L92monster: H/C package-DYNO numbers AND cam specs

#1

Tech Contributor

Thread Starter

Before getting into this write-up, I would like to ask each person reading to know a big part of my motivation is the St. Judes fundraising effort on this board. I dont think its much of a reach to understand why this cause is so important but unless you suffer such a painful loss as a result of a childnood destroyed by various illnesses I dont think you could see it from the point of view of it happening to your world. The death of a child in your life changes you forever and I will never be able to relay the pain associated with it. Take a monemt and send 20 bucks to this charity. You wont even have to do anything more than you do in posting on your computer on this forum. Its the best thing you can do to help this world and make my efforts here more worthwhile. We have the means to send robots to mars so I believe we can beat cancer, sudden infant death, and form new medications. I find it odd that it has to happen to your car before most people recogize a risk some part has to pose before you upgrade to better parts but we are doomed if we have to have things like these illnesses hit out homes before we take the steps to save a life.

---------------Make a difference TODAY------------------

This year you can donate in 3 ways:

1) Personal checks, cashier checks, or money orders, made out to: St. Jude Children's Hospital and mailed to "pewter99,":

Robert Briggs

P.O. Box 17083

Clearwater Fl 33762

Please put your forum name on the memo line of the check

2) paypal: corvettes4stjude@aol.com

#3 New donation option

3) St. Jude Donation page - we get credit for this:

https://waystohelp.stjude.org/sjVPor...1&programId=51

When you go to this page:

1) click "Donate Now

2) click on Florida

3) enter "corv," as the first 4 letters

4) click on link: "CORVETTES FOR ST. JUDE,"

5) and then click on the "Sponsor Event," tag.

OK, now that I typed the words DYNO NUMBERS, I should have the highest hit count in the history of my posting. The entire install is detailed within and all parts, cam specs, and build pics are included to further the knowledge base of all those interested in these heads. I have long been upset that the corvette comunity is so secretive but these heads have been shrouded in mystery with no meeting of the minds to help further the results. Most tuners dont want to share cutting edge tech but this is way out of the norm with these heads...

The entire install is detailed within and all parts, cam specs, and build pics are included to further the knowledge base of all those interested in these heads. I have long been upset that the corvette comunity is so secretive but these heads have been shrouded in mystery with no meeting of the minds to help further the results. Most tuners dont want to share cutting edge tech but this is way out of the norm with these heads...

HAVE YOUR LAUGHS

As some know, I enjoyed eating my words with a nice cream sauce and white wine about a year ago when I didn’t like the results from installing these heads. For those that dont know what heads I am referring to, they are the L92 truck heads that later appeared on the 2008 corvette. There are 3 different casting numbers to date with no apparent changes to the casting.

My complaints were a loss of low and mid-band TQ and lack of ability to use a big cam. Later, I found the LG headers to boost mah ride with TQ and the Cory Harris ported intake manifold for gains through most of the midband since there isn’t a FAST manifold for the rectangle ports out. More than the usual SPINhaters joined in the roasting of my opinion but in my defense I still don’t think they are the be-all, end-all cylinder head. The best cathedral heads are better but at what cost? There is a level where these heads fit the ticket. They are cheap and I stand by the opinion that they represent a bargain in their box-stock or near box-stock form. When you delete the cost savings and start comparing to a trick flow 225 with a 236 cam and 12:1 compression you see what 450rwtq at 4k rpms is. But they are 3.5k more with a FAST manifold. If you start porting and getting carried away with such things, the value of these heads begins to disappear. I think head porters doing L92 heads, do a service for the stroker motor community but the 6 liter deal appears to not benefit nearly as much. These heads are here to stay but that doesn’t mean that a guy with an LS3 isnt going to try the heads in his garage that made great power on his earlier LS engine. The 6.2 liter and 225 trick flows or ETP’s may make 530+rwhp. Who knows?

WARRANTY?

Puh-leeze.

WHAT’S IN A CLONE?

When Craigster05's woman mentioned she wanted him to get the H/C pacakge I suggested staying close to the specs of my car so we would have a reference to compare what works for him or not. He refered to it as the CLONEmonster, but it really isnt. It was in some ways better and yet didnt have some things my had that gave me a boost. Often in a copy of a design, one tries to duplicate the results of something that was successful. Being that my H/C package was a work in progress when I had time to do it, you cant exactly call this a clone of my car. Craigs install actually included all the changes I was going to include in the revision to the H/C package on my car. In other words, if calculations and software was correct with predictions, his car should be faster than mine. There wasn’t a lot changed, but the changes are:

Cam advanced 2 degrees

Ported exhaust runner

Better timing chain

Stainless intake valve

A slight bump in compression

THE PACKAGE

I understand the need to have secrecy in this business but sometimes it makes no sense.

In this package the cam specs are:

XER Comp cams lobes 228/232 .588/.595 lift 114+2 LSA

The heads are box stock L92’s that were ported on the exhaust side slightly to get rid of the bump near the headers side and to narrow down the valve guide bosses.

Springs are: Patriot gold extreme duals which Scoggins says have a perfect track record leading them to sell very few comp921's at twice the price. They are 275 bucks with hardened seats, titanium retainers, series 7 locks (beefy like chef boy-r-dee), and valve stem oil seals. Dats a bargain….

The intake manifold:

And the new Cory Haris stage 2 ported TB:

Note the thinner center shaft that holds the TB blade:

The timing chain is the IWIS from Lingenfelter and is much stronger. Held side by side with the stock LS2 it has so much less slack leading me to believe that the stock is retarding the cam its used with by 2-3 degrees. Out side of a double roller chain, this is the best there is.

The heads used Manley Race Flow intake and exhaust one piece stainless valves.

Powerbond under drive pulley. Its better looking than all black ones.

Supporting mods were

Vararam

LG headers-because the heads need the TQ

4.10 gears, because wimps that think you cant have 30mpg on a 4.10 geared car are wrong.

Catch can: because Cartek does that best.

MGW shifter because 6900rpm comes up really fast

THE INSTALL

Remember that 99 degree week when the humidity was insane a few weeks agoin NY in early June? Yeah of course all New Yawkas do. Especially the Sicilians; one was with me and I saw the horns. Well that was hell week. If this wasn’t for Craig, I would have shut down all work until it passed but…

Craig’s shop, Elite Motors was 120 degrees. The rip down was done by both of us.

The start took it down to turkey appearance after Thanksgiving:

Sliding the shaft in slow-like….keep turning and careful of the cam bearings (actually this was a test that you failed....thats the stock cam coming out. See the lobes??). Be sure to lube up for the new bump stick:

As I got to the valvetrain in the first 30 minutes Craig looked at me and in a low unsure voice, said, “You have no idea how much I’m trusting you right now.”

I didn’t know what to say so I gave him a reassuring response, “Relax, I’m bound to get good at this sooner or later.” He smiled and said, “you’re kidding….haha. Right?”

“Guy, you’re kidding right?.................................. .......Guy?”

Enjoy the silence.

Craig was assigned tasks that he completed in a timely manner prior to my appearance each day. I like to sleep in everyday because I can. Besides not going to bed until sunrise while racing my car all night takes much out of me.

