New forged LS1 blowing out dipstick

#1

Drifting

Thread Starter

Hey guys, looking for some ideas/tips moving forward in the diagnosis of the car. Here are the facts:

New forged piston/rod LS1, nothing crazy. Car is a 2003 Z06, so it has the LS6 valley cover with normal/external PCV valve.

Drove car 500 miles on motul 10w40 break in oil. Did a proper break in but didn't beat on it, 4000 rpm and 50 throttle max, varying rpm. No issues during this time...car ran great, didnt burn any oil, nothing abnormal at all.

Changed oil and starting to get into some WOT action and tuning on the car in prep for track day coming up.

Out driving the car today, I see smoke coming out behind the car (actually under the hood). Dipstick popped out, sprayed some oil around, hot headers burning it caused the smoke.

It seemed to smoke at high rpms under load, but also I had it smoke (actively spraying oil out the tube presumably) just holding rpms high 4000+ lets say (but engine in vaccum).

Drive the car home, look around the engine bay... Notice the shop put the catch can/pcv lines backwards--doh (pcv valve installed backwards basically).

I figure this had to be it, clean up the engine bay, go back out to confirm. It does it again, drive back home.

Take apart all pcv system components, everything seems to be OK... but I notice the internal filter on the catch can may be adding some restriction (very scientific mouth blow test). PCV valve seems to work fine. Compare to old pics to confirm PCV valve orientation etc.

I haven't driven the car since taking the can filter out, but that's my next step. Temp removing the whole catch can setup and new PCV valve are probably a good idea for good measure.

For my own sanity tonight I did a compression test on all cylinders. All were 220-225psi. Last one was a little lower, but I figured that might be due to the engine cooling off significantly and battery juice getting low, so I tested a couple other random ones-- both within a few psi of cylinder 8. I pulled out the leakdown tester but I was getting annoyed trying to get the cylinders at TDC (last time I just removed the rocker arms, made things easy). But the couple cylinders I did get to test showed like 3% leakdown at 100psi.

Any thoughts on this/ideas what to try next? Seriously stressing out over here... one thing after another. Obviously I have lots of blowby or it's not getting out like it should and thus going out the dipstick. Going to post my pcv routing below.

New forged piston/rod LS1, nothing crazy. Car is a 2003 Z06, so it has the LS6 valley cover with normal/external PCV valve.

Drove car 500 miles on motul 10w40 break in oil. Did a proper break in but didn't beat on it, 4000 rpm and 50 throttle max, varying rpm. No issues during this time...car ran great, didnt burn any oil, nothing abnormal at all.

Changed oil and starting to get into some WOT action and tuning on the car in prep for track day coming up.

Out driving the car today, I see smoke coming out behind the car (actually under the hood). Dipstick popped out, sprayed some oil around, hot headers burning it caused the smoke.

It seemed to smoke at high rpms under load, but also I had it smoke (actively spraying oil out the tube presumably) just holding rpms high 4000+ lets say (but engine in vaccum).

Drive the car home, look around the engine bay... Notice the shop put the catch can/pcv lines backwards--doh (pcv valve installed backwards basically).

I figure this had to be it, clean up the engine bay, go back out to confirm. It does it again, drive back home.

Take apart all pcv system components, everything seems to be OK... but I notice the internal filter on the catch can may be adding some restriction (very scientific mouth blow test). PCV valve seems to work fine. Compare to old pics to confirm PCV valve orientation etc.

I haven't driven the car since taking the can filter out, but that's my next step. Temp removing the whole catch can setup and new PCV valve are probably a good idea for good measure.

For my own sanity tonight I did a compression test on all cylinders. All were 220-225psi. Last one was a little lower, but I figured that might be due to the engine cooling off significantly and battery juice getting low, so I tested a couple other random ones-- both within a few psi of cylinder 8. I pulled out the leakdown tester but I was getting annoyed trying to get the cylinders at TDC (last time I just removed the rocker arms, made things easy). But the couple cylinders I did get to test showed like 3% leakdown at 100psi.

Any thoughts on this/ideas what to try next? Seriously stressing out over here... one thing after another. Obviously I have lots of blowby or it's not getting out like it should and thus going out the dipstick. Going to post my pcv routing below.

Last edited by aaronc7; 01-24-2017 at 10:16 PM.

#2

You didn't say anything about the oil pressure readings. Did you notice them? This is weird considering a recent post where the oil pressure was too low.

But we haven't actually determined that your pressure is too high.

