Anyone have problems with drive axle CV joints or bearings?

#21

Le Mans Master

Thread Starter

Originally Posted by jbauch357

Fixed the rear popping and the weird noise under acceleration!

I took the rear wheels off and removed the drive shaft spindle nuts on both sides. Got a can of penetrating fluid and sprayed the crap out of the outside splines on the drive shaft. Also took a brass hammer to lightly compress the drive shaft so that I could work in some more of the penetrating fluid. After a little while of spraying and working the shaft in and out it flowed smoothly in and out of the hub. I then replaced the spindle nut and tightened down to 125 ft/lbs. Took for a test drive and all of the noises are gone!!!

You will need:

6-point, 33mm, deep well socket

torque wrench

penetrating fluid

brass hammer (or you can pad a regular hammer with a rag, just don't want steel on steel cause it could hurt the internals of the CV joint)

I took the rear wheels off and removed the drive shaft spindle nuts on both sides. Got a can of penetrating fluid and sprayed the crap out of the outside splines on the drive shaft. Also took a brass hammer to lightly compress the drive shaft so that I could work in some more of the penetrating fluid. After a little while of spraying and working the shaft in and out it flowed smoothly in and out of the hub. I then replaced the spindle nut and tightened down to 125 ft/lbs. Took for a test drive and all of the noises are gone!!!

You will need:

6-point, 33mm, deep well socket

torque wrench

penetrating fluid

brass hammer (or you can pad a regular hammer with a rag, just don't want steel on steel cause it could hurt the internals of the CV joint)

I removed the axle nut, and with the wheel off, found that there was enough end-play in the CV joint to push the axle in about 1/4" and expose the surface between the CV joint hub and the back of the bearing. I swabbed light lube on the bearing/hub interface and the inner part of the spline making sure I coated the entire surface, re-torqued the axle nut, and the noise was gone.

NOTE: I did tap on the end of the axle with a rubber mallet once, but after that, the spline slid easily in the hub. I pressed on the end of the axle with my knee to free up both hands while I cleaned and lubed the inner hub and spline.

Some people are just removing the nut and spraying lube on the outboard end of the spline. This relies on the lube working its way the length of the spline to get to where it needs to be.

My service manual says axle torque is 118 ft-lbs.

Last edited by TEXHAWK0; 09-01-2006 at 11:10 AM.

#22

Drifting

Originally Posted by TEXHAWK0

3rd Childhood has it right. The key is getting the lube to the inboard end of the spline, but there is no need for a hammer.

I removed the axle nut, and with the wheel off, found that there was enough end-play in the CV joint to push the axle in about 1/4" and expose the surface between the CV joint hub and the back of the bearing. I swabbed light lube on the bearing/hub interface and the inner part of the spline making sure I coated the entire surface, re-torqued the axle nut, and the noise was gone.

NOTE: I did tap on the end of the axle with a rubber mallet once, but after that, the spline slid easily in the hub. I pressed on the end of the axle with my knee to free up both hands while I cleaned and lubbed the inner hub and spline.

Some people are just removing the nut and spraying lube on the outboard end of the spline. This relies on the lube working its way the length of the spline to get to where it needs to be.

My service manual says axle torque is 118 ft-lbs.

I removed the axle nut, and with the wheel off, found that there was enough end-play in the CV joint to push the axle in about 1/4" and expose the surface between the CV joint hub and the back of the bearing. I swabbed light lube on the bearing/hub interface and the inner part of the spline making sure I coated the entire surface, re-torqued the axle nut, and the noise was gone.

NOTE: I did tap on the end of the axle with a rubber mallet once, but after that, the spline slid easily in the hub. I pressed on the end of the axle with my knee to free up both hands while I cleaned and lubbed the inner hub and spline.

Some people are just removing the nut and spraying lube on the outboard end of the spline. This relies on the lube working its way the length of the spline to get to where it needs to be.

My service manual says axle torque is 118 ft-lbs.

Texhawk0,

Thanks for all the details... that helps a lot !!

Also thanks for the correct troque !!

