FINALLY got around to the engine upgrades!

#41

Tech Contributor

Member Since: Dec 1999

Location: Anthony TX

Posts: 32,736

Received 2,180 Likes

on

1,583 Posts

CI 6,7,8,9,11 Vet

St. Jude Donor '08

When you stated that you drove throught the water,,,,, I got that SICK feeling you mentioned.

Then when you stated that the engine JUST STOPPED!

You didn't need to say anything else..

If your going to build it,,,,,, build it the correct way and the WAY YOU WANT IT!

Don't scrimp on the rotating assy! Get a good aftermarket crank, some nice pistons, use some ARP Bolts and you will be able to spin it up a little higher more reliability!

Make sure that you have the block machined for a timing chain dampener if it doesn't come machined.

If my LS6 ever dies,, it WILL have a bigger displacement engine!!! YES SIR!!

BUD,,, I really feel bad for you. When my starter boss broke off, (due to coolant leaking in #1 Cylinder over night) I had the same SICK FEELING. I was able to reweld the damaged area as good as new!

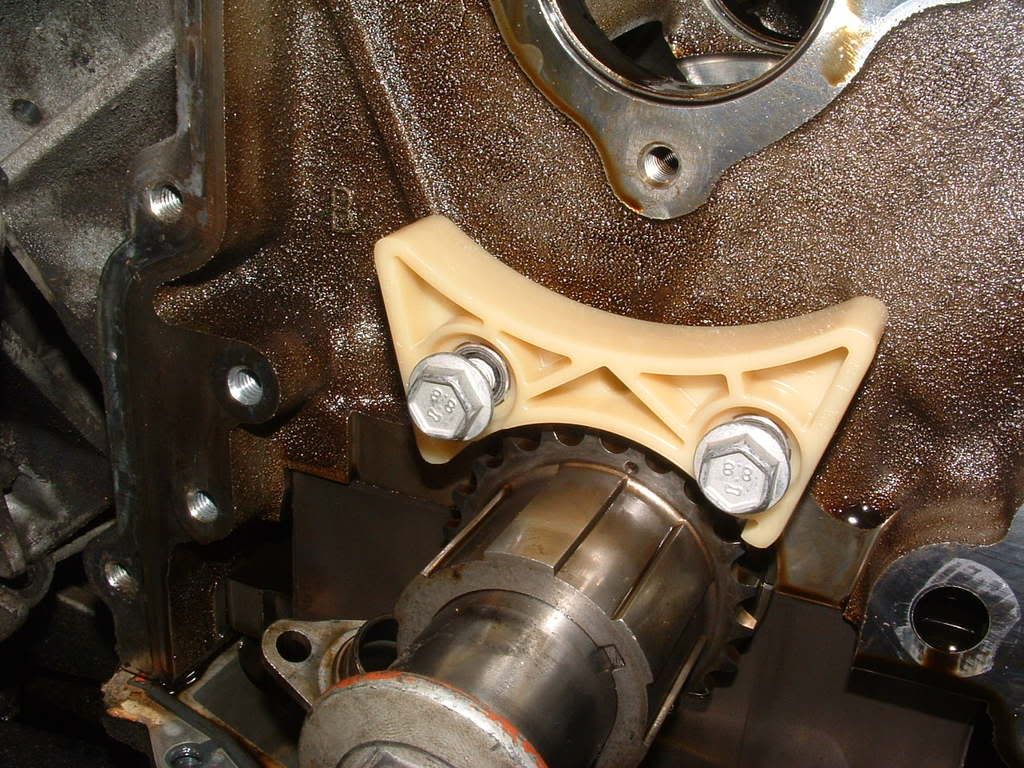

C5 LS engine Timing Chain Dampener:

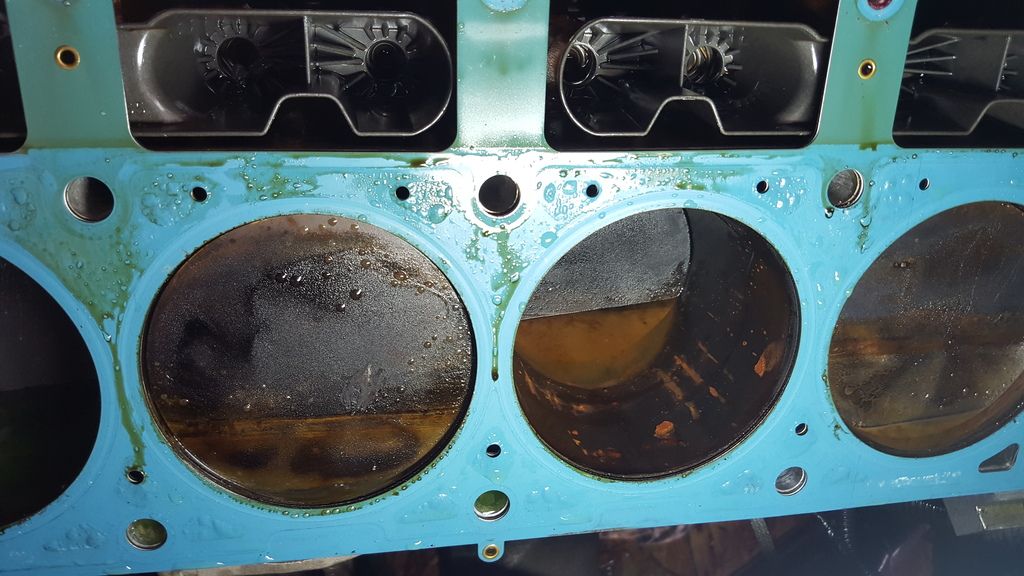

Broken Starter Boss:

Coolant in #1 Cylinder (due to a flaw in the head casting)

Bill

Then when you stated that the engine JUST STOPPED!

You didn't need to say anything else..

If your going to build it,,,,,, build it the correct way and the WAY YOU WANT IT!

Don't scrimp on the rotating assy! Get a good aftermarket crank, some nice pistons, use some ARP Bolts and you will be able to spin it up a little higher more reliability!

Make sure that you have the block machined for a timing chain dampener if it doesn't come machined.

If my LS6 ever dies,, it WILL have a bigger displacement engine!!! YES SIR!!

BUD,,, I really feel bad for you. When my starter boss broke off, (due to coolant leaking in #1 Cylinder over night) I had the same SICK FEELING. I was able to reweld the damaged area as good as new!

C5 LS engine Timing Chain Dampener:

Broken Starter Boss:

Coolant in #1 Cylinder (due to a flaw in the head casting)

Bill

#42

Safety Car

Look for a good short and put some of your parts on it ? Need to see what kind of mess you got inside and what is good and what is bad. I ran a LT-4 under water once the hole front of the motor was under water was blowing water out of the mufflers like pump never stopped running it's like dropping a a jelly sandwich sometime they land jelly side up and sometimes not.. Short block if you still got some good parts to install on it ..

#43

Pro

Thread Starter

Hi Bill,

Thanks for your recommendations.

I just got off of the phone with Caleb from Jeg's. He was very courteous and seemed to be knowledgeable, was able to answer my list of questions.

He indicated that it does come prepped for a TC damper.

He said that it will ship in a 3x5x3' crate, and will weigh +/- 425 lbs.

We talked about break-in procedures and oil, and referred me to the Blueprint website.

Jeg's will allow me to substitute head studs for the included head bolts for an additional cost, and that because Jeg's builds the kits to suit, I could add or substitute other parts, as well.

I spent the entire night researching and comparing options. Clapped out LS1 /6 pull-outs are expensive...to the point of costing close to, and in many cases MORE than this forged bottom end short block will. I considered that if I bought a pull-out engine many come as "complete" meaning that they come with EVERYTHING as removed from the car.....all accessories, heads, intake, exhaust, harness, computer, etc. I thought about maybe recouping some of the cost by selling the parts that I wouldn't re-use (which is everything outside of the short block) but being where I am geographically makes shipping anything an expensive proposition....so much so that I couldn't sell the parts at a price that would be reasonable for someone to pay, all because of the shipping expense.

So, I'd have another pile of crap that just sits on the shelves.

So, new short block it is!

I'll keep you guys informed as I tear into the engine.

Thanks for all of your comments so far.

Regards,

KoreaJon

Thanks for your recommendations.

I just got off of the phone with Caleb from Jeg's. He was very courteous and seemed to be knowledgeable, was able to answer my list of questions.

He indicated that it does come prepped for a TC damper.

He said that it will ship in a 3x5x3' crate, and will weigh +/- 425 lbs.

We talked about break-in procedures and oil, and referred me to the Blueprint website.

Jeg's will allow me to substitute head studs for the included head bolts for an additional cost, and that because Jeg's builds the kits to suit, I could add or substitute other parts, as well.

I spent the entire night researching and comparing options. Clapped out LS1 /6 pull-outs are expensive...to the point of costing close to, and in many cases MORE than this forged bottom end short block will. I considered that if I bought a pull-out engine many come as "complete" meaning that they come with EVERYTHING as removed from the car.....all accessories, heads, intake, exhaust, harness, computer, etc. I thought about maybe recouping some of the cost by selling the parts that I wouldn't re-use (which is everything outside of the short block) but being where I am geographically makes shipping anything an expensive proposition....so much so that I couldn't sell the parts at a price that would be reasonable for someone to pay, all because of the shipping expense.

So, I'd have another pile of crap that just sits on the shelves.

So, new short block it is!

I'll keep you guys informed as I tear into the engine.

Thanks for all of your comments so far.

Regards,

KoreaJon

When you stated that you drove throught the water,,,,, I got that SICK feeling you mentioned.

Then when you stated that the engine JUST STOPPED!

You didn't need to say anything else..

If your going to build it,,,,,, build it the correct way and the WAY YOU WANT IT!

Don't scrimp on the rotating assy! Get a good aftermarket crank, some nice pistons, use some ARP Bolts and you will be able to spin it up a little higher more reliability!

Make sure that you have the block machined for a timing chain dampener if it doesn't come machined.

If my LS6 ever dies,, it WILL have a bigger displacement engine!!! YES SIR!!

BUD,,, I really feel bad for you. When my starter boss broke off, (due to coolant leaking in #1 Cylinder over night) I had the same SICK FEELING. I was able to reweld the damaged area as good as new!

Bill

Then when you stated that the engine JUST STOPPED!

You didn't need to say anything else..

If your going to build it,,,,,, build it the correct way and the WAY YOU WANT IT!

Don't scrimp on the rotating assy! Get a good aftermarket crank, some nice pistons, use some ARP Bolts and you will be able to spin it up a little higher more reliability!

Make sure that you have the block machined for a timing chain dampener if it doesn't come machined.

If my LS6 ever dies,, it WILL have a bigger displacement engine!!! YES SIR!!

BUD,,, I really feel bad for you. When my starter boss broke off, (due to coolant leaking in #1 Cylinder over night) I had the same SICK FEELING. I was able to reweld the damaged area as good as new!

Bill

#44

Pro

Thread Starter

Well, as the title says, it got worse.

My buddy, the Pied Piper in the Corvette I followed through the water came over this morning to help me tear into the engine....I think he did it because he feels guilty for leading me through the water. I really, really wish that I could blame it on him!!

