[Z06] LS7 broken rocker arm needle bearings issue

#41

This may be nitpicking, but the thread you link to has pictures, one of which I borrowed (thanks blitzu), and you have to agree that it does not have "stock appearance" and "the HS conversion is internal to the rocker" because one can easily see the C-clips on the modified ones.

Still, this seems like an attractive option down the road.

-kg

Still, this seems like an attractive option down the road.

-kg

I wish I would have taken pictures before and after with them on the motor... ohh well maybe next time I have the valve covers pulled.

I wish I would have taken pictures before and after with them on the motor... ohh well maybe next time I have the valve covers pulled.

#42

Racer

Thread Starter

magnetic drain plugs

I just wanted to add the info about the magnetic drain plugs to this thread. If you search you will find lots on info on this, but I think it can be sumarized as:

2006 Z06 does not have magnetic drain plugs (except for maybe late build ones).

2007 Z06 has magnetic drain plugs

2008 Z06 has magnetic drain plugs until it was deleted from the build sometime in January 08.

I just wanted to add the info about the magnetic drain plugs to this thread. If you search you will find lots on info on this, but I think it can be sumarized as:

2006 Z06 does not have magnetic drain plugs (except for maybe late build ones).

2007 Z06 has magnetic drain plugs

2008 Z06 has magnetic drain plugs until it was deleted from the build sometime in January 08.

#43

Le Mans Master

Having a magnetic drain plug does not mean the needles were not pecking and gouging away at pistons, cylinder walls and nicking the titanium rods before the magnet caught them. If I had needles on the magnet I would pull the pan for a look inside. I bet the pan and the piston skirts are pecked up inside from the needles being hit by the spinning crankshaft and thrown at everything in the crankcase. Get those rockers out of there fast.

#44

Racer

Thread Starter

Having a magnetic drain plug does not mean the needles were not pecking and gouging away at pistons, cylinder walls and nicking the titanium rods before the magnet caught them. If I had needles on the magnet I would pull the pan for a look inside. I bet the pan and the piston skirts are pecked up inside from the needles being hit by the spinning crankshaft and thrown at everything in the crankcase. Get those rockers out of there fast.

#45

Le Mans Master

What about loose needle bearings falling down through drainback openings in the block on the way down into the pan? They get hit by the spinning crankshaft for a while before they can go anywhere else.

#46

Le Mans Master

A dry sump actually serves several purposes but the main features are it allows more oil capacity, allows the engine to be mounted lower in the frame because typical drysump pans are shallower which increases ground clearance, gives greater control over the oil by insuring an uninterupted supply of oil to the engine during hard cornering and braking. And for safety in racing applications; an engine failure does not result in all of the on board oil ending up on the track, or providing fuel for an oil fire.

#47

Burning Brakes

the thread should be renamed the 2007 and up watered down version of the ls7 broken rocker arm needle bearings issue.

so it will not deteriorate the original bad a$$ 06 z's like mine.

so it will not deteriorate the original bad a$$ 06 z's like mine.

#49

I hope that's the case, I really do. But, have you put in magnetic drain plugs in your motor? Spend the $4 to get two of them, put them in for an oil change or two... and if you have a half hour pull the valve covers to double check. It does zero harm, requires no special parts or expertise, and only requires I believe a 10mm socket. Check the sides of each rocker... if one is hallow then you have a problem. Most owners report they noticed NO difference until they saw the bearings attached to their drain plugs.

#51

Le Mans Master

I hope that's the case, I really do. But, have you put in magnetic drain plugs in your motor? Spend the $4 to get two of them, put them in for an oil change or two... and if you have a half hour pull the valve covers to double check. It does zero harm, requires no special parts or expertise, and only requires I believe a 10mm socket. Check the sides of each rocker... if one is hallow then you have a problem. Most owners report they noticed NO difference until they saw the bearings attached to their drain plugs.

#52

Le Mans Master

Discover needles on your drain plug at your regularly scheduled oil change? No problem, GM will pay to replace the failed rocker arm and you simply keep a crib sheet handy to update your current needle count... drive and purge strategy. At each regularily scheduled oil change you simply instruct your oil change technician to save the needles if any more show up and cross them off the list I guess until you have all 33 accounted for.

