Need a camshaft choice 66 327

#61

Advanced

Thread Starter

i havent pulled the pan.. ran out of time.. need to get something to store the lifters .. the lifter faces look brand new.. not even a scratch..

there is hone marks on the cylinders .. as soon as i can secure the lifters ill pull the cam and pan and look at the bottom end.

there is hone marks on the cylinders .. as soon as i can secure the lifters ill pull the cam and pan and look at the bottom end.

the engine is immaculate inside but on the out side its grungy oily and paint flakey. Since it appears rebuilt it must have been along time ago and just not had any mileage ..

i did mic the head gasket but i cant remember the number off the top of my head. . the heads say 8880462 . I didnt pull a valve but i did put a caliper on the chamber and the intake valve is smaller than 2.02..

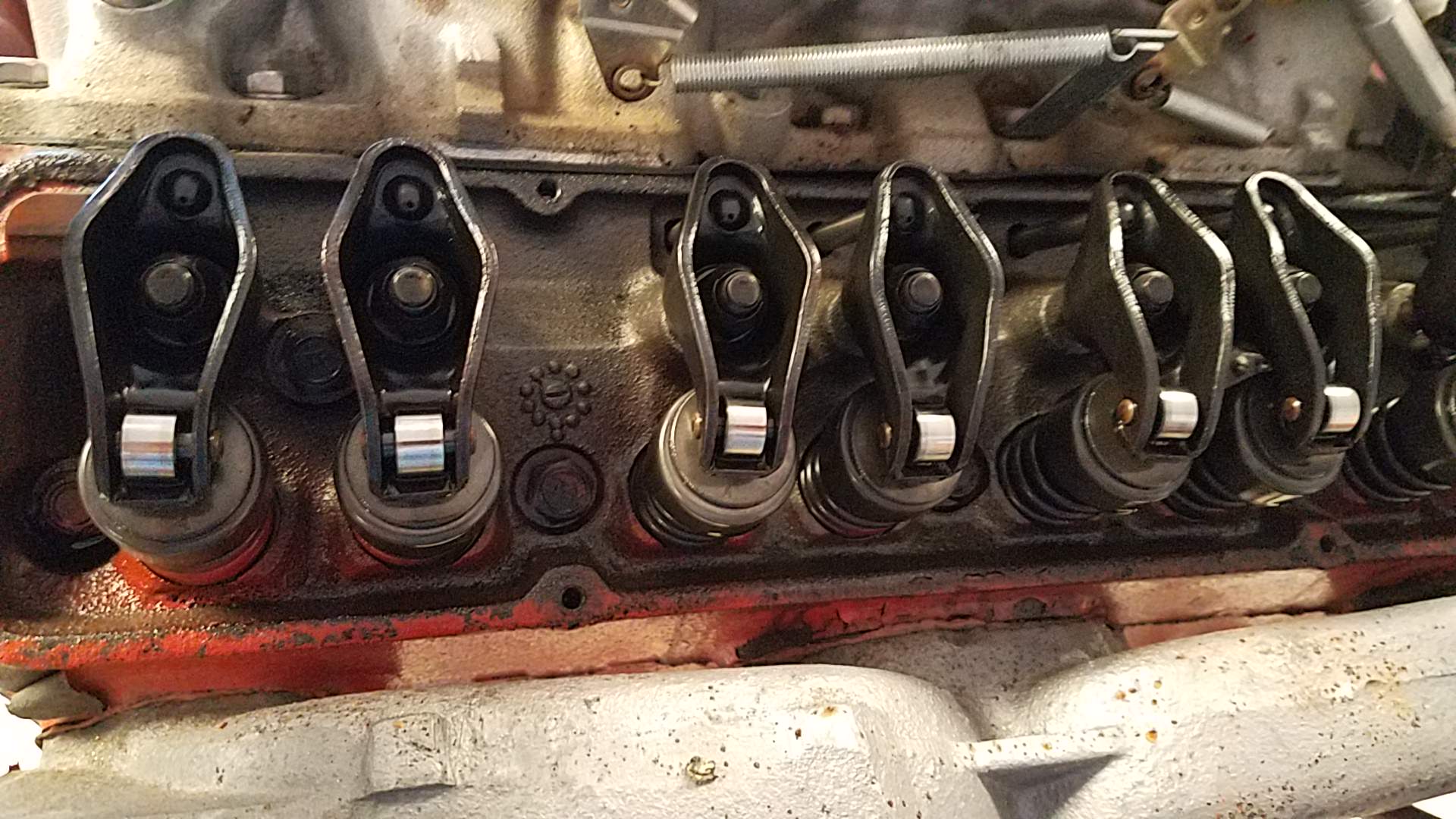

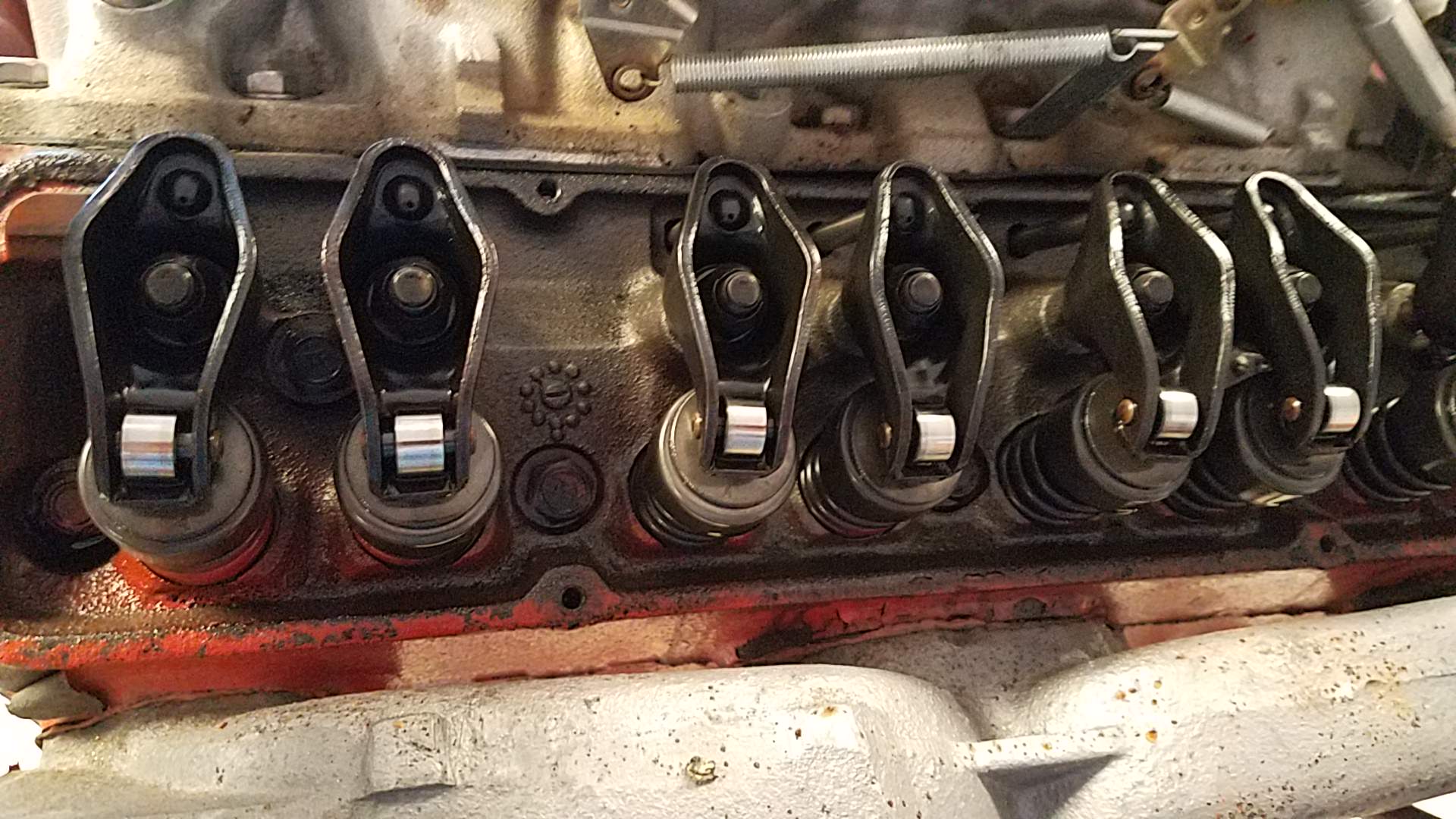

its got screw in rocker studs and cheap stamped rockers with the roller tip... all appear new or very little milage.