Anyhow, we started at 10 AM, and here is the first sign of how much water got into the engine:

We had the intake off in pretty short order, and here's a video of how much water came out of it:

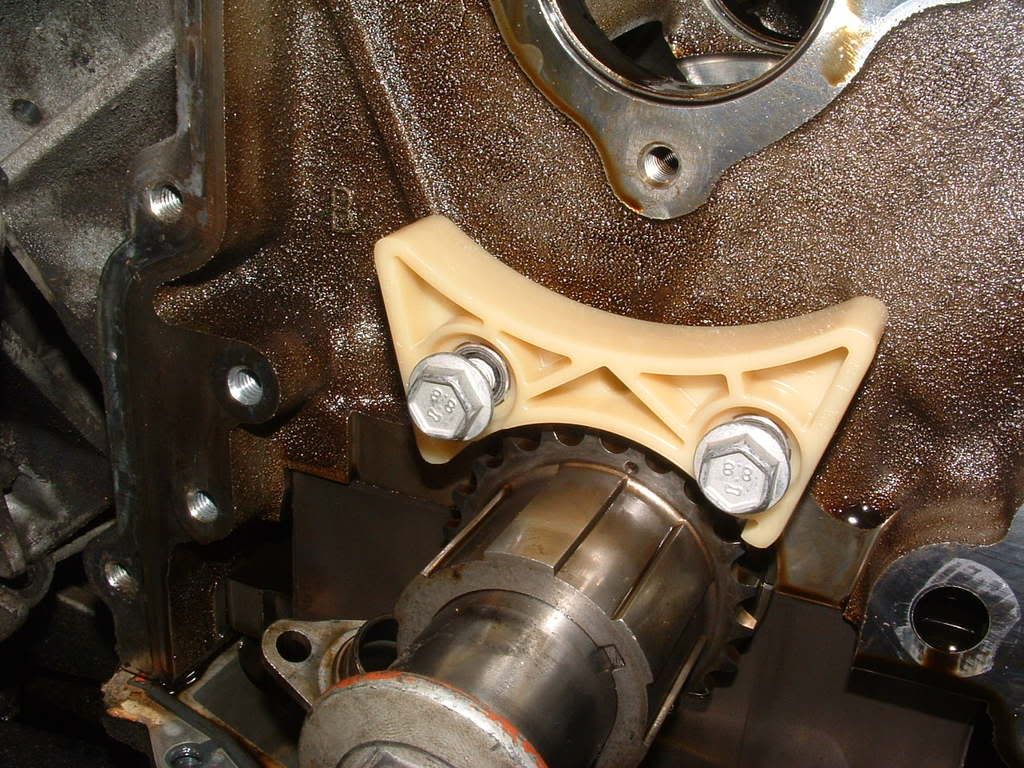

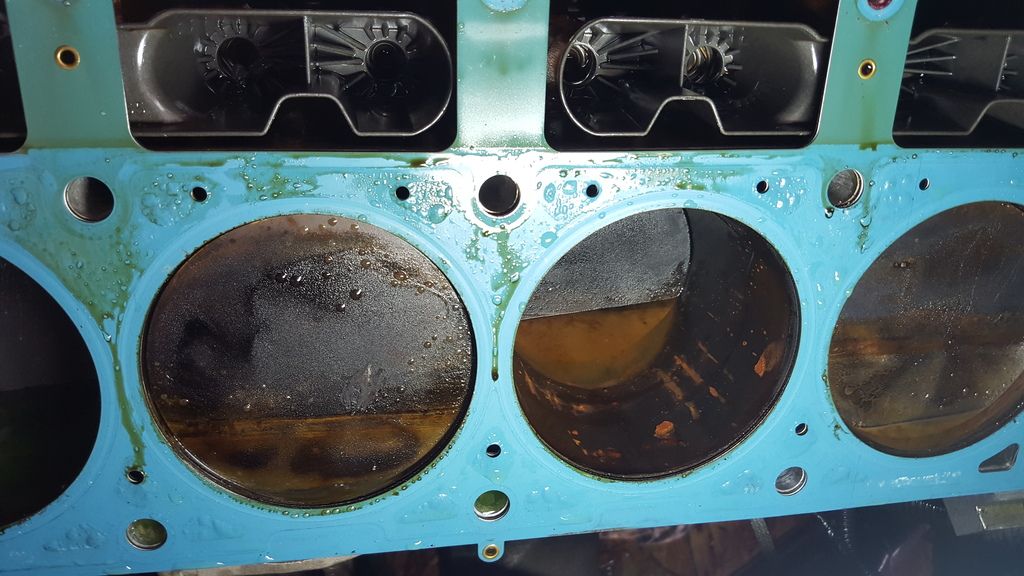

We proceeded to get the heads off, and here you can see which cylinders were actually holding water by the surface rust that formed in the 1 1/2 days since the mishap:

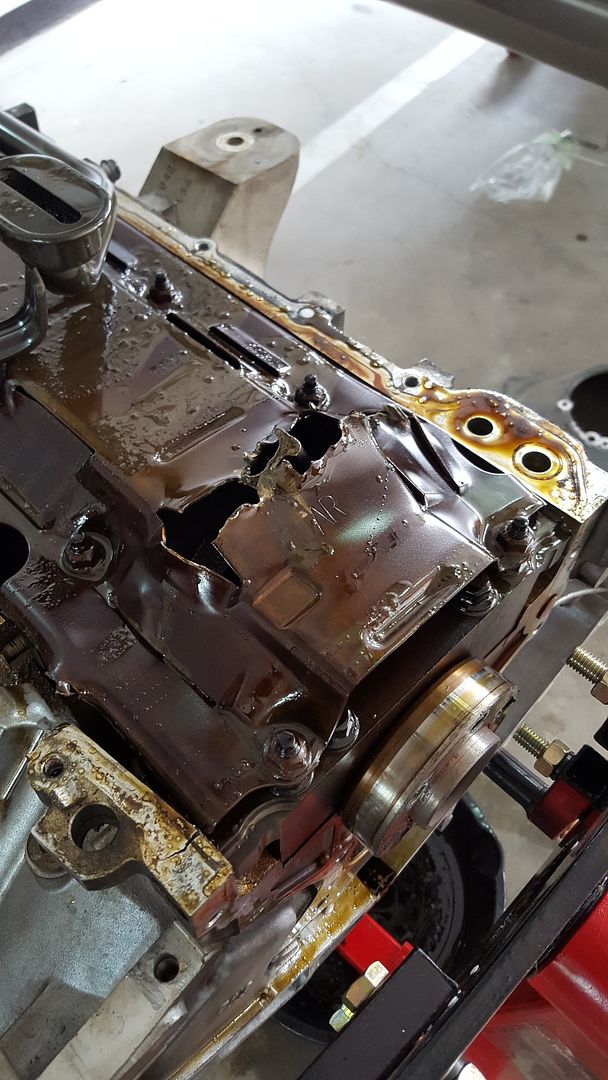

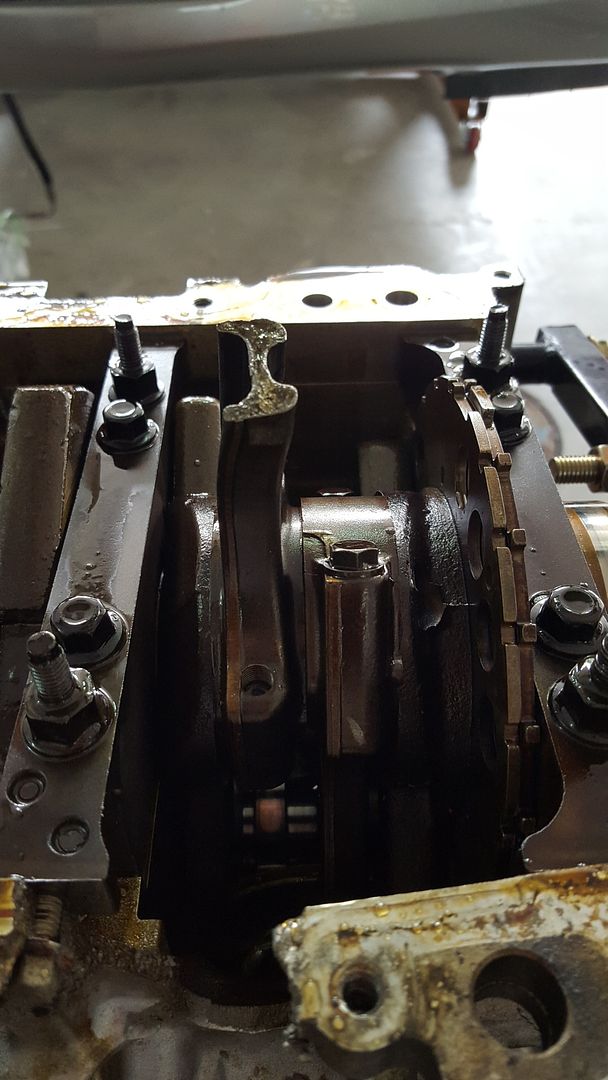

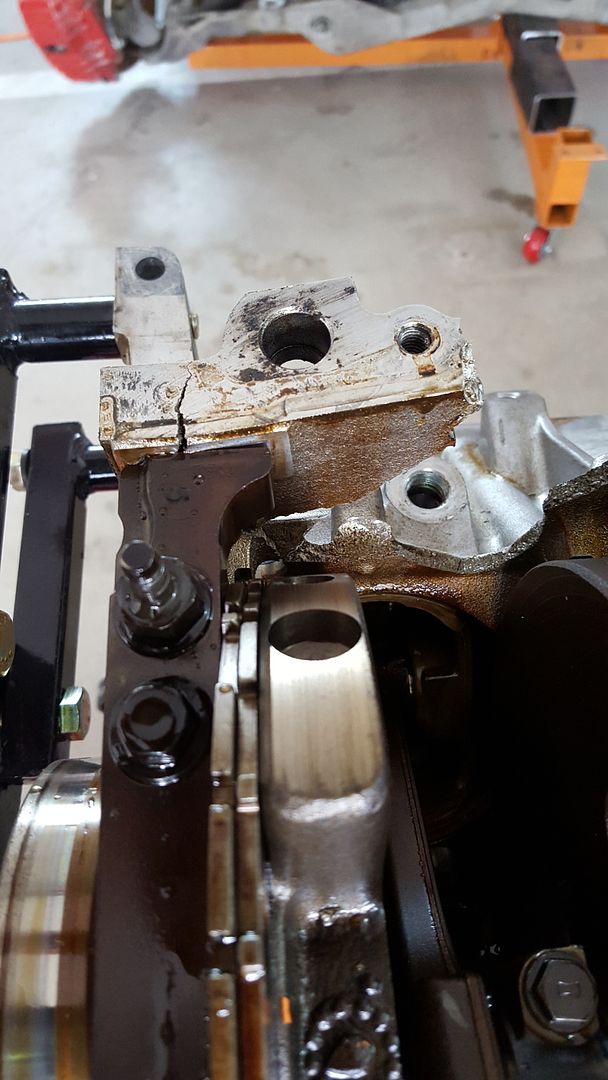

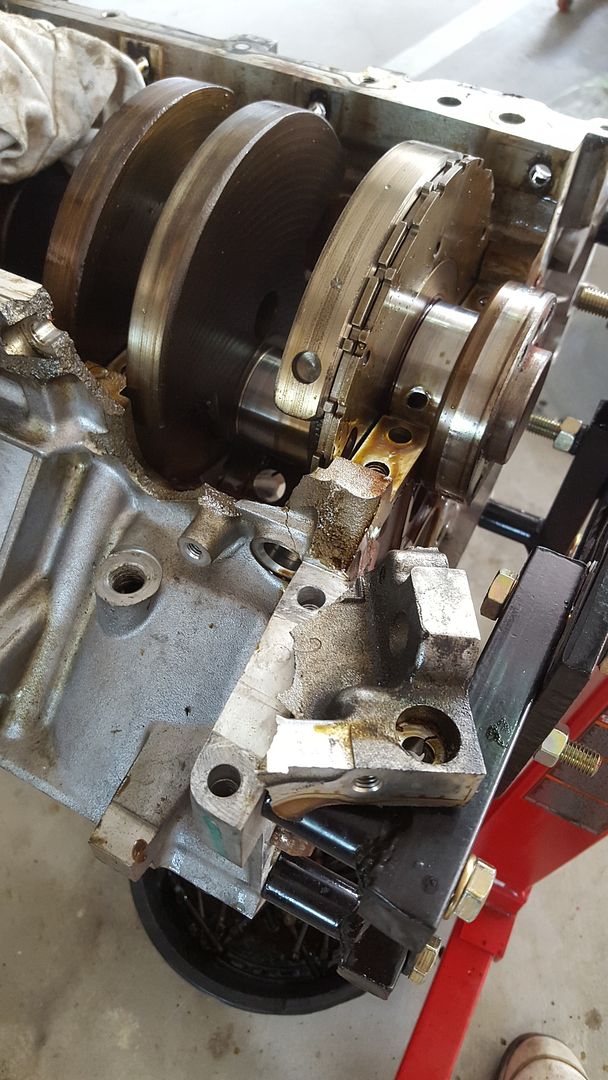

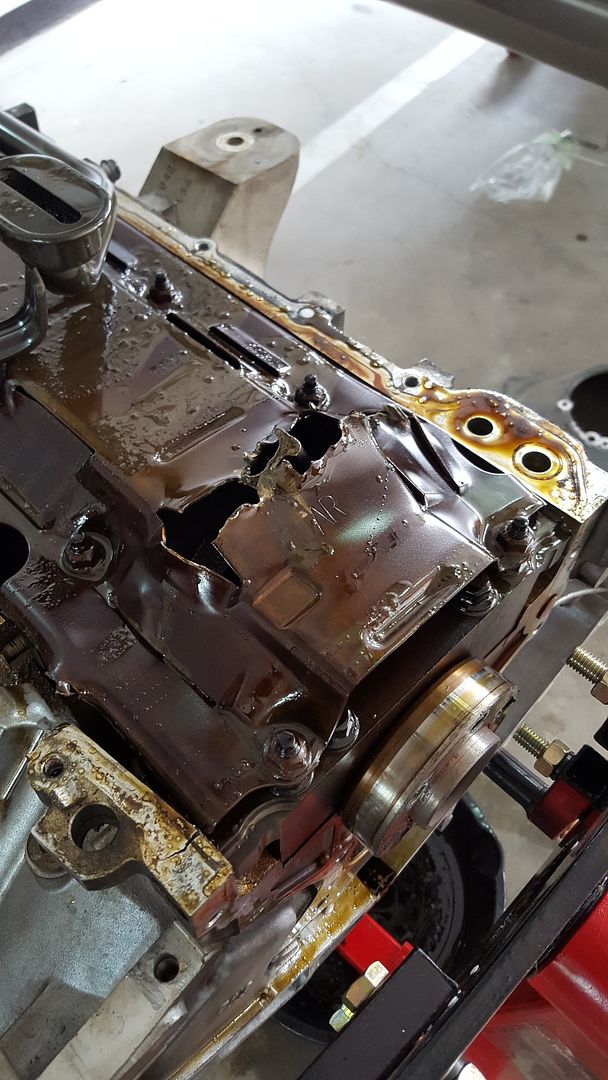

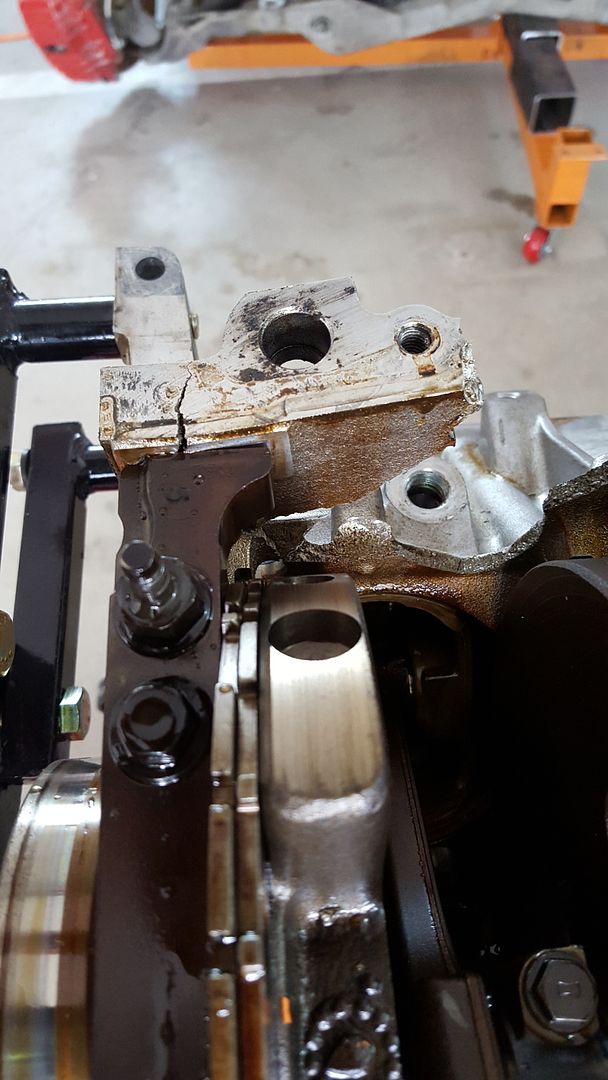

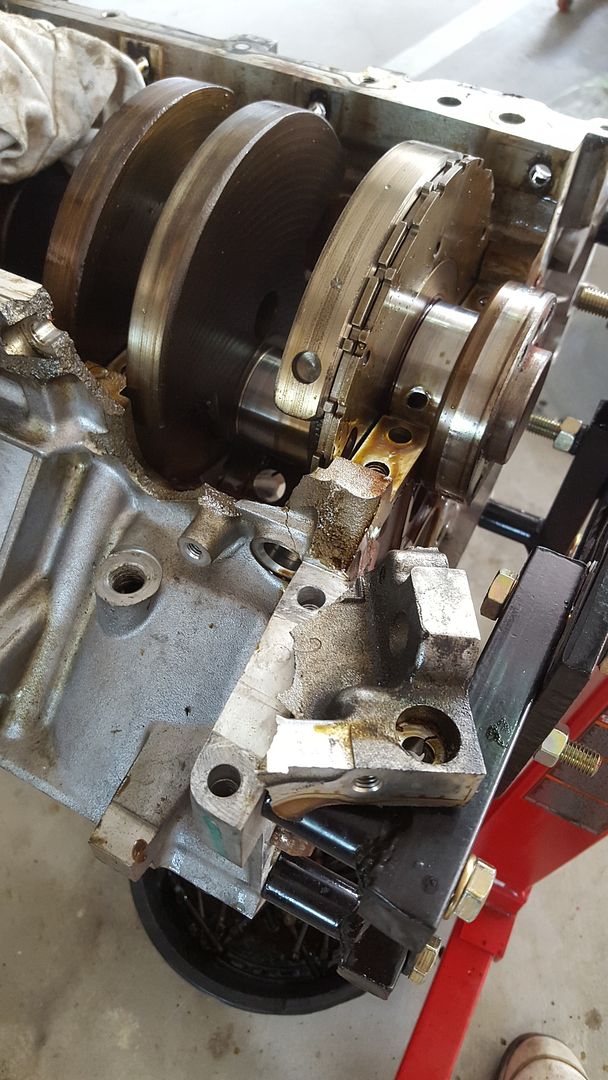

And here are some pics of just how bad the damage to the block is. The #7 rod exploded the side of the block, taking out the top rail of the oil pan in the process!

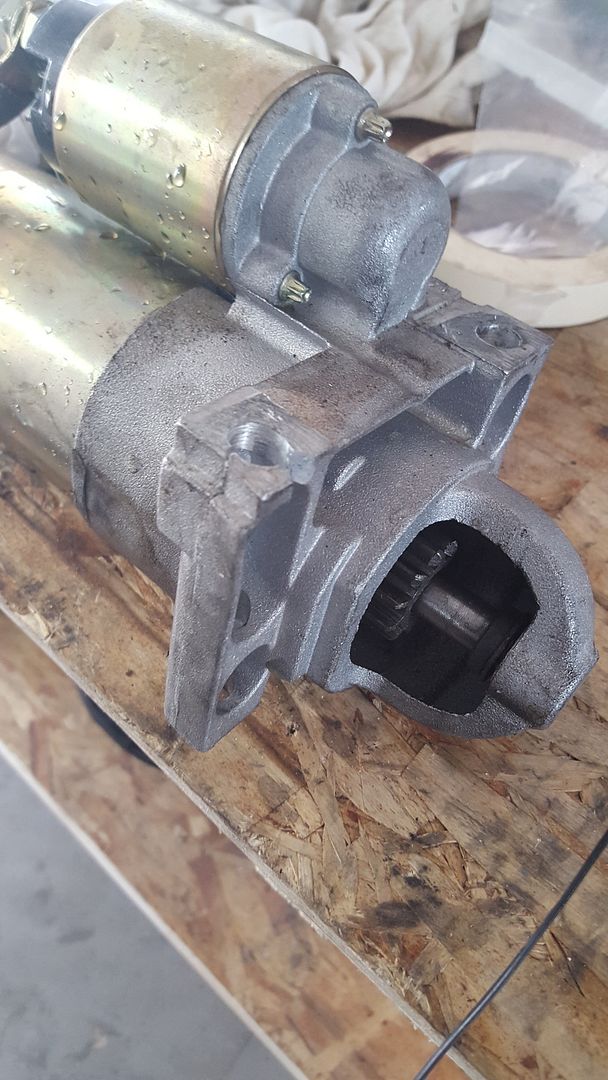

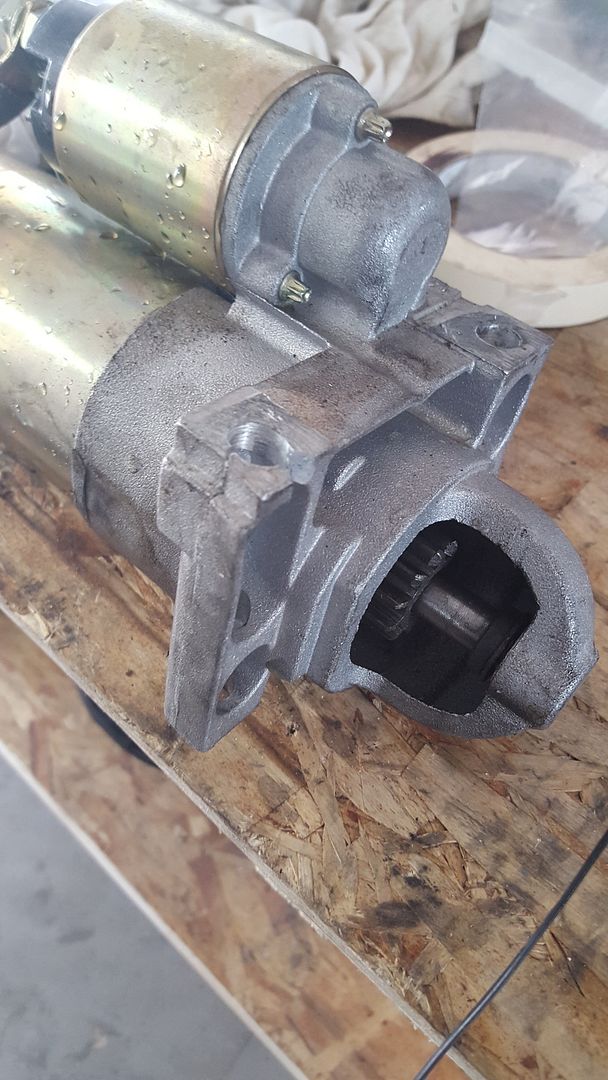

And to add insult to injury, took out my new starter too!