FLY-CUTTING 101-back in session

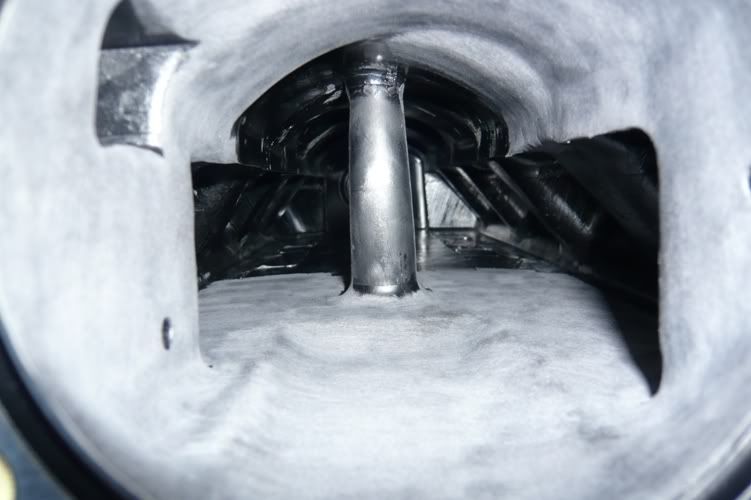

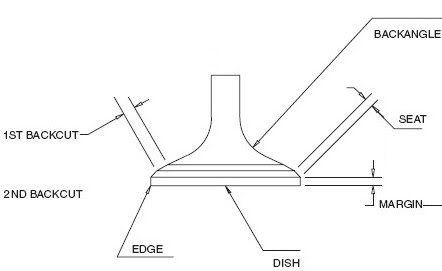

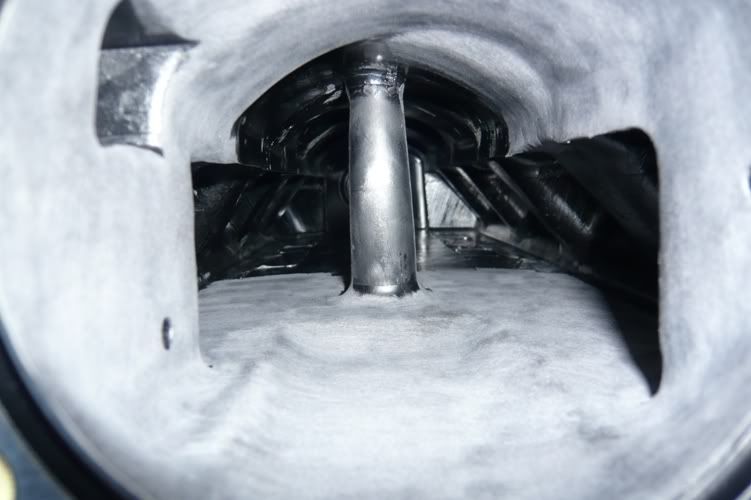

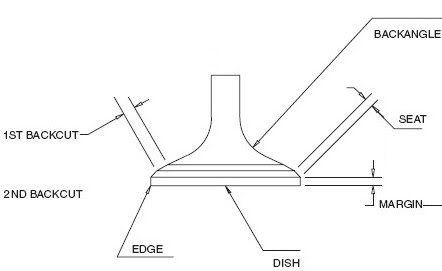

In most L92 set-ups like this one, the pistons would have to be cut. Each car is different and every cam, even the same grind, will vary. The Manley race flow valve has a thicker margin than the stock valve by .030”. Yes I measured them. In the picture below the various parts of a valve are labeled.

The margin takes away from P/V clearance therefore by about that amount. The heads being milled, and thinner gaskets are other factors. This install also advanced the cam 2 degrees from the original. Before everyone gets confused, my cam is a 230/234 XER on a 114LSA. The last cam I had was a 228/232 and it was stronger in the mid-band. These are very small differences but a man knows his ‘tool’. Duration takes away from P/V clearance too as it grows. I wouldnt be a bit surprised if a 226/230 or a 226/232 would do as good or better than this cam did. Data from various sources suggests that smaller works better on this head.

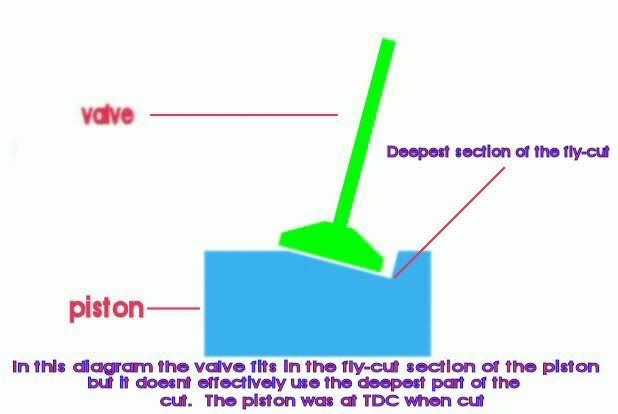

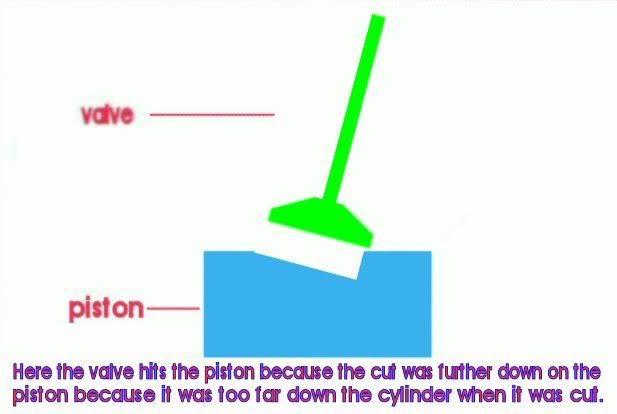

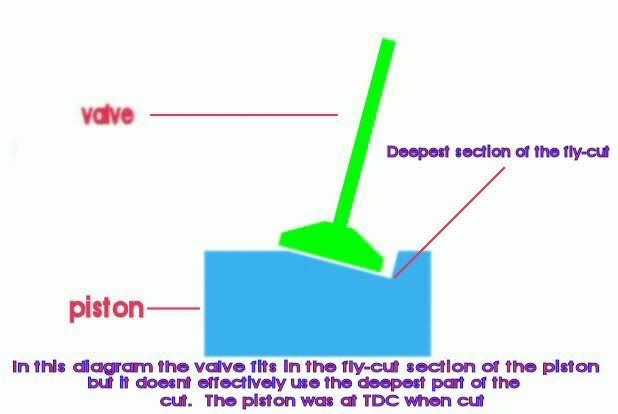

When you determine what clearance you need and decide to fly-cut a certain amount you have to realize that there is a difference between the fly-cut cut depth and the usable depth. Just because you cut a certain amount doesn’t mean the depth is the needed depth where the valve actually touches.

Taped up prior to fly-cutting:

Completed fly-cuts:

Pistons were cleaned by Craig before reassembly.

TECH POINT (NEON LIGHTS)

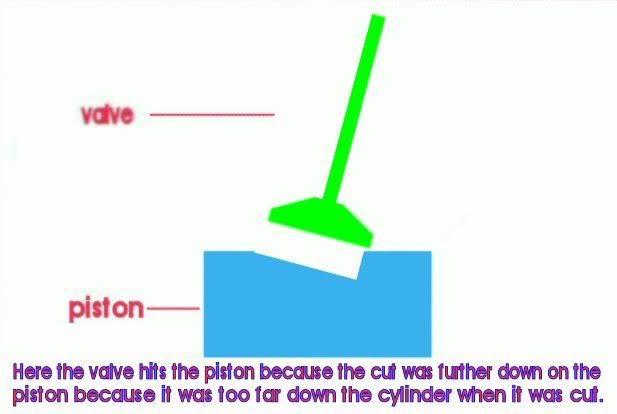

In the following hand drawn diagram, (because I care about all of you), shows the place where a valve actually touches a piston and where the cut is actually made. First thing to note is that when a piston is close to a valve that’s off the seat, the piston is not at top dead center (TDC). The intake valve’s contact (or near contact) occurs between 0 and 15 degrees after TDC when the piston is heading down. On the top diagram, the cut made is at TDC which is made with a 2.25” cutter. Since the valve is 2.165”, the cut has a wasted space of about .0425” that isn’t where the valve would touch. The deepest part of the cut is actually too high for the valve because of two reasons: The cutter is bigger than the valve and the piston has to be cut higher in the cylinder bore than where the piston would be if it would contact the valve at 0-15 degrees past TDC. Diagram 2 shows the piston further down the bore during contact IF YOU HAD THE PISTON TOO LOW FOR THE FLY-CUT and the edge of the valve touches the edge of the cut. Unfortunately you cant take a chance of putting the cut too far down the piston. What this amounts too is that the cut is unlikely to be deepest where the valve would touch and so the real cut depth is deeper than your actual gained clearance distance. Since the piston is limited in how deep you can cut, the distance must be discriminated. LG has had experience with deep cuts that worked fine and Louis’ Jr’s accuracy can be banked on. If you get an .080” cut, the usable depth is less. How much? You guess. While compression is your friend, the ring lands get close to the cut at the edges.

