First Time Engine Builder Success with a 1973 Vette and a Vortec Block

#1

Instructor

Thread Starter

It's ALIVE!!!!! It's ALIVE!!!!! My White 1973 is back on the road with a new motor and a bad attitude.

The project started as a plan to simply pull an old Goodwrench motor to replace gaskets to address a bunch of leaks, maybe throw on some paint and drop it back in. Then I thought, "since the motor is coming out and since it is horribly underpowered, why not add a few performance parts?" This led to wondering why bother putting them in an old worn out block.... you know how it goes. Classic mission creep. So I built a new motor.

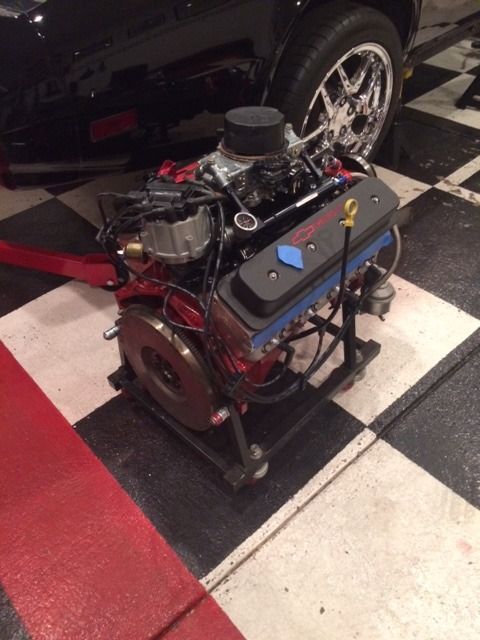

I researched a bunch decided on a Vortec Gen I block to get a roller cam. Following are specs, my plan of attack and a few lessons learned. To keep this from being an even longer first entry, I'll add some pictures later on anything interesting (at least to me) or that might help someone else in the future.

Block: 880 roller cam block out of a '98 or '99 suburban (can't remember). Vatted, magnafluxed, bored 0.020 over. 2 bolt mains. Painted black. All new plugs, gaskets, bearings, oil pan, water pump, PS pump.

Heads: Used vortec heads bought off of Craigslist, stock original valves, cleaned and hand lapped. I inspected these 28 different times an found no cracks. Cleaned them up with a wire wheel on a dremel tool. New Comp Cams pushrods, seals, rockers, locks. GM LS1 beehive springs (blue). Heads cleaned and painted black to match the block.; COMP Cams Magnum Steel Roller Tip Rocker Arms 1417-16

Using an online calculator, I think the compression ratio is ~9.4.

Intake: Edelbrock, Vortec, used. (Small problem, see below)

Carb: Quadrajet, original to car I think. Needs to be rebuilt but it make the prior motor run OK and I did not want to introduce too many variables at once.

Distributor: DUI Performance Distributors. Livewire wires by same folks. They are awesome and sent me a replacement wire for free when I first installed the distributor and found one wire too short.

Crank: stock, turned 0.010 under. Stock damper, painted performance red

Rods: original, stock with stock bolts/nuts

Pistons: Sealed Power, 4.020" Hypereutectic, Federal Mogul Premium Engine Rebuild Kits CSMHP761-201

Cam: new, Comp Cams roller cam, PN XR270HR-10

Flywheel: new, Chevrolet Performance Flywheels 14088648

Clutch: new, RAM HDX Clutch Kits 88764HDX

Headers: Used off CL, Hooker, hot jet/ceramic coated. 300x better looking than my original Hedmans which I tried to paint and looked like crap.

Other stuff:

- Rotating assembly balanced (machine shop argued but I told then I plan to drive this like I stole it and will spin it up pretty high. )

- new oil pump

- new oil pan

- had to cut down windage tray to clear rods and edge of oil pump.

- new stock starter

- New 2.5" exhaust I welded up. Used my existing MagnaFlow mufflers. Old exhaust system was a hacked together mess obviously built by a blind monkey with a MIG machine.

- washed block and scrubbed and scrubbed oil passages until operating room clean. Once clean, WD40 coated on all surfaces.

Plan of attack I generally followed:

Not wanting to introduce too many variable at once, I installed an electric fuel pump to run with the old engine with a block off plate. Glad I did this test since original Holley red was LOOOOOUUUUUD and had a hunk of foam in it which jammed the impeller. I ALSO found that the relay that came with the Summit pump harness kit was bad. Replaced Holley pump after a horrible customer service experience with a Carter pump, got a replacement relay and was good to go. Drove car with electric pump and old motor for a month or so. It all worked fine.

Block machine work was done by Scroggins Machine in Houston, TX. Very, very happy with their work. They were very patient with my questions.