Ditto on valve stem tips . i want to pull an I and E valve and look at the valve job and see what pressure the springs are.

i am very curious to see what cam is in it...its definitely not a stock cam.

On the piston comment some 340 mopar pistons had steel inside the skirt to wrist pin broach..fwiw.

unless the crank has an issue I am not going to be stroking this engine..

ill will check the deck surface to see if looks cut. It didnt look cut on first impression.. but I was preoccupied with other things going on.

had a wild hair and just pulled the intake and heads...

*question.. the harmonic balancer..there is no bolt holding it on the crank? there is no provision on the crank for a bolt. I suppose these were just press on/interference fit..? does this need to be addressed.? again been along time since ive done a chevy. . It looks visibly ok as far as the rubber ring.. If i get a new one are these typically zero balance or are the balancers externally balanced?

i did mic the head gasket but i cant remember the number off the top of my head. . the heads say 8880462 . I didnt pull a valve but i did put a caliper on the chamber and the intake valve is smaller than 2.02..

its got screw in rocker studs and cheap stamped rockers with the roller tip... all appear new or very little milage.

Ditto on valve stem tips . i want to pull an I and E valve and look at the valve job and see what pressure the springs are.

i am very curious to see what cam is in it...its definitely not a stock cam.

On the piston comment some 340 mopar pistons had steel inside the skirt to wrist pin broach..fwiw.

unless the crank has an issue I am not going to be stroking this engine..

ill will check the deck surface to see if looks cut. It didnt look cut on first impression.. but I was preoccupied with other things going on.

had a wild hair and just pulled the intake and heads...

*question.. the harmonic balancer..there is no bolt holding it on the crank? there is no provision on the crank for a bolt. I suppose these were just press on/interference fit..? does this need to be addressed.? again been along time since ive done a chevy. . It looks visibly ok as far as the rubber ring.. If i get a new one are these typically zero balance or are the balancers externally balanced?

Last edited by cheapstreetduster; 03-05-2018 at 11:38 PM.

#62

Drifting

*question.. the harmonic balancer..there is no bolt holding it on the crank? there is no provision on the crank for a bolt. I suppose these were just press on/interference fit..? does this need to be addressed.? again been along time since ive done a chevy. . It looks visibly ok as far as the rubber ring.. If i get a new one are these typically zero balance or are the balancers externally balanced?[/left]

Balancers on the lower HP engines were about 6" in diameter and were simply pressed on. On those engines, there was no threaded hole in the crank snout.

So, if your crank has no threaded hole, it is not an original 350HP crank. It would be physically possible to simply press on the larger 350 HP balancer and use no retention bolt, but I don't think that would be wise. If necessary, it is possible to drill and tap a hole in a crank that does not have the hole.

All 327 engines were internally balanced, so the balancer is neutral-balanced.

Since we have been discussing this engine as being a 1966 350 HP, I went back and looked at the casting and pad info you posted. It appears that this would actualy be a 1967 350 HP block, since it is a 3892657 casting, the engine was assembled in December 1966, and the assembly suffix is reportedly HD. Production for the 1967 model year began in August 1966.

Note that if the suffix is actually HO instead of HD, it's a 300 HP engine that would have the smaller, pressed-on balancer and no threaded hole in the crank.

BTW, if the pad does not also have a partial VIN number stamped on the pad, this block was not installed in a Corvette at the factory. All Corvette engines got a partial VIN stamping in addition to the assembly code stamping.

#63

Advanced

Thread Starter

thanks Joe.. this balancer definately had me questioning everything it was "supposed to be"

typical for donors. and since its been "rebuilt" all bets are off..

still keeping hope that i dont have to rebuild the shortblock.

and the 12-66 it is awfully late engine.build date .. I didnt call it a 67 or change so as not to confuse. but i am with you.....it is a 67 model yr engine

anyone know if the head casting number is the right number? its not coming up on searches.