Craig was cut .075” at the deepest but at TDC so the effective depth is more like .055". The depth wasnt really needed but if things work out on a future grind, it may benefit from the added available space.

TIMING CHAIN SECURITY

I sit here late night or actually early morning as I see the sun is about to rise with a friend's car on my mind. Last night his timing chain broke. He had a 228 cam too and wouldnt have thought his cam-only car would have needed more but...

I am not saying the sky is falling but the stock timing chain isn’t the best of ideas for higher power. I am telling of the broken timing chain as a data point. With the common knowledge that double roller chains are the best option, the point here is that double rollers need to be fitted in our motors. The cam position sensor is in the timing cover and needs to be clearanced. Various reports of the oil pump bolts hitting and gear line-up issues, the double roller is harder to install. While the LS2 chain is reported to be much stronger than the previous LS1/6 chain, its still an item that stretches. When I removed Craig’s timing chain and held it next to the new IWIS chain, the difference in length was big. The added stretch allows the gears to lead each other which changes the actual cam timing setting. The IWIS chain is much stronger and is a new minimum for me on cam installs.

HEAD PREP/PORTING

The intake runner is a whopping 260cc’s and is already too big for this application. Since it already flows 330cfm out of the box, it makes no sense to increase this side of the head’s performance. Yes ported it will make 350cfm but ported casting have more times than not, cost low end TQ for the added cost. The heads are $380 for the pair and 100 bucks or so for the milling to get the compression up. The exhaust side is the weaker.

SPINNING the die grinder..get it SPINNING….

While a high velocity port runner will perform better than a slower velocity bigger runner, many believe that the cams needed to work with these heads must be huge splits. This is BS. Texas speed has gottem 460rwhp with a single pattern 228/228 cam, I have gotten repeated great results with a 228/232 and 230/234, and I have even seen a reverse split make the same power on these heads as a 243 ported casting. So the next time someone tells you that you need a 228/238 or a 228/242, tell them to keep the overlap grind for their car.

Once you do this minor clean-up that I did, the heads will work with exactly the same cams as a cathedral port head. Even box stock, my car pulled similar power to Craig’s with the same cam grind. I dyno’ed 471rwhp through 4.10’s with the 228 cam. I have some mods he doesn’t have, namely an aluminum flywheel, and much lighter rear wheels which lessen driveline losses.

Oh no I used that word….DYNO….

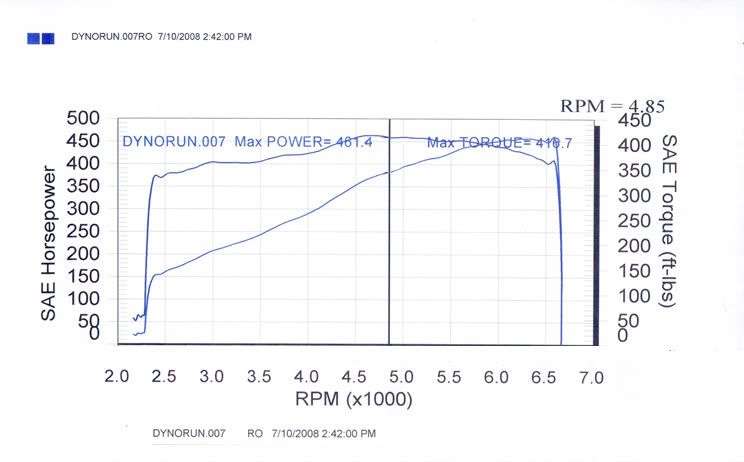

Yes we dyno’ed the car. We went to an independent shop to do the dyno’s so there wasn’t a conflict of interest. The owner of Vettech in Great Neck is an honest [to be truthful in communication; free of knowingly false information] guy that works with you and wanted to see true results. I didn’t have to worry about getting a set of manually entered false weather data designed to make you think you picked the wrong shop for the install. Since I am allowed to operate the dyno if I wanted to, I know there isn’t anything shady going on. The weather data is at the top of this power vs rpm listing

NOTE: The shop's wideband was giving all sorts of weird readings and simply needed to be recalibrated or something. The part throttle steady a/f reading was reading 17-18:1 for stoic so something was off so we used an LM-1 mounted before the cats to do the tune. The narrow bands were also reading way rich so ignore the a/f column:

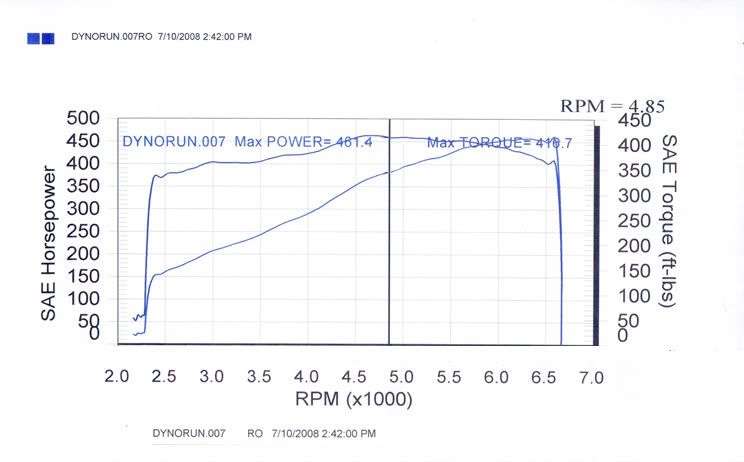

This is the dyno sheet on the 4th pull after optimizing the tune on the dyno. I came pretty close with a street tune and was also close on the HP prediction within 1.4HP.

Keep in mind that the car has 4.10’s and that makes the reading 10-12HP lower at this level so the final numbers are 472-474rwhp and 425-430rwtq.

The midband TQ is free of dips in the troublesome 3k-4k rpms and output at 4krpms is 380rwtq and hits 400rwtq at 4300rpm. Keep in mind that this sheet reflects the power through 4.10 gears and as such the 3.42's would likely have been a bit better 385-390 or so. In any event the car pulls great for a 228 cam. Another fact is that the TQ stays over this level all the way out to 6300rpm's.

I was happy with the numbers but felt it should have bettered my car’s last dyno. The factors of the aluminum flywheel and lightened rear wheels (16lbs less) are the items I have to thank.

My car mae 471rwhp and 434rwtq through 4.10's and hit 410rwtq at 4k when I had this same cam....minus the 2 degree advance. I havent dyno'ed with the current 230 but I think its worse actually.

The results are great for a 228 cam. There are zero driveabiltiy issues. With the exhaust cutouts closed the car sounds as quiet as a caddy on the hiway. The car has posted video footage of its performance including 30mpg gallon not only verified on the DIC but on actual miles traveled vs gallons filled.