I built the motor over several months. I'm very slow and then hunting season started which took up a lot of free time! Plus, I've NEVER built a motor before. Always wanted to rebuild a motor but honestly, I was intimidated and had no one to ask for help. I ended up doing everything but machine work myself. ;-)

I HIGHLY recommend the following 2 books and ESPECIALLY the videos. This guy at MyVintageIron7512 has some of the best instruction videos on YouTube in my opinion. I watched his small block rebuilt series several times, took notes and checked everything 3 times. He has videos on cleaning blocks, SBC heads, etc. Can't say enough positive things here. Never met him but he's like the cool uncle I never had. (I'm now the proud owner of dial calipers, bore gauges, feeler gauges, and know how to use them. ;-)

YouTube Tutorials

https://www.youtube.com/user/Myvintageiron7512

Books I used

"How to Build Max-Performance Chevy Small-Blocks on a Budget" by David Vizard

"How to Rebuild Small Block Chevy" by David Vizard (older but useful)

Pulled 4 speed to address a leak/stripped out hole.

Pulled old motor. It was leaking like Exxon Valdez but still fetched $300 on Craigslist. Apparently is now lives in an old boat.

Installed clutch, flywheel, and as much as I could outside the car. Dropped in motor by myself after getting up the nerve. Yes, one skinny middle aged guy can do this by himself but I REALLY wish I had a helper for this part. I had about 0.5" of room between the bolts on the water pump and the hood. (Yes, I did NOt pull the hood) Still, got it wedged in with minimal cussing.

I had aligned the clutch with the little plastic tool while the motor was on the stand. I just about killed myself getting the transmission to line up and seated in the clutch and pilot bearing. Wrestled with it off and on for 2 days. Buying a metal clutch alignment tool did the trick. This was probably the worst part of the project and I was hating it during that time.

I made a "sling" out of a huge ratchet strap to go under the motor to keep it up while the tranny was out. Pics will show this later.

Took care of the little odds and ends but kept putting off the inevitable I blamed hunting season... and being busy at work.... and family obligations.... but I'm big enough to admit, I was simply scared to butch up and start it. Even though I measured everything 3 times and followed several good, credible sources, my fear was I forgot something stupid and it would destroy my motor and the time and $$$ would be up in smoke!

Well, I finally manned up, finished up the 2.5" exhaust (another convenient delay) and just started the damn thing after priming it with a tool on a drill. (One thing I did forget was to hook up the gigantic wire to the starter. That one is sorta important.) Had too much timing in it at first but got it sorted out.

Bottom line: The car runs and sounds EXCELLENT. Vortec heads, bigger cam, 2.5" exhaust should make it breath well. I've only slowly driven around the neighborhood and will take it easy for 10 miles, change the oil, and drive it increasingly harder after it has had some time to break in.

Like with most things in life, it was not nearly as hard as I thought if you simply take it really slow and take LOTS of pictures along the way so you know how everything goes back together.

I'll post some pics in the next few days! Hopefully something finds this interesting or helpful.

Larry

Houston, TX

The project started as a plan to simply pull an old Goodwrench motor to replace gaskets to address a bunch of leaks, maybe throw on some paint and drop it back in. Then I thought, "since the motor is coming out and since it is horribly underpowered, why not add a few performance parts?" This led to wondering why bother putting them in an old worn out block.... you know how it goes. Classic mission creep. So I built a new motor.

I researched a bunch decided on a Vortec Gen I block to get a roller cam. Following are specs, my plan of attack and a few lessons learned. To keep this from being an even longer first entry, I'll add some pictures later on anything interesting (at least to me) or that might help someone else in the future.

Block: 880 roller cam block out of a '98 or '99 suburban (can't remember). Vatted, magnafluxed, bored 0.020 over. 2 bolt mains. Painted black. All new plugs, gaskets, bearings, oil pan, water pump, PS pump.

Heads: Used vortec heads bought off of Craigslist, stock original valves, cleaned and hand lapped. I inspected these 28 different times an found no cracks. Cleaned them up with a wire wheel on a dremel tool. New Comp Cams pushrods, seals, rockers, locks. GM LS1 beehive springs (blue). Heads cleaned and painted black to match the block.; COMP Cams Magnum Steel Roller Tip Rocker Arms 1417-16

Using an online calculator, I think the compression ratio is ~9.4.

Intake: Edelbrock, Vortec, used. (Small problem, see below)

Carb: Quadrajet, original to car I think. Needs to be rebuilt but it make the prior motor run OK and I did not want to introduce too many variables at once.

Distributor: DUI Performance Distributors. Livewire wires by same folks. They are awesome and sent me a replacement wire for free when I first installed the distributor and found one wire too short.

Crank: stock, turned 0.010 under. Stock damper, painted performance red

Rods: original, stock with stock bolts/nuts

Pistons: Sealed Power, 4.020" Hypereutectic, Federal Mogul Premium Engine Rebuild Kits CSMHP761-201

Cam: new, Comp Cams roller cam, PN XR270HR-10

Flywheel: new, Chevrolet Performance Flywheels 14088648

Clutch: new, RAM HDX Clutch Kits 88764HDX

Headers: Used off CL, Hooker, hot jet/ceramic coated. 300x better looking than my original Hedmans which I tried to paint and looked like crap.

