Behind the Scenes: Touring the GM Performance Build Center

Content provided by CorvetteBlogger.com

Article and photos contributed by Steve Burns

As part of the NCRS national convention last week we were able to participate in a tour of GM’s Performance Build Center. The facility is located about an hour northwest of Detroit in Wixom, MI. The low-volume plant hand assembles all of the dry sump motors for Corvettes. Previously, they also made the powerplants for the Cadillac STS-V and XLR-V.

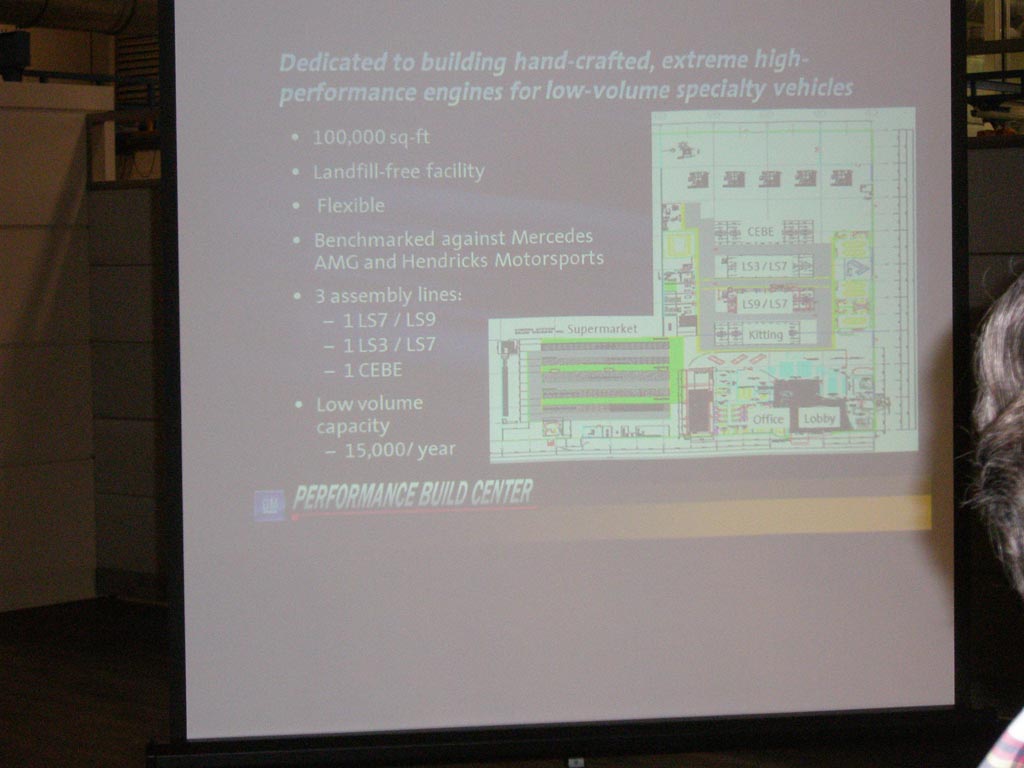

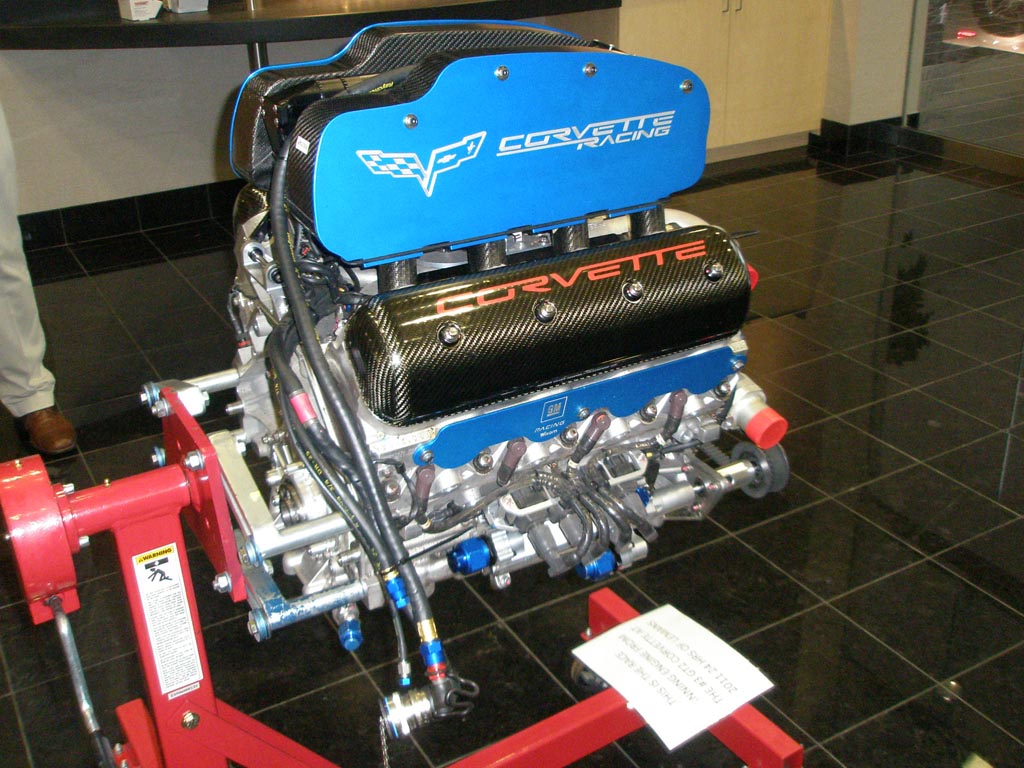

The GM Performance Build Center (PBC) is a 100,000 square foot facility that houses 26 employees. During development its setup was benchmarked against Mercedes’ AMG tuner brand and NASCAR’s Hendrick motorsports. Before entering the build floor, visitors are greeted by an early pilot Z06 (with an EX VIN) and the first “series 2 VIN #1” ZR1 built in 2009. (We’re stilled confused by what that actually means) The 2 cars are front and center in the glass-front main lobby which is also adorned by the motors which are built there. In between the main lobby and the plant itself is a small glass walled atrium. During our visit the LeMans winning motor out of the #3 C6R Corvette was on display in this room. If you follow us on Twitter you got a peek at this motor last week. Our tour guide mentioned that all of the other LeMans motors had already been torn down.

