Fiberglass glue???

#1

I need to repair some pretty bad cracks in my 72 vette body and I have heard that Vettebond is extremely hard to work with. Does anyone have any suggestions of something else that works well? I can't just fiberglass over these because the fiberglass is separated in some pretty bad places and it needs to be glued together first.

Thanks for helping!!!

Bridget

Thanks for helping!!!

Bridget

#2

Burning Brakes

I need to repair some pretty bad cracks in my 72 vette body and I have heard that Vettebond is extremely hard to work with. Does anyone have any suggestions of something else that works well? I can't just fiberglass over these because the fiberglass is separated in some pretty bad places and it needs to be glued together first.

Thanks for helping!!!

Bridget

Thanks for helping!!!

Bridget

Several choices as to what to use are available.

#4

I can't post pics, I'm too new. I can describe one area though...The 1/2 inch rim around the wheel well is almost completely broken off. It is still attached by about 12 inches and even that part is cracking. I need something that will set pretty quickly since I don't have an easy way of clamping these parts. I figured I'd glue a few inches at a time and work my way around the rim until it was all glued and then patch the back side like crazy. I think I need to buy stock in fiberglass and bondo for this car!!!

#5

Instructor

Member Since: Aug 2005

Location: Covington, Virginia

Posts: 234

Likes: 0

Received 0 Likes

on

0 Posts

I need to repair some pretty bad cracks in my 72 vette body and I have heard that Vettebond is extremely hard to work with. Does anyone have any suggestions of something else that works well? I can't just fiberglass over these because the fiberglass is separated in some pretty bad places and it needs to be glued together first.

Thanks for helping!!!

Bridget

Thanks for helping!!!

Bridget

If you have some areas that are seperated/glass missing....You MUST repair it on both sides (if you can get to it). That means you need to prep it on both sides.

Easiest way to do this.....scratch up the back (rough it up a little so something will stick to it.

Get it lined up on the outside so it will stay...duct tape/clamps/pop rivets....use whatever works.

Back to the inside, Body filler and cardboard works pretty well here, cut a piece of cardboard that will cover the area to be repaired. Mix some filler and apply a layer to the cardboard. About the thickness of peanut butter that you would use to make a PBJ sandwich. Press the cardboard to the back of the repair area, making sure you don't disturb what is on the "show" side.

Back to the outside...Remove any support "stuff"...GRIND the damaged glass edges to a very thin taper. The c'board will hold the shape from the back. Apply resin/mat to the front (68-73) SMC repair matl's (74-8????) and after that sets.....go to the back, remove the c'board and the filler, grind the glass, taper edge with the taper toward the damage. Add resin/mat...

Back to the outside, do the body repair, grinding the resin/mat to conform to the body shape (adding more material if needed) and finishing/surface prep as needed...

back to the inside, grind it smooth, prep for finish.

Fiberglass repair scares a lot of folks. With corvettes, it is as much an art form as it is science. There are many variables, resin/mat..SMC being the biggest. You need to familiarize yourself with the materials, mix small test batches to see how it acts/reacts...as always, all f'glass liquids are caustic/poisonous/flammable....

AND, smear baby powder on any and all exposed skin BEFORE you grind/sand fiberglass....the talcum will prevent some itching...

Good luck....

#6

That was fantastic help! Thank you so much! One more question. On the back of the car there is a bracket that attaches to the body of the car and, I am assuming, to the bumper as well. Only problem is my fiberglass is missing where the bracket should attach. Can I attach a strip of metal behind the body and build fiberglass up on top of it that I can bolt the bracket to? A bit like a splint???

#7

Instructor

Member Since: Aug 2005

Location: Covington, Virginia

Posts: 234

Likes: 0

Received 0 Likes

on

0 Posts

That was fantastic help! Thank you so much! One more question. On the back of the car there is a bracket that attaches to the body of the car and, I am assuming, to the bumper as well. Only problem is my fiberglass is missing where the bracket should attach. Can I attach a strip of metal behind the body and build fiberglass up on top of it that I can bolt the bracket to? A bit like a splint???

I do not recommend leaving metal as a splint...the glass will turn loose and the vibration will cause problems..All those that have had problems with the nose panel rivets will understand.

If you are missing a chunk, larger than say, a silver dollar??? I have a solution for you. I have at my disposal some body parts, If I have a part with the section you need?? I can pull a mold off of that section and send you a part out of the mold. You would then be able to trim the new part and fit it in....then glass it in place.

Wheel well openings are probably about the most aggravating and hard to deal with sections on the whole car. They are time consuming and frustrating...If someone could come up with a better way to deal with them, vette owners would beat a path to their door....

If you have a camera, we can step you thru the pic process....

#8

Race Director

Here are some pics to describe the process a little better from this thread.

http://forums.corvetteforum.com/c3-t...g-fenders.html

Itís much, much easier to tape the outside and prep and glass the inside or backside first. That gives you a stable surface to glass and finish the outside. The good pro grade foil tape is a lot stiffer than duct tape and can be built up to be very rigid for glassing. No need for any bondo.

As far as your rear missing glass, just form some metal behind the existing glass over the brace, put some saran wrap or similar over it behind the old glass and layer up some new glass. then remove the metal (and brace if necessary) and finish glassing if necessary.

http://forums.corvetteforum.com/c3-t...g-fenders.html

Itís much, much easier to tape the outside and prep and glass the inside or backside first. That gives you a stable surface to glass and finish the outside. The good pro grade foil tape is a lot stiffer than duct tape and can be built up to be very rigid for glassing. No need for any bondo.

You can rag on it all you want.