TO PORT OR NOT TO PORT the intake side

If you search for results of the ported L92 heads you will find that huge cams tend to not result in gains proportional to the cam size increases. Major tuners get results such as 480+rwhp but the cam is big and the savings that justify using these heads. I have seen 234-236 cams do 480-490rwhp unported and I have seen 234-236 cams do 480 ported. It seems there isn’t much benefit to porting. DTE got 470rwhp with a 224 cam and is the package I respect so highly for its low end too. Phil was a Linegnfelter guy before his DTE days so I know I was up against some top shelf brains here.

One area that I didn’t explore is to do a professional competition valve job. Supporting tuners on this board have done this and realized notable gains. One tuner noted only a loss of 10rwtq and a gain of 6rwhp at peak with a well known porter’s 2000 dollar version of these heads. Stay box stock and enjoy the savings or just do a valve job. A valve job also moves the valve into the direction of the runner gaining some precious cclearance back. If the compression was left at 11:1 and not higher as it is here coupled with a valve job, this cam may have cleared without a fly-cut.

In summing up, I have to say that the results of tuners such as RPM motors, LG motorsports, Cartek, and DTE powertrain have had some great results. I am most impressed with DTE’s results which beat my results here with a smaller cam and it was on the same style dyno.

All back together:

I like the clean install look. Not that I dont like the FAST but this looks stock and appeals to a lot of guys that want it to look that way. The stock fuel rail covers fit if you use the shorter injectors as the LS2 injecotrs are talled and make the covers look 'off'.

TUNING

These heads are the same casting as those that appear on the LS3 motor. The casting number while 823 and the corvettes castings being 821, not withstanding, porters report there is no difference. The new LS3 tune on the 2008 has a change to the timing curve. There is a notable increase in the timing values between 3k and 4k from the factory so it made sense that I try this increase on my L92 headed car. I went to my curve and found that it had already started to take on that curve as I kept adding timing. Timing is higher in places because of inefficiencies. When a cylinder head is inefficient it allows more timing to be run.

The car gained plenty on the dyno with about 6hp gained and 12rwtq in some places. Charlie from RPM has a point when he states that dyno tuning always has more found in the power curve than a street only tune. Its difficult to safely duplicate it on the street. Street tunes are definitely second best. You live and learn Spin. I had limited time and pulls since I was falling asleep and the tune has som much left in it.

I had limited time and pulls since I was falling asleep and the tune has som much left in it.

THE FUTURE

To FAST or not to FAST…FAST (comp cams) states they are near done with a FAST manifold for the LS3’s which will fit these heads. The L76 intake manifold is very restrictive and the gains from Cory Harris’ porting shows that the gains can be strong when the restriction is lessened. LG motorsports has the current record for the ls3 at 517 RWHP and 485RWTQ. Any takers for the title?

Thanks for all your support and for taking the time to read my long winded report here. I hope some people benefit. Craig is happy that the entire project cost him about 450 bucks after selling his FAST and stock heads. The install was free on labor because the guy had it coming to him for all he has done for others including me: He who is typing on a great laptop he built for me.

---------------Make a difference TODAY------------------

This year you can donate in 3 ways:

1) Personal checks, cashier checks, or money orders, made out to: St. Jude Children's Hospital and mailed to "pewter99,":

Robert Briggs

P.O. Box 17083

Clearwater Fl 33762

Please put your forum name on the memo line of the check

2) paypal: corvettes4stjude@aol.com

#3 New donation option

3) St. Jude Donation page - we get credit for this:

https://waystohelp.stjude.org/sjVPor...1&programId=51

When you go to this page:

1) click "Donate Now

2) click on Florida

3) enter "corv," as the first 4 letters

4) click on link: "CORVETTES FOR ST. JUDE,"

5) and then click on the "Sponsor Event," tag.

OK, now that I typed the words DYNO NUMBERS, I should have the highest hit count in the history of my posting.

The entire install is detailed within and all parts, cam specs, and build pics are included to further the knowledge base of all those interested in these heads. I have long been upset that the corvette comunity is so secretive but these heads have been shrouded in mystery with no meeting of the minds to help further the results. Most tuners dont want to share cutting edge tech but this is way out of the norm with these heads...

The entire install is detailed within and all parts, cam specs, and build pics are included to further the knowledge base of all those interested in these heads. I have long been upset that the corvette comunity is so secretive but these heads have been shrouded in mystery with no meeting of the minds to help further the results. Most tuners dont want to share cutting edge tech but this is way out of the norm with these heads...

HAVE YOUR LAUGHS

As some know, I enjoyed eating my words with a nice cream sauce and white wine about a year ago when I didn’t like the results from installing these heads. For those that dont know what heads I am referring to, they are the L92 truck heads that later appeared on the 2008 corvette. There are 3 different casting numbers to date with no apparent changes to the casting.

My complaints were a loss of low and mid-band TQ and lack of ability to use a big cam. Later, I found the LG headers to boost mah ride with TQ and the Cory Harris ported intake manifold for gains through most of the midband since there isn’t a FAST manifold for the rectangle ports out. More than the usual SPINhaters joined in the roasting of my opinion but in my defense I still don’t think they are the be-all, end-all cylinder head. The best cathedral heads are better but at what cost? There is a level where these heads fit the ticket. They are cheap and I stand by the opinion that they represent a bargain in their box-stock or near box-stock form. When you delete the cost savings and start comparing to a trick flow 225 with a 236 cam and 12:1 compression you see what 450rwtq at 4k rpms is. But they are 3.5k more with a FAST manifold. If you start porting and getting carried away with such things, the value of these heads begins to disappear. I think head porters doing L92 heads, do a service for the stroker motor community but the 6 liter deal appears to not benefit nearly as much. These heads are here to stay but that doesn’t mean that a guy with an LS3 isnt going to try the heads in his garage that made great power on his earlier LS engine. The 6.2 liter and 225 trick flows or ETP’s may make 530+rwhp. Who knows?

WARRANTY?

Puh-leeze.

WHAT’S IN A CLONE?

When Craigster05's woman mentioned she wanted him to get the H/C pacakge I suggested staying close to the specs of my car so we would have a reference to compare what works for him or not. He refered to it as the CLONEmonster, but it really isnt. It was in some ways better and yet didnt have some things my had that gave me a boost. Often in a copy of a design, one tries to duplicate the results of something that was successful. Being that my H/C package was a work in progress when I had time to do it, you cant exactly call this a clone of my car. Craigs install actually included all the changes I was going to include in the revision to the H/C package on my car. In other words, if calculations and software was correct with predictions, his car should be faster than mine. There wasn’t a lot changed, but the changes are:

Cam advanced 2 degrees

Ported exhaust runner

Better timing chain

Stainless intake valve

A slight bump in compression

THE PACKAGE

I understand the need to have secrecy in this business but sometimes it makes no sense.

In this package the cam specs are:

XER Comp cams lobes 228/232 .588/.595 lift 114+2 LSA

The heads are box stock L92’s that were ported on the exhaust side slightly to get rid of the bump near the headers side and to narrow down the valve guide bosses.

Springs are: Patriot gold extreme duals which Scoggins says have a perfect track record leading them to sell very few comp921's at twice the price. They are 275 bucks with hardened seats, titanium retainers, series 7 locks (beefy like chef boy-r-dee), and valve stem oil seals. Dats a bargain….

The intake manifold:

And the new Cory Haris stage 2 ported TB:

Note the thinner center shaft that holds the TB blade:

The timing chain is the IWIS from Lingenfelter and is much stronger. Held side by side with the stock LS2 it has so much less slack leading me to believe that the stock is retarding the cam its used with by 2-3 degrees. Out side of a double roller chain, this is the best there is.

