Innovators West 10 rib balancer issue??

#1

Pro

Thread Starter

Hey guys,

Long story as short as possible, working on finishing up my new YSI 408 build and it has a Callies crank with a keyway in place. I got a 3/16” key to fit the crank and 10 rib IW blower pulley really well. I installed the pulley, torqued it to 130 ft lbs and now the engine doesn’t turn over…….

The engine was professionally built and turned over easily before the balancer was installed and I installed the bigger crank seal for the bigger hub that’s on the IW pulley and I can see that the backside of the pulley is NOT hitting the front of the timing cover so that only leaves 1 thing that it must be hitting the floating collar in the oil pump correct?

Before I installed the pulley, I measured the smaller OD of the hub that slides into the oil pump that bottoms against the main oil pump keyed drive collar and that matched an OEM C5 pulley but the overall OD of that hub is obviously a lot bigger diameter so I’m thinking that part must be hitting the oil pump case?

If it is how in the hell do I fix that considering if I space it out that will throw off the belt alighnment for all the rest of pulleys?

I am going to remove the pulley tonight and check things out but wanted to see what you guys thought first.

Thanks!!

Long story as short as possible, working on finishing up my new YSI 408 build and it has a Callies crank with a keyway in place. I got a 3/16” key to fit the crank and 10 rib IW blower pulley really well. I installed the pulley, torqued it to 130 ft lbs and now the engine doesn’t turn over…….

The engine was professionally built and turned over easily before the balancer was installed and I installed the bigger crank seal for the bigger hub that’s on the IW pulley and I can see that the backside of the pulley is NOT hitting the front of the timing cover so that only leaves 1 thing that it must be hitting the floating collar in the oil pump correct?

Before I installed the pulley, I measured the smaller OD of the hub that slides into the oil pump that bottoms against the main oil pump keyed drive collar and that matched an OEM C5 pulley but the overall OD of that hub is obviously a lot bigger diameter so I’m thinking that part must be hitting the oil pump case?

If it is how in the hell do I fix that considering if I space it out that will throw off the belt alighnment for all the rest of pulleys?

I am going to remove the pulley tonight and check things out but wanted to see what you guys thought first.

Thanks!!

#2

Tech Contributor

I've had to grind a chamfer on the end of the balancer to keep it from having an interference problem with the oil pump cover plate. When you pull it off, it should be obvious that was the issue if you've turned the motor over much at all.

#3

Pro

Thread Starter

Blown,

I found an old thread of a "Cracked hub" from a couple of guys and this exact subject popped up in that that thread as well. It looks like the issue is due to the double roller timing chain spacers that it spaces the oil pump out, in return makes the pulley bottom out on the pump.

My engine didn't turn over at all and it was one of those deals I luckily realized something was wrongs and stopped before i did any damage.

My question is now, wonder do I take the hub out of the balancer to machine it to fit or ship it back to IW?

I found an old thread of a "Cracked hub" from a couple of guys and this exact subject popped up in that that thread as well. It looks like the issue is due to the double roller timing chain spacers that it spaces the oil pump out, in return makes the pulley bottom out on the pump.

My engine didn't turn over at all and it was one of those deals I luckily realized something was wrongs and stopped before i did any damage.

My question is now, wonder do I take the hub out of the balancer to machine it to fit or ship it back to IW?

#4

Pro

Thread Starter

FYI here is the fast response from Innovators West

Yes on cars with an aftermarket oil pump or a spaced out factory pump, the relief on the end of the damper hub will need to be increased to clear the pump body. The damper will need to be removed and then with some calipers you will need to measure from the front of the oil pump drive gear/timing gear to the front edge of the oil pump. The relief on the back of the hub will need to be increased to that measurement taken plus .050” to give adequate clearance to the pump body. If the damper is sent back here in house we can perform that modification for you or if you have a competent machinist locally that can mount the entire damper up in the lathe, dial it in and perform that machining, that may be an option as well. Unfortunately the hub is pressed into the case of the damper so it should not be removed from the damper.

So this is still assuming this is my issue but I'll update on all this tomorrow after I remove the balancer and see..... stay tuned!

Yes on cars with an aftermarket oil pump or a spaced out factory pump, the relief on the end of the damper hub will need to be increased to clear the pump body. The damper will need to be removed and then with some calipers you will need to measure from the front of the oil pump drive gear/timing gear to the front edge of the oil pump. The relief on the back of the hub will need to be increased to that measurement taken plus .050” to give adequate clearance to the pump body. If the damper is sent back here in house we can perform that modification for you or if you have a competent machinist locally that can mount the entire damper up in the lathe, dial it in and perform that machining, that may be an option as well. Unfortunately the hub is pressed into the case of the damper so it should not be removed from the damper.