#23

Melting Slicks

hhhmmmm, seems I can quit patting myself on the back for doing a half *** job and fixing the problem - the popping is slowly returning.

I was weary about getting under the vehicle with a cheap hydraulic jack and no jack stands. Tonight I buy hockey pucks, jack stands, good lubricant, and actually spend a little time making sure things get fixed right.

I haven't seen a tech tip on this yet, should I take pictures, post true torque specs, and all that good stuff so we can make an article out of it?

I was weary about getting under the vehicle with a cheap hydraulic jack and no jack stands. Tonight I buy hockey pucks, jack stands, good lubricant, and actually spend a little time making sure things get fixed right.

I haven't seen a tech tip on this yet, should I take pictures, post true torque specs, and all that good stuff so we can make an article out of it?

#24

Drifting

Member Since: Dec 2000

Location: Puyallup WA

Posts: 1,723

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by jbauch357

I haven't seen a tech tip on this yet, should I take pictures, post true torque specs, and all that good stuff so we can make an article out of it?

Thanks, Perry

#25

Le Mans Master

Thread Starter

Originally Posted by jbauch357

- the popping is slowly returning.

I haven't seen a tech tip on this yet, should I take pictures, post true torque specs, and all that good stuff so we can make an article out of it?

I haven't seen a tech tip on this yet, should I take pictures, post true torque specs, and all that good stuff so we can make an article out of it?

At least you know that you have found the source of the problem.

You want to coat the inside hub/bearing surface with a lubricant, but don't go too wild. You don't want so much that you end up getting lubricant slinging up on the brake rotors.

#26

Melting Slicks

So here we go with my first try at writing a tech tip. Feel free to let me know how I did, and what I can make better about the post.

Here are all of the tools that you will need: 33mm deep well 6-point socket, 19mm socket, torque wrench, wheel lock key, and some penetrating fluid (I prefer "PB Blaster" but didn't have any handy when I did this).

Pull off the center cap for your wheels and break loose the lug nuts and output shaft spindle nut. The spindle nut could be pretty tight so don't be surprised if it takes a bit of elbow grease to get it to break loose.

Jack up the rear end, support the car, spin the lug nuts off, and remove the rear wheels, you will now be looking at this.

