[C2] Upper & Lower A-Arm Bushing Retainer Bolts

#1

Instructor

Thread Starter

Member Since: Oct 2014

Location: Central Valley New York

Posts: 192

Likes: 0

Received 14 Likes

on

11 Posts

While I had the body off the frame and the frame apart to rebuild the suspension, I rebuilt the A Arms on my 65 Roadster. The instructions said not to install the a-arm bushing retainer bolts until the frame is back together, the engine and transmission installed and the body is back on the frame. I am at that point now where I can install the retainer bolts. The more I tighten all I am doing is squishing the rubber bushing. There must be some point to stop but I am unable to find any instructions. My question is how tight to I tighten the bolts? Thank you very much for any guidance you can provide.Mark

#2

Team Owner

Member Since: Nov 2005

Location: Beach & High Desert Southern California

Posts: 25,480

Received 2,339 Likes

on

890 Posts

While I had the body off the frame and the frame apart to rebuild the suspension, I rebuilt the A Arms on my 65 Roadster. The instructions said not to install the a-arm bushing retainer bolts until the frame is back together, the engine and transmission installed and the body is back on the frame. I am at that point now where I can install the retainer bolts. The more I tighten all I am doing is squishing the rubber bushing. There must be some point to stop but I am unable to find any instructions. My question is how tight to I tighten the bolts? Thank you very much for any guidance you can provide.Mark

#4

Drifting

PH31MWL, I know the bolts you are talking about---The ones that screw into the ends of the control arm shafts. The 65 AIM does not specify any torque values for them, but the 66 & 67 aim's specify 45-55 foot pounds for the lowers, but no specs for the uppers. The uppers are smaller than the lowers if I remember correctly. I don't have access to my car right now, but If the uppers are 5/16" bolts, I would go about 25 foot pounds, and if they're 3/8" bolts I would go about 35 foot pounds.

RON

RON

#5

Le Mans Master

While I had the body off the frame and the frame apart to rebuild the suspension, I rebuilt the A Arms on my 65 Roadster. The instructions said not to install the a-arm bushing retainer bolts until the frame is back together, the engine and transmission installed and the body is back on the frame. I am at that point now where I can install the retainer bolts. The more I tighten all I am doing is squishing the rubber bushing. There must be some point to stop but I am unable to find any instructions. My question is how tight to I tighten the bolts? Thank you very much for any guidance you can provide.Mark