I've used the foil for years and prefer to use it whenever I can. I've found it to be easier and faster and the best method in a lot of instances. Of course I remove it after glassing and taper and glass the back side like one should to gain the proper strength.

Have done many wheel lips and probably every other part of these cars and no one can tell, not much different than making a mold for each side. I always try and glass the backside first, then glass the good side for finishing.

There was a thread here a bit ago about a broken key area. The repair would be stronger with a layer of glass on the backside too, but in that instance, it would be a lot, lot more work.

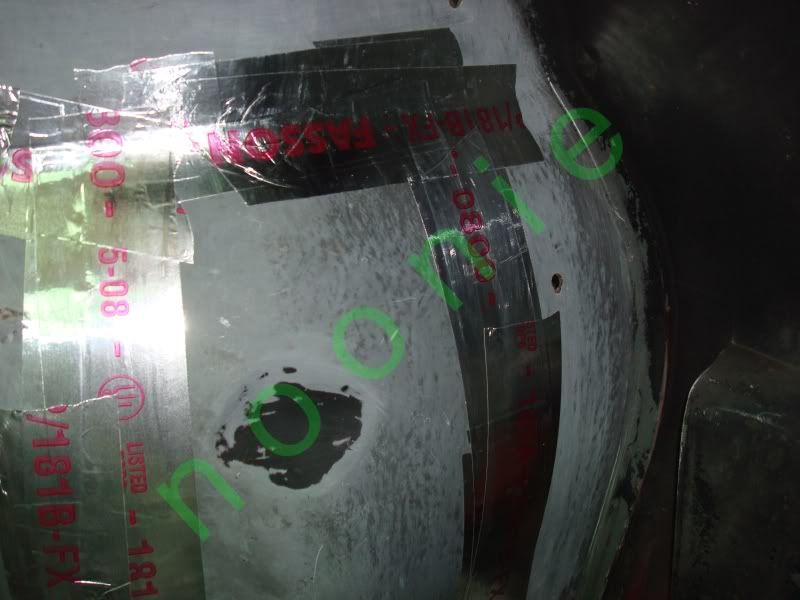

Here is a inner well that someone cut out to access the accumulator. Good thing they saved the 2 large pieces.

The tape is strong enough to hold the pieces perfectly in position without any other backing or screw etc.

Here is the wheel side ground to a nothing taper with 30 grit,ready for glassing. Held only with foil tape on engine side.

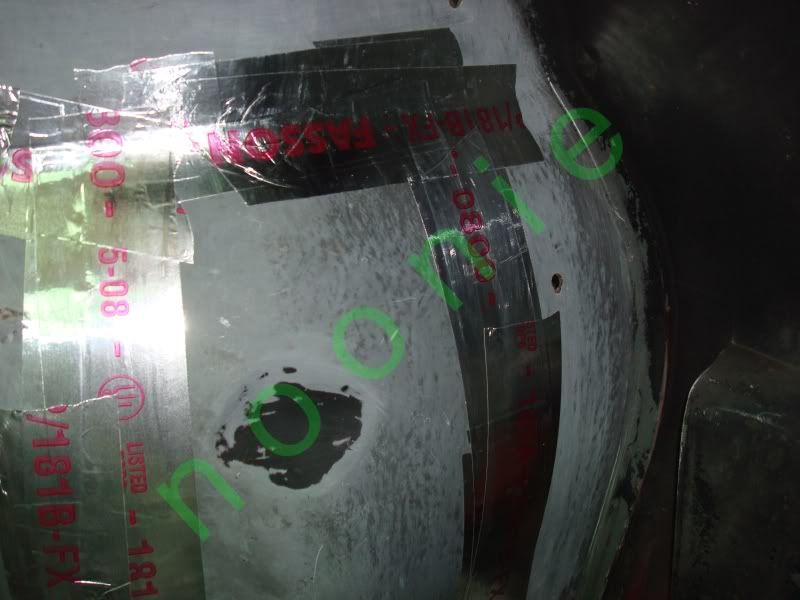

Here is the engine side after the wheel side is glassed, foil removed and ground to a nothing taper.

Here is the sanded repair almost ready for paint and btw, I get no print thru with cloth. Epoxy feathers perfectly with no need for any filler. Engine side looked the same.

I've used the foil for years and prefer to use it whenever I can. I've found it to be easier and faster and the best method in a lot of instances. Of course I remove it after glassing and taper and glass the back side like one should to gain the proper strength.

Have done many wheel lips and probably every other part of these cars and no one can tell, not much different than making a mold for each side. I always try and glass the backside first, then glass the good side for finishing.

There was a thread here a bit ago about a broken key area. The repair would be stronger with a layer of glass on the backside too, but in that instance, it would be a lot, lot more work.

Here is a inner well that someone cut out to access the accumulator. Good thing they saved the 2 large pieces.

The tape is strong enough to hold the pieces perfectly in position without any other backing or screw etc.

Here is the wheel side ground to a nothing taper with 30 grit,ready for glassing. Held only with foil tape on engine side.

Here is the engine side after the wheel side is glassed, foil removed and ground to a nothing taper.

Here is the sanded repair almost ready for paint and btw, I get no print thru with cloth. Epoxy feathers perfectly with no need for any filler. Engine side looked the same.

#10

Team Owner

Member Since: Jun 2000

Location: Southbound

Posts: 38,928

Likes: 0

Received 1,468 Likes

on

1,247 Posts

Cruise-In II Veteran

http://www.glas-ra.com/rearhl1968thru1982.html

They have volumes covering front and rear; order both.

This is pretty good if you can find a copy.

They have volumes covering front and rear; order both.

This is pretty good if you can find a copy.