8880462

i am wondering if its 3880462?

its gotta be 3890462? and if it is this head..Is this a decent head? It looks pretty decent intake port wise...

typical for donors. and since its been "rebuilt" all bets are off..

still keeping hope that i dont have to rebuild the shortblock.

and the 12-66 it is awfully late engine.build date .. I didnt call it a 67 or change so as not to confuse. but i am with you.....it is a 67 model yr engine

anyone know if the head casting number is the right number? its not coming up on searches.

8880462

i am wondering if its 3880462?

its gotta be 3890462? and if it is this head..Is this a decent head? It looks pretty decent intake port wise...

Last edited by cheapstreetduster; 03-06-2018 at 12:48 PM.

#64

Racer

Yes, those are the 3890462 heads. Not too bad for an older set of heads.

Based on the info you’ve supplied, you have around 9:1 compression. I wouldn’t recommend a L79 cam if you don’t plan on changing pistons. With that compression, a ~262/268 cam is about as much cam as I’d run. Of the cams in that range, the Lunati 10120702 is very popular and gets the best reviews. Should be good for about 350hp.

Based on the info you’ve supplied, you have around 9:1 compression. I wouldn’t recommend a L79 cam if you don’t plan on changing pistons. With that compression, a ~262/268 cam is about as much cam as I’d run. Of the cams in that range, the Lunati 10120702 is very popular and gets the best reviews. Should be good for about 350hp.

Last edited by Drothgeb; 03-07-2018 at 08:22 AM.

The following users liked this post:

cheapstreetduster (03-07-2018)

#65

Le Mans Master

Iím not a fan of the XE series cams as I think they are much harder on lifters and springs. They seem to have a higher failure rate than the less aggressive ramp profiles of the older designs.

I like the Comp 270 Magnum cam or the just smaller Comp 268 High Energy cam. Especially if you have done exhaust port work on the heads as SBC donít need split pattern cams IME.

The Comp 270 is similar to the L79 cam with a little tighter lobe center so either one of those would be ideal in my mind.

I like the Comp 270 Magnum cam or the just smaller Comp 268 High Energy cam. Especially if you have done exhaust port work on the heads as SBC donít need split pattern cams IME.

The Comp 270 is similar to the L79 cam with a little tighter lobe center so either one of those would be ideal in my mind.

Agree 100% Comp 268 in Magnum, good street manners but will take advantage of your head work. Nice idle, just a little lope, and good midrange.

Agree 100% Comp 268 in Magnum, good street manners but will take advantage of your head work. Nice idle, just a little lope, and good midrange.

#66

Le Mans Master

Member Since: Oct 2002

Location: Las Vegas - Just stop perpetuating myths please.

Posts: 7,098

Received 373 Likes

on

356 Posts

Well if you have the heads off now then you can measure your above piston volume at TDC and the head chamber with liquid (I use alcohol with food dye). This will nail your compression ratio and allow you to choose the optimized/correct cam.

Shoot for a dynamic compression ratio below 8.2.

If you are keeping the stock exh manifolds the you may need a custom cam grind which really isn't much more money these days. But the old stock iron heads breath best with a cam using a lobe separation angle (LSA) of 108 degrees. And the stock exh manifolds would need extra duration on the exhaust like 8 to 10 degrees greater duration than on the intake lobe.

Good luck.

Shoot for a dynamic compression ratio below 8.2.

If you are keeping the stock exh manifolds the you may need a custom cam grind which really isn't much more money these days. But the old stock iron heads breath best with a cam using a lobe separation angle (LSA) of 108 degrees. And the stock exh manifolds would need extra duration on the exhaust like 8 to 10 degrees greater duration than on the intake lobe.

Good luck.

#67

Advanced

Thread Starter

Well if you have the heads off now then you can measure your above piston volume at TDC and the head chamber with liquid (I use alcohol with food dye). This will nail your compression ratio and allow you to choose the optimized/correct cam.

Shoot for a dynamic compression ratio below 8.2.

If you are keeping the stock exh manifolds the you may need a custom cam grind which really isn't much more money these days. But the old stock iron heads breath best with a cam using a lobe separation angle (LSA) of 108 degrees. And the stock exh manifolds would need extra duration on the exhaust like 8 to 10 degrees greater duration than on the intake lobe.

Good luck.

Shoot for a dynamic compression ratio below 8.2.

