Oil moving from passenger valve cover to the TB... root cause?

#1

Team Owner

Thread Starter

Member Since: Mar 2001

Location: Virginia Beach

Posts: 25,889

Likes: 0

Received 5 Likes

on

5 Posts

CI 3-5-6-7-8 Veteran

In the OEM configuration the line from the passenger side valve cover to the throttle-body is the fresh air feed line. It's the air source for air to move from the TB to the valve cover. With race use oil will flow the opposite way from the valve cover to the TB. What's the cause?

1. Crankcase pressure forcing oil out through the line?

or

2. Vacuum created on the line at high throttle with high airflow through the TB?

Why doesn't the factory baffle on the underside of the cover prevent the oil migration? Does the baffle simply prevent splashing into the line and the oil that does make it into my can is in suspension in the air?

I have two catch cans. One on the OEM LS6 PCV circuit and one on the fresh air feed line. Normally I only get a few tablespoons in each. However, this weekend at VIR running TT with NARRA the can on the fresh air line was nearly full. It was 105+ ambient, hotter than I've ever been on track in. I guess that contributed to more oil making it into the can. Car ran perfectly.

Dual cans from CCA

~Brian

1. Crankcase pressure forcing oil out through the line?

or

2. Vacuum created on the line at high throttle with high airflow through the TB?

Why doesn't the factory baffle on the underside of the cover prevent the oil migration? Does the baffle simply prevent splashing into the line and the oil that does make it into my can is in suspension in the air?

I have two catch cans. One on the OEM LS6 PCV circuit and one on the fresh air feed line. Normally I only get a few tablespoons in each. However, this weekend at VIR running TT with NARRA the can on the fresh air line was nearly full. It was 105+ ambient, hotter than I've ever been on track in. I guess that contributed to more oil making it into the can. Car ran perfectly.

Dual cans from CCA

~Brian

#3

Melting Slicks

I also think it's due to crankcase pressure. I had excessive amounts of oil blowing out of my passenger valve cover with my last ls6. It would fill the catch can every session (actually was probably overflowing and getting to the TB). That engine was a POS from the start and spun a bearing a few months ago and was replaced. I noticed my new crate engine had a different baffle underneath the valve cover. The old one just had aluminum baffles to prevent splashing up to the port. The new cover has a built-in plastic looking baffle directly under the port. I decided to try the new one and I have absolutely zero oil getting into that catch can now. I just removed that catch can after racing 2 days with no oil getting in there. I'm just not sure whether it was less crankcase pressure (better engine) or the different baffle that solved the problem.

The catch can from my valley cover was filling about half way each session, which is more than what my old engine produced. Again, I don't know why.

The catch can from my valley cover was filling about half way each session, which is more than what my old engine produced. Again, I don't know why.

#4

Team Owner

Thread Starter

Member Since: Mar 2001

Location: Virginia Beach

Posts: 25,889

Likes: 0

Received 5 Likes

on

5 Posts

CI 3-5-6-7-8 Veteran

My VCs have the plastic oil/air separaters/baffles. Normally I catch maybe a tablespoon in each can, but it was only this weekend that I was getting something worthwhile in the VC to TB can. It was getting mostly full by the end of a day running 3 full sessions. I'm not worried about anything, just curious if it's crank case pressure pushing or vacuum pulling. Normally that line is an air source i.e. it flows into the VC. Maybe it's a combination of both? Crank pressure and a vacuum is created on the line?

Wouldn't crank pressure vent through the valley cover port? Or is there just too much for that single port to handle so it goes through the VC port too?

Wouldn't crank pressure vent through the valley cover port? Or is there just too much for that single port to handle so it goes through the VC port too?

#5

Le Mans Master

Member Since: Oct 2007

Location: Akron Ohio

Posts: 8,860

Received 1,730 Likes

on

935 Posts

2023 C5 of the Year Finalist - Modified

2022 C5 of the Year Finalist - Modified

St. Jude Donor '09-'10-'11

Another vote here for crankcase pressure. What made me decide to finally rebuild the engine on my '90 was due to the amount of oil it was putting out. I got black flagged for smoking because the oil was going right into the TB and people behind me thought I blew a motor. I rigged up a Gatorade bottle to catch it (since I wanted to finish running that day), but the bottle filled up EVERY 20 min session. I had to pour it back into the engine afterwards. I found broken rings on 3 pistons when the engine came apart. Mine had slightly less miles than yours does.

