Katech Titanium 12x1.5mm 12pt lug nuts. Finally, an affordable, quality Ti lug nut!

#41

Race Director

Jason got back to me via email. He is looking into scientifically testing this, which is great. Really happy to see a company want to put some science behind their response. That being said, he has personally taken them on and off ~20 times and said he hasn't seen any issues. that's pretty good for me.

The thing about some really great high performance parts companies, including all the F1 teams - for example, is they value lightness over durability. We autox/hpde guys don't replace/throw away bits like they do every race. So actually having a "metric" as to how long something will last helps us make a rational decision on whether to pay more for a part or not.

#42

Premium Supporting Vendor

Thread Starter

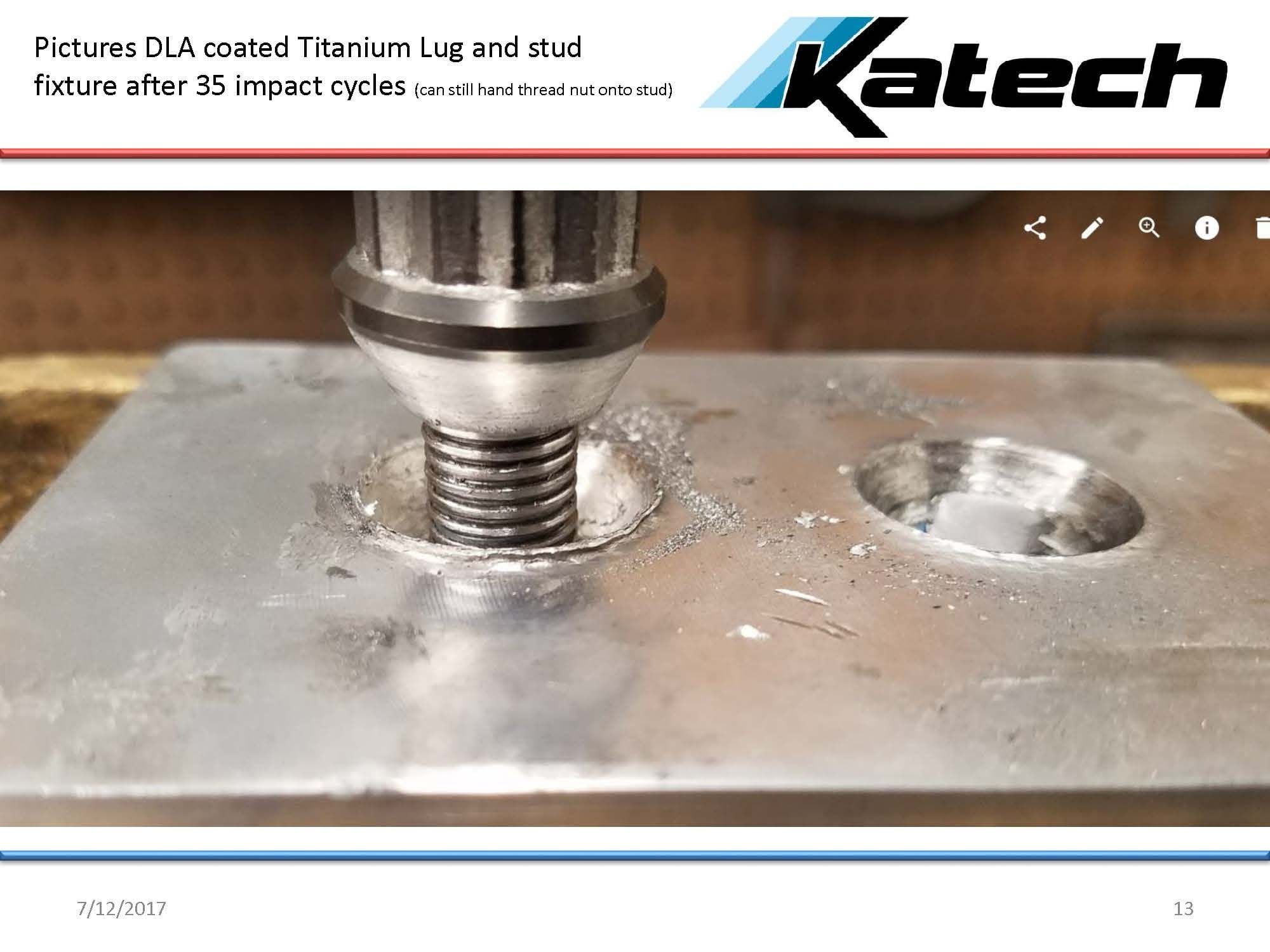

We have been torturing a lug nut with an impact for the last hour. I don't think we have anything to worry about.

