[C2] 65 Electrical Problem

#21

Team Owner

The only way I do it is to twist the wires together then solder them and cover the splice with two layers of shrinkable tubing

#22

Safety Car

Thread Starter

Member Since: Apr 2013

Location: Arlington TX

Posts: 4,833

Received 930 Likes

on

532 Posts

2023 Restomod of the Year Finalist

2023 C1 of the Year Finalist - Unmodified

My way is to use a plastic crimp connector, remove & discard the plastic, crimp and solder and cover with shrinkable tubing (I agree that two layers are better).

My way is to use a plastic crimp connector, remove & discard the plastic, crimp and solder and cover with shrinkable tubing (I agree that two layers are better).

#23

Safety Car

Member Since: Feb 2012

Posts: 4,532

Received 2,130 Likes

on

1,030 Posts

2023 C2 of the Year Finalist - Unmodified

2019 C2 of Year Finalist (stock)

2015 C2 of the Year Finalist

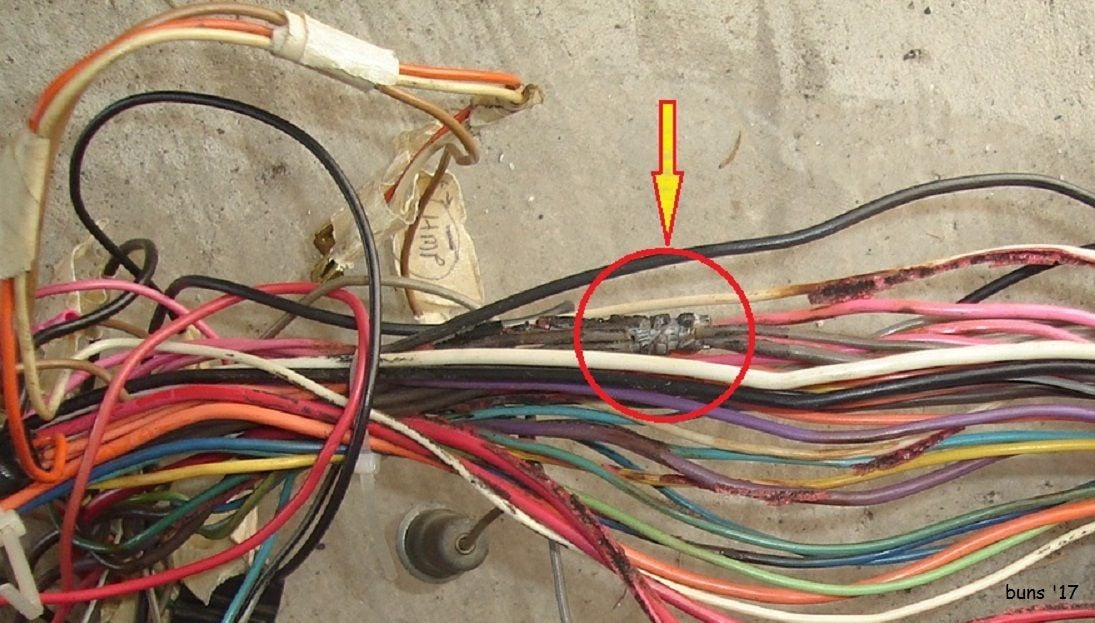

After the photos you've shown and the insistence of others here (who in my view know their craft) that you replace in toto the engine bay harness I am slightly incredulous that you would continue to equivocate. If you cannot afford a harness I perfectly understand. But if a new harness is of little sacrifice yet you elect instead to somehow improve the work of a previous ****-head you will deserve what you get.

That kind of crap is OK for your old work truck, one you could watch burn to the ground without much consequence. Its not OK for a vintage Corvette or other valuable machine.

Respectfully submitted with your welfare in mind. Put in a harness.

Dan

That kind of crap is OK for your old work truck, one you could watch burn to the ground without much consequence. Its not OK for a vintage Corvette or other valuable machine.

Respectfully submitted with your welfare in mind. Put in a harness.

Dan

Last edited by dplotkin; 08-22-2017 at 09:13 PM.

#24

Safety Car

Thread Starter

Member Since: Apr 2013

Location: Arlington TX

Posts: 4,833

Received 930 Likes

on

532 Posts

2023 Restomod of the Year Finalist

2023 C1 of the Year Finalist - Unmodified

Noted. Bad wiring to me is broken, cracked, brittle or cut insulation and/or corrosion in the wire or connections. I don't see that. Some of the wiring you see in the pics are not related to the harness. I don't yet see the need to replace it just because the electrical tape is discolored. I may very well change my mind on further examination. I'm just getting started.

#25

Team Owner

Its your car but that wiring looks Bubba-ed a whole lot but I can't see everything. I can tell you that if you start getting intermittent electrical problems down the road they are the WORST and consume a lot of troubleshooting threads on the forum.

I just hope you ain't "fartin' against thunder" trying to save that old stuff

#26

Actually, that fat wire was cut from the bulkhead connector, spliced and attached to the back of the fuse panel. Assuming the connection to the fuse panel is good, it ought to be as good and reliable as it ever was, maybe more so because you don't have the pin corrosion problem anymore.

The following users liked this post:

59BlueSilver (08-23-2017)

#27

#28

Safety Car

Thread Starter

Member Since: Apr 2013

Location: Arlington TX

Posts: 4,833

Received 930 Likes

on

532 Posts

2023 Restomod of the Year Finalist

2023 C1 of the Year Finalist - Unmodified

I quoted the method I was taught as an avionics apprentice....

Its your car but that wiring looks Bubba-ed a whole lot but I can't see everything. I can tell you that if you start getting intermittent electrical problems down the road they are the WORST and consume a lot of troubleshooting threads on the forum.