#6

Team Owner

Thread Starter

Member Since: Mar 2001

Location: Virginia Beach

Posts: 25,889

Likes: 0

Received 5 Likes

on

5 Posts

CI 3-5-6-7-8 Veteran

10-4... well she's got 122,xxx miles and still made 365 rwhp with a conservative 12.1-12.3 AFR. I plan on running her until she pulls less MPH in the straights. Even if I have to rig up a Poland Springs bottle for a catch can in the passenger seat  Custom active ballast is legal right?

Custom active ballast is legal right?

Again... I agree filling up a can every session is bad. Mine filled up about 1/2 of one of my cans after an entire day of hard running.

Custom active ballast is legal right?

Custom active ballast is legal right?

Again... I agree filling up a can every session is bad. Mine filled up about 1/2 of one of my cans after an entire day of hard running.

#9

Drifting

Member Since: Dec 2005

Location: Dayton, OH

Posts: 1,822

Likes: 0

Received 0 Likes

on

0 Posts

Depends on where you are measuring. If there were no vacuum it would be difficult to get anything resembling an air fuel mixture into the cylinders.

Also the amount of vacuum will change depending on load.

Also the amount of vacuum will change depending on load.

#10

Le Mans Master

I may as well remove my catch can. It fills up so fast and pukes into the TB that it's like it's not even there.

I hardly ever bother cleaning it out anymore.

I hardly ever bother cleaning it out anymore.

#11

Team Owner

Thread Starter

Member Since: Mar 2001

Location: Virginia Beach

Posts: 25,889

Likes: 0

Received 5 Likes

on

5 Posts

CI 3-5-6-7-8 Veteran

Does that fresh air feed line have a vacuum on it at WOT? The port is in the top of the TB and it does seem that air moving through the TB into the manifold would create a vacuum like blowing over a straw.

#12

Team Owner

Thread Starter

Member Since: Mar 2001

Location: Virginia Beach

Posts: 25,889

Likes: 0

Received 5 Likes

on

5 Posts

CI 3-5-6-7-8 Veteran

Filling the cans in a session or two indicates excessive crankcase pressures. Sperkins' LS1 has been flogged on track for years now and has around 150,000 miles on it. A healthy engine and properly routed catch cans will prevent oiling the intake tract.

#13

Safety Car

Not meaning to hijack your thread, but seeing the discussion included the baffled valve covers, I thought I would post here before going to tech section. I have the single can on mine. I got a little more than 2 tbls in it from the last 2 sessions Sunday at VIR. However, oil blows out my ECS breather cap like crazy. I put a paper towel over it the last 2 sessions to keep it from covering my engine and this is what the towel looked like:

[IMG] [/IMG]

[/IMG]

Although the motor is a forged LS2, the valve covers are from my original sc'd LS6 as is the breather. Do I still need the breather with catch can? Should I get better baffled valve covers? It used to be pretty bad the first session when I had the extra qt in there, but with accusump, I cut that down to 1/2 qt extra, but still dumps the bulk of the extra.

[IMG]

[/IMG]

[/IMG]Although the motor is a forged LS2, the valve covers are from my original sc'd LS6 as is the breather. Do I still need the breather with catch can? Should I get better baffled valve covers? It used to be pretty bad the first session when I had the extra qt in there, but with accusump, I cut that down to 1/2 qt extra, but still dumps the bulk of the extra.

#14

Team Owner

Thread Starter

Member Since: Mar 2001

Location: Virginia Beach

Posts: 25,889

Likes: 0

Received 5 Likes

on

5 Posts

CI 3-5-6-7-8 Veteran

Breathers do that  That's why the factory plumbs the line into the throttle-body. If you want to use a breather you need to have it on a catch can away from the engine so the oil condenses in the lines and doesn't get forced out the breather like that.

That's why the factory plumbs the line into the throttle-body. If you want to use a breather you need to have it on a catch can away from the engine so the oil condenses in the lines and doesn't get forced out the breather like that.

Here's the setup on the old SBF in my father's Panoz

That's why the factory plumbs the line into the throttle-body. If you want to use a breather you need to have it on a catch can away from the engine so the oil condenses in the lines and doesn't get forced out the breather like that.

