My A6 tranny cooler install! Lots of pictures

#1

I thought i would share with everyone how i went about installing my trans cooler on my 08 Corvette a6! I haven't been on the forums for very long but from all the research i realized the only thing that would help prolong the life of my transmission was a transcooler. So i went ahead and had a B&M trans cooler installed. Prior to the trans cooler i put in a yank ss3600 torque converter in my car and i have been babying it around until the cooler was put on.

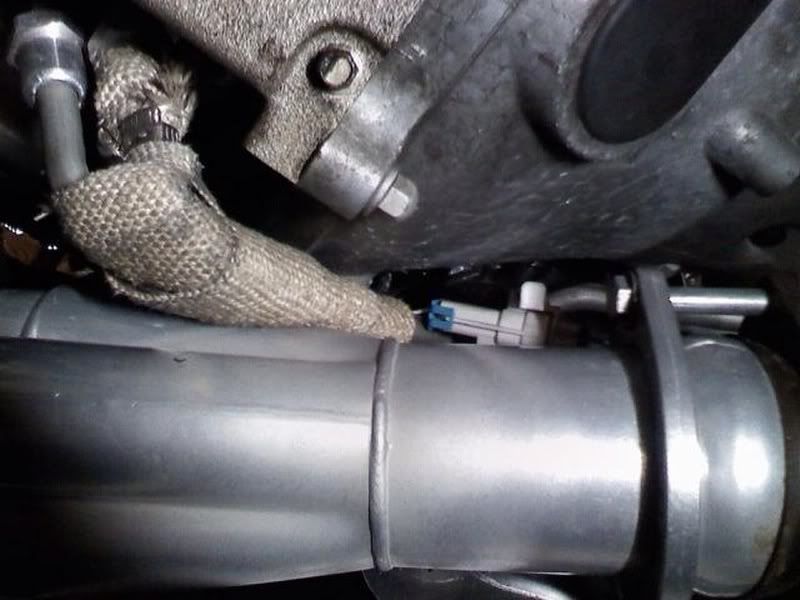

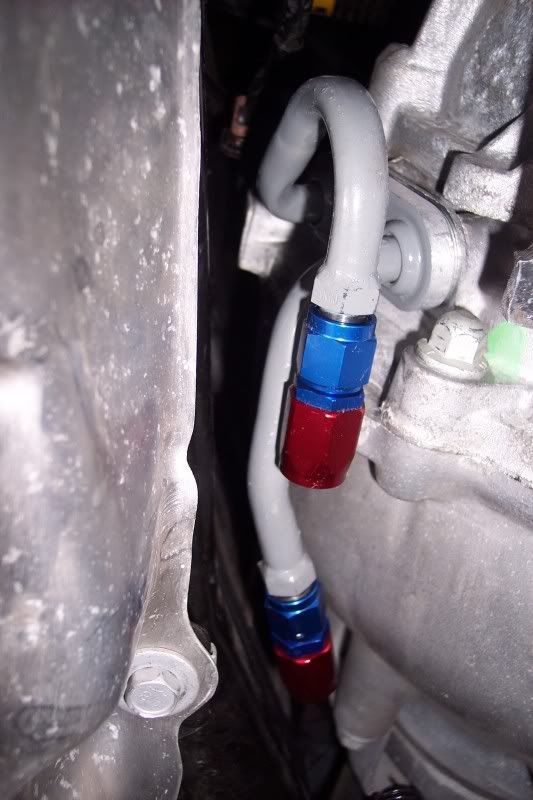

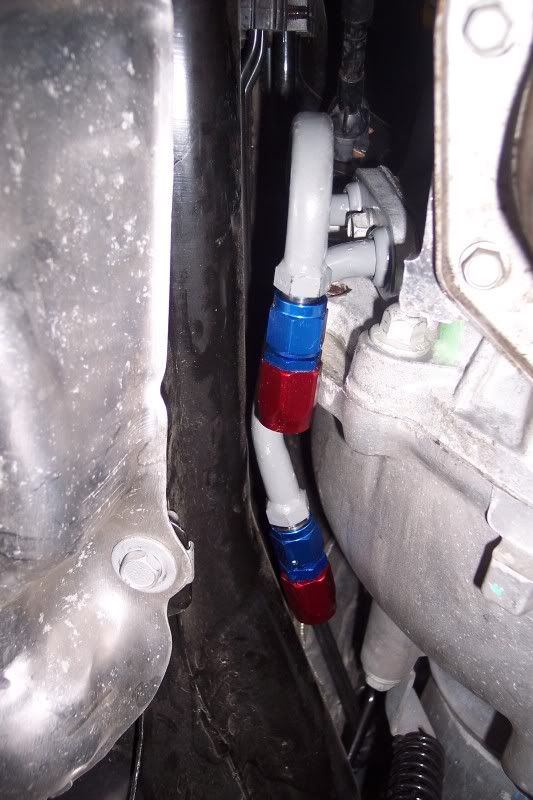

Before i did the install i new i wanted stainless braided -6 hose running from the tranny cooler to the factory lines. So i decided to call my friend who is a welder/fabricator for a very well known turbo shop in chicago. Also well known around the world. I choose not to say the name of the shop for this was a side job. I told him what i needed done and he took on the job. I was originally going to have him weld on AN fitting on the factory lines and just connect everything close by the radiator completely bypassing the factory trans cooling setup. The more he worked on the car he suggested running all new -6 lines to the very back of the transmission, and away from the passenger header as the factory lines were nearly touching.

He completely removed all the factory trans cooling lines

Then welded up the factory fittings that go into the radiator

Cut the factory lines right off the transmission to weld on An fittings

Welding the AN fittings on the factory trans lines

His welds!!!!!!