At least the ring gear is unscathed, and the cam is unharmed, as well. I've got the engine almost ready to pull. I still have to remove the X pipe and tunnel plate, disconnect the driveshaft from the bellhousing, but it's real close to being ready. Ill have plenty of time to get it prepped before my new engine ships in September.

I'll keep y'all updated on the progress. Meanwhile, if one of you has a batwing oil pan laying around gathering dust, please consider making me a good deal for it!

Regards,

KoreaJon

My buddy, the Pied Piper in the Corvette I followed through the water came over this morning to help me tear into the engine....I think he did it because he feels guilty for leading me through the water. I really, really wish that I could blame it on him!!

Anyhow, we started at 10 AM, and here is the first sign of how much water got into the engine:

We had the intake off in pretty short order, and here's a video of how much water came out of it:

We proceeded to get the heads off, and here you can see which cylinders were actually holding water by the surface rust that formed in the 1 1/2 days since the mishap:

And here are some pics of just how bad the damage to the block is. The #7 rod exploded the side of the block, taking out the top rail of the oil pan in the process!

And to add insult to injury, took out my new starter too!

At least the ring gear is unscathed, and the cam is unharmed, as well. I've got the engine almost ready to pull. I still have to remove the X pipe and tunnel plate, disconnect the driveshaft from the bellhousing, but it's real close to being ready. Ill have plenty of time to get it prepped before my new engine ships in September.

I'll keep y'all updated on the progress. Meanwhile, if one of you has a batwing oil pan laying around gathering dust, please consider making me a good deal for it!

Regards,

KoreaJon

#45

Well at least you DESTROYED the block lol. Definitely didn't go easy on it.

Just imagine your car running again with a new, badass forged bottom end in it. That will make you happy

Just imagine your car running again with a new, badass forged bottom end in it. That will make you happy

#46

Safety Car

Hi Bill,

Thanks for your recommendations.

I just got off of the phone with Caleb from Jeg's. He was very courteous and seemed to be knowledgeable, was able to answer my list of questions.

He indicated that it does come prepped for a TC damper.

He said that it will ship in a 3x5x3' crate, and will weigh +/- 425 lbs.

We talked about break-in procedures and oil, and referred me to the Blueprint website.

Jeg's will allow me to substitute head studs for the included head bolts for an additional cost, and that because Jeg's builds the kits to suit, I could add or substitute other parts, as well.

I spent the entire night researching and comparing options. Clapped out LS1 /6 pull-outs are expensive...to the point of costing close to, and in many cases MORE than this forged bottom end short block will. I considered that if I bought a pull-out engine many come as "complete" meaning that they come with EVERYTHING as removed from the car.....all accessories, heads, intake, exhaust, harness, computer, etc. I thought about maybe recouping some of the cost by selling the parts that I wouldn't re-use (which is everything outside of the short block) but being where I am geographically makes shipping anything an expensive proposition....so much so that I couldn't sell the parts at a price that would be reasonable for someone to pay, all because of the shipping expense.

So, I'd have another pile of crap that just sits on the shelves.

So, new short block it is!

I'll keep you guys informed as I tear into the engine.

Thanks for all of your comments so far.

Regards,

KoreaJon

Thanks for your recommendations.

I just got off of the phone with Caleb from Jeg's. He was very courteous and seemed to be knowledgeable, was able to answer my list of questions.

He indicated that it does come prepped for a TC damper.

He said that it will ship in a 3x5x3' crate, and will weigh +/- 425 lbs.

We talked about break-in procedures and oil, and referred me to the Blueprint website.

Jeg's will allow me to substitute head studs for the included head bolts for an additional cost, and that because Jeg's builds the kits to suit, I could add or substitute other parts, as well.

I spent the entire night researching and comparing options. Clapped out LS1 /6 pull-outs are expensive...to the point of costing close to, and in many cases MORE than this forged bottom end short block will. I considered that if I bought a pull-out engine many come as "complete" meaning that they come with EVERYTHING as removed from the car.....all accessories, heads, intake, exhaust, harness, computer, etc. I thought about maybe recouping some of the cost by selling the parts that I wouldn't re-use (which is everything outside of the short block) but being where I am geographically makes shipping anything an expensive proposition....so much so that I couldn't sell the parts at a price that would be reasonable for someone to pay, all because of the shipping expense.

So, I'd have another pile of crap that just sits on the shelves.

So, new short block it is!

I'll keep you guys informed as I tear into the engine.

Thanks for all of your comments so far.

Regards,

KoreaJon

#47

Pro

Thread Starter

Maybe a set of inflatable pontoons, too?!!

Maybe a set of inflatable pontoons, too?!!

[/QUOTE].. OK got to say it STAY out of WATER.. I am using your install to install a new cam top Etc. end in 04 Z.. Good luck..[/QUOTE]

Yep, I deserve that!

Right now I'm prepping to place my order for parts. I'm gonna go ahead and do the 25% UD pulley and find a new batwing. The rod did what looks to be some slight damaged to the rail of the oil pan where it meets the block. I might be able to straighten and dress the area so that it would seal adequately, but I just don't want to get it apart and find out otherwise.....or worse, do the repair and worry about it forever.

Guys, gimmee some feedback before I push the "Pay Now" button....

1. What other things should I be looking at while I'm in here? (I rebuilt the torque tube with new bearings and guibo's last year)

2. The forged bottom end is $2800 US Pesos. The cast bottom end is $2000 US Dollares....

Is there any ~real~ reason for me to go forged? (....other than bragging rights, of course!) There are a LOT of you that are running FI on stock bottom end w/ no ill effects, so what's the REAL value of spending the extra $800?

3. Is there somewhere else for me to look besides Jeg's and Summit?

Thanks for watching,

KoreaJon

#48

Since you're doing all of this work already... spend the little extra for a stronger setup. Even if you dont use it... will be more attractive to a buyer later on. As it's a great building block for a bunch of directions you could go.

Id rather buy 120k mile car with a new forged bottom end in it, than one with just an oem rebuilt personally. Even if it was 500-1000 more and stock otherwise.

Id rather buy 120k mile car with a new forged bottom end in it, than one with just an oem rebuilt personally. Even if it was 500-1000 more and stock otherwise.

#49

Safety Car

.. OK got to say it STAY out of WATER.. I am using your install to install a new cam top Etc. end in 04 Z.. Good luck..[/QUOTE]

Yep, I deserve that!

Right now I'm prepping to place my order for parts. I'm gonna go ahead and do the 25% UD pulley and find a new batwing. The rod did what looks to be some slight damaged to the rail of the oil pan where it meets the block. I might be able to straighten and dress the area so that it would seal adequately, but I just don't want to get it apart and find out otherwise.....or worse, do the repair and worry about it forever.

Guys, gimmee some feedback before I push the "Pay Now" button....

1. What other things should I be looking at while I'm in here? (I rebuilt the torque tube with new bearings and guibo's last year)

2. The forged bottom end is $2800 US Pesos. The cast bottom end is $2000 US Dollares....

Is there any ~real~ reason for me to go forged? (....other than bragging rights, of course!) There are a LOT of you that are running FI on stock bottom end w/ no ill effects, so what's the REAL value of spending the extra $800?

3. Is there somewhere else for me to look besides Jeg's and Summit?

Thanks for watching,

KoreaJon[/QUOTE]

Forged is good if might want to big later on if just staying were your at what you got is good . Brian Tooley Racing Parts 888-959-8865... put not just parts there guys know the ins and outs of the LS deal and can save you some money what you need and don't need to do what you want to do hands on deal not just selling parts you can buy parts anywhere what you can,t get is people that really us there stuff ..I am doing a cam heads all new stuff on my 04 Z LS -6 and I call all the time what do I need for what I am doing ,they know what will work and what will not and stand behind there stuff ,What I like is I found out that I do not need the $350.. timing chain just a $90.00 to get were I need to be .Give then a call just might save some money and learn something ,I like the service parts come fast ..

Yep, I deserve that!

Right now I'm prepping to place my order for parts. I'm gonna go ahead and do the 25% UD pulley and find a new batwing. The rod did what looks to be some slight damaged to the rail of the oil pan where it meets the block. I might be able to straighten and dress the area so that it would seal adequately, but I just don't want to get it apart and find out otherwise.....or worse, do the repair and worry about it forever.

Guys, gimmee some feedback before I push the "Pay Now" button....

1. What other things should I be looking at while I'm in here? (I rebuilt the torque tube with new bearings and guibo's last year)

2. The forged bottom end is $2800 US Pesos. The cast bottom end is $2000 US Dollares....

Is there any ~real~ reason for me to go forged? (....other than bragging rights, of course!) There are a LOT of you that are running FI on stock bottom end w/ no ill effects, so what's the REAL value of spending the extra $800?

3. Is there somewhere else for me to look besides Jeg's and Summit?

Thanks for watching,

KoreaJon[/QUOTE]

Forged is good if might want to big later on if just staying were your at what you got is good . Brian Tooley Racing Parts 888-959-8865... put not just parts there guys know the ins and outs of the LS deal and can save you some money what you need and don't need to do what you want to do hands on deal not just selling parts you can buy parts anywhere what you can,t get is people that really us there stuff ..I am doing a cam heads all new stuff on my 04 Z LS -6 and I call all the time what do I need for what I am doing ,they know what will work and what will not and stand behind there stuff ,What I like is I found out that I do not need the $350.. timing chain just a $90.00 to get were I need to be .Give then a call just might save some money and learn something ,I like the service parts come fast ..

#50

Pro

Thread Starter

Hi Folks,

I just got my new engine ordered!

