Alignment using CSM hub stands by froggy

#21

Race Director

Thread Starter

i bought sand bags to fill. Figured I'd put them in trash bags to make sure they dont make a mess. I would use weightlifting plates, but those run about a $1/lb. Plus with the sandbag, i think they'll wear the seat less.I thought maybe I was being too **** wanting to mimic my bodyweight, but I'm about 235-240 so i think that could make a noticeable impact, no?

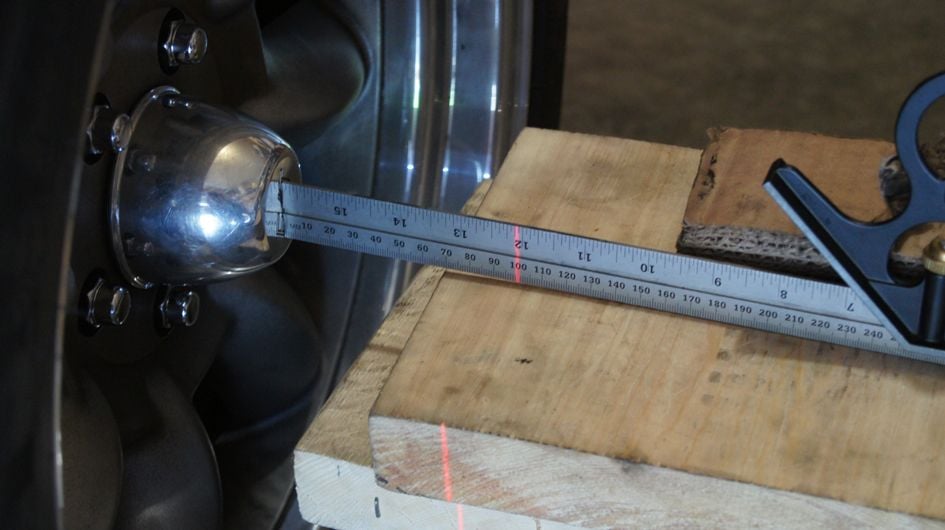

I really can't remember the last time I had fun learning a tool. The GM Tech 2 was a little heavy on the software like 100%, but this has beautiful machined aluminum stands, lasers, laser targets, plus good old fashioned tape measures. WooHoo.

You can see for yourself in the videos, the craftsmanship here.

Like tools you are proud to own.

Last edited by froggy47; 04-30-2019 at 05:44 PM.

#22

Racer

I use Weightlifting Plates, put the seat all the way back, put a towel down and put the plates on the floor. Not perfect but close enough for me.

#23

Race Director

Thread Starter

Here is front toe demo, I did not have time/need to change toe. Maybe do another later showing that.

Comments welcome.

Froggy

Comments welcome.

Froggy

Last edited by froggy47; 05-01-2019 at 01:37 AM.

#24

Race Director

Thread Starter

Rear toe, and before I get called on it, I misspoke and the measure shows toe out which is what you want in an autox car.

Questions, comments.

I learned this tool as I shot the video & it gets faster better each time as you become expert with the tool.

Froggy

Questions, comments.

I learned this tool as I shot the video & it gets faster better each time as you become expert with the tool.

Froggy

Last edited by froggy47; 05-01-2019 at 01:38 AM.

#26

Former Vendor

Looking Great Froggy! Froggy and I spoke last night and I wanted to add some clarification for measuring the rear toe with the laser line. When measuring, the user must adjust out the toe at the front wheel from that measured at the rear wheel. They simply add together when following the convention of toe in being positive and Toe Out being negative. The Laser is attached to the front Toe Bar so it shoots a line parallel to the that Toe Bar, therefore matching the toe of that wheel.

Rear Wheel Toe Equation:

Front Wheel Toe + Rear Wheel Toe Relative to Laser Line = Rear Wheel Toe

Example:

If a car has an 1/8" of Toe In in the front and the thrust has been set, we know that each wheel has 1/16" of Toe In. If I measure 2" from the laser line at the forward most position of the rear Toe Bar and 2 1/8" at the rear most position of the rear Toe Bar that shows a Toe Out of 1/8" relative to the Laser Line. To convert that to Toe relative to the vehicle (what we actually need to know) we need to adjust for the Toe In that the laser line has from being attached to the front wheel. We use a convention of Toe In being positive and Toe Out being negative.

