New Best With 2200R 10Rib Direct Drive A6 C6

#21

Le Mans Master

Bob repaired my jack shaft pulley setup, he modified it quite a bit..so far I only have 700 miles on it but no issues... A couple trips to 7k rpms and the belt holds fine. (Although I never had a problem keeping the belt on with the first cogged jack shaft pulley).

The key is good alignment and don't get the belt too tight...

#22

Bob repaired my jack shaft pulley setup, he modified it quite a bit..so far I only have 700 miles on it but no issues... A couple trips to 7k rpms and the belt holds fine. (Although I never had a problem keeping the belt on with the first cogged jack shaft pulley).

The key is good alignment and don't get the belt too tight...

The key is good alignment and don't get the belt too tight...

#23

Bob repaired my jack shaft pulley setup, he modified it quite a bit..so far I only have 700 miles on it but no issues... A couple trips to 7k rpms and the belt holds fine. (Although I never had a problem keeping the belt on with the first cogged jack shaft pulley).

The key is good alignment and don't get the belt too tight...

The key is good alignment and don't get the belt too tight...

Would you be able to elaborate on exactly what was modified or how they changed it?

#24

Premium Supporting Vendor

Member Since: Oct 2004

Location: Providing the most proven supercharger kits for your C5/6/7 609-752-0321

Posts: 23,319

Received 1,086 Likes

on

657 Posts

Also we have to make it more clear that the concentric idler which adjusts the belt has to turn counter clockwise when tightening. Going clockwise squishes the belt between the balancer and idler, taking the belt out very quickly.

Shay, your parts are in the works.

#25

Team Owner

10k miles on mine, and no issues. Strange.

#27

Le Mans Master

I had this same issue with the jackshaft pulley from A&A.... it just wore out and got wobbly. I don't have a cog and it didn't throw any belts but some noise alerted me to it. I got a new one from Josh, which he says is an improved unit over what I had, although I cant say exactly what they changed. Since both companies seem to have this issue, I would assume that the jackshaft takes a lot of pressure.

