What is the best way to mount an LS motor on an engine stand

#1

Drifting

Thread Starter

I'm getting ready to mount my motor on my new engine stand. The engine stand is a collapsible, 360' rotating engine stand from Summit. This is new territory for me. I've never done this before.

Are there any specific tricks or best practices that you have to suggest?

Are there any specific tricks or best practices that you have to suggest?

Last edited by CWerner; 01-26-2013 at 02:08 PM.

#2

Team Owner

Member Since: Jul 2004

Location: Redondo Beach, California

Posts: 39,518

Received 546 Likes

on

374 Posts

Do you have an engine hoist to lift the engine up to the level of the engine mounting "fingers" of the engine stand?

If you don't have an engine hoist, buy one from Harbor Freight. They are about $170 last time I looked. You can rent an engine hoist for about $35 a day, but it's a whole lot less hassle and more convenient to buy it. What appears to be the same engine hoist is available from Snap On for $1070. (last time I looked.) Hate to buy Chinese but this kind of a price differential is just too hard to pass up.

With an engine hoist, it's a pretty simple one man job. Bolt a chain to, say, the right rear intake manifold bolt and the other end of chain to the left front intake manifold bolt. Use the hoist hook mid way to hook up to the chain and lift. If you are going to insert the engine into the car; say a complete stack of the engine/bellhousing/tranny, get a "load leveler" for your hoist. With the engine hanging from the hoist, you turn a crank on the load leveler and move the engine from horizontal to as much as maybe 45 degrees from horizontal. This makes engine/bellhousing/tranny installation so easy. What does a load leveler cost??? maybe a $100. The load leveler will make mating the engine to the engine stand more easy also, since you can accurately without hassle line up the engine mounting holes with the engine stand bolts.

An LS engine??...I have a ZZ4 in my 68. To do it over, I'd look seriously at putting a LS3 into it.

If you don't have an engine hoist, buy one from Harbor Freight. They are about $170 last time I looked. You can rent an engine hoist for about $35 a day, but it's a whole lot less hassle and more convenient to buy it. What appears to be the same engine hoist is available from Snap On for $1070. (last time I looked.) Hate to buy Chinese but this kind of a price differential is just too hard to pass up.

With an engine hoist, it's a pretty simple one man job. Bolt a chain to, say, the right rear intake manifold bolt and the other end of chain to the left front intake manifold bolt. Use the hoist hook mid way to hook up to the chain and lift. If you are going to insert the engine into the car; say a complete stack of the engine/bellhousing/tranny, get a "load leveler" for your hoist. With the engine hanging from the hoist, you turn a crank on the load leveler and move the engine from horizontal to as much as maybe 45 degrees from horizontal. This makes engine/bellhousing/tranny installation so easy. What does a load leveler cost??? maybe a $100. The load leveler will make mating the engine to the engine stand more easy also, since you can accurately without hassle line up the engine mounting holes with the engine stand bolts.

An LS engine??...I have a ZZ4 in my 68. To do it over, I'd look seriously at putting a LS3 into it.

Last edited by 68/70Vette; 01-26-2013 at 03:14 PM.

The following users liked this post:

ericdwong (01-27-2016)

#3

Safety Car

Member Since: May 2004

Location: los altos hills california

Posts: 3,597

Received 1,116 Likes

on

726 Posts

Just be sure to use metric bolts in the bellhousing holes. The stock bolts fit just fine but a little loose. That's what I used the first time. I still have anxiety about having done that. However I did block up the front of the motor so there really wasn't as much stress as there could have been. And eventually everything torqued down when I bolted up the rest of the drivetrain.

#4

Drifting

Buy some new metric bolts,grade 5 stuff from the local big box store will be fine,usually the factory bell to block bolts are a bit short for most engine stands.Set the engine on the floor,remove the mounting plate from the stand and bolt it to the engine while its planted firmly on the floor.Align the crank shaft with the center of the pivot,also a bit of lube will help when its time to rotate the engine.After everything is lined up and tightened down,lift the engine slightly higher than the height of the stand,slide the stand onto the mount,insert the pin, and gently set it down on the stand's wheels.

Last edited by tfi racing; 01-26-2013 at 09:11 PM.

#5

Race Director

I mounted the engine to engine feet that mount to the engine mount on the side of the block. These engine feet let the motor sit on the ground and you can mount the flywheel and clutch and even the bellhousing. You could actually mount the trans to but it get a little tail heavy at that point. I have a set of these feet and would be happy to let you use them. I don't like mounting the front of the engine but did mount mine for a few weeks while the cam change was going on by the bellhousing mounts. I do have some pictures somewhere of all this if you need them.