I just hope you ain't "fartin' against thunder" trying to save that old stuff

Its your car but that wiring looks Bubba-ed a whole lot but I can't see everything. I can tell you that if you start getting intermittent electrical problems down the road they are the WORST and consume a lot of troubleshooting threads on the forum.

I just hope you ain't "fartin' against thunder" trying to save that old stuff

#30

Team Owner

You can still get the nice copper crimp connectors withOUT the plastic housings (butt and ring connectors) from Mad Electric and the RIGHT electrical tape from them as well (not the shiny sticky stuff from Ace Hardware)...

#31

Safety Car

Thread Starter

Member Since: Apr 2013

Location: Arlington TX

Posts: 4,833

Received 930 Likes

on

532 Posts

2023 Restomod of the Year Finalist

2023 C1 of the Year Finalist - Unmodified

BTW, I, too, worked in the aircraft industry for around 40 years, doing structural work, never avionics though. Closest I got to that was working the flight line at Greenville, Tx in '68 & 69.

#32

Team Owner

Norfolk Naval Air Station in '72-'80 range....they still had WW-II aircraft coming through back then.. I did repairs on a LOT of wiring.....a helluva lot...

#33

Safety Car

Thread Starter

Member Since: Apr 2013

Location: Arlington TX

Posts: 4,833

Received 930 Likes

on

532 Posts

2023 Restomod of the Year Finalist

2023 C1 of the Year Finalist - Unmodified

That will make you an expert. We built C130 gunships for Nam, modification work on C121's & stretched C130's. Enjoyed my time there.

#34

Team Owner

P-2s...one of the few aircraft of the era to be fitted with piston and jet engines..

When it came time to 'turn it up' on the flight line...they had to fly an old time pilot from Gitmo to Norfolk...nobody else knew how to do it. I got to sit in the cockpit at the time...

Never forget it.

Totally OFF topic -- I know..

When it came time to 'turn it up' on the flight line...they had to fly an old time pilot from Gitmo to Norfolk...nobody else knew how to do it. I got to sit in the cockpit at the time...

Never forget it.

Totally OFF topic -- I know..

#35

Safety Car

Thread Starter

Member Since: Apr 2013

Location: Arlington TX

Posts: 4,833

Received 930 Likes

on

532 Posts

2023 Restomod of the Year Finalist

2023 C1 of the Year Finalist - Unmodified

That's cool, I've never seen an actual P-2. Love any WWII aircraft. The company I retired from built the F4U Corsair during the war, my favorite fighter.

Are there any P-2's flying today? Most of these old aircraft end up as stationary museum objects.

I know it's off topic but it doesn't happen very often.

Are there any P-2's flying today? Most of these old aircraft end up as stationary museum objects.

I know it's off topic but it doesn't happen very often.

#36

Team Owner

From my Dad's ole Marine Corps album..he was ground crew (for P-51s as well)... Still flying in Korea and a Marine pilot actually shot down a jet-powered MIG in one of these.

I doubt any P2s are still airborne...they were a cranky bird and replaced by the P3.

I doubt any P2s are still airborne...they were a cranky bird and replaced by the P3.

Last edited by Frankie the Fink; 08-24-2017 at 08:01 AM.

#37

Safety Car

Thread Starter

Member Since: Apr 2013

Location: Arlington TX

Posts: 4,833

Received 930 Likes

on

532 Posts

2023 Restomod of the Year Finalist

2023 C1 of the Year Finalist - Unmodified

Yeah, they were fast! Cool pic, don't see many of those. I'll add this one to my collection. My Dad was also ground crew for bombers during the war, mostly stationed in the Ukraine, Russia.

#38

Team Owner

Member Since: Oct 2000

Location: Washington Michigan

Posts: 38,899

Received 1,857 Likes

on

1,100 Posts

I wouldn't feed ANYTHING directly from the old/inadequate fuse block and existing wiring; anything with moderate to high current draw like an electric fan or electric fuel pump should be wired through a relay from the horn relay power buss.

The following users liked this post:

59BlueSilver (08-25-2017)

#39

Safety Car

Thread Starter

Member Since: Apr 2013

Location: Arlington TX

Posts: 4,833

Received 930 Likes

on

532 Posts

2023 Restomod of the Year Finalist

2023 C1 of the Year Finalist - Unmodified

And the fuse box wiring is part of the under dash wiring, not the engine harness, right?

Last edited by 59BlueSilver; 08-26-2017 at 08:22 AM.

#40

Team Owner

Its a good practice to wire high-draw items through the relays as a matter of course...then the old wiring is merely providing a 'trigger' source for the component and not the full current required. For one thing, no matter how good your wiring may look, its age is causing increased voltage drop, -- another argument for a new harness. The 14.1V your alternator puts out may be just 11.5V at the headlight connector with 50 year old wires.

Read up on headlight relays on the Mad Electric site for examples:

http://www.madelectrical.com/electri...adlights.shtml

To wit, the pros on here aren't telling you to get a new harness just because of the Bubba fixes - age is a factor.

The second thing is that such high-current items' main power feed needs to come off the horn buss relay which will let the voltage regulator "sense" the proper current requirements and adjust alternator output accordingly AND make your dash gauge read correctly.

Read up on headlight relays on the Mad Electric site for examples:

http://www.madelectrical.com/electri...adlights.shtml

To wit, the pros on here aren't telling you to get a new harness just because of the Bubba fixes - age is a factor.

The second thing is that such high-current items' main power feed needs to come off the horn buss relay which will let the voltage regulator "sense" the proper current requirements and adjust alternator output accordingly AND make your dash gauge read correctly.

Last edited by Frankie the Fink; 08-26-2017 at 08:37 AM.