That's why the factory plumbs the line into the throttle-body. If you want to use a breather you need to have it on a catch can away from the engine so the oil condenses in the lines and doesn't get forced out the breather like that.Here's the setup on the old SBF in my father's Panoz

#15

Drifting

Member Since: Dec 2005

Location: Dayton, OH

Posts: 1,822

Likes: 0

Received 0 Likes

on

0 Posts

Yes but not for that reason. It is because the vacuum port behind the throttle plate is applying a vacuum to the crankcase and the crankcase is drawing the fresh air through that port.

#16

Drifting

Member Since: Dec 2005

Location: Dayton, OH

Posts: 1,822

Likes: 0

Received 0 Likes

on

0 Posts

However, oil blows out my ECS breather cap like crazy. I put a paper towel over it the last 2 sessions to keep it from covering my engine and this is what the towel looked like:

[IMG] [/IMG]

[/IMG]

[IMG]

[/IMG]

[/IMG]

Really BAD idea!

#17

Team Owner

Thread Starter

Member Since: Mar 2001

Location: Virginia Beach

Posts: 25,889

Likes: 0

Received 5 Likes

on

5 Posts

CI 3-5-6-7-8 Veteran

And yes... Jimmy that's a fire waiting to happen

#18

Melting Slicks

Not meaning to hijack your thread, but seeing the discussion included the baffled valve covers, I thought I would post here before going to tech section. I have the single can on mine. I got a little more than 2 tbls in it from the last 2 sessions Sunday at VIR. However, oil blows out my ECS breather cap like crazy. I put a paper towel over it the last 2 sessions to keep it from covering my engine and this is what the towel looked like:

Although the motor is a forged LS2, the valve covers are from my original sc'd LS6 as is the breather. Do I still need the breather with catch can? Should I get better baffled valve covers? It used to be pretty bad the first session when I had the extra qt in there, but with accusump, I cut that down to 1/2 qt extra, but still dumps the bulk of the extra.

Although the motor is a forged LS2, the valve covers are from my original sc'd LS6 as is the breather. Do I still need the breather with catch can? Should I get better baffled valve covers? It used to be pretty bad the first session when I had the extra qt in there, but with accusump, I cut that down to 1/2 qt extra, but still dumps the bulk of the extra.

#19

Drifting

Member Since: Dec 2005

Location: Dayton, OH

Posts: 1,822

Likes: 0

Received 0 Likes

on

0 Posts

Yes, this is a loooonnnngggg post.

And just remember, this is my 2 cents and it may only be worth what you paid for it

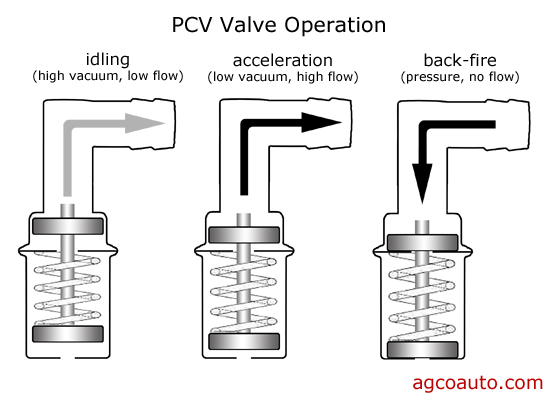

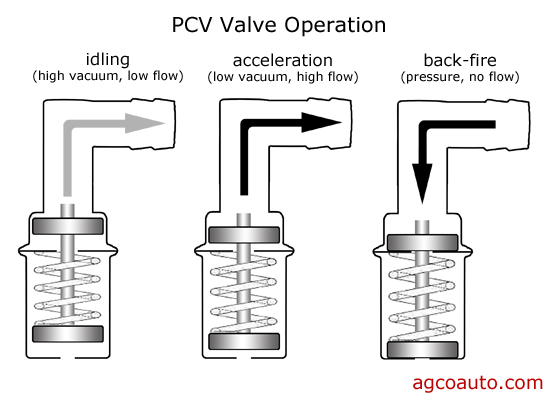

First thing that needs to be clarified is what the Crankcase Ventilation (CV, not PCV) system is for, which is to relieve blow by pressure from the crankcase. There are many ways to do this and how you do it best, depends on the reason you are doing it!

The current/modern PCV or Positive CV systems have some additional purposes which are emissions and to extend oil life. By positively evacuating the byproducts of combustion, hydrocarbons and condensation the oil will last longer and the emissions part should be self-explanatory. The reason this is a big problem for manufactures is that most people don't drive their cars long enough or hard enough to burn off these byproducts and they also build up large amounts of condensation because they don't get the motor/oil warm enough for long enough to get rid of the large amounts of water which are a normal byproduct of combustion.