The heads used Manley Race Flow intake and exhaust one piece stainless valves.

Powerbond under drive pulley. Its better looking than all black ones.

Supporting mods were

Vararam

LG headers-because the heads need the TQ

4.10 gears, because wimps that think you cant have 30mpg on a 4.10 geared car are wrong.

Catch can: because Cartek does that best.

MGW shifter because 6900rpm comes up really fast

THE INSTALL

Remember that 99 degree week when the humidity was insane a few weeks agoin NY in early June? Yeah of course all New Yawkas do. Especially the Sicilians; one was with me and I saw the horns. Well that was hell week. If this wasn’t for Craig, I would have shut down all work until it passed but…

Craig’s shop, Elite Motors was 120 degrees. The rip down was done by both of us.

The start took it down to turkey appearance after Thanksgiving:

Sliding the shaft in slow-like….keep turning and careful of the cam bearings (actually this was a test that you failed....thats the stock cam coming out. See the lobes??). Be sure to lube up for the new bump stick:

As I got to the valvetrain in the first 30 minutes Craig looked at me and in a low unsure voice, said, “You have no idea how much I’m trusting you right now.”

I didn’t know what to say so I gave him a reassuring response, “Relax, I’m bound to get good at this sooner or later.” He smiled and said, “you’re kidding….haha. Right?”

“Guy, you’re kidding right?.................................. .......Guy?”

Enjoy the silence.

Craig was assigned tasks that he completed in a timely manner prior to my appearance each day. I like to sleep in everyday because I can. Besides not going to bed until sunrise while racing my car all night takes much out of me.

FLY-CUTTING 101-back in session

In most L92 set-ups like this one, the pistons would have to be cut. Each car is different and every cam, even the same grind, will vary. The Manley race flow valve has a thicker margin than the stock valve by .030”. Yes I measured them. In the picture below the various parts of a valve are labeled.

The margin takes away from P/V clearance therefore by about that amount. The heads being milled, and thinner gaskets are other factors. This install also advanced the cam 2 degrees from the original. Before everyone gets confused, my cam is a 230/234 XER on a 114LSA. The last cam I had was a 228/232 and it was stronger in the mid-band. These are very small differences but a man knows his ‘tool’. Duration takes away from P/V clearance too as it grows. I wouldnt be a bit surprised if a 226/230 or a 226/232 would do as good or better than this cam did. Data from various sources suggests that smaller works better on this head.

When you determine what clearance you need and decide to fly-cut a certain amount you have to realize that there is a difference between the fly-cut cut depth and the usable depth. Just because you cut a certain amount doesn’t mean the depth is the needed depth where the valve actually touches.

Taped up prior to fly-cutting:

Completed fly-cuts:

Pistons were cleaned by Craig before reassembly.

TECH POINT (NEON LIGHTS)

In the following hand drawn diagram, (because I care about all of you), shows the place where a valve actually touches a piston and where the cut is actually made. First thing to note is that when a piston is close to a valve that’s off the seat, the piston is not at top dead center (TDC). The intake valve’s contact (or near contact) occurs between 0 and 15 degrees after TDC when the piston is heading down. On the top diagram, the cut made is at TDC which is made with a 2.25” cutter. Since the valve is 2.165”, the cut has a wasted space of about .0425” that isn’t where the valve would touch. The deepest part of the cut is actually too high for the valve because of two reasons: The cutter is bigger than the valve and the piston has to be cut higher in the cylinder bore than where the piston would be if it would contact the valve at 0-15 degrees past TDC. Diagram 2 shows the piston further down the bore during contact IF YOU HAD THE PISTON TOO LOW FOR THE FLY-CUT and the edge of the valve touches the edge of the cut. Unfortunately you cant take a chance of putting the cut too far down the piston. What this amounts too is that the cut is unlikely to be deepest where the valve would touch and so the real cut depth is deeper than your actual gained clearance distance. Since the piston is limited in how deep you can cut, the distance must be discriminated. LG has had experience with deep cuts that worked fine and Louis’ Jr’s accuracy can be banked on. If you get an .080” cut, the usable depth is less. How much? You guess. While compression is your friend, the ring lands get close to the cut at the edges.

Craig was cut .075” at the deepest but at TDC so the effective depth is more like .055". The depth wasnt really needed but if things work out on a future grind, it may benefit from the added available space.

TIMING CHAIN SECURITY

I sit here late night or actually early morning as I see the sun is about to rise with a friend's car on my mind. Last night his timing chain broke. He had a 228 cam too and wouldnt have thought his cam-only car would have needed more but...

I am not saying the sky is falling but the stock timing chain isn’t the best of ideas for higher power. I am telling of the broken timing chain as a data point. With the common knowledge that double roller chains are the best option, the point here is that double rollers need to be fitted in our motors. The cam position sensor is in the timing cover and needs to be clearanced. Various reports of the oil pump bolts hitting and gear line-up issues, the double roller is harder to install. While the LS2 chain is reported to be much stronger than the previous LS1/6 chain, its still an item that stretches. When I removed Craig’s timing chain and held it next to the new IWIS chain, the difference in length was big. The added stretch allows the gears to lead each other which changes the actual cam timing setting. The IWIS chain is much stronger and is a new minimum for me on cam installs.

HEAD PREP/PORTING

The intake runner is a whopping 260cc’s and is already too big for this application. Since it already flows 330cfm out of the box, it makes no sense to increase this side of the head’s performance. Yes ported it will make 350cfm but ported casting have more times than not, cost low end TQ for the added cost. The heads are $380 for the pair and 100 bucks or so for the milling to get the compression up. The exhaust side is the weaker.

SPINNING the die grinder..get it SPINNING….

While a high velocity port runner will perform better than a slower velocity bigger runner, many believe that the cams needed to work with these heads must be huge splits. This is BS. Texas speed has gottem 460rwhp with a single pattern 228/228 cam, I have gotten repeated great results with a 228/232 and 230/234, and I have even seen a reverse split make the same power on these heads as a 243 ported casting. So the next time someone tells you that you need a 228/238 or a 228/242, tell them to keep the overlap grind for their car.

Once you do this minor clean-up that I did, the heads will work with exactly the same cams as a cathedral port head. Even box stock, my car pulled similar power to Craig’s with the same cam grind. I dyno’ed 471rwhp through 4.10’s with the 228 cam. I have some mods he doesn’t have, namely an aluminum flywheel, and much lighter rear wheels which lessen driveline losses.

Oh no I used that word….DYNO….

Yes we dyno’ed the car. We went to an independent shop to do the dyno’s so there wasn’t a conflict of interest. The owner of Vettech in Great Neck is an honest [to be truthful in communication; free of knowingly false information] guy that works with you and wanted to see true results. I didn’t have to worry about getting a set of manually entered false weather data designed to make you think you picked the wrong shop for the install. Since I am allowed to operate the dyno if I wanted to, I know there isn’t anything shady going on. The weather data is at the top of this power vs rpm listing

NOTE: The shop's wideband was giving all sorts of weird readings and simply needed to be recalibrated or something. The part throttle steady a/f reading was reading 17-18:1 for stoic so something was off so we used an LM-1 mounted before the cats to do the tune. The narrow bands were also reading way rich so ignore the a/f column:

This is the dyno sheet on the 4th pull after optimizing the tune on the dyno. I came pretty close with a street tune and was also close on the HP prediction within 1.4HP.

Keep in mind that the car has 4.10’s and that makes the reading 10-12HP lower at this level so the final numbers are 472-474rwhp and 425-430rwtq.

