Head swap: Anyone try this??

#1

Racer

Thread Starter

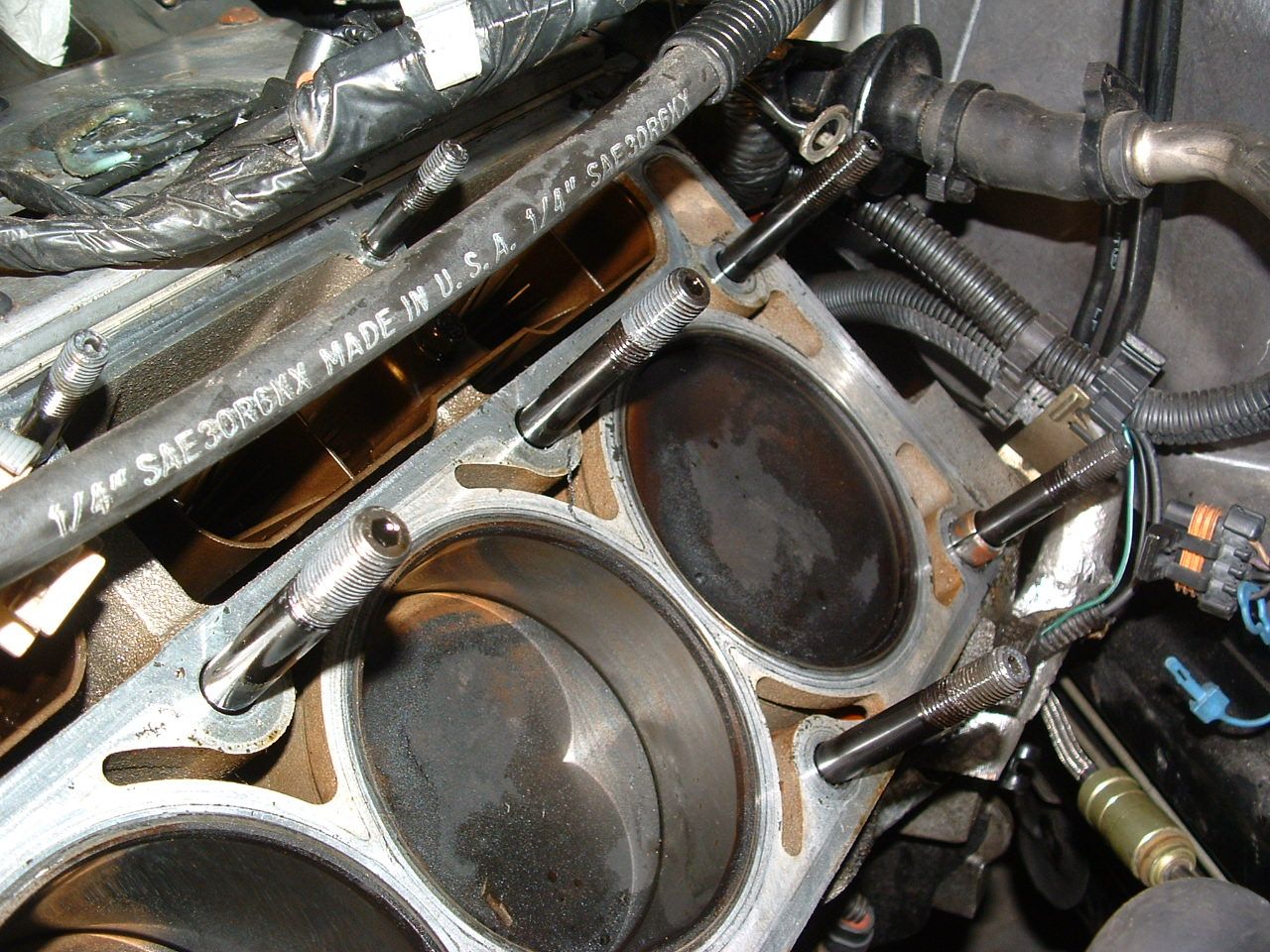

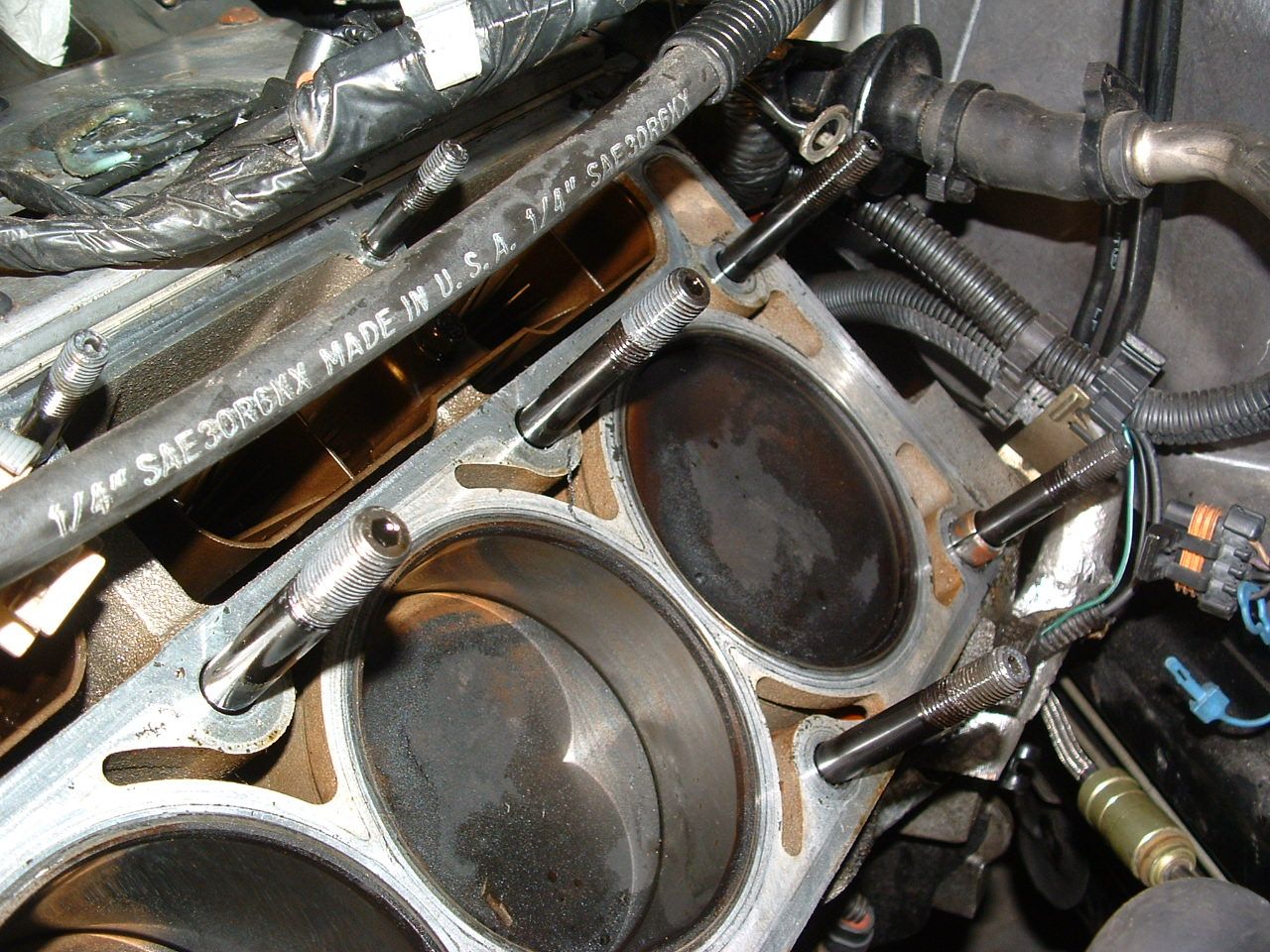

So I am about to jump into a head/cam swap and I am concerned (as it seems everyone is) about ensuring I clear ALL the coolant from the bolt holes when replacing the GM bolts with my ARP studs.

Has anyone tried loosening the stock bolts enough to get about an 1/8" of clearance and then cutting the bolts heads off to remove the heads? This would keep the bolts IN the holes until you can clean everything up. THEN remove the original bolts the rest of the way and you should have clean/clear holes for your ARP studs......? Obviously you are trashing your stock bolts but these are theoretically supposed to be single-use only right?