Is there supposed to be a baffle in the oil pan that got bent in the wrong direction? Or some other oil pan issue?

But we haven't actually determined that your pressure is too high.

Is there supposed to be a baffle in the oil pan that got bent in the wrong direction? Or some other oil pan issue?

#3

OP, based on your post, it's clear to me that you know your way around under the hood far better than I do, so please feel free to laugh me off stage or throw tomatoes at me for what follows:

I recently had an issue with the installation of a catch can. My engine is out of a 2001 Trans Am (not sure if that makes any difference to an 03 Corvette). But, the lower hose... isn't is supposed to route around the back of the engine to the other bank? Yours appears to "disappear" somewhere up front in the pic...?

I recently had an issue with the installation of a catch can. My engine is out of a 2001 Trans Am (not sure if that makes any difference to an 03 Corvette). But, the lower hose... isn't is supposed to route around the back of the engine to the other bank? Yours appears to "disappear" somewhere up front in the pic...?

Last edited by Naaman; 01-23-2017 at 02:10 AM.

#5

Drifting

Thread Starter

Thanks guys for the 1 a.m. replies LOL.

one other thing that just crossed my mind was in regards to the passenger side valve cover vent that runs to the throttle body. If you were to take the hose off the throttle body and blow into the valve cover how much resistance would you expect? I feel like majority of the pressure is being relieved slowly through the oil filler cap and there is definitely some resistance. Maybe for whatever reason flow is restricted between that cylinder head and the crankcase... Just a hunch. I'll take a closer look tonight and see if anything is strange with that while the engine is running.

I have watch them like a hawk being a new motor and all. On the old motor I was running a stock volume high pressure pump. Now I have one of those higher volume pumps which I was skeptical of, but I went with the engine builders recommendation who has been doing this for a long time and knows how wide of clearances he runs etc. Either way or pressure is basically identical on the same oil on the new engine. I actually have a data log of a couple runs. Idle is a little over 40 hot, wide open throttle up for RPM probably in the seventies,, I have the data log at home I can confirm but nothing looked out of place.

I'm guessing you have the LS1 Valley cover. On the LS6 Valley cover there's a nipple that comes out the front, right below the nipple on the intake manifold. On the stock setup there is just a PCV valve and short u shaped hose here. Mine mimics that with just a catch can insert it in the middle. Might just be hard to see in the picture.

yep that is definitely the next logical step. I'm thinking I can try this with the engine free revving, at least initially, so I can possibly get a better idea of what is going on with each PCV Outlet.

one other thing that just crossed my mind was in regards to the passenger side valve cover vent that runs to the throttle body. If you were to take the hose off the throttle body and blow into the valve cover how much resistance would you expect? I feel like majority of the pressure is being relieved slowly through the oil filler cap and there is definitely some resistance. Maybe for whatever reason flow is restricted between that cylinder head and the crankcase... Just a hunch. I'll take a closer look tonight and see if anything is strange with that while the engine is running.

You didn't say anything about the oil pressure readings. Did you notice them? This is weird considering a recent post where the oil pressure was too low.

But we haven't actually determined that your pressure is too high.

Is there supposed to be a baffle in the oil pan that got bent in the wrong direction? Or some other oil pan issue?

But we haven't actually determined that your pressure is too high.

Is there supposed to be a baffle in the oil pan that got bent in the wrong direction? Or some other oil pan issue?

OP, based on your post, it's clear to me that you know your way around under the hood far better than I do, so please feel free to laugh me off stage or throw tomatoes at me for what follows:

I recently had an issue with the installation of a catch can. My engine is out of a 2001 Trans Am (not sure if that makes any difference to an 03 Corvette). But, the lower hose... isn't is supposed to route around the back of the engine to the other bank? Yours appears to "disappear" somewhere up front in the pic...?

I recently had an issue with the installation of a catch can. My engine is out of a 2001 Trans Am (not sure if that makes any difference to an 03 Corvette). But, the lower hose... isn't is supposed to route around the back of the engine to the other bank? Yours appears to "disappear" somewhere up front in the pic...?

yep that is definitely the next logical step. I'm thinking I can try this with the engine free revving, at least initially, so I can possibly get a better idea of what is going on with each PCV Outlet.

