How-To repair EBCM avoiding costly repairs through ABSfixer or Fleabay

#401

Drifting

Yes there is a thread on repair the AC display you will have to search. There is also one on replacing relays in the driver door module that controls memory/windows/locks

OMG.....I've been searching for so long and found this thread and almost peed myself. I am so going to do this tomorrow morning on my 02 Vette. I've read and studying the instructions 3 times tonight at 2am in the morning and once more in the morning and I should be ready. I was ready to pull the unit and ship it off but I think I'll try this method. Does anyone know if there is a thread like this for the Climate Control module? The LED's on mine starting getting dim but still worked, now I get nothing. No lights and none of the features work. Like AC which I really need since it was 105degrees in Northern California and my dog puked in the car the other day. I pulled the unit out and resoldered the 8 little prongs on the back side, I thought I did a pretty good job put it all back together and still nothing. I checked the #27 fuse under the passenger side and its Good. Any links you can connect me to would be great!!!

Thanks guys.....this forum has saved my butt so many times!!

Thanks guys.....this forum has saved my butt so many times!!

#402

Burning Brakes

This thread is awesome. My father's 2002 was having the active service and ABS codes pop up. I disassembled the ABS, and re-soldered the 5 joints. No more codes!! Thank you.

#403

Instructor

About a month ago I did the relay replacement and all was good until today when I got the c1214 again, but this time I can't clear the code. I go the relay from Digikey and it was a pain to get in, but I got it in. I haven't had much time to look at it yet, but what should I do next to diagnose this?

#404

nvusgt, my heartfelt thanks for your procedure. I just repaired my EBCM (replaced relay) and reinstalled it and NO MORE CODE 1214 or error messages!!! Other than a few skinned knuckles and the cost of the relay (less than $5 as I recall) I'm back in business. Gotta love this forum for the wealth of information available and the willingness of the members to help one another.

Thanks again...

Thanks again...

#405

Burning Brakes

...and another success story for the thread that just keeps on giving! My 02 with 110k miles also began throwing the error message trifecta on every start whereas prior I would see it only on occasion. I'm currently in an apartment having moved to CA less than a year ago, so all my tools are in storage. However, thanks to all the info in this thread, I was able to gather up all tools I thought I'd need and did the repair in my parking garage.

A couple items to add -

I had both T20 screwdriver as well as a T20 bit that attached to a small ratchet. Screwdriver was pretty much all I needed as the screws weren't super tight.

An extra set of hands helps, mostly in my case to pull the power steering hose off to the side for better screwdriver approach.

Once out, I used a screw that looks pretty much in the pics. In my case, I used 4 identical screws since I'd start stripping the Phillips head using a drill once the screw bottomed out. 4th screw was a charm as it finally broke the seal and allowed a flathead pry. Lesson here is don't give up, it eventually gives.

Definitely undo passenger side of radiator hose and bend out of way.

In my case, it looks like just one of the solder tabs on the relay lost its connection. I still hit all 5 tabs just in case with my iron. Did a quick, two screw reattach along with connectors and fired it up. Bingo! The display is now clear!

A couple items to add -

I had both T20 screwdriver as well as a T20 bit that attached to a small ratchet. Screwdriver was pretty much all I needed as the screws weren't super tight.

An extra set of hands helps, mostly in my case to pull the power steering hose off to the side for better screwdriver approach.

Once out, I used a screw that looks pretty much in the pics. In my case, I used 4 identical screws since I'd start stripping the Phillips head using a drill once the screw bottomed out. 4th screw was a charm as it finally broke the seal and allowed a flathead pry. Lesson here is don't give up, it eventually gives.

Definitely undo passenger side of radiator hose and bend out of way.

In my case, it looks like just one of the solder tabs on the relay lost its connection. I still hit all 5 tabs just in case with my iron. Did a quick, two screw reattach along with connectors and fired it up. Bingo! The display is now clear!

#407

Burning Brakes

Figured id add my two cents in. I just removed mine with the intent to send to ABS Fixer. But with the help of this threaI figured what the hell lets give it a whirl. 45 mins to take it out 30 mins to flux and solder 30 mins to put it back in and BOOM codes are gone.