1/16" (Front Toe) + (-1/8") (Rear Toe Relative to Laser Line) = -1/16" Toe (Rear Toe) or 1/16" Toe Out

There are additional examples on our website @: https://csmperformance.com/laser-thr...gnment-system/

Thanks!

Colton @ CSM Performance LLC

Rear Wheel Toe Equation:

Front Wheel Toe + Rear Wheel Toe Relative to Laser Line = Rear Wheel Toe

Example:

If a car has an 1/8" of Toe In in the front and the thrust has been set, we know that each wheel has 1/16" of Toe In. If I measure 2" from the laser line at the forward most position of the rear Toe Bar and 2 1/8" at the rear most position of the rear Toe Bar that shows a Toe Out of 1/8" relative to the Laser Line. To convert that to Toe relative to the vehicle (what we actually need to know) we need to adjust for the Toe In that the laser line has from being attached to the front wheel. We use a convention of Toe In being positive and Toe Out being negative.

1/16" (Front Toe) + (-1/8") (Rear Toe Relative to Laser Line) = -1/16" Toe (Rear Toe) or 1/16" Toe Out

There are additional examples on our website @: https://csmperformance.com/laser-thr...gnment-system/

Thanks!

Colton @ CSM Performance LLC

Last edited by CSM Performance; 05-01-2019 at 10:43 AM.

#27

Race Director

Thread Starter

Looking Great Froggy! Froggy and I spoke last night and I wanted to add some clarification for measuring the rear toe with the laser line. When measuring, the user must adjust out the toe at the front wheel from that measured at the rear wheel. They simply add together when following the convention of toe in being positive and Toe Out being negative. The Laser is attached to the front Toe Bar so it shoots a line parallel to the that Toe Bar, therefore matching the toe of that wheel.

Rear Wheel Toe Equation:

Front Wheel Toe + Rear Wheel Toe Relative to Laser Line = Rear Wheel Toe

Example:

If a car has an 1/8" of Toe In in the front and the thrust has been set, we know that each wheel has 1/16" of Toe In. If I measure 2" from the laser line at the forward most position of the rear Toe Bar and 2 1/8" at the rear most position of the rear Toe Bar that shows a Toe Out of 1/8" relative to the Laser Line. To convert that to Toe relative to the vehicle (what we actually need to know) we need to adjust for the Toe In that the laser line has from being attached to the front wheel. We use a convention of Toe In being positive and Toe Out being negative.

1/16" (Front Toe) + (-1/8") (Rear Toe Relative to Laser Line) = -1/16" Toe (Rear Toe) or 1/16" Toe Out

There are additional examples on our website @: https://csmperformance.com/laser-thr...gnment-system/

Thanks!

Colton @ CSM Performance LLC

Rear Wheel Toe Equation:

Front Wheel Toe + Rear Wheel Toe Relative to Laser Line = Rear Wheel Toe

Example:

If a car has an 1/8" of Toe In in the front and the thrust has been set, we know that each wheel has 1/16" of Toe In. If I measure 2" from the laser line at the forward most position of the rear Toe Bar and 2 1/8" at the rear most position of the rear Toe Bar that shows a Toe Out of 1/8" relative to the Laser Line. To convert that to Toe relative to the vehicle (what we actually need to know) we need to adjust for the Toe In that the laser line has from being attached to the front wheel. We use a convention of Toe In being positive and Toe Out being negative.

1/16" (Front Toe) + (-1/8") (Rear Toe Relative to Laser Line) = -1/16" Toe (Rear Toe) or 1/16" Toe Out

There are additional examples on our website @: https://csmperformance.com/laser-thr...gnment-system/

Thanks!

Colton @ CSM Performance LLC

And of course this makes sense now that I wrap my head around it. With the (old) strings you were measuring rear toe AT THE rear wheel. Using CSM laser off the FRONT toe bar simply adjust for that additional measurement to get true/final rear toe.

Easy Peasy.