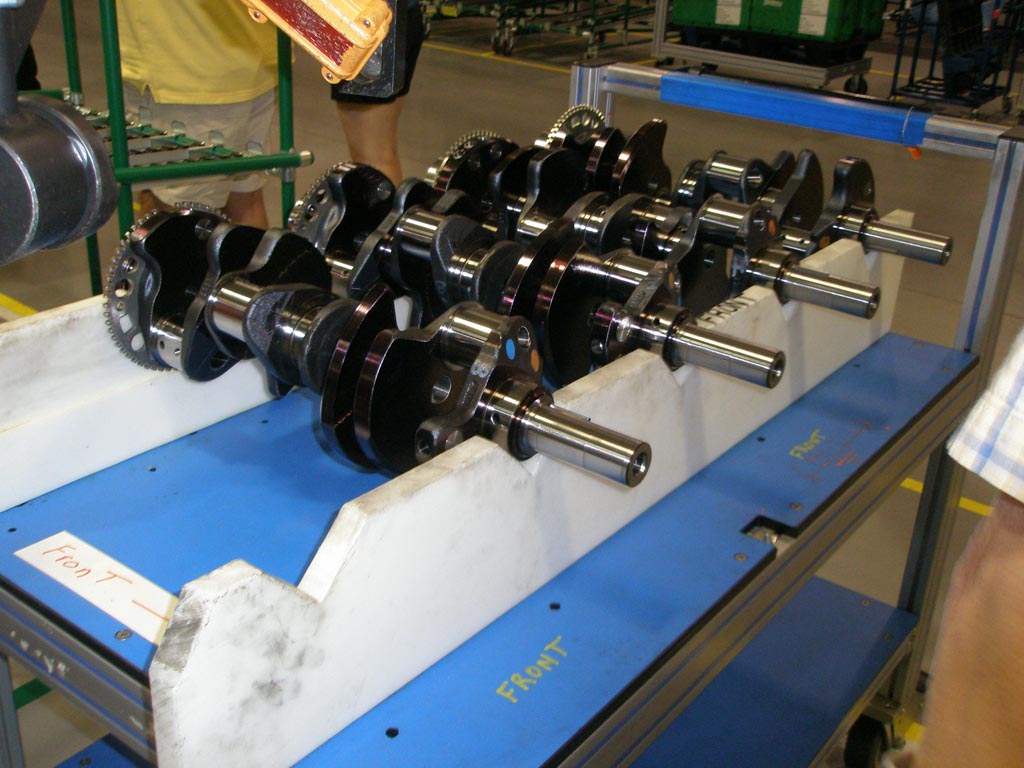

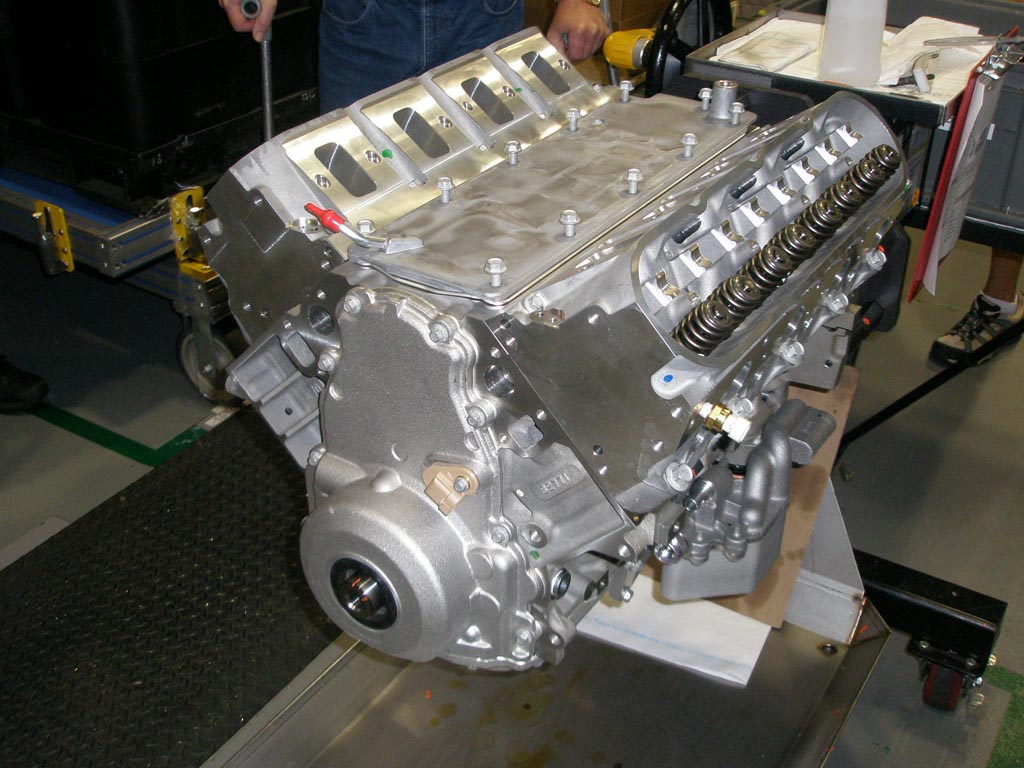

Currently they are working 4-10 hour shifts Monday through Thursday each week. The plant utilizes 3 assembly lines to produce Corvette engines. One line is dedicated to the Z06’s LS7 and the ZR1’s LS9. The 2nd line also produces LS7’s as well as the LS3’s that go into the 6 speed Grand Sport coupes. The third line is reserved for the Corvette Engine Build Experience. As of today the PBC has hosted a total of 16 owners who wanted to build their own engines. Each of the owner-builders has their photos placed on a wall near the entrance to the production floor.

The assembly process takes about 3-4 hours per motor and 1 person builds the engine from start to finish. Our guide mentioned that most of the builders have 30-40 years experience at GM and that absenteeism is a non-issue at the PBC. Each builder’s name goes on the engine so owners can see who built the heart of their Corvette. During our tour owners of PBC-built motors were also able to meet the person who assembled their LS3, LS7, or LS9.

After each motor is built it goes through a series of tests to makes sure it’s ready to go to Bowling Green. If there’s an issue found the engine gets repaired as needed, retested, and then it’s off on its way to Kentucky.

The Performance Build Center is truly a unique low volume build facility. If you or your club is ever in the area you can contact them for a tour. It’s something you’ll definitely want to check out. In the meantime you can check some photos from our tour below or peruse the GM Performance Build Center website.