So now we have two applications that "WE" deal with, LS based race cars and those who drive their LS based cars on the race track but still use them as street cars. As with anything we discuss here in this forum when it is dual use there are compromises and they never work that well! So, if you are in the dual use part of this you will have to deal with something that doesn't work well, in other words there is no "fix" it is what it is, sorry. Catch cans are NOT the answer to this problem IMHO. A properly installed coalescing filter system is a much better solution.

For race cars there is a simple solution but more on that later.

So with all that being said, here's a description of how the factory system is "designed" to work.

GM used a closed crankcase ventilation system in order to provide a more complete scavenging of crankcase vapors. (Read as, increased emission controls required by the government, required us to come up with a cleaner system)

The way the system works is fresh air from the throttle body is supplied to the crankcase, mixed with the blow-by vapors in the crankcase and then passes through the PCV into the intake manifold. This valve meters the flow of blow-by vapors at a certain rate depending on manifold vacuum. In order to maintain idle quality, the PCV valve restricts the vapor flow when manifold vacuum is high. If abnormal operating conditions arise (read as, continuous WOT while making high G maneuvers), the PCV system is designed to allow excessive amounts of blow-by vapors to back flow through the crankcase vent tube and into the engine air inlet to be consumed be normal combustion.

The LS1 and LS6 systems in theory are basically the same but in implementation are different.

On the LS1 engine, filtered fresh air is routed from up stream of the throttle blade (top connection) to the front of the right valve rocker arm cover (near oil fill). To reduce the potential of oil pullover into the throttle bore area due to back flow of the ventilation system; the fitting in the right side rocker cover is shielded from the rocker arms and their oil spray. Blow-by vapors are routed from the rear of both rocker covers, through hard lines to a tee fitting located on the centerline of the engine at the rear of the intake manifold. From there, a single hard line routes the vapors to the PCV valve and then enters the intake manifold behind the throttle body (bottom connection).

The dual draw PCV system was designed to make sure the system would always have a clear air/ventilation path. As we all know, during sustained high G corners the outboard valve cover may fill with oil. The dual draw system passively switches sides, allowing the PCV to draw on the rocker cover which has the least resistance. This is supposed to result in the system drawing on the air filled, or inboard rocker cover and is supposed to minimize oil pullover due to drawing on the oil filled outboard rocker cover.

The LS6 engine utilizes an integral PCV system in the engine's valley. The valley cover has oil separating baffles and PCV plumbing built in. The filtered fresh air is routed from up stream of the throttle blade to the front of the right valve rocker arm cover same as the LS1. Blow-by vapors are routed from the valley cover instead of the rear of the valve covers, to the PCV and to the intake manifold behind the throttle body just like the LS1.

Side note: For those of you wondering what the braided cable connected to the PCV on the LS1 system is for, here's your answer: the cable transfers heat from the head to the PCV valve to eliminate condensation build-up in the PCV itself which keeps it from rusting and helps the check ball not seize up.

So, now that you understand how the system is supposed to work we can figure out how to "break it" to work the way we need.

A couple of things that are important to remember,

1) The back side of the throttle plate always has a vacuum! Otherwise you wouldn't be able to get the fuel air mixture into the cylinders. The big thing is just how much vacuum. At idle or under deceleration it is MUCH higher than at WOT. At WOT it is approximately "equivalent" to 10psi.

2) On the LS motors we know that during high rpm driving there is a lot of oil on top of the heads. This isn't really a bad thing. It helps keep the heads and valve train cool and also dampens some harmonics in the valve springs which keep them from failing during sustained high rpm operation. This is all great as long as enough oil drains back to the pan so you wont run into the "oil starvation" problems that are common on cars which run at tracks with long high G corners and still utilize the factory or modified factory PCV system.

Before we move on let me give you a little illustration I used in another one of my posts.

You have a gallon milk jug full of water with no cap on it.

You turn the jug over and the water goes glub, glub, glub, glub, glub, glub, glub until all the water finally comes out. It works but it is slow.

So, if you want it to go faster when you turn the jug over you poke a hole in the bottom which is now the top and the water pours out in a steady stream and faster. Poke a bigger hole, say the same size as the one the water is coming out and it comes out as fast as gravity allows.

Now take this same jug with a whole in the top and the bottom fill it with water and then apply a vacuum to the hole on the bottom (top when turned over to drain the water) and what happens to the water trying to get out? Glub, glub, glub, glub, glub, glub, glub, glub again!