#6

Drifting

Thread Starter

Another observation that's going through my head but not sure what to make of it.

the dipstick blowing out Blow by issue maybe more RPM related than load

for example going wide open throttle around 2500 rpm no dipstick oil issue, but just cruising at a constant speed at 5000 RPM let's say I got lots of oil gushing out the tube. I would imagine that there is definitely more Blow by in the low RPM wide open throttle scenario if we assume that power and blow by are directly related

I'm trying to think if there's anything higher RPM related that might prevent the PCV system from working properly. Just kind of spitballing here. Next test step is still unchanged

the dipstick blowing out Blow by issue maybe more RPM related than load

for example going wide open throttle around 2500 rpm no dipstick oil issue, but just cruising at a constant speed at 5000 RPM let's say I got lots of oil gushing out the tube. I would imagine that there is definitely more Blow by in the low RPM wide open throttle scenario if we assume that power and blow by are directly related

I'm trying to think if there's anything higher RPM related that might prevent the PCV system from working properly. Just kind of spitballing here. Next test step is still unchanged

#7

Subscribing.

Just curious, with the engine running and the oil filler cap removed, can you fill/see any pressure coming out? I ask because that's what my engine is doing. I blew oil out of the dipstick at the track, and even at idle I can see/feel air coming out of the oil filler. Now for me, I believe that's coming from a cylinder 7 failure pressurizing the crankcase. But I'm just curious how much pressure you have coming out.

As for the passenger side valve cover port that vents to the TB, that's the "clean side" of the pcv system. Normally the pcv system vents using vacuum in the intake manifold to draw crankcase pressure. Under WOT though, there's very little vacuum in the intake manifold, so it uses the "clean side" port, which vents through the TB, and uses vacuum from in front of the throttle plate. (I have the Elite Engineering "clean side" separator kit which blocks the valve cover port and vents through a filtered oil filler cap and then routes the line to the TB). I don't believe there is any type of valve that would cause resistance if you were blowing back through that line into the valve cover.

I'd continue on with the leak down test. It really seems that combustion pressure is getting into your crankcase. If it's not getting past the rings, could it be pushing past a valve and valve seal back into the valve cover? Seems less likely, but just spit-balling.

Just curious, with the engine running and the oil filler cap removed, can you fill/see any pressure coming out? I ask because that's what my engine is doing. I blew oil out of the dipstick at the track, and even at idle I can see/feel air coming out of the oil filler. Now for me, I believe that's coming from a cylinder 7 failure pressurizing the crankcase. But I'm just curious how much pressure you have coming out.

As for the passenger side valve cover port that vents to the TB, that's the "clean side" of the pcv system. Normally the pcv system vents using vacuum in the intake manifold to draw crankcase pressure. Under WOT though, there's very little vacuum in the intake manifold, so it uses the "clean side" port, which vents through the TB, and uses vacuum from in front of the throttle plate. (I have the Elite Engineering "clean side" separator kit which blocks the valve cover port and vents through a filtered oil filler cap and then routes the line to the TB). I don't believe there is any type of valve that would cause resistance if you were blowing back through that line into the valve cover.

I'd continue on with the leak down test. It really seems that combustion pressure is getting into your crankcase. If it's not getting past the rings, could it be pushing past a valve and valve seal back into the valve cover? Seems less likely, but just spit-balling.

#8

Drifting

Thread Starter

If nothing comes of the 'remove catch can, check a few things and try again', then my plan will be to do a full leakdown test. With the valvecovers off I should be able to see if anything weird is going on with the valve seals as well. Thanks for the ideas, keep em coming.

What's interesting is when I had the blown piston, 80% leakdown in that cylinder... no dipstick issues and I at least did a few laps around a track like that. The spark plug got jacked up though, so there was probably no combustion going on at all.

What's interesting is when I had the blown piston, 80% leakdown in that cylinder... no dipstick issues and I at least did a few laps around a track like that. The spark plug got jacked up though, so there was probably no combustion going on at all.

Last edited by aaronc7; 01-23-2017 at 02:07 PM.

#9

Heel & Toe

After I built my forged LS1, I had the same experience. Everything was normal after driving 40 miles to my engine tuner, exited the expressway some what aggressively down shifting and stopped at a traffic light and that's when it puked out about one quart from the passenger valve cover. Turns out I didn't have enough ventilation on the valve covers. I only had the LS6 valley cover/PCV to a catch can. Installed an additional larger catch can with 3/4" lines from each valve cover. Problem solved.

The following users liked this post:

aaronc7 (01-23-2017)

#10

I'm not sure I really understand this. I don't see why the new motor would have more ring blow-by, and thus more crankcase pressure, to the extent that the factory pcv system doesn't flow enough. (unless ring gaps were altered). Unless this is a temporary condition until the rings fully seat?