We will post more scientific information later.

We will post more scientific information later.

#45

So your saying that with the Ti nuts you couldn't break the incredibly craptastic stock C7 studs? I wouldn't have guessed that to be the case. No issues with the nuts rounding off?

#46

Drifting

If you guys would like, I have access to a "Skidmore-Wilhelm" bolt tension measuring device at my work.

Essentially it uses two plates compressing hydraulic fluid to register a pressure on the gauge to relate torque and bolt tension.

This way you can see how friction with the different materials and coatings is affecting your clamping force.

I can run the test for you (for free) if you want to send me one of each style lug. Give me a torque value and I will set up the experiment and send you the results.

PM if interested. I am a professional engineer for what it's worth

Essentially it uses two plates compressing hydraulic fluid to register a pressure on the gauge to relate torque and bolt tension.

This way you can see how friction with the different materials and coatings is affecting your clamping force.

I can run the test for you (for free) if you want to send me one of each style lug. Give me a torque value and I will set up the experiment and send you the results.

PM if interested. I am a professional engineer for what it's worth

#47

Premium Supporting Vendor

Thread Starter

If you guys would like, I have access to a "Skidmore-Wilhelm" bolt tension measuring device at my work.

Essentially it uses two plates compressing hydraulic fluid to register a pressure on the gauge to relate torque and bolt tension.

This way you can see how friction with the different materials and coatings is affecting your clamping force.

I can run the test for you (for free) if you want to send me one of each style lug. Give me a torque value and I will set up the experiment and send you the results.

PM if interested. I am a professional engineer for what it's worth

Essentially it uses two plates compressing hydraulic fluid to register a pressure on the gauge to relate torque and bolt tension.

This way you can see how friction with the different materials and coatings is affecting your clamping force.

I can run the test for you (for free) if you want to send me one of each style lug. Give me a torque value and I will set up the experiment and send you the results.

PM if interested. I am a professional engineer for what it's worth

Sure. Email me your address and I'll send you some.

jason@katechengines.com

#53

Premium Supporting Vendor

Thread Starter

#54

Pro

That seems bizarre. Only thing I can think (from working with titanium a fair amount) is that titanium while indeed has a higher tensile strength than many steels, is still a fairly "gushy" material. Could be when the titanium lug nut is slamming into the seat, the titanium nut is absorbing some shock, while the steel but is transferring all the force right back into the stud? Just thinking out loud.

#55

Burning Brakes

The is a bit dated, but a good reference. From pg. 13

https://ntrs.nasa.gov/archive/nasa/c...9900009424.pdf

If a bolt is cycled in tension, it will normally break near

the end of the threaded portion because this is the area of

maximum stress concentration. In order to lessen the stress

concentration factor, the bolt shank can be machined down

to the root diameter of the threads. Then it will survive tensile

cyclic loading much longer than a standard bolt with the shank

diameter equal to the thread outside diameter.

This will add some insight to Katech's test results.

https://www.highpowermedia.com/blog/...tener-material

The use of nuts with lower modulus than the male fastener is known to reduce the stress concentration effect at the first thread, and improves the distribution of load over the length of the engaged threads.

A good failure analysis paper.

http://products.asminternational.org...d=2039&search=

I expect the superior performance that Katech observed is due to the difference in tensile properties of the stud and nut as noted in the Race Engine Technology article linked above.

-Scott

#56

Advanced

Member Since: Jun 2017

Location: Allentown PA

Posts: 91

Likes: 0

Received 0 Likes

on

0 Posts

#57

Advanced

If you guys would like, I have access to a "Skidmore-Wilhelm" bolt tension measuring device at my work.

Essentially it uses two plates compressing hydraulic fluid to register a pressure on the gauge to relate torque and bolt tension.