Welcome to the LS PCV system. The high volume of oil that gets up in the valve covers isn't the problem. As a matter of fact that high volume of oil in the top of the motor serves an important purpose, cooling the heads and valve train and dampening harmonics in the valve train!

Now add a high banked, high G corner for an extended period of time and the sump can run out of oil because the oil trying to drain back is going Glub, glub, glub, glub, glub, glub, glub, glub and it doesn't have all of gravity working to pull it back into the pan.

My assumption now is, since you have all this knowledge you can determine the root of the problems and come up with your own solution based on your particular application and needs.

I have a race car and don't need to worry about emissions, I change my oil on a regular basis and when I run the car I get it plenty warm enough to burn most of the combustion byproducts out of the oil

My solution to the problem(s) was to first remove the vacuum applied to the hole on top of the "milk jug" and then I made sure the vent hole(s) were as big as they could be and stayed open to the air needed to allow free smooth drainage of the oil from the top of the head. This fixed two problems

I ran the crankcase vent lines to a large volume canister and then provided filtered air to the canister. This releases all the crankcase pressure and meets the need to make sure I don't get any oil blow by on the track. It makes sure that any outside air getting into the system/motor is filtered and provides the proper vent so the drain back of oil from the heads isn't impeded.

You can check this link if you want to see pictures. Pictures 6 and 11.

http://forums.corvetteforum.com/auto...ally-done.html

And just remember, this is my 2 cents and it may only be worth what you paid for it

First thing that needs to be clarified is what the Crankcase Ventilation (CV, not PCV) system is for, which is to relieve blow by pressure from the crankcase. There are many ways to do this and how you do it best, depends on the reason you are doing it!

The current/modern PCV or Positive CV systems have some additional purposes which are emissions and to extend oil life. By positively evacuating the byproducts of combustion, hydrocarbons and condensation the oil will last longer and the emissions part should be self-explanatory. The reason this is a big problem for manufactures is that most people don't drive their cars long enough or hard enough to burn off these byproducts and they also build up large amounts of condensation because they don't get the motor/oil warm enough for long enough to get rid of the large amounts of water which are a normal byproduct of combustion.

So now we have two applications that "WE" deal with, LS based race cars and those who drive their LS based cars on the race track but still use them as street cars. As with anything we discuss here in this forum when it is dual use there are compromises and they never work that well! So, if you are in the dual use part of this you will have to deal with something that doesn't work well, in other words there is no "fix" it is what it is, sorry. Catch cans are NOT the answer to this problem IMHO. A properly installed coalescing filter system is a much better solution.

For race cars there is a simple solution but more on that later.

So with all that being said, here's a description of how the factory system is "designed" to work.

GM used a closed crankcase ventilation system in order to provide a more complete scavenging of crankcase vapors. (Read as, increased emission controls required by the government, required us to come up with a cleaner system)

The way the system works is fresh air from the throttle body is supplied to the crankcase, mixed with the blow-by vapors in the crankcase and then passes through the PCV into the intake manifold. This valve meters the flow of blow-by vapors at a certain rate depending on manifold vacuum. In order to maintain idle quality, the PCV valve restricts the vapor flow when manifold vacuum is high. If abnormal operating conditions arise (read as, continuous WOT while making high G maneuvers), the PCV system is designed to allow excessive amounts of blow-by vapors to back flow through the crankcase vent tube and into the engine air inlet to be consumed be normal combustion.

The LS1 and LS6 systems in theory are basically the same but in implementation are different.

On the LS1 engine, filtered fresh air is routed from up stream of the throttle blade (top connection) to the front of the right valve rocker arm cover (near oil fill). To reduce the potential of oil pullover into the throttle bore area due to back flow of the ventilation system; the fitting in the right side rocker cover is shielded from the rocker arms and their oil spray. Blow-by vapors are routed from the rear of both rocker covers, through hard lines to a tee fitting located on the centerline of the engine at the rear of the intake manifold. From there, a single hard line routes the vapors to the PCV valve and then enters the intake manifold behind the throttle body (bottom connection).

The dual draw PCV system was designed to make sure the system would always have a clear air/ventilation path. As we all know, during sustained high G corners the outboard valve cover may fill with oil. The dual draw system passively switches sides, allowing the PCV to draw on the rocker cover which has the least resistance. This is supposed to result in the system drawing on the air filled, or inboard rocker cover and is supposed to minimize oil pullover due to drawing on the oil filled outboard rocker cover.