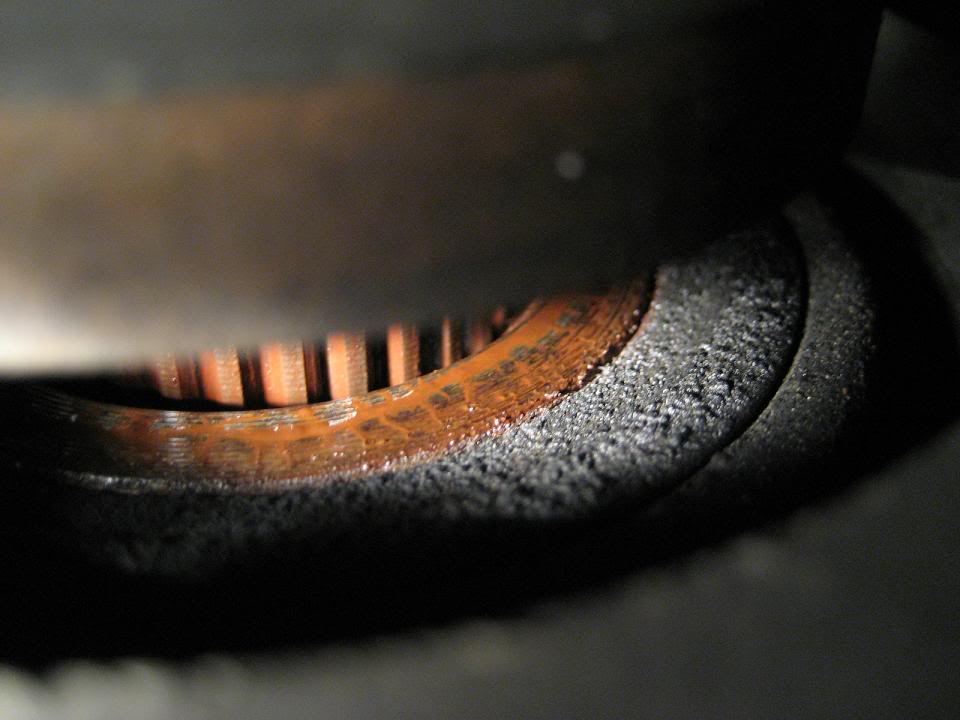

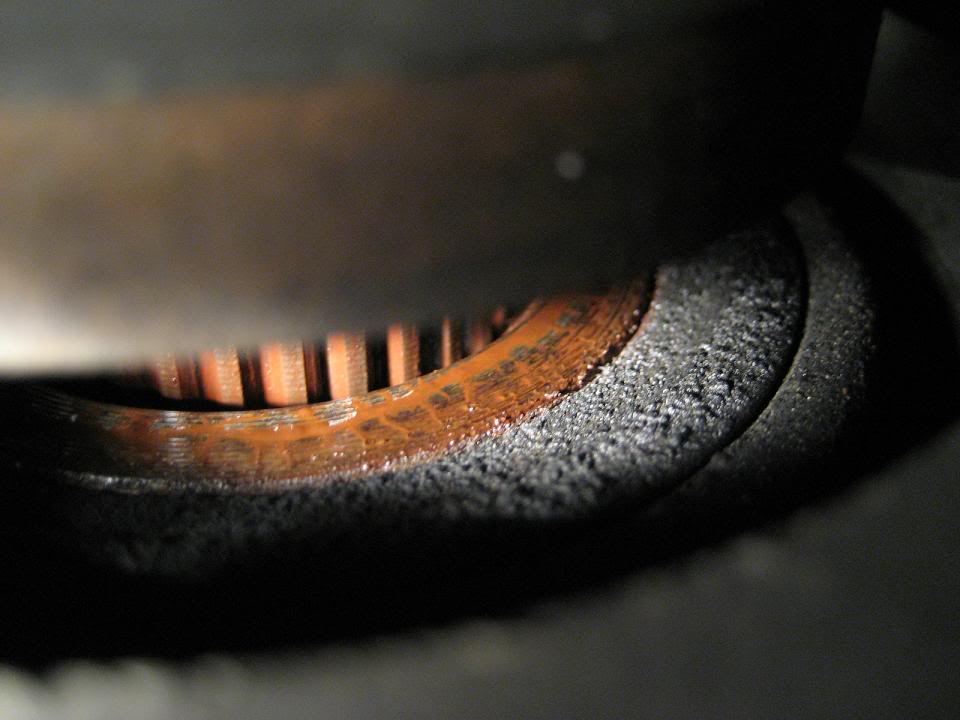

Now you don't have to worry about hitting your wheel with the torque wrench or busting your knuckes open on the wheel. Remove the spindle nut the rest of the way and take a good look at what is behind it.

Now we can see the front side of the splines that mate the output shaft and the hub assembly. Go ahead and give a little squirt of the penetrating fluid into these ridges, but not too much cause this isn't the important part. If you push in (towards the transmission) on the middle of the output shaft it should slide in to the hub. If it's rusted in place a light tap with brass hammer or mallet should break it loose so you can now move it by hand.

Now while pushing in look behind the hub assembly and look at where the drive shaft actually goes into the hub. If you look carefully you can see the splines entering the hub, and the mating surface of where the drive shaft buts against the hub. Give this area a good soaking with the penetrating fluid, both on the splines and the flat portion where output shaft meets hub (grease or oil may work better on the mating surface, but the penetrating fluid worked fine for me - for now).

When I did this all of the runoff went down the hub and then dripped off the lower ball joint, but you still want to try and keep from spraying so much that the brake rotor will get penetrating fluid on it. Work the spindle back and fourth in the hub a few times to make sure that the penetrating fluid has completely covered the splines and all contact areas and you are pretty much done.

Spin the spindle nut back on until snug, put your wheel back on and snug the lug nuts down. Drop back to the ground and torque the spindle nut to 118 ft/lbs and the lug nuts to 100 ft/lbs (make sure to torque in a star pattern so you get even torque).