#28

Hi, new to the site and Corvettes in general, but not new to race alignments.

Correct me if I'm missing something, but I was taught to completely level the car before adjusting anything on the suspension. You mentioned your garage floor was sloped, and I've worked on garage floors I thought were flat as can be, but after shooting a laser lever across it, that wasn't the case. If your car isn't completely level, you aren't going to get accurate results. Am I wrong?

Correct me if I'm missing something, but I was taught to completely level the car before adjusting anything on the suspension. You mentioned your garage floor was sloped, and I've worked on garage floors I thought were flat as can be, but after shooting a laser lever across it, that wasn't the case. If your car isn't completely level, you aren't going to get accurate results. Am I wrong?

#29

Race Director

Thread Starter

Hi, new to the site and Corvettes in general, but not new to race alignments.

Correct me if I'm missing something, but I was taught to completely level the car before adjusting anything on the suspension. You mentioned your garage floor was sloped, and I've worked on garage floors I thought were flat as can be, but after shooting a laser lever across it, that wasn't the case. If your car isn't completely level, you aren't going to get accurate results. Am I wrong?

Correct me if I'm missing something, but I was taught to completely level the car before adjusting anything on the suspension. You mentioned your garage floor was sloped, and I've worked on garage floors I thought were flat as can be, but after shooting a laser lever across it, that wasn't the case. If your car isn't completely level, you aren't going to get accurate results. Am I wrong?

#30

Looking Great Froggy! Froggy and I spoke last night and I wanted to add some clarification for measuring the rear toe with the laser line. When measuring, the user must adjust out the toe at the front wheel from that measured at the rear wheel. They simply add together when following the convention of toe in being positive and Toe Out being negative. The Laser is attached to the front Toe Bar so it shoots a line parallel to the that Toe Bar, therefore matching the toe of that wheel.

Rear Wheel Toe Equation:

Front Wheel Toe + Rear Wheel Toe Relative to Laser Line = Rear Wheel Toe

Example:

If a car has an 1/8" of Toe In in the front and the thrust has been set, we know that each wheel has 1/16" of Toe In. If I measure 2" from the laser line at the forward most position of the rear Toe Bar and 2 1/8" at the rear most position of the rear Toe Bar that shows a Toe Out of 1/8" relative to the Laser Line. To convert that to Toe relative to the vehicle (what we actually need to know) we need to adjust for the Toe In that the laser line has from being attached to the front wheel. We use a convention of Toe In being positive and Toe Out being negative.

1/16" (Front Toe) + (-1/8") (Rear Toe Relative to Laser Line) = -1/16" Toe (Rear Toe) or 1/16" Toe Out

There are additional examples on our website @: https://csmperformance.com/laser-thr...gnment-system/

Thanks!

Colton @ CSM Performance LLC

Rear Wheel Toe Equation:

Front Wheel Toe + Rear Wheel Toe Relative to Laser Line = Rear Wheel Toe

Example:

If a car has an 1/8" of Toe In in the front and the thrust has been set, we know that each wheel has 1/16" of Toe In. If I measure 2" from the laser line at the forward most position of the rear Toe Bar and 2 1/8" at the rear most position of the rear Toe Bar that shows a Toe Out of 1/8" relative to the Laser Line. To convert that to Toe relative to the vehicle (what we actually need to know) we need to adjust for the Toe In that the laser line has from being attached to the front wheel. We use a convention of Toe In being positive and Toe Out being negative.

1/16" (Front Toe) + (-1/8") (Rear Toe Relative to Laser Line) = -1/16" Toe (Rear Toe) or 1/16" Toe Out

There are additional examples on our website @: https://csmperformance.com/laser-thr...gnment-system/

Thanks!

Colton @ CSM Performance LLC

I like the units but here is what I would do to measure toe using your equipment and would have a greater margin of error.

Do a setup similar to this.

Again first setup the thrust angles with the rear wheels relative to the front axle. Laser mounted on the rear hub pointing to the front axle and set equal distance left vs right. To measure total toe place a spacer equal length front and back of the hubs ( I believe your hub plates are equal distance from the center of the axle ).

Lay down the measure tape across the floor at the end of the spacers.