This is actually a genius decision cost-wise on the part of GM. Install magnetic drainplugs and sell the idea to owners and prospective buyers that the magnet is all you need to ensure your LS-7 is protected. Much less expensive than pulling the pan to clean them out of the crankcase. Idea is to hope a magnet will attract and pick them out of the oil while you drive your car so you can be confident you are doing the right thing.

This is actually a genius decision cost-wise on the part of GM. Install magnetic drainplugs and sell the idea to owners and prospective buyers that the magnet is all you need to ensure your LS-7 is protected. Much less expensive than pulling the pan to clean them out of the crankcase. Idea is to hope a magnet will attract and pick them out of the oil while you drive your car so you can be confident you are doing the right thing.

Last edited by Greg Gore; 04-12-2008 at 02:43 PM.

#53

Safety Car

Thinking out loud here---has there been any positive proof that the rocker arms losing the needle bearings are causing the broken valve springs, i.e. do ALL broken valve spring engines have a gutted rocker arm too?

Or are we looking at a totally separate issue.

Or are we looking at a totally separate issue.

#54

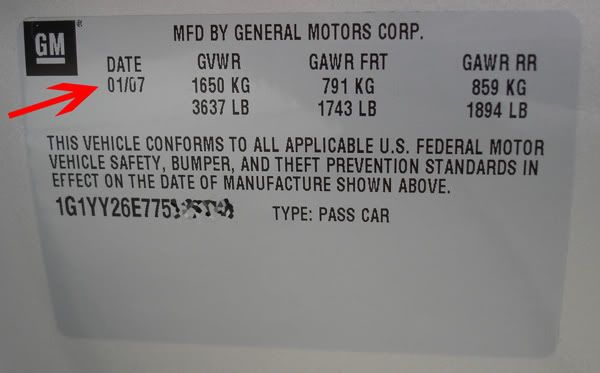

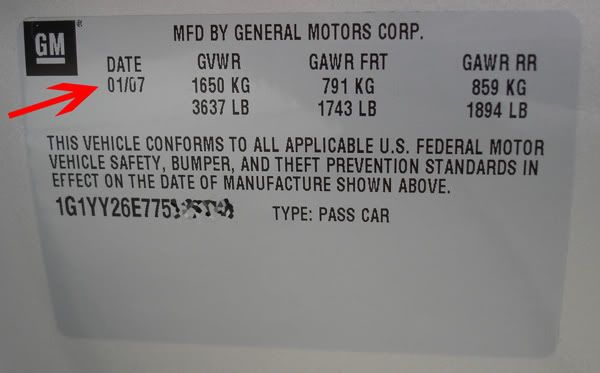

Ya know, I just checked my engine build date ('08) and it was 010, so January 10 2008, although the sticker in the passenger side wheel well states Jan 03 2008. Just seems weird that the engine was built after the car at least appears to have been built.

Again the Jan 03 2008 sticker is in the inner front wheel well on the passengers side. On the drivers side I can't make sense out of the grease pen writing.

Again the Jan 03 2008 sticker is in the inner front wheel well on the passengers side. On the drivers side I can't make sense out of the grease pen writing.

How to find your car's build month:

Look at the back of the driver's side door:

How to get your car's build date:

Email Betty@corvettemuseum.com with you VIN (at least that was the case when I got mine back in Feb 07).

How to get your engine’s build date:

Look up the engine number (instructions here) and then post it to the same thread and someone hopefully will respond with the engine build date, or calculate it yourself from this info:

The engine number looks like this 10ZLD XXDDDXXXX (it will start with 10ZKD for 06, 10ZLD for 07, and 10ZAD for 08, AFAIK), and the 3rd, 4th, and 5th digits (DDD) are the day of the year the engine was built.

To turn the day-of-year number into a date you can use this link: http://www-air.larc.nasa.gov/tools/jday.htm

-kg

Look at the back of the driver's side door:

How to get your car's build date:

Email Betty@corvettemuseum.com with you VIN (at least that was the case when I got mine back in Feb 07).