This way you can see how friction with the different materials and coatings is affecting your clamping force.

I can run the test for you (for free) if you want to send me one of each style lug. Give me a torque value and I will set up the experiment and send you the results.

PM if interested. I am a professional engineer for what it's worth

Essentially it uses two plates compressing hydraulic fluid to register a pressure on the gauge to relate torque and bolt tension.

This way you can see how friction with the different materials and coatings is affecting your clamping force.

I can run the test for you (for free) if you want to send me one of each style lug. Give me a torque value and I will set up the experiment and send you the results.

PM if interested. I am a professional engineer for what it's worth

#58

Drifting

Just got the email notification that this thread got bumped back up.

I sort of let this fall to the back burner for a while.. Katech shipped me a few nuts to play around with but I needed a conical seat machined for the testing device I have here. Our shop was extremely busy for a few months and I wasn't able to get the seats machined for a long time. Then things got crazy in the office and I didn't have time but eventually I did get around to testing a few of them. I'll have to try and find the test data when I get home tonight.

I did my best to control the variables affecting friction (thoroughly cleaned all components with de-greaser and checked everything over for any burrs or imperfections on surfaces and threads).

The bad news is that I ran into one problem... the conical seat adapters (steel) machined to interface with the lug nuts were spinning while being torqued. Therefore, the effect of the "nut face friction" was lost, which I have read, can make up 50% of the torque distribution.

The good news is that this happened for both the Ti and steel lug nuts. Therefore, the resulting clamping force may not be accurate, but a direct comparison should still be possible between steel and Ti as only the thread interfaces were at play during the experiment. (Nut face friction was the same for both types of lug nuts as the material was both steel.)

The results of preload / bolt tension for a specific torque were very similar to the regular steel lug nuts (again, I'll have to try and find the numbers when I get home). Therefore, the coefficient of friction between some generic steel lugs (I believe some looked like zinc chromate finish) and bare steel test surface vs. Ti DLC and bare steel test surface must be reasonably similar. I would conclude that no drastic change to torque values should be necessary.

This doesn't offer any insight to the inability for Katech to break a steal stud while torquing them in their fixture. That part I still haven't spent too much time thinking about.

I sort of let this fall to the back burner for a while.. Katech shipped me a few nuts to play around with but I needed a conical seat machined for the testing device I have here. Our shop was extremely busy for a few months and I wasn't able to get the seats machined for a long time. Then things got crazy in the office and I didn't have time but eventually I did get around to testing a few of them. I'll have to try and find the test data when I get home tonight.

I did my best to control the variables affecting friction (thoroughly cleaned all components with de-greaser and checked everything over for any burrs or imperfections on surfaces and threads).

The bad news is that I ran into one problem... the conical seat adapters (steel) machined to interface with the lug nuts were spinning while being torqued. Therefore, the effect of the "nut face friction" was lost, which I have read, can make up 50% of the torque distribution.

The good news is that this happened for both the Ti and steel lug nuts. Therefore, the resulting clamping force may not be accurate, but a direct comparison should still be possible between steel and Ti as only the thread interfaces were at play during the experiment. (Nut face friction was the same for both types of lug nuts as the material was both steel.)

The results of preload / bolt tension for a specific torque were very similar to the regular steel lug nuts (again, I'll have to try and find the numbers when I get home). Therefore, the coefficient of friction between some generic steel lugs (I believe some looked like zinc chromate finish) and bare steel test surface vs. Ti DLC and bare steel test surface must be reasonably similar. I would conclude that no drastic change to torque values should be necessary.

This doesn't offer any insight to the inability for Katech to break a steal stud while torquing them in their fixture. That part I still haven't spent too much time thinking about.

Last edited by doublec4; 03-12-2018 at 11:46 AM.

#59

Le Mans Master

https://www.highpowermedia.com/blog/...tener-material

The use of nuts with lower modulus than the male fastener is known to reduce the stress concentration effect at the first thread, and improves the distribution of load over the length of the engaged threads.

The Young's Modulus of 8740 is 205 GPa

The Young's Modulus of Ti-6Al-4V Titanium is 113.8 GPa

In a nutshell, the Titanium does a better job of distributing stress across the threads given its lower modulus of elasticity.