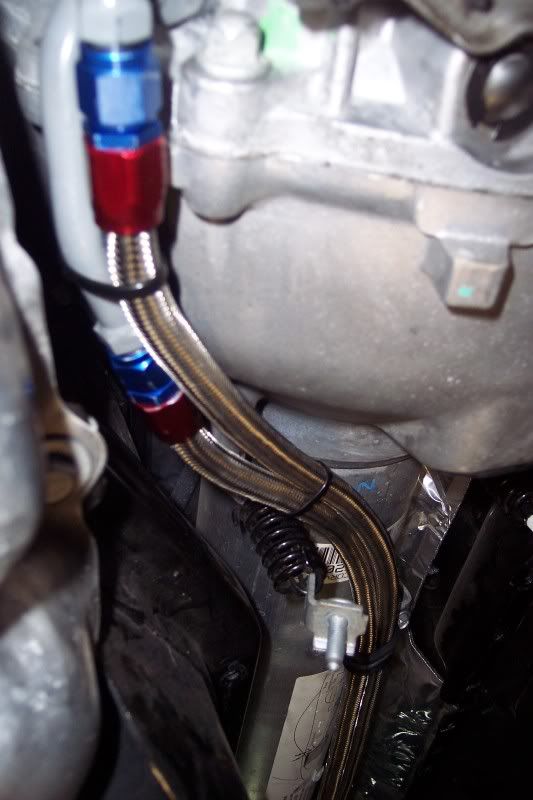

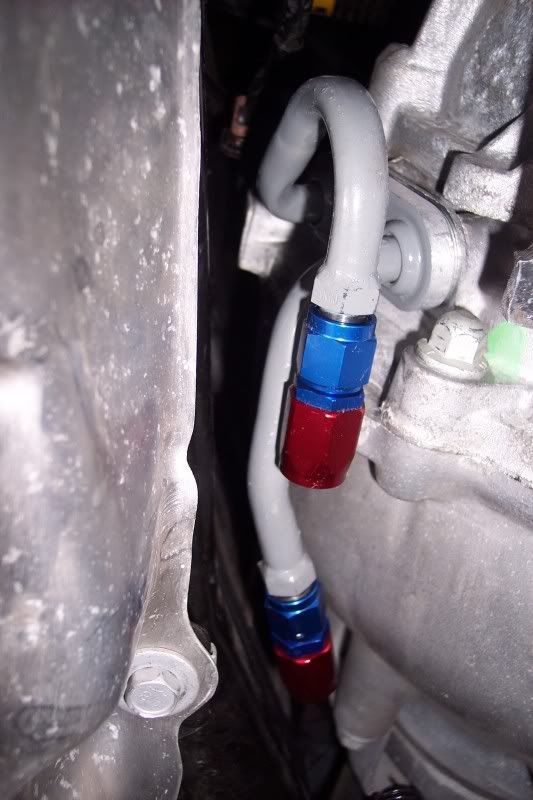

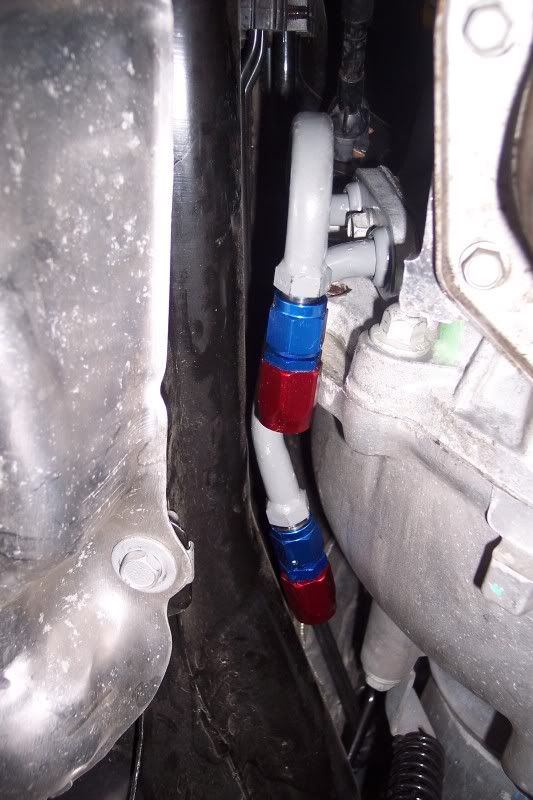

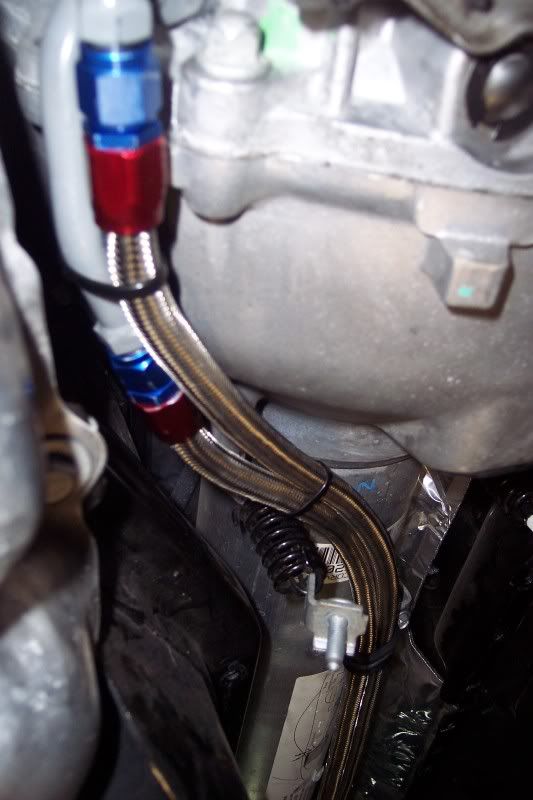

Trans lines back on transmission with AN fittings welded on

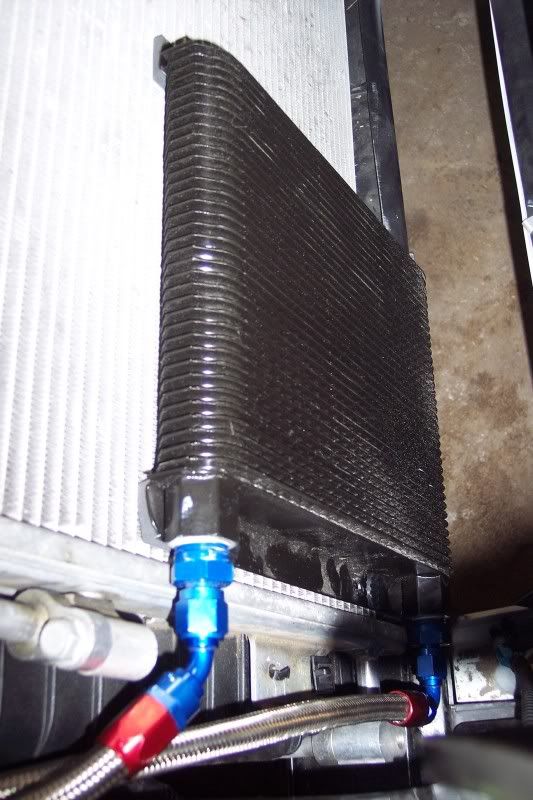

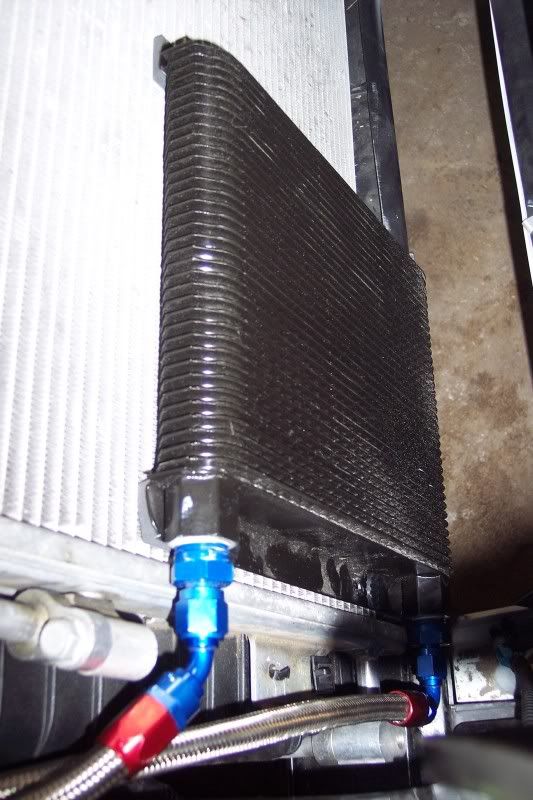

Trans cooler mounted

New -6 lines ran away from the exhaust

Cooler with shroud back in place

Just some pics of the car we took at the end of the day

The nights here in chicago are a bit cooler, tonight was 60, but cruising around the city stop and go i never once saw above 180 degress, on the highway doing about 70mph trans temps were at a constant 140 sometimes