If you are keeping the stock exh manifolds the you may need a custom cam grind which really isn't much more money these days. But the old stock iron heads breath best with a cam using a lobe separation angle (LSA) of 108 degrees. And the stock exh manifolds would need extra duration on the exhaust like 8 to 10 degrees greater duration than on the intake lobe.

Good luck.

4.03 bore

3.25 stroke

4.06 fire ring @ .049 compressed thickness . 7.119

combustion chamber 63.4 cc

pistons are flat and .041 in the hole. 9.750 cc

i calculate 9.28-1 compression ratio

#68

Le Mans Master

Member Since: Oct 2002

Location: Las Vegas - Just stop perpetuating myths please.

Posts: 7,098

Received 373 Likes

on

356 Posts

Okay I see you pulled the heads but how did you measure above the piston volume and head chamber volume? With liquid? I hope so as that is really the only accurate way to measure those volumes. And if you nailed a static compression ratio of 9.28 like you posted then you are in good shape to run most any cam you want though the greater the duration the less low RPM power and throttle response will you have.

Myself I would keep it less than 270 degrees full duration on a 108 LSA. Split pattern with 8 to 10 degrees more duration on the exhaust. BTW that tighter LSA is better compensated by a short duration camshaft. And you can and 4 to 8 degrees of advance with the intake centerline for more torque with a short cam. Try a dynamic compression calculator to play with the intake centerline advance.

Again I think you will need a custom grind as I don't recall many cams like that on the shelf.

Good luck and let us know how it works out. Feedback helps us all.

Myself I would keep it less than 270 degrees full duration on a 108 LSA. Split pattern with 8 to 10 degrees more duration on the exhaust. BTW that tighter LSA is better compensated by a short duration camshaft. And you can and 4 to 8 degrees of advance with the intake centerline for more torque with a short cam. Try a dynamic compression calculator to play with the intake centerline advance.

Again I think you will need a custom grind as I don't recall many cams like that on the shelf.

Good luck and let us know how it works out. Feedback helps us all.

The following users liked this post:

cheapstreetduster (03-11-2018)

#69

Drifting

When measuring piston height, make sure you measure at the center of the piston to avoid the effects of piston rock. Also measure all four corner pistons, because sometimes the deck heights are not uniform end-to-end or bank-to-bank.

The easiest way to increase compression is to use a head gasket that is thinner than the .049" you used in your calculation.

Some of the new technology MLS gaskets can be made very thin, as can a simple shim steel gasket. However, these gaskets may have trouble sealing against a 50-year old deck surface.

I've had good luck with the Fel-Pro Permatorque Blue gasket that is .039". Some people had done fine with steel gaskets down to about .020", but you should be sure to check whether there are any requirements for the surface finish on the deck.

The following users liked this post:

cheapstreetduster (03-11-2018)

#70

Team Owner

Member Since: Nov 2005

Location: Beach & High Desert Southern California

Posts: 25,501

Received 2,346 Likes

on

891 Posts

No valve reliefs in the pistons? With typical pistons with two valve reliefs (-5cc) the CR drops to 8.78:1, and down to 8.36 if the pistons have four valve relief eyebrows.

.

I can assume this is a budget build, avoiding the cost to mill the decks to optimize the chambers?

The resulting 0.090" quench is quite a wide gap and "loose" for advocates of modern engine theory. Use a thin head gasket, and polish the chamber's sharp edges to minimize pre-ignition detonation potential.

.

The recommended Comp XE268 (a GM L-48/L-82 copy) cam will net a very poor sub-6:1 dynamic compression ratio unless you advance the cam. This results in poor torque below 2000 rpm.

.

A little block machine work could help with the CR and an improved cam selection.

#71

Advanced

Thread Starter

I May end up doing more work...i pulled the pan and just may feel more comfortable knowing the bottom end is sound.

which will of course mean a complete tear down ..and go through.. Not what i had intended...but i just dont want to take a risk.

The engine was advertised as low mileage on the rebuild ... it does in fact look rebuilt internally.. the crank has been balanced..and all wear items look low mileage.. Its fairly clean inside..but filthy out side.. I dont see putting this thing back together with out completely cooking the block and going item by item blue printing.. and at a min re assembly with super clean parts..

this will probably end up meaning some parts end up either modified or changed.. might as well while its apart take control of all aspects..