Now go for a test drive and listen to the beautiful silence coming from the rear end. After driving a few miles I like to double check torque on the spindle nut, but I don't know how necessary that really is.

Hope this helps!!!

Here are all of the tools that you will need: 33mm deep well 6-point socket, 19mm socket, torque wrench, wheel lock key, and some penetrating fluid (I prefer "PB Blaster" but didn't have any handy when I did this).

Pull off the center cap for your wheels and break loose the lug nuts and output shaft spindle nut. The spindle nut could be pretty tight so don't be surprised if it takes a bit of elbow grease to get it to break loose.

Jack up the rear end, support the car, spin the lug nuts off, and remove the rear wheels, you will now be looking at this.

Now you don't have to worry about hitting your wheel with the torque wrench or busting your knuckes open on the wheel. Remove the spindle nut the rest of the way and take a good look at what is behind it.

Now we can see the front side of the splines that mate the output shaft and the hub assembly. Go ahead and give a little squirt of the penetrating fluid into these ridges, but not too much cause this isn't the important part. If you push in (towards the transmission) on the middle of the output shaft it should slide in to the hub. If it's rusted in place a light tap with brass hammer or mallet should break it loose so you can now move it by hand.

Now while pushing in look behind the hub assembly and look at where the drive shaft actually goes into the hub. If you look carefully you can see the splines entering the hub, and the mating surface of where the drive shaft buts against the hub. Give this area a good soaking with the penetrating fluid, both on the splines and the flat portion where output shaft meets hub (grease or oil may work better on the mating surface, but the penetrating fluid worked fine for me - for now).

When I did this all of the runoff went down the hub and then dripped off the lower ball joint, but you still want to try and keep from spraying so much that the brake rotor will get penetrating fluid on it. Work the spindle back and fourth in the hub a few times to make sure that the penetrating fluid has completely covered the splines and all contact areas and you are pretty much done.

Spin the spindle nut back on until snug, put your wheel back on and snug the lug nuts down. Drop back to the ground and torque the spindle nut to 118 ft/lbs and the lug nuts to 100 ft/lbs (make sure to torque in a star pattern so you get even torque).

Now go for a test drive and listen to the beautiful silence coming from the rear end. After driving a few miles I like to double check torque on the spindle nut, but I don't know how necessary that really is.

Hope this helps!!!

Last edited by jbauch357; 01-30-2007 at 12:41 PM.

#27

I would just make one other suggestion. I would lightly grease the contact faces while you are in there. The popping occurs when these faces break loose under torque. The grease will prevent the sticking part of "stick/slip" which is the real root cause of the problem.

Good job BTW. I was thinking about doing something similar but didn't really need to take mine apart. You saved me the trouble.

Good job BTW. I was thinking about doing something similar but didn't really need to take mine apart. You saved me the trouble.

#28

Le Mans Master

Thread Starter

Originally Posted by 3rd Childhood

I would just make one other suggestion. I would lightly grease the contact faces while you are in there. The popping occurs when these faces break loose under torque. The grease will prevent the sticking part of "stick/slip" which is the real root cause of the problem.

I agree. I think "penetrating oil" may be too light a lubricant to keep the problem from coming back since it is primarily used as a solvent. I stopped short of using grease, but I did swab the surfaces with oil.

#29

Melting Slicks

I noted the use of grease or oil.

Now who needs to see this to make it a tech tip, cause it seems to be a pretty common problem.

Now who needs to see this to make it a tech tip, cause it seems to be a pretty common problem.

#30

Drifting

Originally Posted by jbauch357

I noted the use of grease or oil.

Now who needs to see this to make it a tech tip, cause it seems to be a pretty common problem.

Now who needs to see this to make it a tech tip, cause it seems to be a pretty common problem.

Thanks a million. I'm ready to do mine now. Your tech tip has been very helpful. I think a moderator can post this to the tech tip library.

Clark

#31

Drifting

Great job on the write up and pics!

The only thing I might add is that the nut is not intended to be reused. If you do this procedure and the clunk comes back, it may be that the nut is loosening.