FYI If you have big hands and arms be prepared to get cut up

FYI If you have big hands and arms be prepared to get cut up

#408

Melting Slicks

#409

Drifting

Thread Starter

You can indeed drive without the unit, but just be aware that you will obviously not have ABS/Traction Control (plus you may want to cover the whole where the box went inside the car). So with that said driving without one is at your own risk and I our anyone else cannot be held responsible for any accidents/mishaps.

#410

Instructor

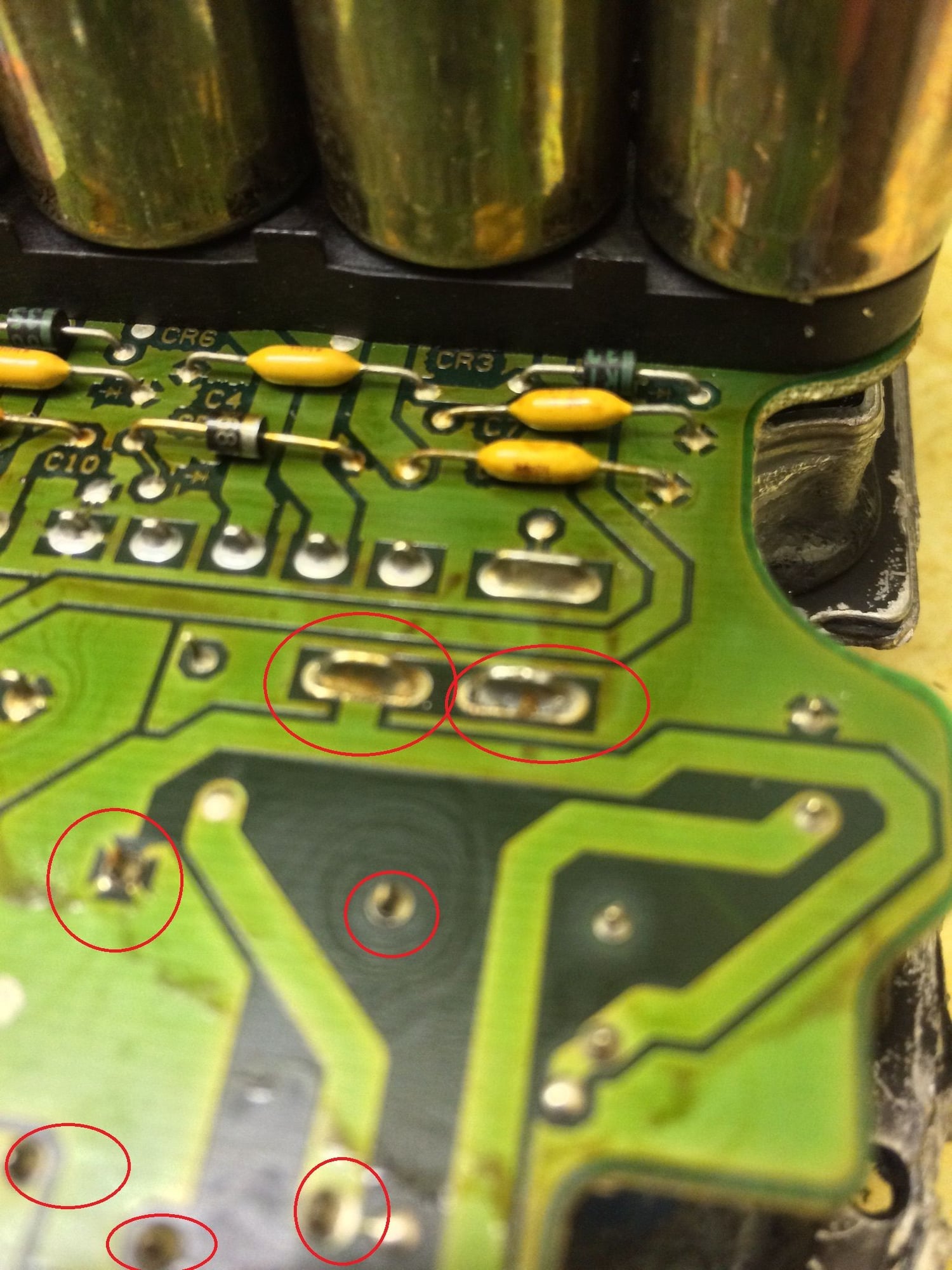

looking at the pc board of this, it seems like some of the posts of the relay are not used for anything. the darker green sections do not have copper under them to make a circuit. anyone know about this? it seems like only 3 posts are soldered to copper cladding on the board. reason i mention this is that i resoldered mine a few years ago and started having trouble again recently. i am just trying to understand the circuit to troubleshoot my ebcm before i trash it and buy a new one.

thanks.

thanks.