I tried to order the engine through Jeg's this morning...what a PITA! First was the extremely surly sales guy who seemed to be truly pissed that I actually had some questions regarding parts compatibility with the new Blueprint engine I was trying to order ....when I asked him if my questions were bothering him, his nasty reply was "NO! I've just never been ASKED that before...!" I told him that I'd call back and speak with someone who might be in a better mood.

....when I asked him if my questions were bothering him, his nasty reply was "NO! I've just never been ASKED that before...!" I told him that I'd call back and speak with someone who might be in a better mood.

I called back and got a sales lady who couldn't get off of the phone fast enough....who knows, maybe she's getting paid by the call.

I tried a third time....I started the conversation by confirming that the sales guy wasn't pissed or in a hurry....he was nice, friendly, even joking. Seemed genuinely interested in selling me some stuff. The only thing was that he had to refer me to another guy who could answer my questions regarding freight forwarding.

Fast-forward to an hour ago.....

I spoke to the freight forwarding guru. As it turns out, if I pay for the engine over the phone, I can then go pick it up at their location in person, but I cannot have my freight company go pick it up.....I have to pay Jeg's $160 to send it to the freight forwarders location....

Sooooo..... I call Summit. Their website has the same engine, same price. I sat on hold three times for 15 minutes each time......waiting......waiting.... I hung up out of frustration....keep in mind that this is 1AM in South Korea.

I hung up out of frustration....keep in mind that this is 1AM in South Korea.

I go back to the Bluepringengines.com website.....and there's their 1-800 order number at the top of the page......

So......I call Blueprint directly and am greeted quickly and courteously by a happy sounding fella named Scott. He tells me that I can get the same engine that's advertised on the Summit and Jeg's website for the same price!

In 20 minutes we had my new 369.4 cubic inches of forged goodness engine ordered, paid for, and laughed a little over him recognizing my story from having read about it here on the forum! This was a totally positive experience....quick, helpful, and friendly!

Anyway, I just wanted to give a shout-out to the folks over at Blueprint engines, and vent a little over the service from Jeg's.

Thanks again, Scott.....now don't forget to go tell the guys that are assembling my motor that I need for them to put a rush on it.....My C5 needs to get back to patrolling the DMZ!!

Thanks for tuning in!

KoreaJon

I just got my new engine ordered!

I tried to order the engine through Jeg's this morning...what a PITA! First was the extremely surly sales guy who seemed to be truly pissed that I actually had some questions regarding parts compatibility with the new Blueprint engine I was trying to order

....when I asked him if my questions were bothering him, his nasty reply was "NO! I've just never been ASKED that before...!" I told him that I'd call back and speak with someone who might be in a better mood.

....when I asked him if my questions were bothering him, his nasty reply was "NO! I've just never been ASKED that before...!" I told him that I'd call back and speak with someone who might be in a better mood.I called back and got a sales lady who couldn't get off of the phone fast enough....who knows, maybe she's getting paid by the call.

I tried a third time....I started the conversation by confirming that the sales guy wasn't pissed or in a hurry....he was nice, friendly, even joking. Seemed genuinely interested in selling me some stuff. The only thing was that he had to refer me to another guy who could answer my questions regarding freight forwarding.

Fast-forward to an hour ago.....

I spoke to the freight forwarding guru. As it turns out, if I pay for the engine over the phone, I can then go pick it up at their location in person, but I cannot have my freight company go pick it up.....I have to pay Jeg's $160 to send it to the freight forwarders location....

Sooooo..... I call Summit. Their website has the same engine, same price. I sat on hold three times for 15 minutes each time......waiting......waiting....

I hung up out of frustration....keep in mind that this is 1AM in South Korea.

I hung up out of frustration....keep in mind that this is 1AM in South Korea.I go back to the Bluepringengines.com website.....and there's their 1-800 order number at the top of the page......

So......I call Blueprint directly and am greeted quickly and courteously by a happy sounding fella named Scott. He tells me that I can get the same engine that's advertised on the Summit and Jeg's website for the same price!

In 20 minutes we had my new 369.4 cubic inches of forged goodness engine ordered, paid for, and laughed a little over him recognizing my story from having read about it here on the forum! This was a totally positive experience....quick, helpful, and friendly!

Anyway, I just wanted to give a shout-out to the folks over at Blueprint engines, and vent a little over the service from Jeg's.

Thanks again, Scott.....now don't forget to go tell the guys that are assembling my motor that I need for them to put a rush on it.....My C5 needs to get back to patrolling the DMZ!!

Thanks for tuning in!

KoreaJon

Last edited by KoreaJon; 08-26-2015 at 09:27 AM. Reason: Added detail

#51

Safety Car

Hi Folks,

I just got my new engine ordered!

I tried to order the engine through Jeg's this morning...what a PITA! First was the extremely surly sales guy who seemed to be truly pissed that I actually had some questions regarding parts compatibility with the new Blueprint engine I was trying to order ....when I asked him if my questions were bothering him, his nasty reply was "NO! I've just never been ASKED that before...!" I told him that I'd call back and speak with someone who might be in a better mood.

....when I asked him if my questions were bothering him, his nasty reply was "NO! I've just never been ASKED that before...!" I told him that I'd call back and speak with someone who might be in a better mood.

I called back and got a sales lady who couldn't get off of the phone fast enough....who knows, maybe she's getting paid by the call.

I tried a third time....I started the conversation by confirming that the sales guy wasn't pissed or in a hurry....he was nice, friendly, even joking. Seemed genuinely interested in selling me some stuff. The only thing was that he had to refer me to another guy who could answer my questions regarding freight forwarding.

Fast-forward to an hour ago.....

I spoke to the freight forwarding guru. As it turns out, if I pay for the engine over the phone, I can then go pick it up at their location in person, but I cannot have my freight company go pick it up.....I have to pay Jeg's $160 to send it to the freight forwarders location....

Sooooo..... I call Summit. Their website has the same engine, same price. I sat on hold for 15 minutes......waiting......waiting....:ma d: I hung up out of frustration....keep in mind that this is 1AM in South Korea.

I go back to the Bluepringengines.com website.....and there's their 1-800 order number at the top of the page......

So......I call Blueprint directly and am greeted quickly and courteously by a happy sounding fella named Scott. He tells me that I can get the same engine that's advertised on the Summit and Jeg's website for the same price!

In 20 minutes we had my new 369.4 cubic inches of forged goodness engine ordered, paid for, and laughed a little over him recognizing my story from having read about it here on the forum! This was a totally positive experience....quick, helpful, and friendly!

Anyway, I just wanted to give a shout-out to the folks over at Blueprint engines, and vent a little over the service from Jeg's.

Thanks again, Scott.....now don't forget to go tell the guys that are assembling my motor that I need for them to put a rush on it.....My C5 needs to get back to patrolling the DMZ!!

Thanks for tuning in!

KoreaJon

I just got my new engine ordered!

I tried to order the engine through Jeg's this morning...what a PITA! First was the extremely surly sales guy who seemed to be truly pissed that I actually had some questions regarding parts compatibility with the new Blueprint engine I was trying to order

....when I asked him if my questions were bothering him, his nasty reply was "NO! I've just never been ASKED that before...!" I told him that I'd call back and speak with someone who might be in a better mood.

....when I asked him if my questions were bothering him, his nasty reply was "NO! I've just never been ASKED that before...!" I told him that I'd call back and speak with someone who might be in a better mood.I called back and got a sales lady who couldn't get off of the phone fast enough....who knows, maybe she's getting paid by the call.

I tried a third time....I started the conversation by confirming that the sales guy wasn't pissed or in a hurry....he was nice, friendly, even joking. Seemed genuinely interested in selling me some stuff. The only thing was that he had to refer me to another guy who could answer my questions regarding freight forwarding.

Fast-forward to an hour ago.....

I spoke to the freight forwarding guru. As it turns out, if I pay for the engine over the phone, I can then go pick it up at their location in person, but I cannot have my freight company go pick it up.....I have to pay Jeg's $160 to send it to the freight forwarders location....

Sooooo..... I call Summit. Their website has the same engine, same price. I sat on hold for 15 minutes......waiting......waiting....:ma d: I hung up out of frustration....keep in mind that this is 1AM in South Korea.

I go back to the Bluepringengines.com website.....and there's their 1-800 order number at the top of the page......

So......I call Blueprint directly and am greeted quickly and courteously by a happy sounding fella named Scott. He tells me that I can get the same engine that's advertised on the Summit and Jeg's website for the same price!

In 20 minutes we had my new 369.4 cubic inches of forged goodness engine ordered, paid for, and laughed a little over him recognizing my story from having read about it here on the forum! This was a totally positive experience....quick, helpful, and friendly!

Anyway, I just wanted to give a shout-out to the folks over at Blueprint engines, and vent a little over the service from Jeg's.

Thanks again, Scott.....now don't forget to go tell the guys that are assembling my motor that I need for them to put a rush on it.....My C5 needs to get back to patrolling the DMZ!!

Thanks for tuning in!

KoreaJon

#54

Pro

Thread Starter

#55

Pro

Thread Starter

#56

Burning Brakes

#57

Pro

Thread Starter

Here you go!

Short Block Assembly

6.0L Cast Iron 364 LS Block (Bored .030")

Internally Balanced

Forged Pistons (Mahle)

Factory Forged Crank

GM Rods (w/ ARP bolts)

10.8:1 Compression with 70cc Heads & .051" Gasket

Regards,

KoreaJon

#58

Pro

Thread Starter

Hi Guys,

I just thought that I'd give an update on my on-going saga.

I'm doing the work out of my garage at home. My work space is a little more than a one car, plus I have a small workshop behind the garage. As such, all of my work till now has been on jack stands.

Removing the engine will probably require that the car be lifted higher than when I removed the differential and transmission, and it will definitely be heavier and more difficult, as well. I generally work by myself, and have to plan accordingly, even though I sometimes get help from a buddy or two.

I did not want to try to pull the engine out the top w/ a cherry picker; mostly because I want to install the new motor completely assembled....everything from the oil pan to the water pump. I'm really really tired of leaning over the fenders.

I have some big jack stands (6 tons) but once the engine / cradle is on the ground, I'd have to struggle to drag the cradle from under the car. This might be something that I would have done when I was younger and a lot stronger, but not today. Also when the cradle is out, with the car on jack stands, there's no way to get the car outside to clean the engine bay or the garage floor.