(laser pointer would need to be mounted at the center line of the hub unit)

Then move the tape measure to a set point eg 12" then point the laser on the rear wheel to the opposite direction. again move the tape to the same point @ 12"

Then move the laser to the opposite side and take 2 readings.

Lets say it reads 48 1/4" pointing to the front and 48 1/2" at the rear.

Measure the distance between the 2 tape measures. lets say = 108" using 4ft spacers.

total toe = 48 1/4" - 48 1/2" = 1/4" over 108" = inv tan (.25/108) = 0.13262 degrees. so for a 26.68 dia tire (325 30R 19) = 1.976 / 32nd's or 1/16" toe in.

Its easier if you use the metric system you would set the initial point at 100mm distance would read as ~ 1225.5 mm and ~ 1232mm

difference of 6.5 mm over 2743mm = .1357 degrees. again for a 26.68 = 2.0229 / 32nd's again 1/16th toe in.

or don't care about toe inches and just use toe degrees which most specs now give.

But here is the improvement in the margin of error.

If you only measure at your toe bars and lets say the front vs rear distance is 30" (not sure on your toe bar length)

and you guess at which 1/32 marker with your eyes. the best result = inv tan 1/32" / 30 = 0.05968 degrees total toe.

as you increase the distance your margin of error is reduced

so in my example 1mm (very easy to determine 1mm at the tape measure with laser line) = 1/2743 = 0.02089 degrees total toe.

You can be off by 2-3mm which is a lot and get the same result.

Now the laser level will also add error at different distances. and will also vary laser unit to unit.

To remove or cancel out the laser error you need to use the same unit for all measurements and the distance you measure at is also the same.

To test your laser error I would do the following.

1. setup the laser 1 on the rear toe bar pointing to the front and measure a distance at the center of the hub stand. Then switch to laser 2 and take the same measurement. If it reads the same distance, then you would be lucky both units match, but I would guess they won't but it may not be off enough to matter.

The unit in the kit is a GLL 50 which is spec'd at "±1/8 in @ 33 ft" but if you use the proper techniques the error doesn't matter. So I would recommend you check laser 1 vs laser 2 to know how different they are. Only matters for the thrust measurement.

For total toe measurement both units can vary and doesn't add any error to the measurement since we only need to know the difference. And with the laser mounted at the center of the hub, the distance measured front vs rear is equal the error cancels out.

I like the units since you can make the adjustments to the car and yet keep the measurement system in place.

Anyone that has tried strings knows the pain I am speaking about.

Hope to see more videos and improvements to the system.

#31

Former Vendor

I'll tear into the technical details on this to help relieve some concern. On the Lasers mounted to the front toe bar it is based off of that Toe Bar measurement. Is there a margin for error, yes. The adjustment made from to the rear toe relative to the laser line is at the discretion of that front toe measurement. There's a very quick and easy way to solve this. Once you've finished setting rear toe with the laser line you can swap the lasers to the rear and put the grid plate on the front to ensure the rear's are now in line (rear thrust) with the front. We found through our testing that this step was not needed as the measurement from the laser line was basically dead on. You can also again check your rear toe by tape measuring across the toe bars.

So we now have two more methods to check the accuracy of our rear toe measurement, ensuring it is in line (thrust) and checking the toe with a different method (based off laser and measuring with tape measures). With every system it comes down to the amount of time you can dedicate to it. For someone at the track that needs to do it quickly, our standard method will get it done with extreme accuracy. If you want to take it further and swap the lasers to ensure thrust at the rear (which is already achieved by measuring from the laser line through the standard method) and the grid plates to the front you can. Additionally you can measure between the rear Toe Bars to guarantee your measurement. Again, we determined through our testing that this wasn't needed.

The laser shoots over a distance of roughly 8 feet generally, 8ft/33ft ~ 1/4th -> ±1/32" on the laser position, so in most cases it's negligible. The angle of the laser relative to the center-line of the car is what really matters. It matches that of the Toe Bar it's mounted to with a possible degree variance due to the ±1/8 of 33ft of ±0.0746 degrees, again relatively negligible.