even hit 132. Getting off the highway doing a couple rips down a open road still never saw temps above 190 realistically never saw above 182!

In the end im very satisfied with the idea my friend had of completely bypassing the factory system and running the lines away from any exhaust heat! If anyone is local in the chicagoland area and would like some work like this done please feel free to pm me!!! Just trying to help a friend get his name out there! I will go ahead and show off some of his other work as he is a phenomenal welder and fabricator!

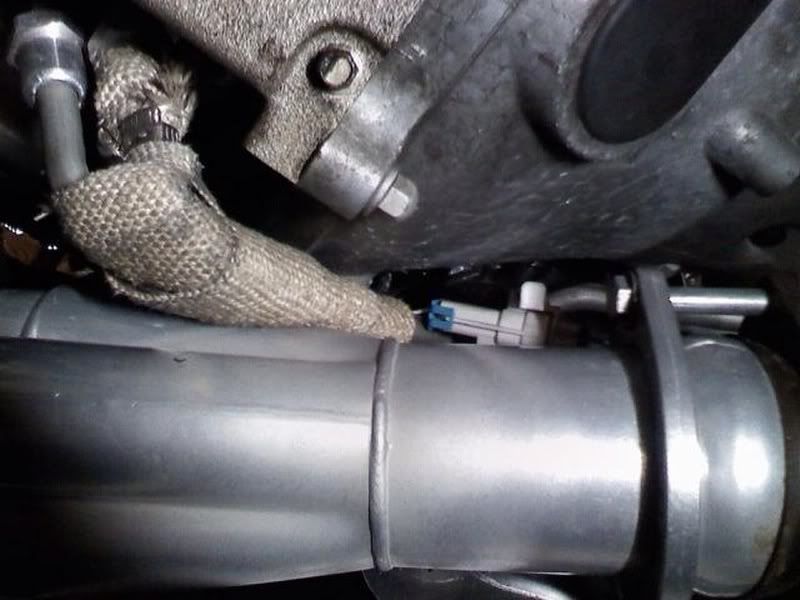

Custom Evo exhaust manifold

Before i did the install i new i wanted stainless braided -6 hose running from the tranny cooler to the factory lines. So i decided to call my friend who is a welder/fabricator for a very well known turbo shop in chicago. Also well known around the world. I choose not to say the name of the shop for this was a side job. I told him what i needed done and he took on the job. I was originally going to have him weld on AN fitting on the factory lines and just connect everything close by the radiator completely bypassing the factory trans cooling setup. The more he worked on the car he suggested running all new -6 lines to the very back of the transmission, and away from the passenger header as the factory lines were nearly touching.