How to get your engine’s build date:

Look up the engine number (instructions here) and then post it to the same thread and someone hopefully will respond with the engine build date, or calculate it yourself from this info:

The engine number looks like this 10ZLD XXDDDXXXX (it will start with 10ZKD for 06, 10ZLD for 07, and 10ZAD for 08, AFAIK), and the 3rd, 4th, and 5th digits (DDD) are the day of the year the engine was built.

To turn the day-of-year number into a date you can use this link: http://www-air.larc.nasa.gov/tools/jday.htm

-kg

#55

Racer

"Or are we looking at a totally separate issue" Yes

#56

Racer

When the needle bearing go away the rocker will tilt on top of the valve spring producing unequal pressure on the valve stem. When this happens the cap can rock releasing the retainers. Then you really have a problem. Valve drops into cylinder and spring flies off at a high rate of speed

#57

Safety Car

I guess if GM admitted there was something wrong they would then have to recall all the vehicles instead of just fixing them as they break. What would be nice though is if they would actually come out and state that if I want to prevent this from happening and use after market or modified stock rockers my warranty won't be voided. I don't mind paying out of my own pocket for a little piece of mind but if they are going to jerk me around come warranty time then I don't care if there are bearings in the pan or not.

Grant

Grant

#58

Le Mans Master

In a well sorted and developed competition engine the valve spring is the single most critical part without exception. It is the one single thing that always limits the amount of lift we can have and the maximum RPM we can safely turn the engine. If we exceed the RPM limits of the spring they simply fatigue and break. If we could find a way to get yet better cleaner wire for valve springs we could make even better valve springs which would enable us to make more power which is the reason we continue research world wide in that area. We pay over $1000 for a set of springs now and only race them one time. Just for comparison the springs in the LS-7 are made by Mubea (Muhr Bender in Germany) and GM probably pays less than a dollar a piece for them. You can buy one at your local dealer for $5. This is getting into atom smashing a little on a stock engine that only turns 7000 RPM but for the sake of discussion if you drove the car at high RPM with a loose rocker arm from lost needles the excessive lash would hammer the valve spring possibly fatiguing it. Fatigue always results in loss of spring load. A spring that has lost enough load will always break if you run it hard. The only way you could ever know this for sure is you would have to pull the covers and measure each spring to see how they compare with each other with a simple portable spring rater. I would not run the engine hard with one that was 10% lower that the others. You need 100 lb on the seat and 300 lb over the nose to maintain valve train control on this engine at 7000 RPM.

This is the company that supplies the springs for the LS-7

http://www.mubea.com/english/produkt...r_ventilf.html

This is the company that supplies the springs for the LS-7

http://www.mubea.com/english/produkt...r_ventilf.html

#59

In a well sorted and developed competition engine the valve spring is the single most critical part without exception. It is the one single thing that always limits the amount of lift we can have and the maximum RPM we can safely turn the engine. If we exceed the RPM limits of the spring they simply fatigue and break. If we could find a way to get yet better cleaner wire for valve springs we could make even better valve springs which would enable us to make more power which is the reason we continue research world wide in that area. We pay over $1000 for a set of springs now and only race them one time. Just for comparison the springs in the LS-7 are made by Mubea (Muhr Bender in Germany) and GM probably pays less than a dollar a piece for them. You can buy one at your local dealer for $5. This is getting into atom smashing a little on a stock engine that only turns 7000 RPM but for the sake of discussion if you drove the car at high RPM with a loose rocker arm from lost needles the excessive lash would hammer the valve spring possibly fatiguing it. Fatigue always results in loss of spring load. A spring that has lost enough load will always break if you run it hard. The only way you could ever know this for sure is you would have to pull the covers and measure each spring to see how they compare with each other with a simple portable spring rater. I would not run the engine hard with one that was 10% lower that the others. You need 100 lb on the seat and 300 lb over the nose to maintain valve train control on this engine at 7000 RPM.

This is the company that supplies the springs for the LS-7

http://www.mubea.com/english/produkt...r_ventilf.html

This is the company that supplies the springs for the LS-7

http://www.mubea.com/english/produkt...r_ventilf.html

#60

Safety Car

The problem isn't the valve springs. It's the crappy rockers with the pressed in tin inserts. Hell... I'm from Canada and even I got grip on this one....