The midband TQ is free of dips in the troublesome 3k-4k rpms and output at 4krpms is 380rwtq and hits 400rwtq at 4300rpm. Keep in mind that this sheet reflects the power through 4.10 gears and as such the 3.42's would likely have been a bit better 385-390 or so. In any event the car pulls great for a 228 cam. Another fact is that the TQ stays over this level all the way out to 6300rpm's.

I was happy with the numbers but felt it should have bettered my car’s last dyno. The factors of the aluminum flywheel and lightened rear wheels (16lbs less) are the items I have to thank.

My car mae 471rwhp and 434rwtq through 4.10's and hit 410rwtq at 4k when I had this same cam....minus the 2 degree advance. I havent dyno'ed with the current 230 but I think its worse actually.

The results are great for a 228 cam. There are zero driveabiltiy issues. With the exhaust cutouts closed the car sounds as quiet as a caddy on the hiway. The car has posted video footage of its performance including 30mpg gallon not only verified on the DIC but on actual miles traveled vs gallons filled.

TO PORT OR NOT TO PORT the intake side

If you search for results of the ported L92 heads you will find that huge cams tend to not result in gains proportional to the cam size increases. Major tuners get results such as 480+rwhp but the cam is big and the savings that justify using these heads. I have seen 234-236 cams do 480-490rwhp unported and I have seen 234-236 cams do 480 ported. It seems there isn’t much benefit to porting. DTE got 470rwhp with a 224 cam and is the package I respect so highly for its low end too. Phil was a Linegnfelter guy before his DTE days so I know I was up against some top shelf brains here.

One area that I didn’t explore is to do a professional competition valve job. Supporting tuners on this board have done this and realized notable gains. One tuner noted only a loss of 10rwtq and a gain of 6rwhp at peak with a well known porter’s 2000 dollar version of these heads. Stay box stock and enjoy the savings or just do a valve job. A valve job also moves the valve into the direction of the runner gaining some precious cclearance back. If the compression was left at 11:1 and not higher as it is here coupled with a valve job, this cam may have cleared without a fly-cut.

In summing up, I have to say that the results of tuners such as RPM motors, LG motorsports, Cartek, and DTE powertrain have had some great results. I am most impressed with DTE’s results which beat my results here with a smaller cam and it was on the same style dyno.

All back together:

I like the clean install look. Not that I dont like the FAST but this looks stock and appeals to a lot of guys that want it to look that way. The stock fuel rail covers fit if you use the shorter injectors as the LS2 injecotrs are talled and make the covers look 'off'.

TUNING

These heads are the same casting as those that appear on the LS3 motor. The casting number while 823 and the corvettes castings being 821, not withstanding, porters report there is no difference. The new LS3 tune on the 2008 has a change to the timing curve. There is a notable increase in the timing values between 3k and 4k from the factory so it made sense that I try this increase on my L92 headed car. I went to my curve and found that it had already started to take on that curve as I kept adding timing. Timing is higher in places because of inefficiencies. When a cylinder head is inefficient it allows more timing to be run.

The car gained plenty on the dyno with about 6hp gained and 12rwtq in some places. Charlie from RPM has a point when he states that dyno tuning always has more found in the power curve than a street only tune. Its difficult to safely duplicate it on the street. Street tunes are definitely second best. You live and learn Spin.

I had limited time and pulls since I was falling asleep and the tune has som much left in it.

I had limited time and pulls since I was falling asleep and the tune has som much left in it. THE FUTURE

To FAST or not to FAST…FAST (comp cams) states they are near done with a FAST manifold for the LS3’s which will fit these heads. The L76 intake manifold is very restrictive and the gains from Cory Harris’ porting shows that the gains can be strong when the restriction is lessened. LG motorsports has the current record for the ls3 at 517 RWHP and 485RWTQ. Any takers for the title?

Thanks for all your support and for taking the time to read my long winded report here. I hope some people benefit. Craig is happy that the entire project cost him about 450 bucks after selling his FAST and stock heads. The install was free on labor because the guy had it coming to him for all he has done for others including me: He who is typing on a great laptop he built for me.

Last edited by SpinMonster; 08-13-2009 at 05:26 PM.

#2

Tech Contributor

The SPINMANUAL of C6 mods continues.

Great info on the timing chain, glad there's a new choice out there and I hope people hear your words. I've seen a 2 double rollers fail due to improper clearancing and a stock chain fail. It's not pretty when they fail, 2 new engines, one was saved but got a 'free' flycut on some pistons.

Are you using the LS2 injectors and fuel rail? Anything special there to make it work?

Great info on the timing chain, glad there's a new choice out there and I hope people hear your words. I've seen a 2 double rollers fail due to improper clearancing and a stock chain fail. It's not pretty when they fail, 2 new engines, one was saved but got a 'free' flycut on some pistons.

Are you using the LS2 injectors and fuel rail? Anything special there to make it work?

#3

Tech Contributor

Thread Starter

The SPINMANUAL of C6 mods continues.

Great info on the timing chain, glad there's a new choice out there and I hope people hear your words. I've seen a 2 double rollers fail due to improper clearancing and a stock chain fail. It's not pretty when they fail, 2 new engines, one was saved but got a 'free' flycut on some pistons.

Are you using the LS2 injectors and fuel rail? Anything special there to make it work?

Great info on the timing chain, glad there's a new choice out there and I hope people hear your words. I've seen a 2 double rollers fail due to improper clearancing and a stock chain fail. It's not pretty when they fail, 2 new engines, one was saved but got a 'free' flycut on some pistons.

Are you using the LS2 injectors and fuel rail? Anything special there to make it work?

It figures you're the first to post on this of all threads. The injectors here were the stockers and they max out at near 90% duty cycle which means they are near maxed in the cold winter air. Craig has new 40lb'ers on the way and the rescaling of the injector flow rate will get him back to 70% or so. I will work on his tune with the wideband then. It is going to take a lot more timing in the midband which will improve the TQ numbers.

It figures you're the first to post on this of all threads. The injectors here were the stockers and they max out at near 90% duty cycle which means they are near maxed in the cold winter air. Craig has new 40lb'ers on the way and the rescaling of the injector flow rate will get him back to 70% or so. I will work on his tune with the wideband then. It is going to take a lot more timing in the midband which will improve the TQ numbers.I see I am getting away from your question. The stock injectors are taller than the Z06/LS3 shorty 40's and so the fuel LS2 rail is sitting a bit higher. You do realize that once he gets the injectors he will be 1000 bucks away from a 175 dry shot?

We used a few spacers to get the rail to sit higher. I'm not proud of the 'rig' but the 40's will be here in a few days.

We used a few spacers to get the rail to sit higher. I'm not proud of the 'rig' but the 40's will be here in a few days.

#4

Collections Hold

Member Since: Aug 2002

Location: Fort Wayne Indiana

Posts: 2,899

Likes: 0

Received 5 Likes

on

5 Posts

A job well done IMHO and the tech information you selflessly and freely provide for the DIY folks around here is far more important/helpful than any "dyno number" absolute anyway.

Good job- the DIY folks here should be grateful for your informational posts you provide them, because I can tell you this...if I wasn't already in the tuner biz and I didn't know how to do this stuff professionally already, I'd use your pages to assist me in the garage for sure to build my own car.

That's something to be proud of.

Regards,

Phil

Good job- the DIY folks here should be grateful for your informational posts you provide them, because I can tell you this...if I wasn't already in the tuner biz and I didn't know how to do this stuff professionally already, I'd use your pages to assist me in the garage for sure to build my own car.

That's something to be proud of.