The LS6 engine utilizes an integral PCV system in the engine's valley. The valley cover has oil separating baffles and PCV plumbing built in. The filtered fresh air is routed from up stream of the throttle blade to the front of the right valve rocker arm cover same as the LS1. Blow-by vapors are routed from the valley cover instead of the rear of the valve covers, to the PCV and to the intake manifold behind the throttle body just like the LS1.

Side note: For those of you wondering what the braided cable connected to the PCV on the LS1 system is for, here's your answer: the cable transfers heat from the head to the PCV valve to eliminate condensation build-up in the PCV itself which keeps it from rusting and helps the check ball not seize up.

So, now that you understand how the system is supposed to work we can figure out how to "break it" to work the way we need.

A couple of things that are important to remember,

1) The back side of the throttle plate always has a vacuum! Otherwise you wouldn't be able to get the fuel air mixture into the cylinders. The big thing is just how much vacuum. At idle or under deceleration it is MUCH higher than at WOT. At WOT it is approximately "equivalent" to 10psi.

2) On the LS motors we know that during high rpm driving there is a lot of oil on top of the heads. This isn't really a bad thing. It helps keep the heads and valve train cool and also dampens some harmonics in the valve springs which keep them from failing during sustained high rpm operation. This is all great as long as enough oil drains back to the pan so you wont run into the "oil starvation" problems that are common on cars which run at tracks with long high G corners and still utilize the factory or modified factory PCV system.

Before we move on let me give you a little illustration I used in another one of my posts.

You have a gallon milk jug full of water with no cap on it.

You turn the jug over and the water goes glub, glub, glub, glub, glub, glub, glub until all the water finally comes out. It works but it is slow.

So, if you want it to go faster when you turn the jug over you poke a hole in the bottom which is now the top and the water pours out in a steady stream and faster. Poke a bigger hole, say the same size as the one the water is coming out and it comes out as fast as gravity allows.

Now take this same jug with a whole in the top and the bottom fill it with water and then apply a vacuum to the hole on the bottom (top when turned over to drain the water) and what happens to the water trying to get out? Glub, glub, glub, glub, glub, glub, glub, glub again!

Welcome to the LS PCV system. The high volume of oil that gets up in the valve covers isn't the problem. As a matter of fact that high volume of oil in the top of the motor serves an important purpose, cooling the heads and valve train and dampening harmonics in the valve train!

Now add a high banked, high G corner for an extended period of time and the sump can run out of oil because the oil trying to drain back is going Glub, glub, glub, glub, glub, glub, glub, glub and it doesn't have all of gravity working to pull it back into the pan.

My assumption now is, since you have all this knowledge you can determine the root of the problems and come up with your own solution based on your particular application and needs.

I have a race car and don't need to worry about emissions, I change my oil on a regular basis and when I run the car I get it plenty warm enough to burn most of the combustion byproducts out of the oil

My solution to the problem(s) was to first remove the vacuum applied to the hole on top of the "milk jug" and then I made sure the vent hole(s) were as big as they could be and stayed open to the air needed to allow free smooth drainage of the oil from the top of the head. This fixed two problems

I ran the crankcase vent lines to a large volume canister and then provided filtered air to the canister. This releases all the crankcase pressure and meets the need to make sure I don't get any oil blow by on the track. It makes sure that any outside air getting into the system/motor is filtered and provides the proper vent so the drain back of oil from the heads isn't impeded.

You can check this link if you want to see pictures. Pictures 6 and 11.

http://forums.corvetteforum.com/auto...ally-done.html

Last edited by geerookie; 07-11-2012 at 02:56 PM.

#20

Team Owner

Thread Starter

Member Since: Mar 2001

Location: Virginia Beach

Posts: 25,889

Likes: 0

Received 5 Likes

on

5 Posts

CI 3-5-6-7-8 Veteran

Since the crank case vapors rise up through the engine via the oil return drains does that affect oil return rates too? I.e. they're fighting for the same real estate right?

FYI only the 2004 Z06 lacks an external PCV valve. The 2001-2003 still have it in the line between the valley cover and intake manifold. The 2004 got a revised valley cover with a different oil/air separater.

FYI only the 2004 Z06 lacks an external PCV valve. The 2001-2003 still have it in the line between the valley cover and intake manifold. The 2004 got a revised valley cover with a different oil/air separater.