When measuring over a Toe Bar of 24" the tolerance is ±1/128" but that is applied differently. I can get deep into the tolerances and how they'll affect the overall measurement accuracy summation but that gets pretty deep.

It really comes down to this, we did an enormous amount of testing with the LTAS before we released it to ensure the reliability and robustness. Our customers have had great success with the system as well.

An additional 3rd method would be to set front Toe with tape measure and ensure it's thrust with the grid plates. Then swap the laser to the rear and grid plates to the front. Measure the rear Toe with tape measures and ensure it's thrust with the lasers. This is a longer process but again ensures overall accuracy and robustness. There's numerous ways to approach it but we present the method we do due to the time it takes and it's accuracy.

Thanks!

Colton @ CSM Performance LLC

So we now have two more methods to check the accuracy of our rear toe measurement, ensuring it is in line (thrust) and checking the toe with a different method (based off laser and measuring with tape measures). With every system it comes down to the amount of time you can dedicate to it. For someone at the track that needs to do it quickly, our standard method will get it done with extreme accuracy. If you want to take it further and swap the lasers to ensure thrust at the rear (which is already achieved by measuring from the laser line through the standard method) and the grid plates to the front you can. Additionally you can measure between the rear Toe Bars to guarantee your measurement. Again, we determined through our testing that this wasn't needed.

The laser shoots over a distance of roughly 8 feet generally, 8ft/33ft ~ 1/4th -> ±1/32" on the laser position, so in most cases it's negligible. The angle of the laser relative to the center-line of the car is what really matters. It matches that of the Toe Bar it's mounted to with a possible degree variance due to the ±1/8 of 33ft of ±0.0746 degrees, again relatively negligible.

When measuring over a Toe Bar of 24" the tolerance is ±1/128" but that is applied differently. I can get deep into the tolerances and how they'll affect the overall measurement accuracy summation but that gets pretty deep.

It really comes down to this, we did an enormous amount of testing with the LTAS before we released it to ensure the reliability and robustness. Our customers have had great success with the system as well.

An additional 3rd method would be to set front Toe with tape measure and ensure it's thrust with the grid plates. Then swap the laser to the rear and grid plates to the front. Measure the rear Toe with tape measures and ensure it's thrust with the lasers. This is a longer process but again ensures overall accuracy and robustness. There's numerous ways to approach it but we present the method we do due to the time it takes and it's accuracy.

Thanks!

Colton @ CSM Performance LLC

#32

I'll tear into the technical details on this to help relieve some concern. On the Lasers mounted to the front toe bar it is based off of that Toe Bar measurement. Is there a margin for error, yes. The adjustment made from to the rear toe relative to the laser line is at the discretion of that front toe measurement.

And compare the results. Results will vary and you may be lucky that the variance is minimal.

But I use the same laser level on both sides which eliminates the laser accuracy completely.

Also its not the laser accuracy that I am concerned with , its the ruler / human eye determining what the measurement is. Here the distance is the length of the toe bar front side vs rear side to determine the difference. The human needs

to visually determine what he see's.

For testing use the same method but extend the toe bars to a length of 8ft and everything becomes real easy where is human eye can guess anything from 2-3 mm spread with out errors.

I downloaded you instruction sheet and will try to reproduce your procedure. It still doesn't make sense to base 1 measurement from another. Front total toe and rear total toe should be the same procedure and not based on the results of the other.

Also dose your procedure still work if the front track width is less than the rear track width ? example my 1978 corvette front axle width is less than the rear axle width ?

Last edited by cagotzmann; 05-02-2019 at 01:15 AM.

#33

Race Director

Thread Starter

I am going to throw out a few comments based on this recent discussion, and up front both these guys have more knowledge/experience than myself so there. I am just the humble user.

Simple things to consider.

First off it seems we are just talking toe here, so good. One little comment on caster/camber before we proceed, using hub stands vs leaving the wheel on is like, let's say, taking the dash apart to change a radio station each time. It's honestly crazy to do it with wheels on, it's a wonder my back is still in one piece for the number of times off/on the wheels when I did it the old way. 2 to 4 times each corner (2 if lucky, 4 if not).