So this is still assuming this is my issue but I'll update on all this tomorrow after I remove the balancer and see..... stay tuned!

#6

off op thanx for the rack spacers worked out great

great post on this subject..goodluck with your 408ysi build!!

#9

Team Owner

I had my 8-rib IW balancer cleared another .130" to match the clearance I put on my ASP underdrive pulley that was mounted on the crank snout. I'm running a dual Rollmaster with the 3 mm oil pump spacers.

#10

Must be another killer ECS part

#13

#15

Pro

Thread Starter

Update: I bolted the puller onto the front of the dampner and as soon as it pulled it a fraction of an inch the crank turned, I removed it, and timing cover and checked it all out, the oil pump seems to be fine with no cracks or obvious issues.

I then measured from the face of the Melling pump to the oil pump drive collar and it was .353 then added the .050 per IW and it comes out to be .403" would be the correct relief. I measured the current relief but I can't remember what it is.

Anyway no one around here has a 6 jaw chuck so after talking with Chris I sent it back to IW today. TBD how it'll turn out but I'm hoping for the best

A+ on customer service from them!!!

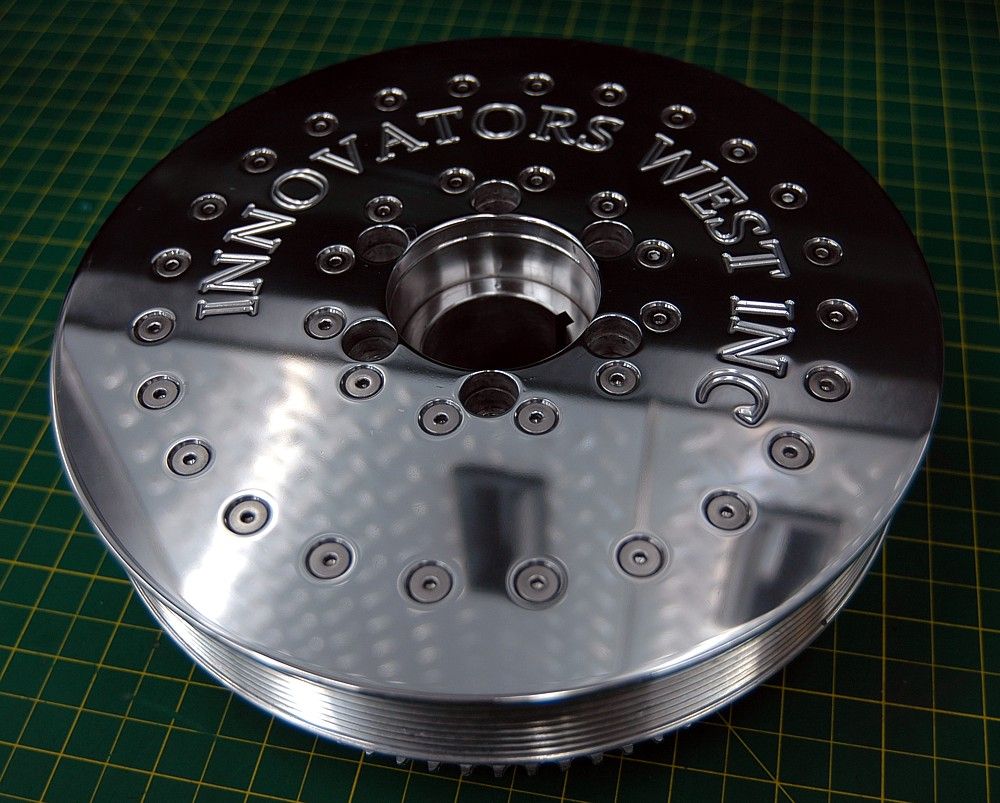

BTW "Blown81" is that an 8 or 10 rib you have pictured cuz my looks different than that. I'm assuming ECS did the cog accessory for you? (Looks great!)

I then measured from the face of the Melling pump to the oil pump drive collar and it was .353 then added the .050 per IW and it comes out to be .403" would be the correct relief. I measured the current relief but I can't remember what it is.

Anyway no one around here has a 6 jaw chuck so after talking with Chris I sent it back to IW today. TBD how it'll turn out but I'm hoping for the best

A+ on customer service from them!!!

BTW "Blown81" is that an 8 or 10 rib you have pictured cuz my looks different than that. I'm assuming ECS did the cog accessory for you? (Looks great!)

Last edited by Ksths2; 04-01-2015 at 05:05 PM.

#16

Safety Car

You don't have a machine shop with a 6 jaw locally? That is all I use aside from 4 jaw independent chucks and I really only use those if I'm threading or crowning firearm barrels. 3 jaw chucks suck.