#7

Team Owner

Member Since: Oct 2000

Location: Washington Michigan

Posts: 38,899

Received 1,857 Likes

on

1,100 Posts

#8

Drifting

#9

Instructor

Thread Starter

Member Since: Oct 2014

Location: Central Valley New York

Posts: 192

Likes: 0

Received 14 Likes

on

11 Posts

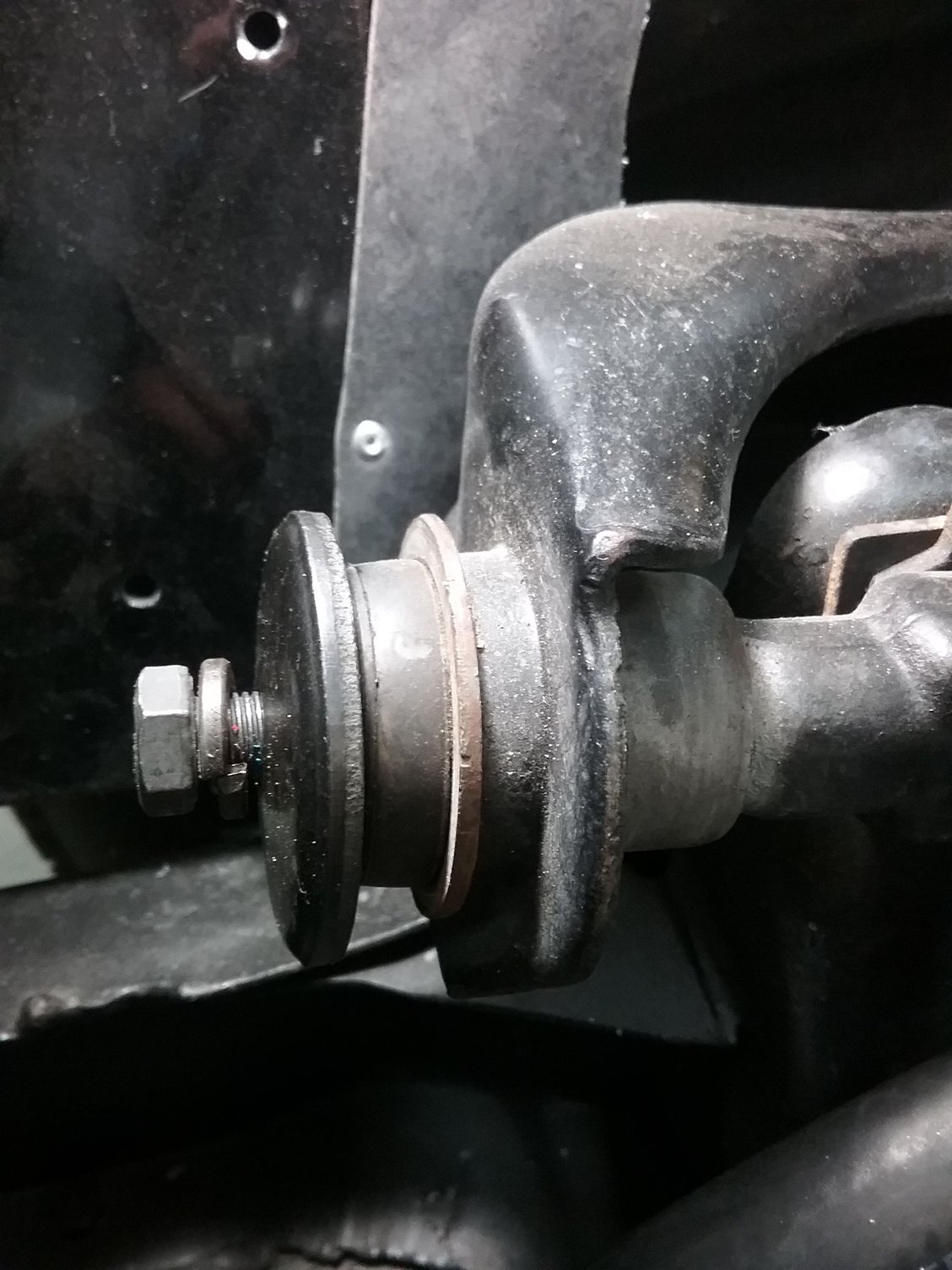

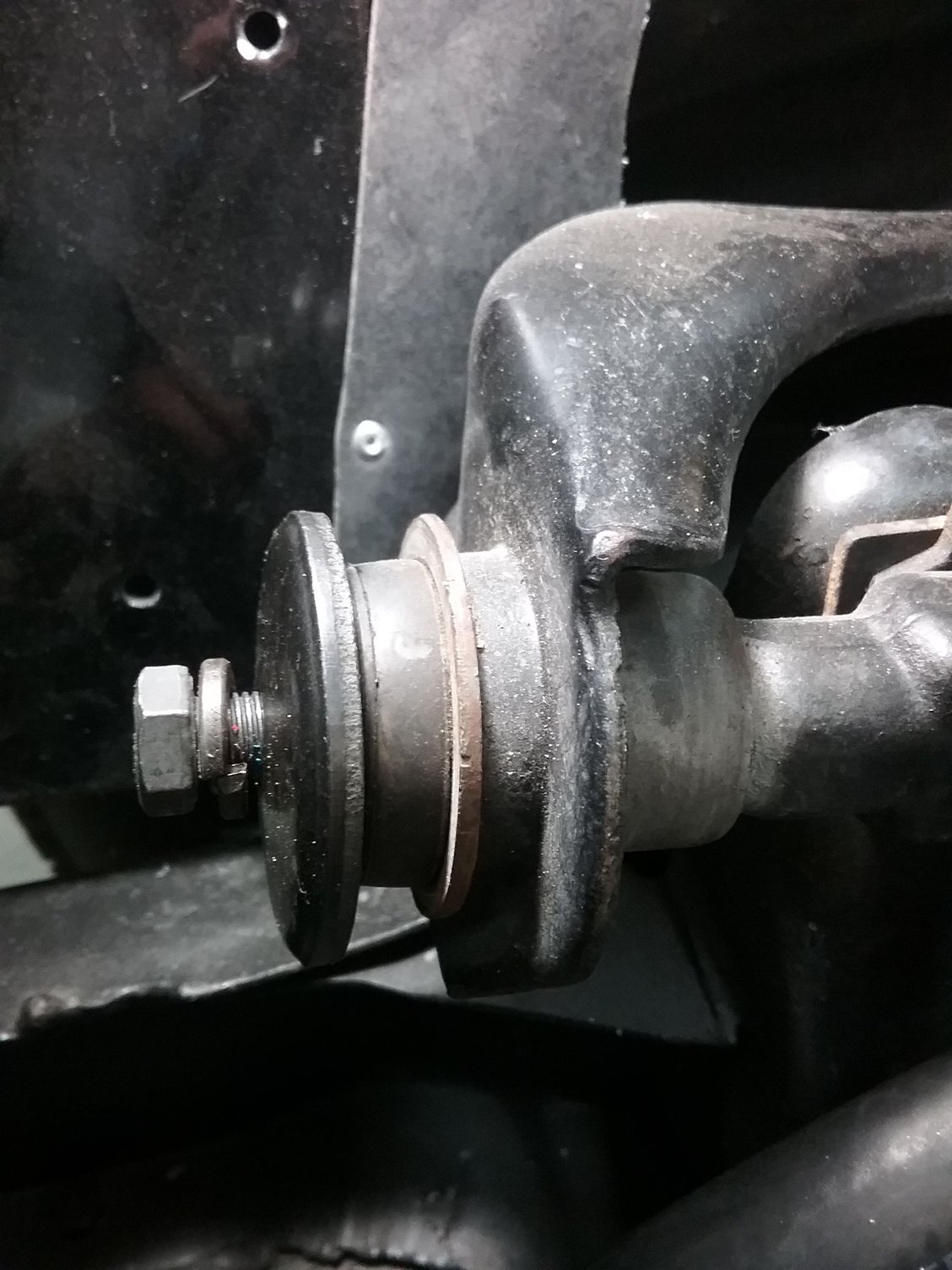

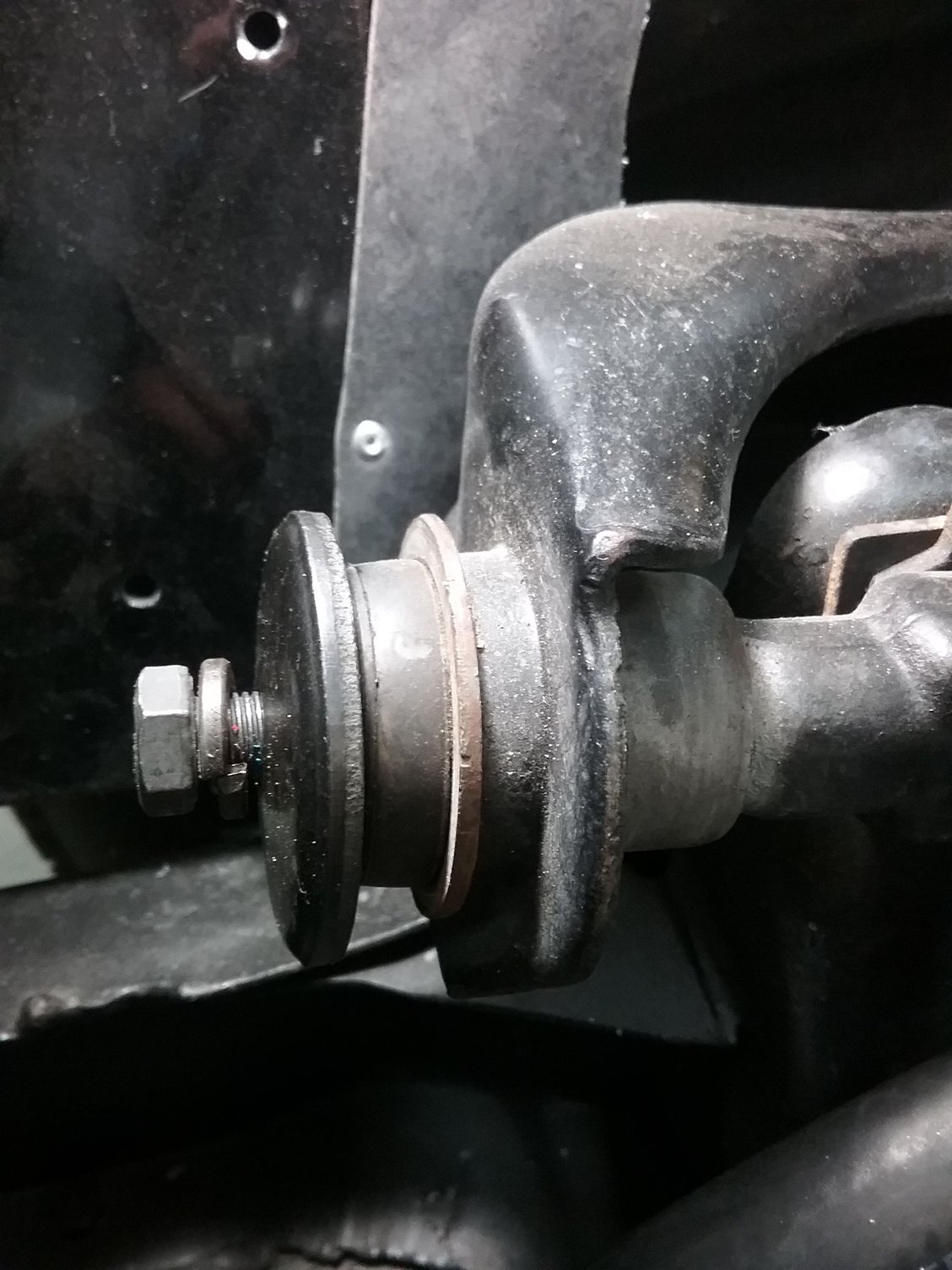

63 340HP,rongold, leif.anderson93, buns, John Z and SWVette, thank you all very much for your responses. I was unable to find the answers anywhere and I want to do this correctly. 63 340HP, I have attached a picture (I hope) of the bold and where it goes in the upper control arm. The lower is the same except it is a bigger bolt. Based on the recommendations and the chart that “buns” has provided, it looks like the uppers are torqued to 35 – 40, and the lowers torqued 45 – 55.Thank you so much for providing this information.Mark