#11

Drifting

Thread Starter

After I built my forged LS1, I had the same experience. Everything was normal after driving 40 miles to my engine tuner, exited the expressway some what aggressively down shifting and stopped at a traffic light and that's when it puked out about one quart from the passenger valve cover. Turns out I didn't have enough ventilation on the valve covers. I only had the LS6 valley cover/PCV to a catch can. Installed an additional larger catch can with 3/4" lines from each valve cover. Problem solved.

#12

Race Director

I'm not sure I really understand this. I don't see why the new motor would have more ring blow-by, and thus more crankcase pressure, to the extent that the factory pcv system doesn't flow enough. (unless ring gaps were altered). Unless this is a temporary condition until the rings fully seat?

did you notice those piston to wall clearances?

your pistons expand with heat. if all is well you simply need more ventilation and or a vacuum pump

the factory pcv is undersized for racing on a stock engine and was revised in 04, at least on the z06

it could be the rings not completely seated OR that lose pwc and the top of the stroke. when the piston rocks in the bore you don't always have a perfect seal. if more pressure than before is slipping past that could do it. if you have 2014 pistons those are often set up really lose so any ring flutter again could be causing this

actual race cars often run vacuum pumps for the pcv. it gains you hp and keeps the crank pressure situation under control

plan b would be to increase valve cover ventilation and plum to a larger, vented catch can. a sealed catch can may or may not work. if your cam doesn't produce a lot of vacuum you won't be pulling and will basically have an air compressor in your engine

also, have your done a line vacuum test? is the needle stable or fluttering?

#13

Drifting

Thread Starter

Thanks racebum, I always enjoy your no bs answers on many things across the forums.

It's a 4032 Mahle piston, I don't know off hand what the PTW clearances are, but it shouldn't be too huge like some other builds/materials.

So maybe LS6 valley cover setup, but might be easier/cheaper to just work larger VC vents with a vented can. Plus from what I understand the 04 Z06 valley cover has an 'internal pcv valve', so might not be an easy way to just open it up for a atm vented setup.

Would you say good leakdown = rings seated or is there more to it? couple cylinders I did test were 3-4% leakdown

By vacuum test you mean just recording what the intake manifold vac levels are at idle/other conditions? I have EFILive and have several datalogs already running on this engine. vacuum levels seem fine and same as they were, and stable. With the cam, MAP is only around 50Kpa or 15 inches of hg. But again I had exact same heads/cam setup on old motor and all was well.

It's a 4032 Mahle piston, I don't know off hand what the PTW clearances are, but it shouldn't be too huge like some other builds/materials.

So maybe LS6 valley cover setup, but might be easier/cheaper to just work larger VC vents with a vented can. Plus from what I understand the 04 Z06 valley cover has an 'internal pcv valve', so might not be an easy way to just open it up for a atm vented setup.

Would you say good leakdown = rings seated or is there more to it? couple cylinders I did test were 3-4% leakdown

By vacuum test you mean just recording what the intake manifold vac levels are at idle/other conditions? I have EFILive and have several datalogs already running on this engine. vacuum levels seem fine and same as they were, and stable. With the cam, MAP is only around 50Kpa or 15 inches of hg. But again I had exact same heads/cam setup on old motor and all was well.

#15

Drifting

Thread Starter

Yeah it's looking more and more like that right now. Usually the answers to these questions are the most obvious ones lol.

I just swapped in a new pcv valve (old one seemed fine) and took the catch can out of the loop. I'll probably go give it a test run tomorrow and see what happens.

Even if this 'fixes' it, I will be looking into better ventilation options. If anyone has any experience or recommendations here, please post up!