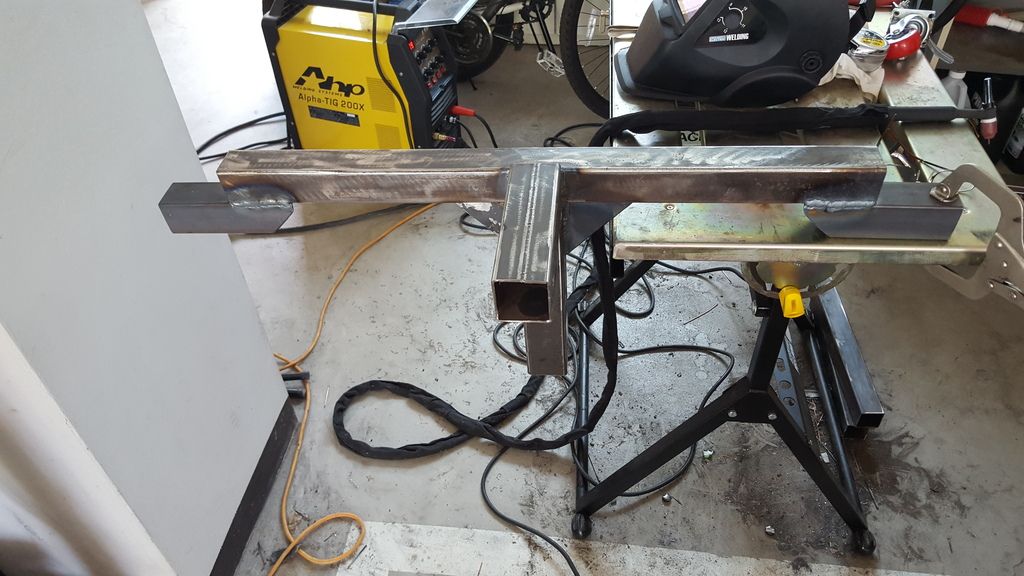

Soooo.... I decided to make a rolling stand that will support the front of the car while the cradle is removed. With the back tires on the ground, and the front on the rolling stand, I can easily move the car around as required.

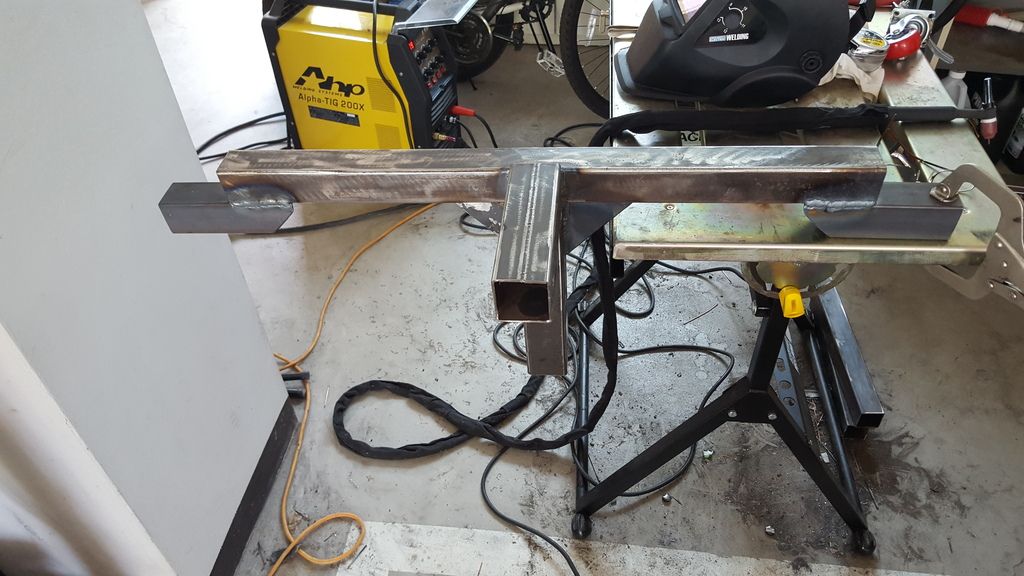

I ordered up some metal from Mr. Kim's house of steel, and got to work.

The metal is all 2" and 2 1/2". The casters are 3" high, each is rated at 300kg.

After the welding was done, I primered and painted them. I know, it looks like Harbor Freight, but.....oh well.

There are two dollies, one on each side of the car. They are tied together with a 53" long piece of 2 x 2" steel.

The pokey-thing at the top of the upright locates into the hole at the jacking point, and the uprights are extendable, but in this picture the holes haven't been drilled for the pins, and I got tired of painting.

And here it is under the car, supporting the weight of the front end w/ shortblock installed. The jack stands and jack are under the car, but none of them are touching. when I'm ready to pull the engine I'll roll the car out and remove the OSB that's keeping the concrete pristine.

In order to lift the car off of the engine / cradle, I whipped this little gem up. It's extendable, and the holes for the lifting clevis are on 2" centers. The bolts at the end of the chains will go down through the upper shock mounts.

I also made a lifting plate to safely lower the engine / cradle.

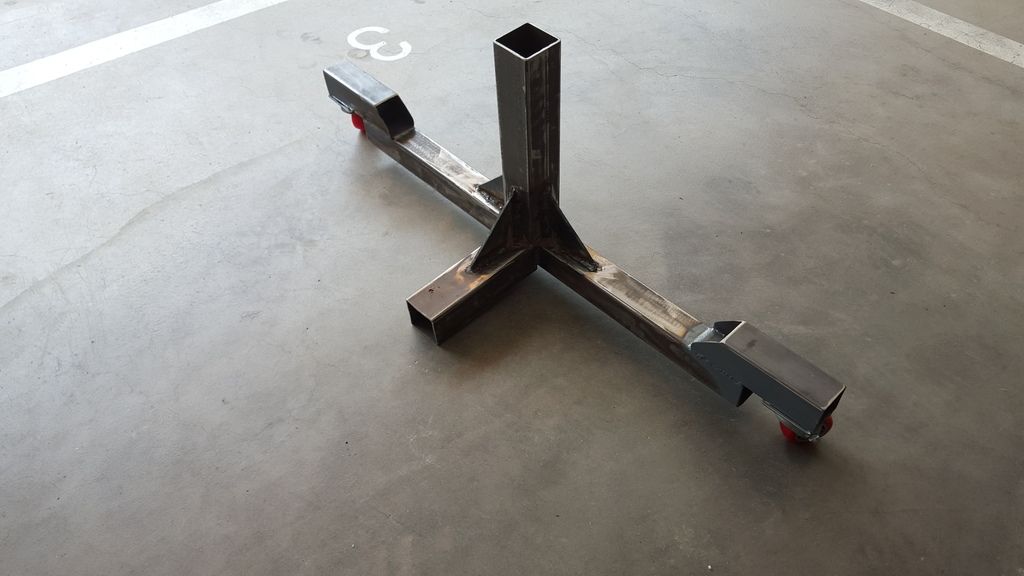

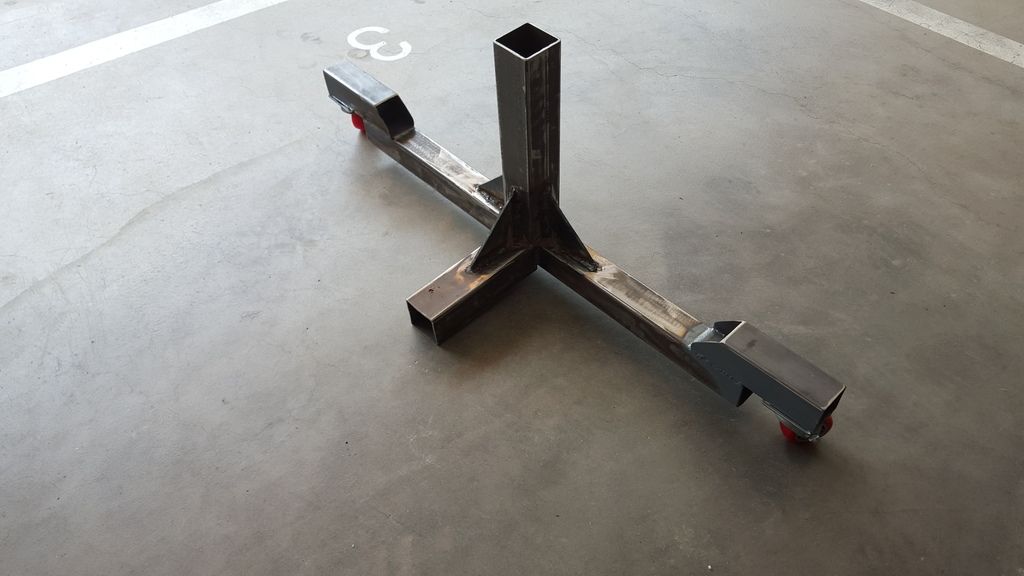

I needed a rolling dolly for the engine / cradle assembly. Once the engine is down, I don't want to try to drag that thing around. I welded this little monstrosity up.....

The single-wheel end goes towards the bellhousing. The two-bolt flange bolts to the bracket that the original H pipe bolted to. The flanges at the two-wheel end mate to the front section of the cradle, with the two uprights extending upwards into the hollow of the cradle. This will very effectively prevent any movement of the engine or cradle on the dolly. Lastly, the long "arm" extend out to just inside of the lower ball joint, keeping the rotors from dragging the ground.

In this picture it looks like it holds the engine high off the ground, but I mocked it up while under the car with one of the upper A arms disconnected from the body, in order to see how far the leaf spring would push the lower A arm down.

No matter what, when I set the engine down, it will never go lower than the bottom of the rotors. This dolly gets the rotors 1/2" off of the floor.

I got these things done over the weekend. This week I'm going to build a collapsible A frame from which to suspend a chain-fall hoist. I have access to a cherry picker, but I don't think that that will work for dropping the engine because I'm pretty sure that the legs of the cherry picker would get in the way of the engine as it's lowered.

That's it for now, thanks for tuning in!!

KoreaJon

I just thought that I'd give an update on my on-going saga.

I'm doing the work out of my garage at home. My work space is a little more than a one car, plus I have a small workshop behind the garage. As such, all of my work till now has been on jack stands.

Removing the engine will probably require that the car be lifted higher than when I removed the differential and transmission, and it will definitely be heavier and more difficult, as well. I generally work by myself, and have to plan accordingly, even though I sometimes get help from a buddy or two.

I did not want to try to pull the engine out the top w/ a cherry picker; mostly because I want to install the new motor completely assembled....everything from the oil pan to the water pump. I'm really really tired of leaning over the fenders.

I have some big jack stands (6 tons) but once the engine / cradle is on the ground, I'd have to struggle to drag the cradle from under the car. This might be something that I would have done when I was younger and a lot stronger, but not today. Also when the cradle is out, with the car on jack stands, there's no way to get the car outside to clean the engine bay or the garage floor.

Soooo.... I decided to make a rolling stand that will support the front of the car while the cradle is removed. With the back tires on the ground, and the front on the rolling stand, I can easily move the car around as required.

I ordered up some metal from Mr. Kim's house of steel, and got to work.

The metal is all 2" and 2 1/2". The casters are 3" high, each is rated at 300kg.

After the welding was done, I primered and painted them. I know, it looks like Harbor Freight, but.....oh well.

There are two dollies, one on each side of the car. They are tied together with a 53" long piece of 2 x 2" steel.

The pokey-thing at the top of the upright locates into the hole at the jacking point, and the uprights are extendable, but in this picture the holes haven't been drilled for the pins, and I got tired of painting.

And here it is under the car, supporting the weight of the front end w/ shortblock installed. The jack stands and jack are under the car, but none of them are touching. when I'm ready to pull the engine I'll roll the car out and remove the OSB that's keeping the concrete pristine.

In order to lift the car off of the engine / cradle, I whipped this little gem up. It's extendable, and the holes for the lifting clevis are on 2" centers. The bolts at the end of the chains will go down through the upper shock mounts.

I also made a lifting plate to safely lower the engine / cradle.

I needed a rolling dolly for the engine / cradle assembly. Once the engine is down, I don't want to try to drag that thing around. I welded this little monstrosity up.....