I would also agree with many that using syntheic grease will last longer than penetrating oil.

We need more of this kind of stuff on the site!

The only thing I might add is that the nut is not intended to be reused. If you do this procedure and the clunk comes back, it may be that the nut is loosening.

I would also agree with many that using syntheic grease will last longer than penetrating oil.

We need more of this kind of stuff on the site!

#32

Le Mans Master

Thread Starter

Originally Posted by FRCTony

The only thing I might add is that the nut is not intended to be reused. If you do this procedure and the clunk comes back, it may be that the nut is loosening.

What is the source of this information? I have a factory service manual and it does not mention to replace the axle nut, whereas it does say that on other fasteners, like the steering wheel nut and brake caliper mounting bolts.

#33

Burning Brakes

Member Since: Oct 2003

Location: Foresters Falls(near Ottawa) Ont

Posts: 1,106

Likes: 0

Received 1 Like

on

1 Post

This info is super!!

My 2001 speed developed this "pop" early summer. I did check the axle nut for tightness, was OK, but I'll go a step farther now and try to get some lube in there.

Here's hoping!!!

RonJ ...

My 2001 speed developed this "pop" early summer. I did check the axle nut for tightness, was OK, but I'll go a step farther now and try to get some lube in there.

Here's hoping!!!

RonJ ...

#34

Le Mans Master

Thread Starter

Originally Posted by RonJ

This info is super!!

My 2001 speed developed this "pop" early summer. I did check the axle nut for tightness, was OK, but I'll go a step farther now and try to get some lube in there.

Here's hoping!!!

RonJ ...

My 2001 speed developed this "pop" early summer. I did check the axle nut for tightness, was OK, but I'll go a step farther now and try to get some lube in there.

Here's hoping!!!

RonJ ...

I still catch myself getting ready to flinch when I put it in gear, expecting to hear the popping again, but so far, the noise has not come back. The light coating of 30 wt oil on the inner hub surface is still working. If I ever have to go in again, I would consider using a light grease instead of just oil.

#35

Burning Brakes

Member Since: Oct 2003

Location: Foresters Falls(near Ottawa) Ont

Posts: 1,106

Likes: 0

Received 1 Like

on

1 Post

Well, I pulled the axle nut off, (left the wheel on) used the long nozzle that comes with most penetrating oil spray cans and put the oil into the splines, worked it back and forth. Some more penetrating oil and then I used an air gun to blow the oil down into the splines until I saw it coming out the back side.

I then used Mobil1 10w30 (what else) ... and blew it through with the air gun.

and blew it through with the air gun.

I tightened the axle nut up to 135 ft.lbs. even though my manual says 120.

THE POPPING NOISE IS GONE!!!

I don't fully understand why the noise was there in the first place. Is the splined axle knocking back and forth in the hub? Why is the torque for the axle nut only 120 ft.lbs.? It's a big nut on a decent thread. Gees, the wheel nut wants 100 ft.lbs!! Bottom line is that you can't argue with success!!!

My thanks and a tip of the hat to the lads who posted this information!!

RonJ ...

I then used Mobil1 10w30 (what else) ...

and blew it through with the air gun.

and blew it through with the air gun.I tightened the axle nut up to 135 ft.lbs. even though my manual says 120.

THE POPPING NOISE IS GONE!!!

I don't fully understand why the noise was there in the first place. Is the splined axle knocking back and forth in the hub? Why is the torque for the axle nut only 120 ft.lbs.? It's a big nut on a decent thread. Gees, the wheel nut wants 100 ft.lbs!! Bottom line is that you can't argue with success!!!

My thanks and a tip of the hat to the lads who posted this information!!

RonJ ...

#36

Le Mans Master

Thread Starter

Originally Posted by RonJ

I then used Mobil1 10w30 (what else) ...  and blew it through with the air gun.

and blew it through with the air gun.

I tightened the axle nut up to 135 ft.lbs. even though my manual says 120.