Regards,

Phil

#6

Team Owner

I was anxiously awaiting the dyno numbers. Four hundred ft lbs at 3000RPM! And climbing across the board! Great numbers. I recently discovered Elite Auto in Port Jefferson and found them to be a First Class Operation. They did my Z06 brake upgrade two weeks ago and did a great job. I havent had the pleasure of meeting Craig yet due to just missing each other there but we will. Your package sounds like the way I looking to go with my car very soon. Thanks for taking the time to keep us all informed. People like you make this the best Corvette site available anywhere. Ill be talking to you and Craig soon.

#7

Team Owner

Member Since: Jul 2004

Location: NJ

Posts: 24,652

Received 297 Likes

on

94 Posts

St. Jude Donor '05-'08

Spin after seeing a handful of RR engines fail because of timing chain IMHO slack is a BIG concern. In RR I am thinking that the shifting of gears (downshift or upshift) is causing the timing chain to flex and then when the clutch is let back out the timing chain snaps back together. That force is causing the chain to break. It is only a thought based on where on the track the timing chain went and I was only looking at RR cars. I dont remember hearing 1/4 mile cars breaking timing chains like this.

I have seen every type of chain break (this includes LS2 and double rollers) so when we built my LS7 setup we looked to see what GM was doing differently and we talked to companies like Katech. Surprisingly we were told the new LS2 timing chain was being used in many applications. People claimed it was stronger than in the past. We also looked at what GM did with the LS7 - they added a tensioner per say in the timing chain area which stops the flexing from happening so we added the same thing to my car.

I am going to take my car apart this winter and do some measurements of the timing chain to see if there is any wear or if there is any deterioration/stressed areas.

BTW - my double roller failed at WGI and I know of a 2 LS2 that failed around the same spot (although I think that was by chance). I always thought my engine would go from just being old not because a failed double roller

As a reference to your dyno numbers I can say my old 01 346 with NO FAST intake with G5X3 cam and 205 AFR heads (plus supporting mods) made 460rwhp / 401rwtq with 4.10 gears too. This was 4 years ago and tuning has come along way since then which is evident by your entire curve.

I have seen every type of chain break (this includes LS2 and double rollers) so when we built my LS7 setup we looked to see what GM was doing differently and we talked to companies like Katech. Surprisingly we were told the new LS2 timing chain was being used in many applications. People claimed it was stronger than in the past. We also looked at what GM did with the LS7 - they added a tensioner per say in the timing chain area which stops the flexing from happening so we added the same thing to my car.

I am going to take my car apart this winter and do some measurements of the timing chain to see if there is any wear or if there is any deterioration/stressed areas.

BTW - my double roller failed at WGI and I know of a 2 LS2 that failed around the same spot (although I think that was by chance). I always thought my engine would go from just being old not because a failed double roller

As a reference to your dyno numbers I can say my old 01 346 with NO FAST intake with G5X3 cam and 205 AFR heads (plus supporting mods) made 460rwhp / 401rwtq with 4.10 gears too. This was 4 years ago and tuning has come along way since then which is evident by your entire curve.

Last edited by Wicked Weasel; 07-11-2008 at 07:50 AM.

#8

Burning Brakes

Great numbers and Great write up!

If you remember you talked with me on the phone for some time about my head options a few months ago. I ended up going with milled and stage 3 heads from Livernois and got 452rwhp with 402rwtq. I would of went with the L92's but Manley was out of stock on the valves at the time and I didn't want to go with the Stock 2 piece type... I did all the work myself including Heads, Porting of the Intake, Throttle body and Tuning. I'm sure a good dyno tune could net some additional benefits, especially in the torque area but I'm pretty happy with the results all things considered. The only down side is I only have .038" P/V clearance with the Stage 3 bigger valves and .030 milling taken into account... So far so good though and I have missed a couple hard high rpm shifts before I recently got MGW Shifter. Thanks for all your help!!!

Thanks for all your help!!!

If you remember you talked with me on the phone for some time about my head options a few months ago. I ended up going with milled and stage 3 heads from Livernois and got 452rwhp with 402rwtq. I would of went with the L92's but Manley was out of stock on the valves at the time and I didn't want to go with the Stock 2 piece type... I did all the work myself including Heads, Porting of the Intake, Throttle body and Tuning. I'm sure a good dyno tune could net some additional benefits, especially in the torque area but I'm pretty happy with the results all things considered. The only down side is I only have .038" P/V clearance with the Stage 3 bigger valves and .030 milling taken into account... So far so good though and I have missed a couple hard high rpm shifts before I recently got MGW Shifter.

Thanks for all your help!!!

Thanks for all your help!!!

#9

Tech Contributor

Spin after seeing a handful of RR engines fail because of timing chain IMHO slack is a BIG concern. In RR I am thinking that the shifting of gears (downshift or upshift) is causing the timing chain to flex and then when the clutch is let back out the timing chain snaps back together. That force is causing the chain to break. It is only a thought based on where on the track the timing chain went and I was only looking at RR cars. I dont remember hearing 1/4 mile cars breaking timing chains like this.

I have seen every type of chain break (this includes LS2 and double rollers) so when we built my LS7 setup we looked to see what GM was doing differently and we talked to companies like Katech. Surprisingly we were told the new LS2 timing chain was being used in many applications. People claimed it was stronger than in the past. We also looked at what GM did with the LS7 - they added a tensioner per say in the timing chain area which stops the flexing from happening so we added the same thing to my car.

I am going to take my car apart this winter and do some measurements of the timing chain to see if there is any wear or if there is any deterioration/stressed areas.

BTW - my double roller failed at WGI and I know of a 2 LS2 that failed around the same spot (although I think that was by chance). I always thought my engine would go from just being old not because a failed double roller

As a reference to your dyno numbers I can say my old 01 346 with NO FAST intake with G5X3 cam and 205 AFR heads (plus supporting mods) made 460rwhp / 401rwtq with 4.10 gears too. This was 4 years ago and tuning has come along way since then which is evident by your entire curve.

I have seen every type of chain break (this includes LS2 and double rollers) so when we built my LS7 setup we looked to see what GM was doing differently and we talked to companies like Katech. Surprisingly we were told the new LS2 timing chain was being used in many applications. People claimed it was stronger than in the past. We also looked at what GM did with the LS7 - they added a tensioner per say in the timing chain area which stops the flexing from happening so we added the same thing to my car.

I am going to take my car apart this winter and do some measurements of the timing chain to see if there is any wear or if there is any deterioration/stressed areas.

BTW - my double roller failed at WGI and I know of a 2 LS2 that failed around the same spot (although I think that was by chance). I always thought my engine would go from just being old not because a failed double roller

As a reference to your dyno numbers I can say my old 01 346 with NO FAST intake with G5X3 cam and 205 AFR heads (plus supporting mods) made 460rwhp / 401rwtq with 4.10 gears too. This was 4 years ago and tuning has come along way since then which is evident by your entire curve.

#10

Great documentary thread. Takes a lot of planning and time to share a process at this level. Thanks.

I'd love to hear more on what you think is behind that torque curve-- I'm new to NA head porting and cam selection, but given what I've seen in the past for the LS2 (and LS3) setups that's some serious area under the curve from pretty darn low in the rpm curve. To my unseasoned eye that's pretty unusual for these motors. To what do you attribute this?

Again, thanks for documenting this little project.

Scott

I'd love to hear more on what you think is behind that torque curve-- I'm new to NA head porting and cam selection, but given what I've seen in the past for the LS2 (and LS3) setups that's some serious area under the curve from pretty darn low in the rpm curve. To my unseasoned eye that's pretty unusual for these motors. To what do you attribute this?

Again, thanks for documenting this little project.

Scott

#11

Safety Car

What can I say that hasn't already been said?