The single-wheel end goes towards the bellhousing. The two-bolt flange bolts to the bracket that the original H pipe bolted to. The flanges at the two-wheel end mate to the front section of the cradle, with the two uprights extending upwards into the hollow of the cradle. This will very effectively prevent any movement of the engine or cradle on the dolly. Lastly, the long "arm" extend out to just inside of the lower ball joint, keeping the rotors from dragging the ground.

In this picture it looks like it holds the engine high off the ground, but I mocked it up while under the car with one of the upper A arms disconnected from the body, in order to see how far the leaf spring would push the lower A arm down.

No matter what, when I set the engine down, it will never go lower than the bottom of the rotors. This dolly gets the rotors 1/2" off of the floor.

I got these things done over the weekend. This week I'm going to build a collapsible A frame from which to suspend a chain-fall hoist. I have access to a cherry picker, but I don't think that that will work for dropping the engine because I'm pretty sure that the legs of the cherry picker would get in the way of the engine as it's lowered.

That's it for now, thanks for tuning in!!

KoreaJon

#59

Really clean fab work!!! but did you have to use orange :P haha it does look like HF.

I can't believe those casters hold the weight... they look puny.

Can't wait til you tear into her more and put her back together

I can't believe those casters hold the weight... they look puny.

Can't wait til you tear into her more and put her back together

#60

Pro

Thread Starter

Hello Guys!

Well, this weekend I pulled the engine out. I spent several days last week building an "A" frame, because a cherry picker just wouldn't work with how I wanted to do the job. The A frame is built out of 2" and 2 1/2" square, 1/4" wall tubing. It took a lot longer for me to build, as I made it so that the legs are two piece, the upper leg slides into a welded socket on the lower leg, and the "A" section at the top of the legs has sockets that the legs slide into. The cross beam is out of 3" x 1/4" wall square, with a piece of 3" x 3/8" steel seam welded in the center. It is also mounted on casters, and can very easily be disassembled and stored in a very compact manner. I am very tired of painting, so it'll have to wait till later!

The engine cradle, lifting beam, and the car dolly all worked great. It was very easy to just lower the engine onto the dolly, disconnect the come-along from the engine plate, connect it to the lifting beam, pick up the entire car, slide the car dolly underneath, and set the car down. Piece of cake!

The car dolly allows me to very easily roll the car back and forth; if I planned to use this more often, I would go with the next size bigger caster, though. These roll fine, but it feels like they are at their limit, weight wise.

I spent a little time making some enhancements to the three-wheeled engine stand I bought. I welded up the "T" section to add to the front of the stand, and installed two casters there. It simply bolts to the leg, so it can be very easily used as a 3 or as a 4 wheel stand. I also added the stabilizers on the rear leg (there's a nut welded on the bottom, through which the stabilizers thread) This will allow me to prevent the stand from rolling around when I don't want it to:

The engine cradle worked well. It is really nice to be able to very easily roll the cradle and associated bits and pieces around. While lowering the engine, I discovered that the spring drooped farther than I had planned, so the cradle didn't want to sit down on to the dolly; the A arms were resting on the outriggers of the dolly, preventing the cradle from registering on the 2 vertical tabs. After I removed the engine I welded longer uprights in place of the tabs, so that the uprights would register into the cradle before the A arms contacted the outriggers. It is much easier to use now.

Anyway, on to the teardown!

The ugly underbelly:

Greeted by this on the inside of the pan.

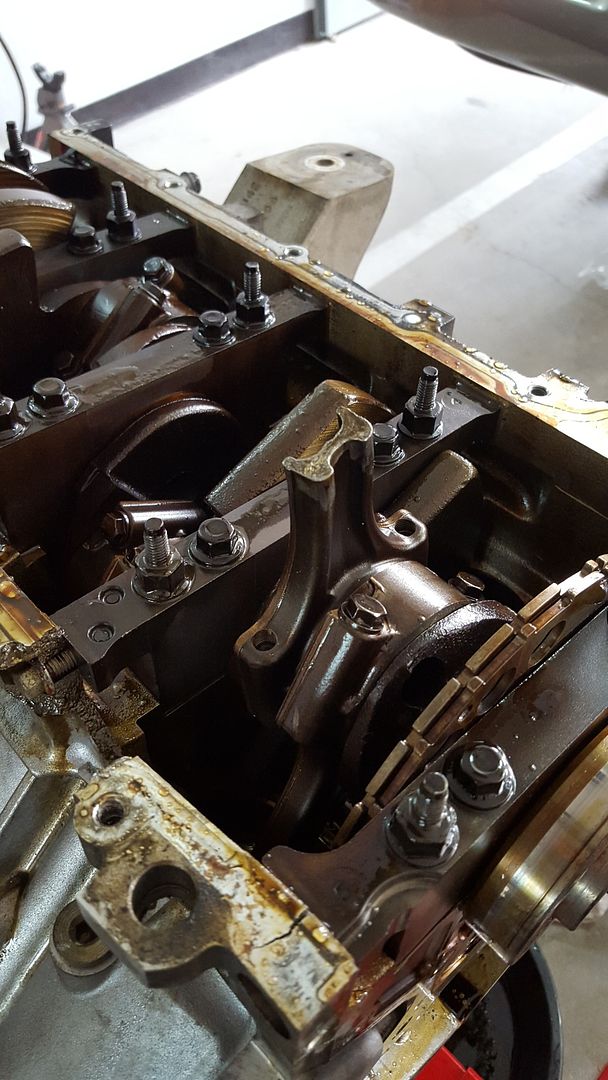

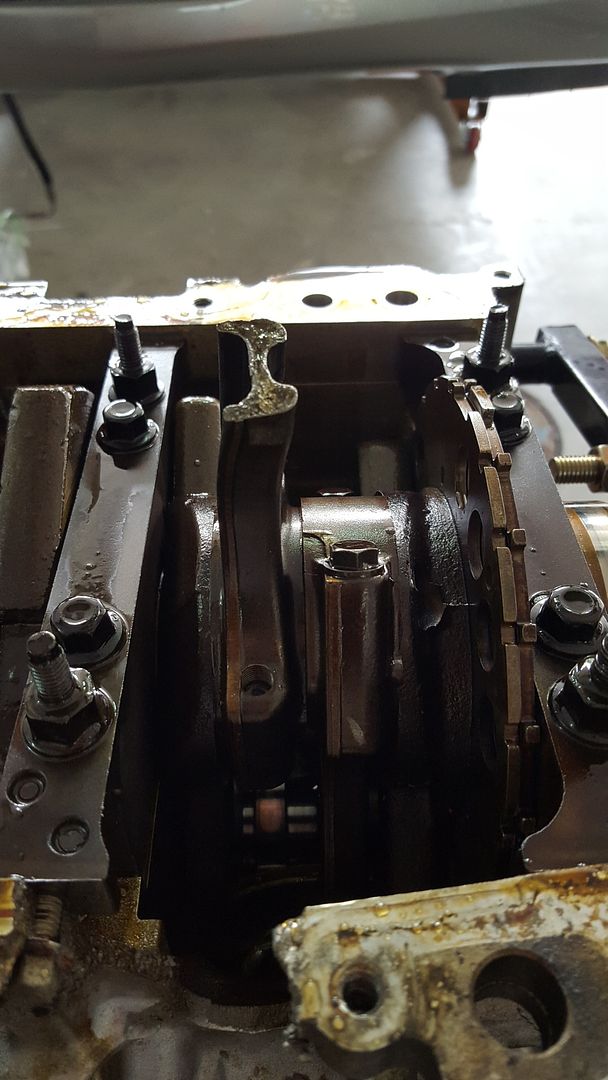

And here's the windage tray:

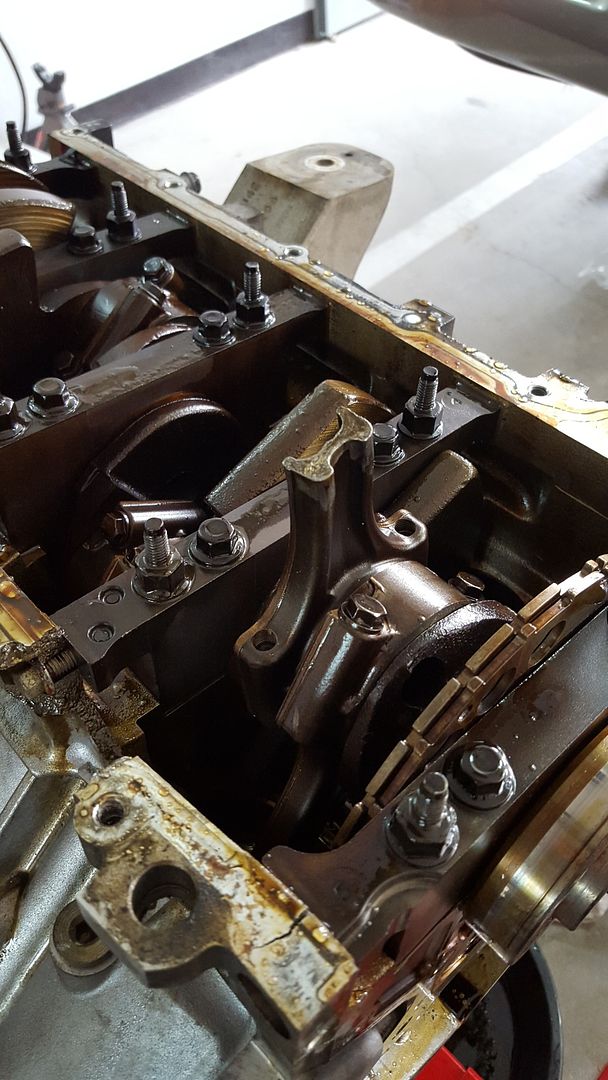

Followed by this:

And this...

And this....the corner of the block is only held in place by the main bearing cross bolt!