So for toe, generally, you need to be able to read a laser/tape mark/bubble or really don't try this. I have done all and reading 64th's on a tape is pretty hard with "old eyes". Bubbles better and laser best. I decided to base ALL laser reads to the inner line of laser light rather than try to judge the middle of the laser light. Seems to have worked. Colton correct me if I am wrong.

Cagotzmann arguably has a very precise way to set toe, but when the math gets into inv tan and hundreths of thousands of degrees (if that's right) my brain doesn't go there. Anything beyond algebra is a stretch. Personally I choose not to use systems based on math I don't understand (no offense).

I do toe in inches because I get that a little better than degrees of toe, but I do use degrees for camber. Just me. Go figure.

For laser error, next time I will switch the two & verify, if either is off, I am sure there is a manufacturer warranty on them, same with the Longacre part. You do need to be sure/careful that the attach to the bar is solid each time.

That's about it, and I was hoping that this thread would spark a friendly discussion like this, we all learn.

Back to the garage.

Simple things to consider.

First off it seems we are just talking toe here, so good. One little comment on caster/camber before we proceed, using hub stands vs leaving the wheel on is like, let's say, taking the dash apart to change a radio station each time. It's honestly crazy to do it with wheels on, it's a wonder my back is still in one piece for the number of times off/on the wheels when I did it the old way. 2 to 4 times each corner (2 if lucky, 4 if not).

So for toe, generally, you need to be able to read a laser/tape mark/bubble or really don't try this. I have done all and reading 64th's on a tape is pretty hard with "old eyes". Bubbles better and laser best. I decided to base ALL laser reads to the inner line of laser light rather than try to judge the middle of the laser light. Seems to have worked. Colton correct me if I am wrong.

Cagotzmann arguably has a very precise way to set toe, but when the math gets into inv tan and hundreths of thousands of degrees (if that's right) my brain doesn't go there. Anything beyond algebra is a stretch. Personally I choose not to use systems based on math I don't understand (no offense).

I do toe in inches because I get that a little better than degrees of toe, but I do use degrees for camber. Just me. Go figure.

For laser error, next time I will switch the two & verify, if either is off, I am sure there is a manufacturer warranty on them, same with the Longacre part. You do need to be sure/careful that the attach to the bar is solid each time.

That's about it, and I was hoping that this thread would spark a friendly discussion like this, we all learn.

Back to the garage.

Last edited by froggy47; 05-02-2019 at 01:39 PM.

The following 2 users liked this post by froggy47:

CSM Performance (05-02-2019),

Mick14 (05-02-2019)

#34

Former Vendor

So that's what I don't like. If you front toe is off then the reference is off. eg miss read the front toe, and using the tape measure across the toe bars isn't that accurate because you have tension in the tape measure , Plus you need to use the human eye and at best guess which 1/32" mark to use. The human eye cannot easily see the difference. The toe bar measurement at best is 1/32" over the length of the toe bar. So I believe this can be improved by increasing the measurement point. The same reason strings are not very accurate. You are measuring the difference at the width of the rim ~ 16 - 20".

The only time laser accuracy is a concern for me, is with the thrust measurement, and only if I use 2 different laser's one on each side. But this is easy to identify by doing a second measurement switching the lasers side to side.

And compare the results. Results will vary and you may be lucky that the variance is minimal.

But I use the same laser level on both sides which eliminates the laser accuracy completely.

And compare the results. Results will vary and you may be lucky that the variance is minimal.

But I use the same laser level on both sides which eliminates the laser accuracy completely.

Also its not the laser accuracy that I am concerned with , its the ruler / human eye determining what the measurement is. Here the distance is the length of the toe bar front side vs rear side to determine the difference. The human needs to visually determine what he see's.

I hope I've answered your questions/cleared up any confusion! I'm more than happy to talk through these!

Thanks!

Colton @ CSM Performance LLC

#35

Former Vendor

I am going to throw out a few comments based on this recent discussion, and up front both these guys have more knowledge/experience than myself so there. I am just the humble user.

Simple things to consider.