Seems like it should work to me, but this will be my first head swap so I cant say I've seen this work in practice.

Thoughts??

Has anyone tried loosening the stock bolts enough to get about an 1/8" of clearance and then cutting the bolts heads off to remove the heads? This would keep the bolts IN the holes until you can clean everything up. THEN remove the original bolts the rest of the way and you should have clean/clear holes for your ARP studs......? Obviously you are trashing your stock bolts but these are theoretically supposed to be single-use only right?

Seems like it should work to me, but this will be my first head swap so I cant say I've seen this work in practice.

Thoughts??

#2

Team Owner

I'm assuming you're thinking of using a Dremel or similar tool to remove the bolt heads. The metal particulate/shavings you would generate doing this would migrate into the block through the drain ports causing more problems than it's worth, IMO. Bite the bullet and remove the bolts intact and clean the holes thoroughly on your first removal - then install the studs and you're golden from there on out. That's what I did. I just recently r&r'ed my heads for the 4th or 5th time and the ARP head studs made it a breeze.

#4

Race Director

Member Since: Apr 2007

Location: South Western Ontario

Posts: 11,061

Received 845 Likes

on

721 Posts

Way too much work and the shavings will make a mess. Just clean the holes out. Air hose, shop vac or put a small groove in a bolt to push the coolant out as you thread it in and then use Q-tips or similar to dry the holes. You'll only cause damage if you crank the bolts in with a wrench forcing the coolant to be compressed. There are lots of simple ways to clean the holes so why bother with cutting the bolts?

#5

Team Owner

I went into each hole with a Miti-vac and just removed the fluid and then dried with a rolled up paper towel. That method is way too much work and risk in my opinion. Just make sure you inspect each hole prior to reassembly. You also need to chase the threads to clean out the gunk.

#6

Burning Brakes

Studs are different then bolts. With bolts you have to worry more about water then with studs. Your over thinking it IMO. Studs go in hand tight. So its not really a big deal. Bolts on the other hand you need to make sure you get the water out or you can possibly crack the block.

#8

Burning Brakes

What i normally do with bolts is use a vacuum and a straw to clean out each hole idvidually. I put the straw on the tip of the vacuum hose and seal up the rest. Makes cleaning the holes a very quick process.

#9

Tech Contributor

Member Since: Dec 1999

Location: Anthony TX

Posts: 32,736

Received 2,180 Likes

on

1,583 Posts

CI 6,7,8,9,11 Vet

St. Jude Donor '08

My 2 cents,, Whether you are using OEM Head Bolts, ARP Head Bolts or ARP Head Studs,, getting ALL the water/moisture out of the bolt holes is a MUST!

If you use the ARP Head Studs, you want the stud to go ALL the way into the bolt hole as far as its possible to get the most head stud to block thread contact. If there's water in the hole, the stud will not be able to bottom out in the block bolt hole.

That being said; I strongly recommending using HEAD STUDS vs Head Bolts.

Using studs significantly reduces the chance of pulling the threads out of the bolt holes in the block. It also simplifies doing the head installation!

Some questions that I have been asked:

Q' Will the heads fit over the studs without interference from the hood cowl? YES,,, The heads slide right on to the studs with out ANY issues!

There are dozens of ways to get the water/coolant/moisture out of the holes. Just use a long Q Tip as a finial check. If its DRY when you bottom it out and pull it back out of the bolt hole, you are good to go!

Bill

If you use the ARP Head Studs, you want the stud to go ALL the way into the bolt hole as far as its possible to get the most head stud to block thread contact. If there's water in the hole, the stud will not be able to bottom out in the block bolt hole.

That being said; I strongly recommending using HEAD STUDS vs Head Bolts.

Using studs significantly reduces the chance of pulling the threads out of the bolt holes in the block. It also simplifies doing the head installation!

Some questions that I have been asked:

Q' Will the heads fit over the studs without interference from the hood cowl? YES,,, The heads slide right on to the studs with out ANY issues!

There are dozens of ways to get the water/coolant/moisture out of the holes. Just use a long Q Tip as a finial check. If its DRY when you bottom it out and pull it back out of the bolt hole, you are good to go!

Bill

Thanks!

Thanks!