#411

Instructor

looking at the pc board of this, it seems like some of the posts of the relay are not used for anything. the darker green sections do not have copper under them to make a circuit. anyone know about this? it seems like only 3 posts are soldered to copper cladding on the board. reason i mention this is that i resoldered mine a few years ago and started having trouble again recently. i am just trying to understand the circuit to troubleshoot my ebcm before i trash it and buy a new one.

thanks.

thanks.

#412

Instructor

i did replace the relay and no luck. i should have mentioned that. i also have checked the grounds. i replaced some of the splice packs by soldering the wires together and crimping on a copper grounding lug. also did the ignition switch check on the fuse block under the hood. thanks.

#415

Intermediate

Had to re solder all those connections, under magnifying glass you can see the cracks. Removing this thing is a pain in the ***, tore my hands apart, many curse words later I saved $$$, I guess it was worth it.

#416

I would like to say thanks this diy fixed my issue ,I've noticed a lot of people having issue with getting it apart

1st think you need to get all of the silicon out of the whole ,The way i did that was with a 5/32 drill bit then blow it clean might need to run the drill in 2 or 3 times

2nd was to tap it with 5 mm x .90 tap you can buy from sears or snap on

3rd go to a hardware store and buy a 2 inch bolt 5mm x.90 thread pitch

Make sure to tap in so far then pull tap out blow off chips if not you could break the tap off

Apply a bit of wd 40 then when you use the bolt use only a wrench dont force it,also take the bolt in then back it out if it gets hard

Thank

1st think you need to get all of the silicon out of the whole ,The way i did that was with a 5/32 drill bit then blow it clean might need to run the drill in 2 or 3 times

2nd was to tap it with 5 mm x .90 tap you can buy from sears or snap on

3rd go to a hardware store and buy a 2 inch bolt 5mm x.90 thread pitch

Make sure to tap in so far then pull tap out blow off chips if not you could break the tap off

Apply a bit of wd 40 then when you use the bolt use only a wrench dont force it,also take the bolt in then back it out if it gets hard

Thank

#417

Is there anyway to test the relay once you have the EBCM out of the car and taken apart?

I have never soldered anything befor and kind of scared to try to attempt this on my own.

Just out of curiosity has anyone here ( I'm sure there is) that has used ABSFIXER?

What is the gereral consensus of them? Good / Bad?

Thanks, JKent

I have never soldered anything befor and kind of scared to try to attempt this on my own.

Just out of curiosity has anyone here ( I'm sure there is) that has used ABSFIXER?

What is the gereral consensus of them? Good / Bad?

Thanks, JKent

#418

Corvette Cowboy

If it were me I would send it in look at this way if you mess it up you need to buy another one just like it then it goes out start all over I have sent 5 of them for people in our club got everyone back good as new and work on cars I weld solder. Just my 02 they do great work with a great turnaround time and you said it you don't know how to solder so their you go reason #1

Dale

Dale

#419

Burning Brakes

I followed the detailed instructions provided by NVUSGT, Bill Curlee and others and successfully repaired my balky EBCM.

Like others, I found that a faulty relay solder joint was the culprit that was triggering warning lights and the C-1214 fault code.

Here's something I will add to NVUSGT's write up, specifically his comment that reads:

"Now in order to remove the case I followed these steps:

1. remove 4 x screws

2. remove silicon from that hole on the back lower corner of the EBCM.

3. use a 2BA (or similar) 'thread tap' to cut a thread in that hole

4. screw matching thread screw/bolt into hole, (it misses pcb inside) until it touches cover plate (screw/bolt needs to be 3" long max).

5. carry on winding the screw in until it starts pushing the cover plate away enough to break that gasket seal and allow space to insert those flat blade screwdrivers and work around the remainder. (Thank You JerseyC5)."

In my case, I used a #8-32 thread tap (bought at Home Depot) to successfully cut a thread in the hole on the back corner of the EBCM. After opening the box with a 2" #8-32 stainless steel screw, I discovered why employing a thread tap was necessary. A combination of silicon and, I think, box wall material were obstructing the screw's path to the plate, and nothing short of a thread tap could have cleared up that path.