First off it seems we are just talking toe here, so good. One little comment on caster/camber before we proceed, using hub stands vs leaving the wheel on is like, let's say, taking the dash apart to change a radio station each time. It's honestly crazy to do it with wheels on, it's a wonder my back is still in one piece for the number of times off/on the wheels when I did it the old way. 2 to 4 times each corner (2 if lucky, 4 if not).

So for toe, generally, you need to be able to read a laser/tape mark/bubble or really don't try this. I have done all and reading 64th's on a tape is pretty hard with "old eyes". Bubbles better and laser best. I decided to base ALL laser reads to the inner line of laser light rather than try to judge the middle of the laser light. Seems to have worked. Colton correct me if I am wrong.

Cagotzmann arguably has a very precise way to set toe, but when the math gets into inv tan and hundreths of thousands of degrees (if that's right) my brain doesn't go there. Anything beyond algebra is a stretch. Personally I choose not to use systems based on math I don't understand (no offense).

I do toe in inches because I get that a little better than degrees of toe, but I do use degrees for camber. Just me. Go figure.

For laser error, next time I will switch the two & verify, if either is off, I am sure there is a manufacturer warranty on them, same with the Longacre part. You do need to be sure/careful that the attach to the bar is solid each time.

That's about it, and I was hoping that this thread would spark a friendly discussion like this, we all learn.

Back to the garage.

Simple things to consider.

First off it seems we are just talking toe here, so good. One little comment on caster/camber before we proceed, using hub stands vs leaving the wheel on is like, let's say, taking the dash apart to change a radio station each time. It's honestly crazy to do it with wheels on, it's a wonder my back is still in one piece for the number of times off/on the wheels when I did it the old way. 2 to 4 times each corner (2 if lucky, 4 if not).

So for toe, generally, you need to be able to read a laser/tape mark/bubble or really don't try this. I have done all and reading 64th's on a tape is pretty hard with "old eyes". Bubbles better and laser best. I decided to base ALL laser reads to the inner line of laser light rather than try to judge the middle of the laser light. Seems to have worked. Colton correct me if I am wrong.

Cagotzmann arguably has a very precise way to set toe, but when the math gets into inv tan and hundreths of thousands of degrees (if that's right) my brain doesn't go there. Anything beyond algebra is a stretch. Personally I choose not to use systems based on math I don't understand (no offense).

I do toe in inches because I get that a little better than degrees of toe, but I do use degrees for camber. Just me. Go figure.

For laser error, next time I will switch the two & verify, if either is off, I am sure there is a manufacturer warranty on them, same with the Longacre part. You do need to be sure/careful that the attach to the bar is solid each time.

That's about it, and I was hoping that this thread would spark a friendly discussion like this, we all learn.

Back to the garage.

Race on!

Colton @ CSM Performance LLC

#36

Race Director

Thread Starter

I do see having a different track v autox alignment now that it's so quick. I never really bought into the guys that rely on just counting the shims ot counting the turns on toe. Parts wear and alignments need to be checked. If you are just cruising around the course for the fresh air, that's different & I have no issues with those guys, god bless you just watch your mirror. But if you are even semi serious this is it. Or like David and cagotzmann use your own tried and true system.

Be safe, have fun.

Froggy

Last edited by froggy47; 05-02-2019 at 04:26 PM.

#37

Put the laser on any smooth surface pointing at a ruler and then place the next laser at the same spot and compare the reading at the laser.

The further away the ruler is the better. I usually use about 20 - 30 ft. but it doesn't matter what distance you use only knowing the further the distance the easier to see the variance. Now don't except both laser to be perfect, very rarely they will be. But they are expected to be +- 1/8" over 50ft ( your unit ).

So what you can do is shim one of the lasers on the hub. So once you find the laser unit that is the lower of the 2 use the elements/ fingers from a feeler gauge and shim the laser until they both match. Then when mounting the

laser on the hubs they will be perfect and no need to worry about any errors. Hopefully your units will be close enough you wont need to shim anything. Or you can use the same laser unit on both sides (moving it ) and the laser error doesn't matter since the true error of the laser is cancelled because the distance is the same on both side.

I like the idea of the hubs and big time saving on doing the alignments. Not as great for just taking measurements, but beats any other process that uses any string setup.