#28

Le Mans Master

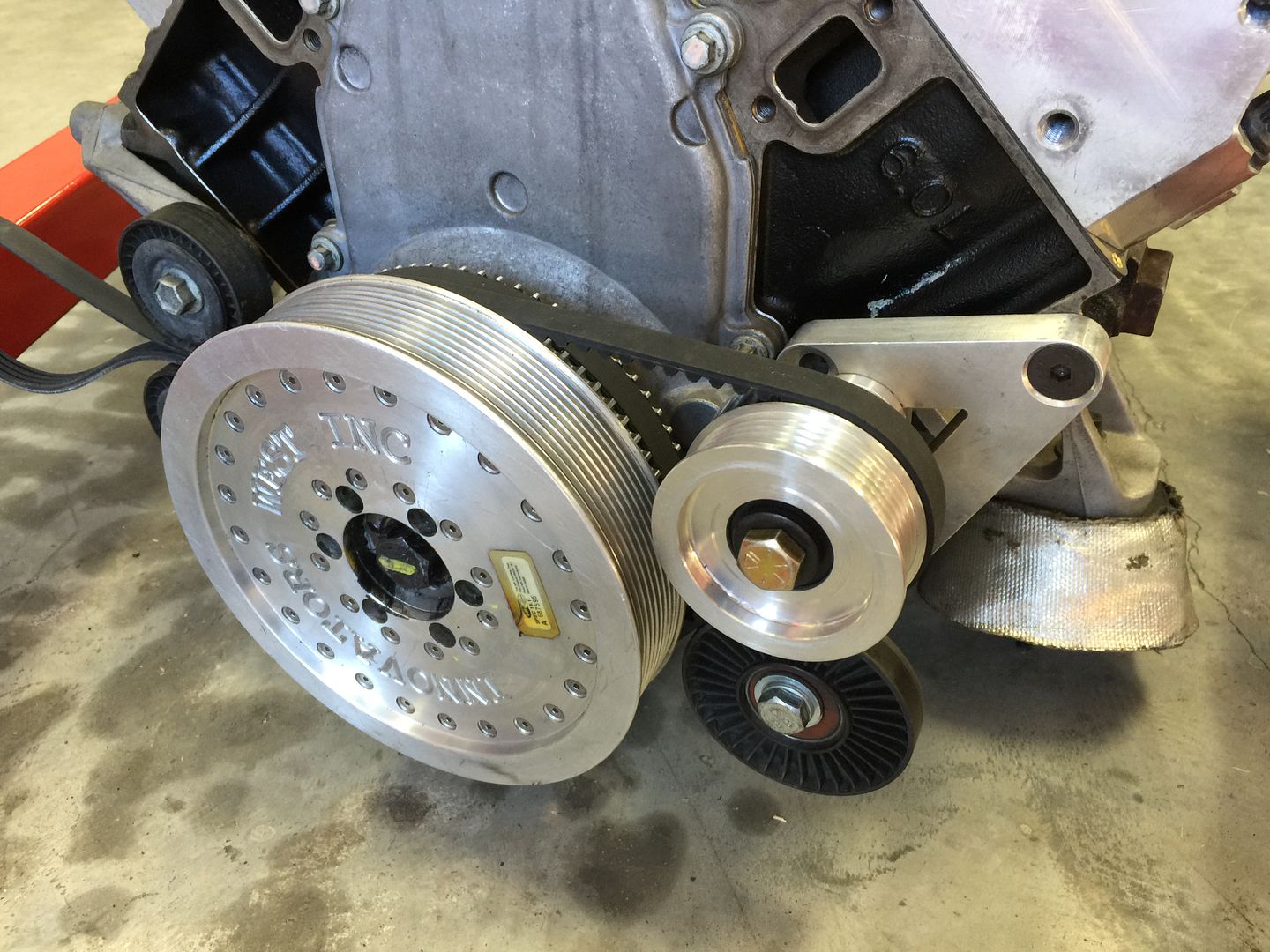

I kept having problems with the pulley itself wallowing out, bearings fitting loose in the pulley and allowing it to start wobbling within a couple thousand miles. We sleeved it once and put new Timken bearings.. It made it 2k miles before wobbling again.

I sent it back to the machinist, he noticed significant wear on the cogged portion of the pulley after only 2k miles..so he decided to redesign the whole thing.

He made me a new pulley with different bearing location to distribute the load differently, he also used a low drag, high speed bearing that will not create as much heat, and hopefully thus not expanding the pulley material allowing the bearings to get sloppy in the pulley. Lastly he made a steel tooth cog ring with a belt guide attached, and screwed it all together..

This new design I feel is a big improvement. Hopefully it lasts.

Just note that the problems I had were not really related to the cog mod, more so of the direct drive design and materials themselves...(Dallas Performance)

ECS is your source for this cogged direct drive setup.

Last edited by ajrothm; 04-03-2016 at 01:07 PM.

The following 2 users liked this post by ajrothm:

DOUG @ ECS (04-04-2016),

Shayc5 (04-03-2016)

#29

Team Owner

I wonder if it is just because I have the DP one, and I think that is the only DP one ECS ever cogged. Maybe the material/etc DP used is higher grade/etc because after 10k+ miles it shows no wear.

#30

Le Mans Master

Mine is the DP direct drive, I had the pulley wallow out and bearings get sloppy in it before I ever had the cog mod done on it... I probably only had 4K miles on it before I started noticing a little noise on cold start ups... After it got hot, it was relatively quiet. I never had a belt break or come off..

When I pulled the motor out at 8k miles to fix it, that's when I noticed the pulley was loose on the bearings..(8k miles on the direct drive at this point.) So I decided to do the cog mod then, and have them fix the pulley.. (Sleeved). Well that repair lasted only 2k miles, so I sent the whole thing back and they redesigned it.... Much better materials and design... Hopefully..

If you haven't had your cog belt off in a while, you may not know you have a problem... Belt tension of the two belts is probably keeping your pulley snug when it's not running.. Grab the pulley and try to wobble it..

Last edited by ajrothm; 04-03-2016 at 03:57 PM.

#31

Team Owner

It was off ~500 miles ago.

#32

Le Mans Master

On mine it wasn't a problem with the bearings. The actual pulley had worn inside, making the bearing fit loosely and the pulley wobble.

#33

Le Mans Master

I was told that the pulley gets so much heat developed in it, that the aluminum can expand and the bore grows .001-.002.. Then the bearings get loose in it... Once it cools down, it never really contracts back to its original size, so the bearings are still loose..

We bored my original DP pulley out, put a stainless sleeve in it along with new bearings... It was good and tight, for about 2k miles... Then the sleeve even got loose in the pulley.. No actual wear was noticed in the bore of the pulley....but it was just "bigger"

The new style has screws that set the bearings in place instead of a snap ring also to keep the bearings in tighter.

The following users liked this post:

Shayc5 (04-03-2016)