FYI, I used a stainless steel screw to reduce the possibility that it would snap off in the EBCM box...a problem noted by an earlier poster to this thread.

As a final note, my C5 "ate" one of the six T20 screws that afix the EBCM to the Brake Control Module...the screw fell out while I was attempting to thread it into a hole in the EBCM and I could never find it. The local Chevy dealership didn't have these special torx screws in stock (nor could they find any at any other area GM dealership or at the zone warehouse that services the DFW area), so I ended up ordering a couple of them...$4.00 each with delivery promised in three days. Next time, I'll drape a drop cloth directly underneath the EBCM (or any other underhood component I'm working on) to hopefully catch any other screws that I might drop.

So...after considering my refinements/alterations to others' excellent instructions, I encourage the owners of other C-1214-afflicted C5s to take on this EBCM fix.

The Lizzard

Like others, I found that a faulty relay solder joint was the culprit that was triggering warning lights and the C-1214 fault code.

Here's something I will add to NVUSGT's write up, specifically his comment that reads:

"Now in order to remove the case I followed these steps:

1. remove 4 x screws

2. remove silicon from that hole on the back lower corner of the EBCM.

3. use a 2BA (or similar) 'thread tap' to cut a thread in that hole

4. screw matching thread screw/bolt into hole, (it misses pcb inside) until it touches cover plate (screw/bolt needs to be 3" long max).

5. carry on winding the screw in until it starts pushing the cover plate away enough to break that gasket seal and allow space to insert those flat blade screwdrivers and work around the remainder. (Thank You JerseyC5)."

In my case, I used a #8-32 thread tap (bought at Home Depot) to successfully cut a thread in the hole on the back corner of the EBCM. After opening the box with a 2" #8-32 stainless steel screw, I discovered why employing a thread tap was necessary. A combination of silicon and, I think, box wall material were obstructing the screw's path to the plate, and nothing short of a thread tap could have cleared up that path.

FYI, I used a stainless steel screw to reduce the possibility that it would snap off in the EBCM box...a problem noted by an earlier poster to this thread.

As a final note, my C5 "ate" one of the six T20 screws that afix the EBCM to the Brake Control Module...the screw fell out while I was attempting to thread it into a hole in the EBCM and I could never find it. The local Chevy dealership didn't have these special torx screws in stock (nor could they find any at any other area GM dealership or at the zone warehouse that services the DFW area), so I ended up ordering a couple of them...$4.00 each with delivery promised in three days. Next time, I'll drape a drop cloth directly underneath the EBCM (or any other underhood component I'm working on) to hopefully catch any other screws that I might drop.

So...after considering my refinements/alterations to others' excellent instructions, I encourage the owners of other C-1214-afflicted C5s to take on this EBCM fix.

The Lizzard

#420

Burning Brakes

Is there anyway to test the relay once you have the EBCM out of the car and taken apart?

I have never soldered anything befor and kind of scared to try to attempt this on my own.

Just out of curiosity has anyone here ( I'm sure there is) that has used ABSFIXER?

What is the gereral consensus of them? Good / Bad?

Thanks, JKent

I have never soldered anything befor and kind of scared to try to attempt this on my own.

Just out of curiosity has anyone here ( I'm sure there is) that has used ABSFIXER?

What is the gereral consensus of them? Good / Bad?

Thanks, JKent

Simply taking the EBCM apart and examining the relay's solder joints will, in all likelihood identify the source of your issue (it did for me, and apparently for most others). Furthermore, repairing the defective solder joint is a straightforward task (although I urge you to use a soldering iron with a long needle point and very thin solder - this is, after all, very "precise" work).

I repaired the defective solder joint, then reassembled the EBCM (without screwing it back together) and fitted the EBCM onto the Brake Control Module (again, without screwing these two components together). I then started the car's engine...I immediately noted that the traction control idiot lights were no longer lit. Then I shut off the engine and pulled the DIC codes...this confirmed that the dreaded C-1214 fault code was now recorded only as an H (historical) and no longer a C (current) problem.

Having done that, I then reassembled everything as per the NVUSGT/Curlee, et al instructions. Everything was good.

Bottom line here...a defective relay is apparently an unlikely scenario. So go ahead and open everything up...you've nothing to lose, and hopefully a lot to gain/save.

Feel free to PM me if you want further conversation.

The Lizzard