I check my alignment before and after every track event, usually every 2 weeks, so I came up with a process to take measurements very quickly. The process I use takes me about 15 minutes total to measure caster / camber / toe. and I use 2 processes.

1. Direct tires on the concrete just driving on set spots in the garage.

2. Then drive on car to the same spots, but with slip plates with grease between the plates so the suspension settles to the max.

The difference between the 2 measurements I use as suspension wear references. Once the total toes changes more than 1/8th " I start to look for worn out parts. or camber changes more than .3 degrees.

With the hubs I would apply pressure to one rotor and see how much movement it takes to effect the other hub to also see movement. But its worth to take measurements before and after you change parts to see the difference. Then

you will know what to check / look for worn parts.

Last edited by cagotzmann; 05-02-2019 at 09:26 PM.

#38

Former Vendor

No need to mount the lasers to the hubs to test.

Put the laser on any smooth surface pointing at a ruler and then place the next laser at the same spot and compare the reading at the laser.

The further away the ruler is the better. I usually use about 20 - 30 ft. but it doesn't matter what distance you use only knowing the further the distance the easier to see the variance. Now don't except both laser to be perfect, very rarely they will be. But they are expected to be +- 1/8" over 50ft ( your unit ).

Put the laser on any smooth surface pointing at a ruler and then place the next laser at the same spot and compare the reading at the laser.

The further away the ruler is the better. I usually use about 20 - 30 ft. but it doesn't matter what distance you use only knowing the further the distance the easier to see the variance. Now don't except both laser to be perfect, very rarely they will be. But they are expected to be +- 1/8" over 50ft ( your unit ).

Thanks!

Colton @ CSM Performance LLC

#39

Cagotzmann arguably has a very precise way to set toe, but when the math gets into inv tan and hundreths of thousands of degrees (if that's right) my brain doesn't go there. Anything beyond algebra is a stretch. Personally I choose not to use systems based on math I don't understand (no offense).

You will also find using the hubs the same quick process.

So the first time you do the alignment double and triple check you are happy with the setup.

Note 3 main measurements.

1. Camber of each wheel

2. Thrust measurement of the rear wheels (laser mounted on the rear wheels). While the plates they provide do not have very precise measurement points but use the precision ruler provided and measure the left and right wheel with in 1/32" distance the laser is from the hub at the center line of the axle.

3. Then mount the laser on the front wheels. Use your GM Tech II unit to center the wheel (steering sensor) to the 0 mark. And again measure the distances from the rear hub.

Once you have these reference points all you need to do is adjust until you get the same readings. So changing from auto-x, to street, to road track, you don't need to take measurement since you only worry about the actual numbers the first time. If you set the alignment to the same reference points the measurements should be exactly the same.

This is an example what reference I measure to set the alignment back again.

Set the rear wheels to the 100mm mark gives me a 3/32" toe in. set both rear wheels to the same reference and done. No counting of turns, measurement of shims etc.

Then you need to do only 3 measurements/ adjustments.

1. check /set the camber of the wheels

2. check /set the thrust of the rear wheels

3. check /set the thrust of the front wheels

The only thing to remember is that changing camber effects toe. ( but you already know this) So if your camber has changed or you want to try a difference camber setting you will need to again measure toe and then record a new reference set for the given camber setup.

This will make a big difference to what you have been doing. As you suggested adding suspension setup and part of the normal maintenance just became very feasible.

Its nice when the tools make things for the better.

Last edited by cagotzmann; 05-02-2019 at 09:57 PM.

#40

The Lasers need to be mounted to the toe bars for this test. The force from being tightened down compresses the rubber gripper on the bottom of the laser until the laser bottom sits flush against the toe bar. Without compressing it, if there is a slight difference in rubber gripper height it will cause a false error. Again, we've performed this test with numerous lasers attached to Toe Bars side by side with them tightened down and they've shown to be dead on.

Thanks!

Colton @ CSM Performance LLC

Thanks!

Colton @ CSM Performance LLC

But as suggested mount on the toe bars, but I would measure at a 20-30 ft distance so you can see the difference. If you cannot see any difference at that distance using the 8ft distance required will be perfect.

Last edited by cagotzmann; 05-02-2019 at 09:43 PM.