#10

Drifting

RON

Last edited by rongold; 06-22-2018 at 07:18 PM.

#11

Burning Brakes

63 340HP,rongold, leif.anderson93, buns, John Z and SWVette, thank you all very much for your responses. I was unable to find the answers anywhere and I want to do this correctly. 63 340HP, I have attached a picture (I hope) of the bold and where it goes in the upper control arm. The lower is the same except it is a bigger bolt. Based on the recommendations and the chart that “buns” has provided, it looks like the uppers are torqued to 35 – 40, and the lowers torqued 45 – 55.Thank you so much for providing this information.Mark

#12

Le Mans Master

#13

Team Owner

Member Since: Nov 2005

Location: Beach & High Desert Southern California

Posts: 25,480

Received 2,339 Likes

on

890 Posts

63 340HP,rongold, leif.anderson93, buns, John Z and SWVette, thank you all very much for your responses. I was unable to find the answers anywhere and I want to do this correctly. 63 340HP, I have attached a picture (I hope) of the bold and where it goes in the upper control arm. The lower is the same except it is a bigger bolt. Based on the recommendations and the chart that “buns” has provided, it looks like the uppers are torqued to 35 – 40, and the lowers torqued 45 – 55.Thank you so much for providing this information.Mark

The large washer with the small hole will bottom on the shoulder at the end of the threads. This provides enough crush to wedge the inner rubber to the cross shaft, so the future movement is twist in the rubber bushing between the inner and outer edge. You want the car at ride height for the final tightening so the rubber inner edge on the cross shaft does not move, and so the rubber outer edge moves the least amount of rotation to minimize twist away from normal ride height in a bump.