When you finally walk the walk, it is a humbling experience. Spending 24 hours overheated, tired, bent over, bruised knuckled while constantly whipsering to yourself "I am tearing apart a perfectly good $50K car that I'm still paying for....WHAT THE HECK WERE YOU THINKING?!?!?".....gives you a whole new level of respect for each and every tuner shop that does this every day. If you do this yourself, you understand just how much guys like Cartek, Chuck CoW, ECS, DTE, RPM, LG and the rest are REALLY undertaking for you, at most times for a small profit margin, when you add up everything involved. There is so much to keep track of, so much to be careful with, it's astounding.

The car's performance is mind blowing...I need new rubber and probably a new clutch to get it all to stick, but an informal 1/4 mile run with a stop watch on a closed course put me at 11 flat, which I think is going to give the car a deep 10 sec 1/4 with some seat time or a good driver (Cameron...Julian....want to help a guy out????). I can't quite run with the Dvl, but I got the performance of a dream for an amazing savings in cost....having your own shop to work in helps but....

Having a friend like Guy is priceless. No, I'm sorry...not a friend....a brother...someone who has time and time again proven his friendship to be much better than my own brother. I was very wary on doing this project....in fact it was Guy and Chuck who talked me into doing it. Guy wanted to do something for me for all the things I did for him (which was not necessary....I am who I am and those of you who know me know I give of myself to my friends and never ask for anything in return, only that they help out another when needed). Chuck graciously offered his shop to do the work since their would be extra hands and more Corvette parts and equipment if we needed it), but due to the distance and the desire to be able to handle it all myself, we did it at Elite. I did all the grunt work I could for Guy, and he did all the technical and tricky stuff....and I'll be amazed forever that he estimated 460 rwhp and the dyno proved out at 461 RWHP!

Guy, you are the salt of the earth, a friend of the highest order to complete strangers, someone who unselfishly gives of himself for a higher cause, and a loyal brother to all you hold dear (even when "the unmovable object meets the unstoppable force )....even with missing or incorrect parts, untorqued bolts, lousy pizza, 120 degree temps, we managed to get it done without testing brute strength against martial arts mastery. You are the best and as Spock said, "I have been and always shall be your friend".

)....even with missing or incorrect parts, untorqued bolts, lousy pizza, 120 degree temps, we managed to get it done without testing brute strength against martial arts mastery. You are the best and as Spock said, "I have been and always shall be your friend".

Thanks to Dave from Vettetech for all his help and allowing us tuning time during a busy and hectic schedule. Thank you to Chuck CoW for constant input and good times, Cory for his excellent work and support, Julian at Cartek for the support and great Catch Can (write up coming soon) and the countless other members that have supported this project, called and PMd me with words of support and good wishes...and of course, to Tony and Kevin at the shop...you guys are always there for me....where would I be without you?

Thanks for listening, we'll post up track times as soon as we get there.

For those who never saw the video:

When you finally walk the walk, it is a humbling experience. Spending 24 hours overheated, tired, bent over, bruised knuckled while constantly whipsering to yourself "I am tearing apart a perfectly good $50K car that I'm still paying for....WHAT THE HECK WERE YOU THINKING?!?!?".....gives you a whole new level of respect for each and every tuner shop that does this every day. If you do this yourself, you understand just how much guys like Cartek, Chuck CoW, ECS, DTE, RPM, LG and the rest are REALLY undertaking for you, at most times for a small profit margin, when you add up everything involved. There is so much to keep track of, so much to be careful with, it's astounding.

The car's performance is mind blowing...I need new rubber and probably a new clutch to get it all to stick, but an informal 1/4 mile run with a stop watch on a closed course put me at 11 flat, which I think is going to give the car a deep 10 sec 1/4 with some seat time or a good driver (Cameron...Julian....want to help a guy out????). I can't quite run with the Dvl, but I got the performance of a dream for an amazing savings in cost....having your own shop to work in helps but....

Having a friend like Guy is priceless. No, I'm sorry...not a friend....a brother...someone who has time and time again proven his friendship to be much better than my own brother. I was very wary on doing this project....in fact it was Guy and Chuck who talked me into doing it. Guy wanted to do something for me for all the things I did for him (which was not necessary....I am who I am and those of you who know me know I give of myself to my friends and never ask for anything in return, only that they help out another when needed). Chuck graciously offered his shop to do the work since their would be extra hands and more Corvette parts and equipment if we needed it), but due to the distance and the desire to be able to handle it all myself, we did it at Elite. I did all the grunt work I could for Guy, and he did all the technical and tricky stuff....and I'll be amazed forever that he estimated 460 rwhp and the dyno proved out at 461 RWHP!

Guy, you are the salt of the earth, a friend of the highest order to complete strangers, someone who unselfishly gives of himself for a higher cause, and a loyal brother to all you hold dear (even when "the unmovable object meets the unstoppable force

)....even with missing or incorrect parts, untorqued bolts, lousy pizza, 120 degree temps, we managed to get it done without testing brute strength against martial arts mastery. You are the best and as Spock said, "I have been and always shall be your friend".

)....even with missing or incorrect parts, untorqued bolts, lousy pizza, 120 degree temps, we managed to get it done without testing brute strength against martial arts mastery. You are the best and as Spock said, "I have been and always shall be your friend".Thanks to Dave from Vettetech for all his help and allowing us tuning time during a busy and hectic schedule. Thank you to Chuck CoW for constant input and good times, Cory for his excellent work and support, Julian at Cartek for the support and great Catch Can (write up coming soon) and the countless other members that have supported this project, called and PMd me with words of support and good wishes...and of course, to Tony and Kevin at the shop...you guys are always there for me....where would I be without you?

Thanks for listening, we'll post up track times as soon as we get there.

For those who never saw the video:

Last edited by Craigster05; 07-11-2008 at 04:31 PM.

#14

Melting Slicks

Looks like a good write up and thought put in to the project, but why the 114 cam? With huge ports like that, loss of midrange you mention, why not take adv of scavenging and use a 112?

#15

Drifting

Member Since: Feb 2007

Location: Alpharetta Georgia

Posts: 1,843

Likes: 0

Received 12 Likes

on

8 Posts

OT: All of this timing chain failure has me sick to my stomach. I don't get it. Never in my life had I ever heard of a failed timing chain until I got my vette. Timing chains are pretty much the last thing on your mind(and they should be) but it seems like they fail more than any timing belt that I have ever heard of. It must be one weak *** chain because I have never heard of a timing chain snapping until now.

#18

Pro

I can tell you that from what I've seen, on a lot of L92 cam results, is these heads dont need or want much overlap (scavenging). With an intake port that greatly outflows the exhaust port cylinder fill doesn't seem to be an issue. Conventional thinking on cylinder scavenging seems to lead to poor performance with these heads.

#19

Tech Contributor

matter of fact the SOB that stole my 112 C5 from my driveway killed it 3 times getting it out of my driveway...giving me ample time to call the cops who gave chase...but called off the chase at 120 when it was pullng away.

sorry for the diversion....sore subject

sorry for the diversion....sore subject

Last edited by Joe_G; 07-11-2008 at 01:55 PM.

#20

Burning Brakes

Guy once again you've shown not only your mechanical prowess but your ability to write a techincal treatise in an easily understandble language. Thank you, my coupe thanks you too. My Z06 is getting a chubbie knowing it's gonna be SPINNED.

Guy once again you've shown not only your mechanical prowess but your ability to write a techincal treatise in an easily understandble language. Thank you, my coupe thanks you too. My Z06 is getting a chubbie knowing it's gonna be SPINNED.Craig congratulations on your fine new Spin modded Vette, great hp/tq #'s. And yes Craig I agree Spin really is a good friend, brother and does truly give of himself unselfishly, (oops too much praise and the big Guy will need a convertible

).

).BTW untorqued bolts, I'm horrified, oh the shame:o