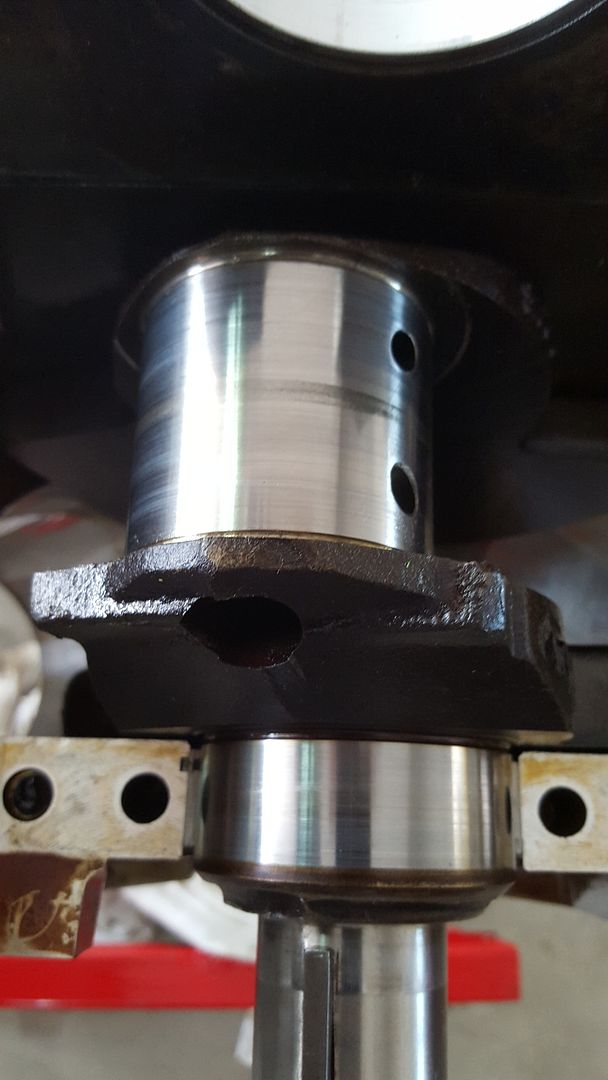

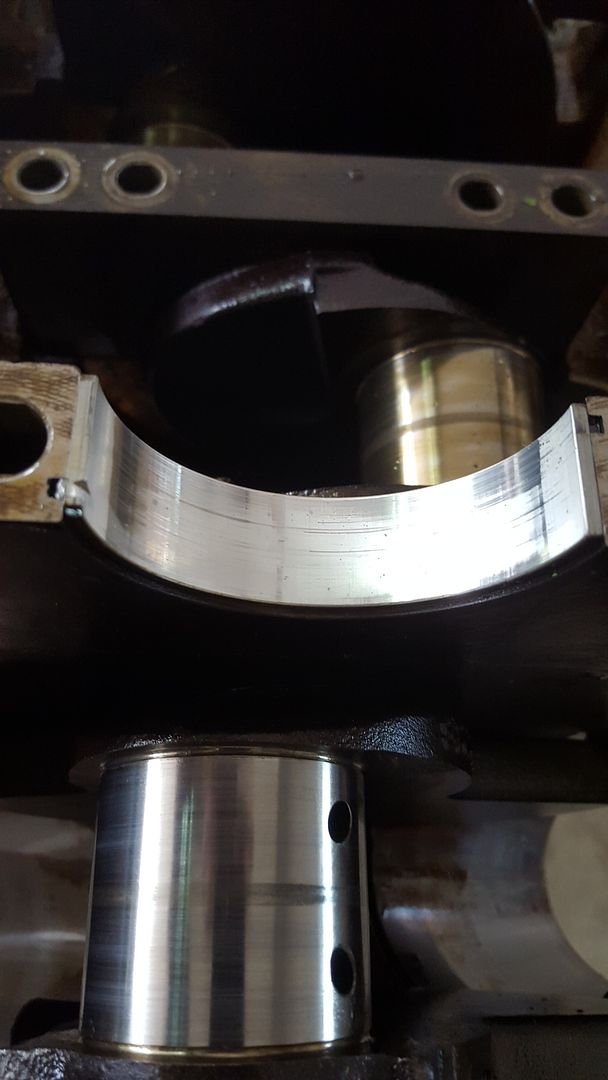

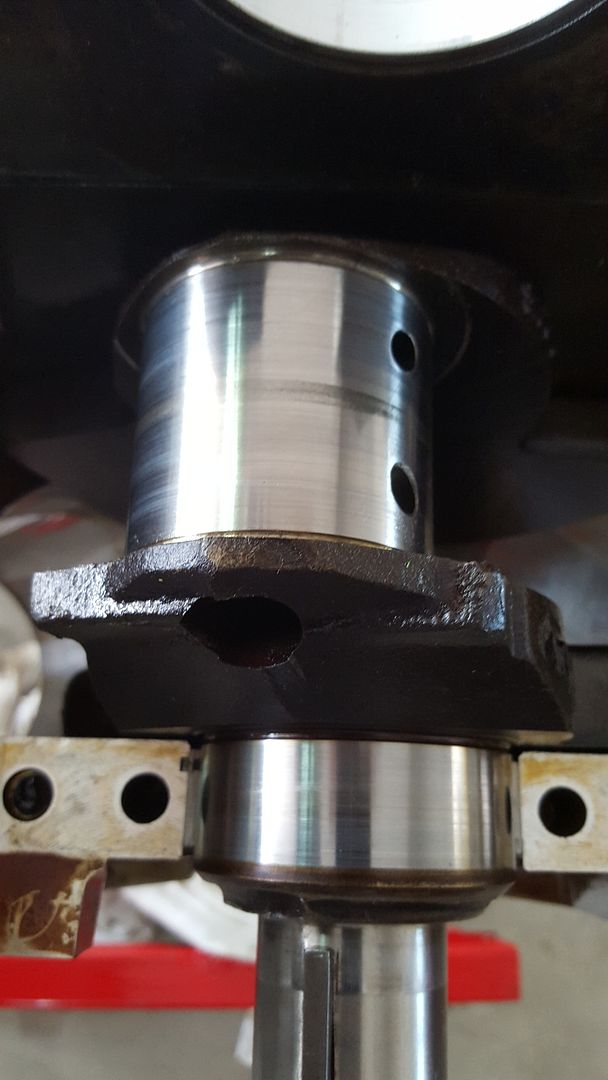

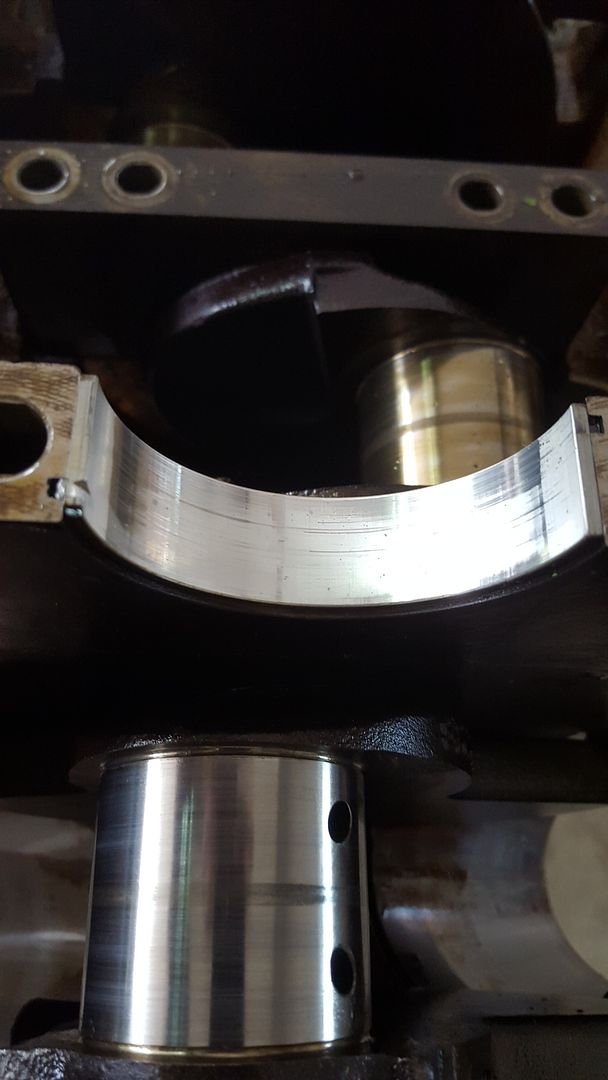

The really sickening part is that prior to the destruction, the lower end was in near perfect shape. I mic'd the rod bearings and found no discernible wear between the low-stress and high stress areas of the bearings. Same with the main bearings! The crank is in pristine condition. I'm gonna preserve the crank and tuck it away for spare parts.

The other 7 rods and pistons look great, too. The cylinders are in fantastic shape as well. It's really too bad to have destroyed such a healthy engine.

If anyone has a need for 7 good rods and pistons, please let me know. I'd really rather give these parts away that throw them in the recycle bin!

I was able to straighten the windage tray. After flattening all of the bent sheetmetal, I cut out the remains from the jagged hole that resulted and welded in a new piece of steel. Except for the fact that the repaired area is shiny, you can't tell that it was ever mangled!

I plan to spend some time tonight cleaning the cradle and suspension, then I'm just awaiting the engine.

I got word today that my new short block arrived in Incheon yesterday, and will be delivered tomorrow, so I'll post an update in a few days.

Thanks for watching!

KoreaJon

Well, this weekend I pulled the engine out. I spent several days last week building an "A" frame, because a cherry picker just wouldn't work with how I wanted to do the job. The A frame is built out of 2" and 2 1/2" square, 1/4" wall tubing. It took a lot longer for me to build, as I made it so that the legs are two piece, the upper leg slides into a welded socket on the lower leg, and the "A" section at the top of the legs has sockets that the legs slide into. The cross beam is out of 3" x 1/4" wall square, with a piece of 3" x 3/8" steel seam welded in the center. It is also mounted on casters, and can very easily be disassembled and stored in a very compact manner. I am very tired of painting, so it'll have to wait till later!

The engine cradle, lifting beam, and the car dolly all worked great. It was very easy to just lower the engine onto the dolly, disconnect the come-along from the engine plate, connect it to the lifting beam, pick up the entire car, slide the car dolly underneath, and set the car down. Piece of cake!

The car dolly allows me to very easily roll the car back and forth; if I planned to use this more often, I would go with the next size bigger caster, though. These roll fine, but it feels like they are at their limit, weight wise.

I spent a little time making some enhancements to the three-wheeled engine stand I bought. I welded up the "T" section to add to the front of the stand, and installed two casters there. It simply bolts to the leg, so it can be very easily used as a 3 or as a 4 wheel stand. I also added the stabilizers on the rear leg (there's a nut welded on the bottom, through which the stabilizers thread) This will allow me to prevent the stand from rolling around when I don't want it to:

The engine cradle worked well. It is really nice to be able to very easily roll the cradle and associated bits and pieces around. While lowering the engine, I discovered that the spring drooped farther than I had planned, so the cradle didn't want to sit down on to the dolly; the A arms were resting on the outriggers of the dolly, preventing the cradle from registering on the 2 vertical tabs. After I removed the engine I welded longer uprights in place of the tabs, so that the uprights would register into the cradle before the A arms contacted the outriggers. It is much easier to use now.

Anyway, on to the teardown!

The ugly underbelly:

Greeted by this on the inside of the pan.

And here's the windage tray:

Followed by this:

And this...

And this....the corner of the block is only held in place by the main bearing cross bolt!

The really sickening part is that prior to the destruction, the lower end was in near perfect shape. I mic'd the rod bearings and found no discernible wear between the low-stress and high stress areas of the bearings. Same with the main bearings! The crank is in pristine condition. I'm gonna preserve the crank and tuck it away for spare parts.

The other 7 rods and pistons look great, too. The cylinders are in fantastic shape as well. It's really too bad to have destroyed such a healthy engine.

If anyone has a need for 7 good rods and pistons, please let me know. I'd really rather give these parts away that throw them in the recycle bin!

I was able to straighten the windage tray. After flattening all of the bent sheetmetal, I cut out the remains from the jagged hole that resulted and welded in a new piece of steel. Except for the fact that the repaired area is shiny, you can't tell that it was ever mangled!

I plan to spend some time tonight cleaning the cradle and suspension, then I'm just awaiting the engine.

I got word today that my new short block arrived in Incheon yesterday, and will be delivered tomorrow, so I'll post an update in a few days.

Thanks for watching!

KoreaJon