Ill post as i get to meaningful parts of this rebuild. so as to bring some conclusion to this endeavor . but ive spoken to the machine shop and its going there soon..

the lifter bores gave decent measurements.. but the cyl walls may need some attention.. the rods have been resized and the mains on the block have been align honed.. this is obvious..and it has .010 under bearings.. but the bearings have some scuffing.. i assume it was due to a lack of cleanliness during assembly. If the cyl wall check out..that will be a relief..but i might deck the block and or heads if that becomes necessary. and since it will be apart and at the machinist for cook/clean .. i will address it then.

so "just a cam swap" is no longer the reality..

which will of course mean a complete tear down ..and go through.. Not what i had intended...but i just dont want to take a risk.

The engine was advertised as low mileage on the rebuild ... it does in fact look rebuilt internally.. the crank has been balanced..and all wear items look low mileage.. Its fairly clean inside..but filthy out side.. I dont see putting this thing back together with out completely cooking the block and going item by item blue printing.. and at a min re assembly with super clean parts..

this will probably end up meaning some parts end up either modified or changed.. might as well while its apart take control of all aspects..

Ill post as i get to meaningful parts of this rebuild. so as to bring some conclusion to this endeavor . but ive spoken to the machine shop and its going there soon..

the lifter bores gave decent measurements.. but the cyl walls may need some attention.. the rods have been resized and the mains on the block have been align honed.. this is obvious..and it has .010 under bearings.. but the bearings have some scuffing.. i assume it was due to a lack of cleanliness during assembly. If the cyl wall check out..that will be a relief..but i might deck the block and or heads if that becomes necessary. and since it will be apart and at the machinist for cook/clean .. i will address it then.

so "just a cam swap" is no longer the reality..

Last edited by cheapstreetduster; 03-11-2018 at 07:27 PM.

#72

Advanced

Thread Starter

Okay I see you pulled the heads but how did you measure above the piston volume and head chamber volume? With liquid? I hope so as that is really the only accurate way to measure those volumes. And if you nailed a static compression ratio of 9.28 like you posted then you are in good shape to run most any cam you want though the greater the duration the less low RPM power and throttle response will you have.

Myself I would keep it less than 270 degrees full duration on a 108 LSA. Split pattern with 8 to 10 degrees more duration on the exhaust. BTW that tighter LSA is better compensated by a short duration camshaft. And you can and 4 to 8 degrees of advance with the intake centerline for more torque with a short cam. Try a dynamic compression calculator to play with the intake centerline advance.

Again I think you will need a custom grind as I don't recall many cams like that on the shelf.

Good luck and let us know how it works out. Feedback helps us all.

Myself I would keep it less than 270 degrees full duration on a 108 LSA. Split pattern with 8 to 10 degrees more duration on the exhaust. BTW that tighter LSA is better compensated by a short duration camshaft. And you can and 4 to 8 degrees of advance with the intake centerline for more torque with a short cam. Try a dynamic compression calculator to play with the intake centerline advance.

Again I think you will need a custom grind as I don't recall many cams like that on the shelf.

Good luck and let us know how it works out. Feedback helps us all.

the block deck looks uncut..but the heads look to be cut.. and there was some basic carbon on the heads chamber when i cc'd it.. only did one chamber and one cyl...

was just looking to get a basic concept of compression.. i am coming to realize that this thing is going to be torn down and slated for some more intense measuring and a bath... then based on calculations it may get more machining..or if something is necessary..

but i see some things already that i want to fix.. if it needs to go .040 on the bore..it will be getting pistons.. so now i have to contemplate this as well...

i get a discount on Kb pistons....are the Hypers for this a good choice? i gotta call though first..not sure if they make .040 pistons..

or if it needs a hone or a re bore yet for that matter.

#73

Advanced

Thread Starter

Are there valve reliefs in the piston tops? These would add to the compressed chamber volume.

When measuring piston height, make sure you measure at the center of the piston to avoid the effects of piston rock. Also measure all four corner pistons, because sometimes the deck heights are not uniform end-to-end or bank-to-bank.

The easiest way to increase compression is to use a head gasket that is thinner than the .049" you used in your calculation.

Some of the new technology MLS gaskets can be made very thin, as can a simple shim steel gasket. However, these gaskets may have trouble sealing against a 50-year old deck surface.