#6

Drifting

Thread Starter

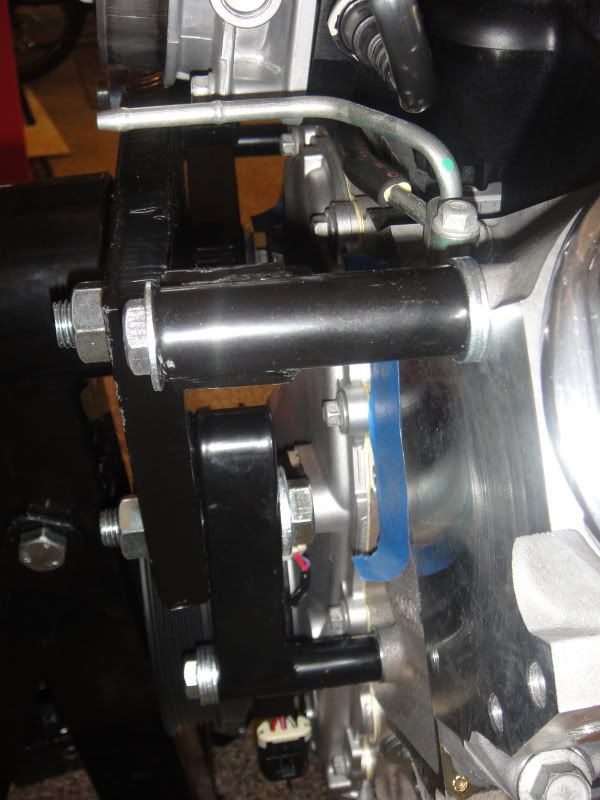

So I was able to mount to the front of the engine block and heads. I purchased grade 2 bolts at Home Depot because that's all they had. I looked up sheer and tensile ratings and they show each bolt has plenty of strength....????.....

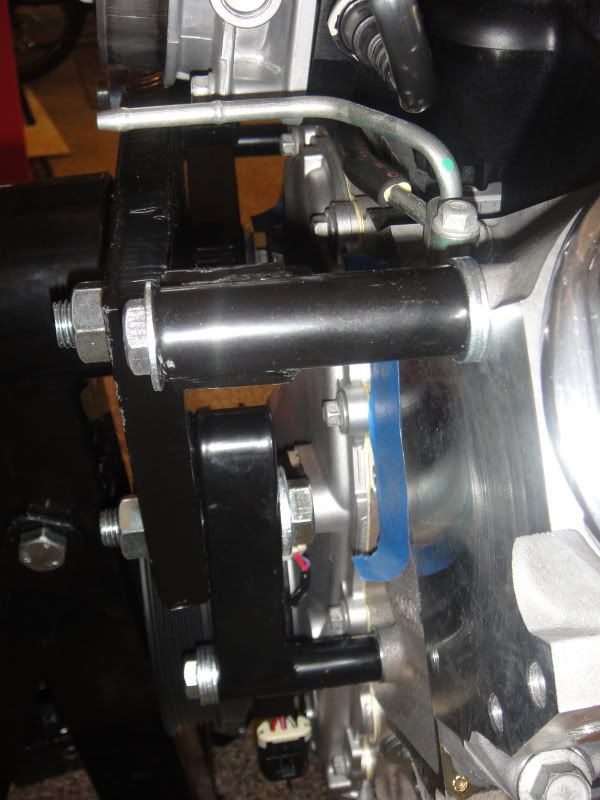

Anyway, I was able to tie one bolt into the block on the drivers side, and also the head on that side. On the other side I had both bolts tie into the heads. I also had to put several washers on that side to ensure it was square with the drivers side. I ended up with a little more than an 1/2" thread penetration. I'm thinking there's about 3/4" total depth. One bolt did bottom out.

Below is drivers side. Top bolt into head, bottom bolt into block (this one bottomed out)

Passenger side with both bolts into the head.....note the washers used as spacers.

My plan is to bolt the transmission on using this approach. Am I safe going this direction?

I'm also thinking about swapping out the bolts for grade 8 before I do it.

Anyway, I was able to tie one bolt into the block on the drivers side, and also the head on that side. On the other side I had both bolts tie into the heads. I also had to put several washers on that side to ensure it was square with the drivers side. I ended up with a little more than an 1/2" thread penetration. I'm thinking there's about 3/4" total depth. One bolt did bottom out.

Below is drivers side. Top bolt into head, bottom bolt into block (this one bottomed out)

Passenger side with both bolts into the head.....note the washers used as spacers.

My plan is to bolt the transmission on using this approach. Am I safe going this direction?

I'm also thinking about swapping out the bolts for grade 8 before I do it.