He completely removed all the factory trans cooling lines

Then welded up the factory fittings that go into the radiator

Cut the factory lines right off the transmission to weld on An fittings

Welding the AN fittings on the factory trans lines

His welds!!!!!!

Trans lines back on transmission with AN fittings welded on

Trans cooler mounted

New -6 lines ran away from the exhaust

Cooler with shroud back in place

Just some pics of the car we took at the end of the day

The nights here in chicago are a bit cooler, tonight was 60, but cruising around the city stop and go i never once saw above 180 degress, on the highway doing about 70mph trans temps were at a constant 140 sometimes even hit 132. Getting off the highway doing a couple rips down a open road still never saw temps above 190 realistically never saw above 182!

In the end im very satisfied with the idea my friend had of completely bypassing the factory system and running the lines away from any exhaust heat! If anyone is local in the chicagoland area and would like some work like this done please feel free to pm me!!! Just trying to help a friend get his name out there! I will go ahead and show off some of his other work as he is a phenomenal welder and fabricator!

Custom Evo exhaust manifold

#4

Melting Slicks

Member Since: Sep 2005

Location: merritt island fl

Posts: 2,670

Received 131 Likes

on

109 Posts

C1 of Year Finalist (stock) 2019

2016 C1 of the Year Finalist

2015 C2 of the Year Finalist

Nice job.

Two comments: You don't really need to plug the in and out of the radiator- but it doesn't hurt.

I'd use some stainless strapping instead of the zip ties to hold the lines together- the nylon won't take the heat for very long.

Two comments: You don't really need to plug the in and out of the radiator- but it doesn't hurt.

I'd use some stainless strapping instead of the zip ties to hold the lines together- the nylon won't take the heat for very long.

#5

Drifting

Member Since: Sep 2009

Location: cinnaminson n.j.

Posts: 1,719

Likes: 0

Received 4 Likes

on

4 Posts

St. Jude Donor '14

That welding is excellent. The whole install is very impressive. I do agree with dave on the zip ties - been there done that - they do melt. How long did the job take? I'm guessing 5 hours.

#9

Thanks for all the comments, I didn't like the black wheels at first the more I look at them more I like them

Last edited by itstockc6; 05-29-2010 at 12:22 PM. Reason: Wording

#10

Racer

Bypassing the radiator end tank cooler is a bad idea. If you drive this car as a DD in Chicago winters the slow warm up or possible never getting the trans up to proper operating temp. will not be good for it. Good luck.

#11

Race Director

Member Since: Sep 2007

Location: Peoria/Phoenix AZ

Posts: 16,555

Received 2,060 Likes

on

1,505 Posts

C6 of Year Finalist (performance mods) 2019

Somewhat. From all I've read, the trans needs to run between 150 and 230 to be the most efficient and least wear. Incorporating a 160 or 180 thermostat inline will avoid the excessive wear problem.

Somewhat. From all I've read, the trans needs to run between 150 and 230 to be the most efficient and least wear. Incorporating a 160 or 180 thermostat inline will avoid the excessive wear problem.Other than that, it's a great write-up with pics. And that guy sure is a damn good welder.

#12

How hot does it get if you drive it say 30 min to a hour. Do they stay that cool or does it eventually heat up? I installed one on my car using -6 line but didn't make a lot of difference. I'm wondering if my intercooler is blocking the fresh air from getting on it.

#16

Drifting

Somewhat. From all I've read, the trans needs to run between 150 and 230 to be the most efficient and least wear. Incorporating a 160 or 180 thermostat inline will avoid the excessive wear problem.

Somewhat. From all I've read, the trans needs to run between 150 and 230 to be the most efficient and least wear. Incorporating a 160 or 180 thermostat inline will avoid the excessive wear problem.Other than that, it's a great write-up with pics. And that guy sure is a damn good welder.

#18

Racer

Welding up the fittings in the end tank toc is a waste of a good cooler. You should have

adapted a male end for the quick connects from 3/8" tubing incase you ever wanted to use the end tank toc again.

adapted a male end for the quick connects from 3/8" tubing incase you ever wanted to use the end tank toc again.

#19

I'd like to tap into the line set at this spot in order to add a B&M cooler 70297, bypassing the radiator.

Where are these connectors located under the car??? (circled in white)

Where are these connectors located under the car??? (circled in white)