I've had good luck with the Fel-Pro Permatorque Blue gasket that is .039". Some people had done fine with steel gaskets down to about .020", but you should be sure to check whether there are any requirements for the surface finish on the deck.

When measuring piston height, make sure you measure at the center of the piston to avoid the effects of piston rock. Also measure all four corner pistons, because sometimes the deck heights are not uniform end-to-end or bank-to-bank.

The easiest way to increase compression is to use a head gasket that is thinner than the .049" you used in your calculation.

Some of the new technology MLS gaskets can be made very thin, as can a simple shim steel gasket. However, these gaskets may have trouble sealing against a 50-year old deck surface.

I've had good luck with the Fel-Pro Permatorque Blue gasket that is .039". Some people had done fine with steel gaskets down to about .020", but you should be sure to check whether there are any requirements for the surface finish on the deck.

I have had some issues with coolant leaking with MLS gaskets.on my smallblock mopars...so unless i can find a way run this engine before i take it to my dad.. i will just use permatorque's

i have been looking at JE Pro Seal MLS gaskets but have not yet used them

Last edited by cheapstreetduster; 03-11-2018 at 07:50 PM.

#74

Drifting

yes i used antifreeze and a plastic burette ..but i didnt remove all the carbon..just scratched off what i could with a razor blade edge.

the block deck looks uncut..but the heads look to be cut.. and there was some basic carbon on the heads chamber when i cc'd it.. only did one chamber and one cyl...

was just looking to get a basic concept of compression.. i am coming to realize that this thing is going to be torn down and slated for some more intense measuring and a bath... then based on calculations it may get more machining..or if something is necessary..

but i see some things already that i want to fix.. if it needs to go .040 on the bore..it will be getting pistons.. so now i have to contemplate this as well...

i get a discount on Kb pistons....are the Hypers for this a good choice? i gotta call though first..not sure if they make .040 pistons..

or if it needs a hone or a re bore yet for that matter.

the block deck looks uncut..but the heads look to be cut.. and there was some basic carbon on the heads chamber when i cc'd it.. only did one chamber and one cyl...

was just looking to get a basic concept of compression.. i am coming to realize that this thing is going to be torn down and slated for some more intense measuring and a bath... then based on calculations it may get more machining..or if something is necessary..

but i see some things already that i want to fix.. if it needs to go .040 on the bore..it will be getting pistons.. so now i have to contemplate this as well...

i get a discount on Kb pistons....are the Hypers for this a good choice? i gotta call though first..not sure if they make .040 pistons..

or if it needs a hone or a re bore yet for that matter.

As you gather more information about the parts you have, and consider your options, please don't forget what I said in post #60 about stroking. It sounds like what you want to build for your dad is more focused on low and mid-range power than peak power, and that is where extra displacement really helps.

Note that if you are going to buy new pistons anyway, some of the cost of stroking is already paid for. The only additional expenses to make this a 350 (maybe even 370) would be to buy a good cast crank for about $200 and have the mains turned down to the 327 size, and then buy a set of budget performance rods such as the Eagle SIR or Scat Pro Stock rods.

Your early '657 casting probably doesn't have the rod notches at the bottom of the cylinder that the later '657 castings had, so getting to 383 CID would be a challenge. However, even without the rod notches in the block, either of the above rods would work fine for stroking the engine to 350-370 CID.

#76

Advanced

Thread Starter

As you gather more information about the parts you have, and consider your options, please don't forget what I said in post #60 about stroking. It sounds like what you want to build for your dad is more focused on low and mid-range power than peak power, and that is where extra displacement really helps.

Note that if you are going to buy new pistons anyway, some of the cost of stroking is already paid for. The only additional expenses to make this a 350 (maybe even 370) would be to buy a good cast crank for about $200 and have the mains turned down to the 327 size, and then buy a set of budget performance rods such as the Eagle SIR or Scat Pro Stock rods.

Your early '657 casting probably doesn't have the rod notches at the bottom of the cylinder that the later '657 castings had, so getting to 383 CID would be a challenge. However, even without the rod notches in the block, either of the above rods would work fine for stroking the engine to 350-370 CID.

Note that if you are going to buy new pistons anyway, some of the cost of stroking is already paid for. The only additional expenses to make this a 350 (maybe even 370) would be to buy a good cast crank for about $200 and have the mains turned down to the 327 size, and then buy a set of budget performance rods such as the Eagle SIR or Scat Pro Stock rods.