I don't fully understand why the noise was there in the first place. Is the splined axle knocking back and forth in the hub? Why is the torque for the axle nut only 120 ft.lbs.? It's a big nut on a decent thread. Gees, the wheel nut wants 100 ft.lbs!! Bottom line is that you can't argue with success!!!

My thanks and a tip of the hat to the lads who posted this information!!

RonJ ...

and blew it through with the air gun.

and blew it through with the air gun.I tightened the axle nut up to 135 ft.lbs. even though my manual says 120.

I don't fully understand why the noise was there in the first place. Is the splined axle knocking back and forth in the hub? Why is the torque for the axle nut only 120 ft.lbs.? It's a big nut on a decent thread. Gees, the wheel nut wants 100 ft.lbs!! Bottom line is that you can't argue with success!!!

My thanks and a tip of the hat to the lads who posted this information!!

RonJ ...

Here is my original description...

Originally Posted by TEXHAWK0

3rd Childhood has it right. The key is getting the lube to the inboard end of the spline, but there is no need for a hammer.

I removed the axle nut, and with the wheel off, found that there was enough end-play in the CV joint to push the axle in about 1/4" and expose the surface between the CV joint hub and the back of the bearing. I swabbed light lube on the bearing/hub interface and the inner part of the spline making sure I coated the entire surface, re-torqued the axle nut, and the noise was gone.

NOTE: I did tap on the end of the axle with a rubber mallet once, but after that, the spline slid easily in the hub. I pressed on the end of the axle with my knee to free up both hands while I cleaned and lubed the inner hub and spline.

Some people are just removing the nut and spraying lube on the outboard end of the spline. This relies on the lube working its way the length of the spline to get to where it needs to be.

My service manual says axle torque is 118 ft-lbs.

#37

Burning Brakes

Member Since: Oct 2003

Location: Foresters Falls(near Ottawa) Ont

Posts: 1,106

Likes: 0

Received 1 Like

on

1 Post

Originally Posted by TEXHAWK0

The noise is not actually originating from the spline, it comes from the sticking and releasing of the surface between the hub and where it contacts the bearing on the inside of the hub. Sounds like you forced oil through the spline from the outside and got the oil all the way through to where the oil needs to be. I pushed the axle in about 1/4 inch and swabbed oil on the inside surface where the source of the noise is. The axle nut is only torqued to 118 ft.-lbs. because the spline is carrying the load. All the nut does is hold the hub and half-shaft together.

The nut itself is self locking, the deformed thread type of lock and is very tight on the threads once the lock is reached. I should have tried it when I was working with the nut, I wouldn't be surprised it's taking 50 ft.lbs. just to overcome the resistance of the self locking nut.

RonJ ...

#38

Le Mans Master

Thread Starter

Originally Posted by RonJ

I did put oil directly on the hub/bearing surface as well as blowing it through the splines. My point with the nut tightness, if it was tighter, perhaps the stick and release problem would be reduced with more torque on the nut. It's a big nut with a large flange to spread it's load out where it contacts the hub. I don't think the assembly will be harmed by increasing the torque on the nut.

The nut itself is self locking, the deformed thread type of lock and is very tight on the threads once the lock is reached. I should have tried it when I was working with the nut, I wouldn't be surprised it's taking 50 ft.lbs. just to overcome the resistance of the self locking nut.

RonJ ...

The nut itself is self locking, the deformed thread type of lock and is very tight on the threads once the lock is reached. I should have tried it when I was working with the nut, I wouldn't be surprised it's taking 50 ft.lbs. just to overcome the resistance of the self locking nut.

RonJ ...

#40

Le Mans Master

Member Since: Dec 2001

Location: Irvine CA

Posts: 5,761

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by gpracer1

I have developed the same click  . I will have to take it apart this weekend and force some redline synthetic grease in there. I love this forum.

. I will have to take it apart this weekend and force some redline synthetic grease in there. I love this forum.

. I will have to take it apart this weekend and force some redline synthetic grease in there. I love this forum.

. I will have to take it apart this weekend and force some redline synthetic grease in there. I love this forum.

You guys are super. The dealership would had charged me an arm and a leg for an axle replacement.