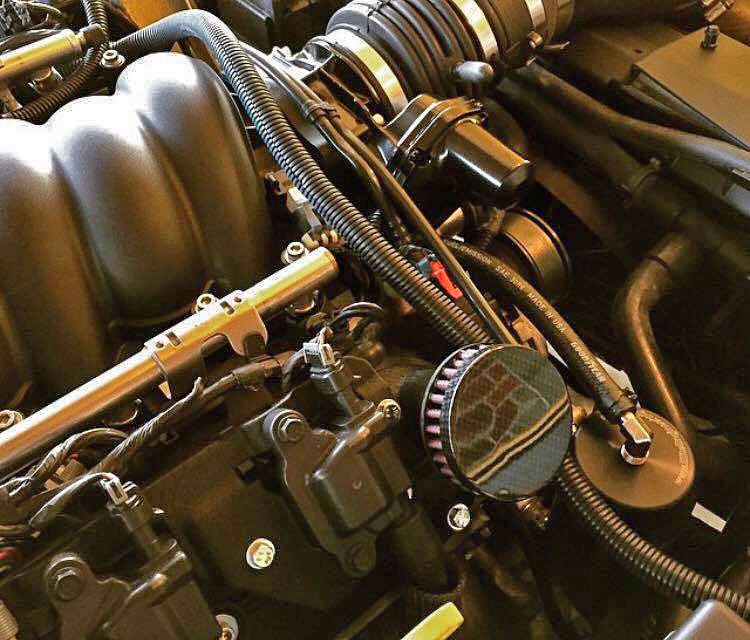

Here's a pic of my super legit setup for the time being until I figure out what to do with the ventilation system.

I just swapped in a new pcv valve (old one seemed fine) and took the catch can out of the loop. I'll probably go give it a test run tomorrow and see what happens.

Even if this 'fixes' it, I will be looking into better ventilation options. If anyone has any experience or recommendations here, please post up!

Here's a pic of my super legit setup for the time being until I figure out what to do with the ventilation system.

Last edited by aaronc7; 01-24-2017 at 10:16 PM.

The following users liked this post:

Naaman (01-23-2017)

#16

Burning Brakes

I was having a problem with overpressure in my crankcase of my LS2 and gave this a try. It has a ball type checkvalve so it's not going to mess up your PCV system. It's been working for 2 years now. It's an option if all else fails.

https://www.c-f-m.com/performancepar...S7-766p230.htm

https://www.c-f-m.com/performancepar...S7-766p230.htm

#17

Drifting

Thread Starter

I was having a problem with overpressure in my crankcase of my LS2 and gave this a try. It has a ball type checkvalve so it's not going to mess up your PCV system. It's been working for 2 years now. It's an option if all else fails.

https://www.c-f-m.com/performancepar...S7-766p230.htm

https://www.c-f-m.com/performancepar...S7-766p230.htm

Is the port on the driver side valve cover worth opening up for anything? I've seen the pcv diagrams for the LS1 vs LS6, but need to look a little more into some of the pros/cons.

Back to the one way breather: does this replace the CAP or the whole filler neck? I like the idea of getting it as high as possible to help with issue mentioned above. I see a couple different pics of their site and I see it both ways.

Last edited by aaronc7; 01-24-2017 at 09:34 AM.

#18

Nice looking breather cap.

NOT FOR SALE/LEGAL IN CALIFORNIA/CARB STATES.

That ALONE will make some people want it. If I can't have it, I want it even more!!

NOT FOR SALE/LEGAL IN CALIFORNIA/CARB STATES.

That ALONE will make some people want it. If I can't have it, I want it even more!!

#19

Drifting

With the factory connections at idle remove the oil fill cap.

Put your hand/palm on the oil fill tube and have someone slightly blip the throttle.

You should feel vacuum on your hand.

The passenger valve cover should breath freely through the front port.

A steady 4k to 5k rpm is a no load situation this is where you will get

blow by.

A good compression reading and leak down test will not guarantee

zero or acceptable blow by.

Was the block cyl. enlarged for the forged pistons?

Did you have forged pistons before. I think most forged pistons are about .007 larger and require cly. honing to size properly.

The problem here is the cly. tapered could be to large at the bottom.

Your oil pressures sound right for the pump you have installed.

Put your hand/palm on the oil fill tube and have someone slightly blip the throttle.

You should feel vacuum on your hand.

The passenger valve cover should breath freely through the front port.

A steady 4k to 5k rpm is a no load situation this is where you will get

blow by.

A good compression reading and leak down test will not guarantee

zero or acceptable blow by.

Was the block cyl. enlarged for the forged pistons?

Did you have forged pistons before. I think most forged pistons are about .007 larger and require cly. honing to size properly.

The problem here is the cly. tapered could be to large at the bottom.

Your oil pressures sound right for the pump you have installed.

Last edited by Mr. Jones; 01-24-2017 at 12:15 PM.

#20

Burning Brakes

Quote " Back to the one way breather: does this replace the CAP or the whole filler neck? I like the idea of getting it as high as possible to help with issue mentioned above. I see a couple different pics of their site and I see it both ways."

Yes it replaces the cap, but you can still keep the neck in place and it will work. I took my neck off and it still fits fine and works great.

Yes it replaces the cap, but you can still keep the neck in place and it will work. I took my neck off and it still fits fine and works great.

The following users liked this post:

aaronc7 (01-24-2017)