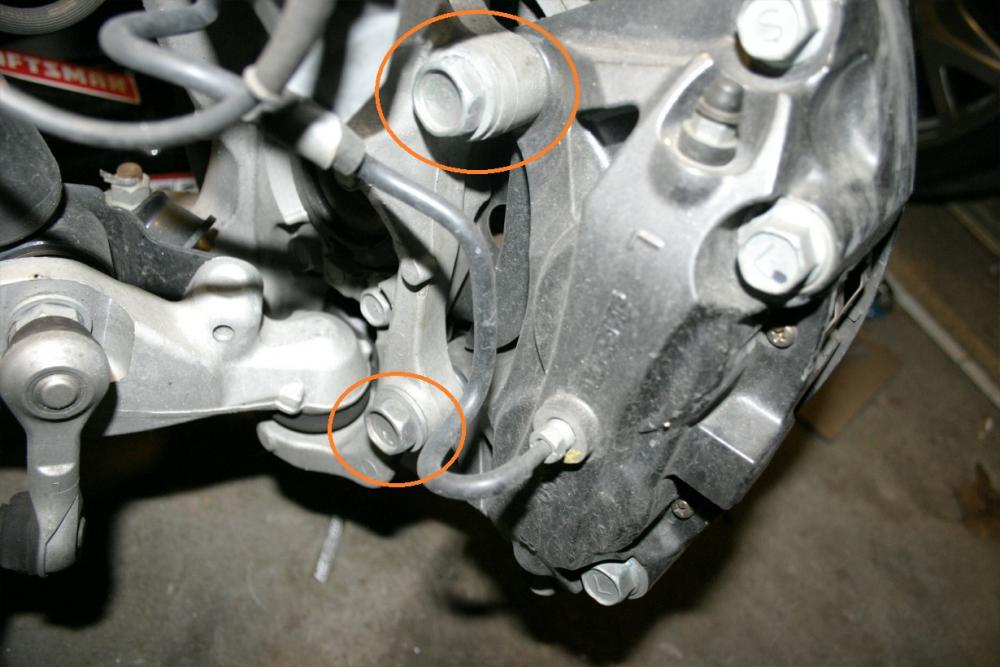

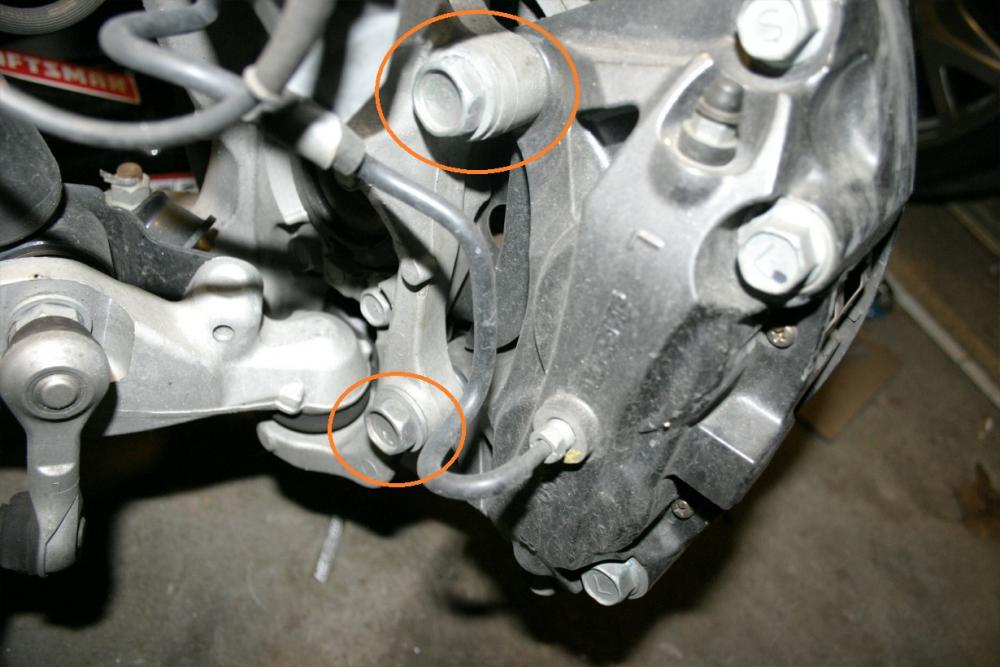

You can see this feature in this pic, to the right of the lower orange circle... Use your eyeballs on it.

...and here is an unground, un-weakend flare wrench....fully engaged w/the nut hex....

None of this matters though, b/c as I said earlier:

You're "mod" only exacerbates that situation by weakening the already weak jaws.

.

Ayuh. Earlier, you said: "Propane torches don't do a damn thing."...but they do. So that was bad advice. Now you're agreeing that they do work. That is good...since they do work.

As for grinding the wrench. I'm not talking about grinding the ID. You grind the wrench so that it lays flat against the fastener. You have just increased the surface area in contact with the fastener. If you don't get how this works...think about it real hard until you do.

You can see this feature in this pic, to the right of the lower orange circle... Use your eyeballs on it.

...and here is an unground, un-weakend flare wrench....fully engaged w/the nut hex....

None of this matters though, b/c as I said earlier:

often, the thin wall of a flare nut wrench allows it to spread, and effectively grab worse than a good quality open end wrench.

.

Last edited by Tom400CFI; 03-21-2017 at 11:58 PM.

#15

No, not really. I'm still saying that propane torches suck, and are pretty much useless. They can get the job done, but you can dig a trench with a teaspoon too. I'm pretty much bored with the whole back and forth crap, so I'm just going to leave it here. You do what you like.

5 posts in...and you start w/the attitude, huh?

Ayuh. Earlier, you said: "Propane torches don't do a damn thing."...but they do. So that was bad advice. Now you're agreeing that they do work. That is good...since they do work.

We are talking about flare nuts....right? With a flare nut, the hexagonal part of the nut where you apply the torque, isn't flush against the surface it's bolted into. it stands out, typically 1/4" or so form the surface it's threaded into. Sooooo, you can get any flare wrench fully engaged to the hexagonal part of the nut quite easily. If you don't get how this works...think about it real hard until you do.

You can see this feature in this pic, to the right of the lower orange circle... Use your eyeballs on it.

...and here is an unground, un-weaked flare wrench....fully engaged w/the nut hex....

None of this matters though, b/c as I said earlier:

.

Ayuh. Earlier, you said: "Propane torches don't do a damn thing."...but they do. So that was bad advice. Now you're agreeing that they do work. That is good...since they do work.

We are talking about flare nuts....right? With a flare nut, the hexagonal part of the nut where you apply the torque, isn't flush against the surface it's bolted into. it stands out, typically 1/4" or so form the surface it's threaded into. Sooooo, you can get any flare wrench fully engaged to the hexagonal part of the nut quite easily. If you don't get how this works...think about it real hard until you do.

You can see this feature in this pic, to the right of the lower orange circle... Use your eyeballs on it.

...and here is an unground, un-weaked flare wrench....fully engaged w/the nut hex....

None of this matters though, b/c as I said earlier:

.

#16

Team Owner

Pro Mechanic