Your early '657 casting probably doesn't have the rod notches at the bottom of the cylinder that the later '657 castings had, so getting to 383 CID would be a challenge. However, even without the rod notches in the block, either of the above rods would work fine for stroking the engine to 350-370 CID.

#77

Instructor

I have had the Comp High Energey cam in a 302 in my Kirkham Cobra for several years now, and it's been great. Lots of low end power and torque, smooth idle, all done by 6000 revs. A car this light did not need an aggressive cam to make enough power to seriously scare folks. For what you are looking to find, I think the HE would be fine.

#78

Racer

had not planned on taking this that far. the only way it would get stroked is if the crank is useless.. just not looking to spend this much money on pistons crank rods and machine shop time...too far into the realm of feasibility on this situation. it would be easier to just find a 350 engine already done for the money... fwiw. its going back as stock looking as possible.. that means old style valve covers and intake manifold.. all that stuff still needs to have the correct bolt holes ..just not in the cards for this situation.

#79

Le Mans Master

Running a Mopar when you use MLS there is only one option. They are known to leak.

Now that you are a Chevy man Fel-Pro makes MLS gaskets for the small block and they do not leak.

For your build you have head gasket options starting at stock replacements all the way up to race MLS gaskets. For a stock application you don't need to spend the money on the MLS. If you plan to add nitros, turbo's or a supercharger the MLS is available in both .026 and .040 thickness.

You had asked about Hypereutectics earlier. They are good to about 6,500 RPM with confidence but hypereutectic pistons do not do well in detonation so your tune needs to be good. Most run Forged pistons in the Corvette engines as the factory did on all the performance versions.

For your fathers engine, he may be just fine with hypereutectic pistons, it just depends on how hard he plans to run it. Most modern passenger cars run hypereutectics today but those are all computer controlled and have knock sensors.

Now that you are a Chevy man Fel-Pro makes MLS gaskets for the small block and they do not leak.

For your build you have head gasket options starting at stock replacements all the way up to race MLS gaskets. For a stock application you don't need to spend the money on the MLS. If you plan to add nitros, turbo's or a supercharger the MLS is available in both .026 and .040 thickness.

You had asked about Hypereutectics earlier. They are good to about 6,500 RPM with confidence but hypereutectic pistons do not do well in detonation so your tune needs to be good. Most run Forged pistons in the Corvette engines as the factory did on all the performance versions.

For your fathers engine, he may be just fine with hypereutectic pistons, it just depends on how hard he plans to run it. Most modern passenger cars run hypereutectics today but those are all computer controlled and have knock sensors.

#80

Advanced

Thread Starter

ive run 250 shot of nitrous on a smallblock mopar with kb hypers... hundreds of runs over multiple yrs with out a piston problem..... at first though before i got a handle on the right set up . i was restricted to spec stuff to use in my class. I did burnt a hole in one ..all the way past the ring lands.. and ive also burnt a hole in a bore early on when i was getting a handle on the right set up .....but never broke a piston. ive even shot it with a 350 hp tune a few times...( i am digressing from the topic).

My point is.

.I think hypers are pretty stout for the money... just get the ring gap right. and fit the hone to the correct clearance... id put them in this chevy with out hesitation... my biggest question on them was/ is.... dome shape matching the combustion chamber ? .. I assume since these heads are ubiquitous they must make a good quench piston for these heads.. I am also not sure they make a .040 over hyper piston for this combo?

if infact i have to bore the cyl walls out to that? I havent called kb yet. i mentioned it because i figured someone reading this may have already done hypers on this type combo.

My point is.

.I think hypers are pretty stout for the money... just get the ring gap right. and fit the hone to the correct clearance... id put them in this chevy with out hesitation... my biggest question on them was/ is.... dome shape matching the combustion chamber ? .. I assume since these heads are ubiquitous they must make a good quench piston for these heads.. I am also not sure they make a .040 over hyper piston for this combo?

if infact i have to bore the cyl walls out to that? I havent called kb yet. i mentioned it because i figured someone reading this may have already done hypers on this type combo.

Last edited by cheapstreetduster; 03-13-2018 at 02:13 AM.