Other stuff:

- Rotating assembly balanced (machine shop argued but I told then I plan to drive this like I stole it and will spin it up pretty high. )

- new oil pump

- new oil pan

- had to cut down windage tray to clear rods and edge of oil pump.

- new stock starter

- New 2.5" exhaust I welded up. Used my existing MagnaFlow mufflers. Old exhaust system was a hacked together mess obviously built by a blind monkey with a MIG machine.

- washed block and scrubbed and scrubbed oil passages until operating room clean. Once clean, WD40 coated on all surfaces.

Plan of attack I generally followed:

Not wanting to introduce too many variable at once, I installed an electric fuel pump to run with the old engine with a block off plate. Glad I did this test since original Holley red was LOOOOOUUUUUD and had a hunk of foam in it which jammed the impeller. I ALSO found that the relay that came with the Summit pump harness kit was bad. Replaced Holley pump after a horrible customer service experience with a Carter pump, got a replacement relay and was good to go. Drove car with electric pump and old motor for a month or so. It all worked fine.

Block machine work was done by Scroggins Machine in Houston, TX. Very, very happy with their work. They were very patient with my questions.

I built the motor over several months. I'm very slow and then hunting season started which took up a lot of free time! Plus, I've NEVER built a motor before. Always wanted to rebuild a motor but honestly, I was intimidated and had no one to ask for help. I ended up doing everything but machine work myself. ;-)

I HIGHLY recommend the following 2 books and ESPECIALLY the videos. This guy at MyVintageIron7512 has some of the best instruction videos on YouTube in my opinion. I watched his small block rebuilt series several times, took notes and checked everything 3 times. He has videos on cleaning blocks, SBC heads, etc. Can't say enough positive things here. Never met him but he's like the cool uncle I never had. (I'm now the proud owner of dial calipers, bore gauges, feeler gauges, and know how to use them. ;-)

YouTube Tutorials

https://www.youtube.com/user/Myvintageiron7512

Books I used

"How to Build Max-Performance Chevy Small-Blocks on a Budget" by David Vizard

"How to Rebuild Small Block Chevy" by David Vizard (older but useful)

Pulled 4 speed to address a leak/stripped out hole.

Pulled old motor. It was leaking like Exxon Valdez but still fetched $300 on Craigslist. Apparently is now lives in an old boat.

Installed clutch, flywheel, and as much as I could outside the car. Dropped in motor by myself after getting up the nerve. Yes, one skinny middle aged guy can do this by himself but I REALLY wish I had a helper for this part. I had about 0.5" of room between the bolts on the water pump and the hood. (Yes, I did NOt pull the hood) Still, got it wedged in with minimal cussing.

I had aligned the clutch with the little plastic tool while the motor was on the stand. I just about killed myself getting the transmission to line up and seated in the clutch and pilot bearing. Wrestled with it off and on for 2 days. Buying a metal clutch alignment tool did the trick. This was probably the worst part of the project and I was hating it during that time.

I made a "sling" out of a huge ratchet strap to go under the motor to keep it up while the tranny was out. Pics will show this later.

Took care of the little odds and ends but kept putting off the inevitable I blamed hunting season... and being busy at work.... and family obligations.... but I'm big enough to admit, I was simply scared to butch up and start it. Even though I measured everything 3 times and followed several good, credible sources, my fear was I forgot something stupid and it would destroy my motor and the time and $$$ would be up in smoke!

Well, I finally manned up, finished up the 2.5" exhaust (another convenient delay) and just started the damn thing after priming it with a tool on a drill. (One thing I did forget was to hook up the gigantic wire to the starter. That one is sorta important.) Had too much timing in it at first but got it sorted out.

Bottom line: The car runs and sounds EXCELLENT. Vortec heads, bigger cam, 2.5" exhaust should make it breath well. I've only slowly driven around the neighborhood and will take it easy for 10 miles, change the oil, and drive it increasingly harder after it has had some time to break in.

Like with most things in life, it was not nearly as hard as I thought if you simply take it really slow and take LOTS of pictures along the way so you know how everything goes back together.

I'll post some pics in the next few days! Hopefully something finds this interesting or helpful.

Larry

Houston, TX

#2

Le Mans Master

Feels good don't it?

I pulled the BB out of my 69 in about 2 hours just piddling around. But it wasn't my first one either. Next time I get 3 or 4 days off in a row, the new one will go back in. Still have to pull the steering box for a teardown and look see, and finish up install of the new dash, ignition and forward light wiring harnesses.

#3

Team Owner

If you REALLY liked those videos, send the guy $10 for the benefit you got from them. That'll make his day!!

#4

Dr. Detroit

Member Since: Mar 2012

Location: New Braunfels Texas

Posts: 9,963

Received 3,892 Likes

on

2,564 Posts

Great job....slow and steady wins the race.

Jebby

Jebby

#6

Drifting

Member Since: Aug 2015

Location: NSW, Australia

Posts: 1,939

Received 472 Likes

on

344 Posts

C3 of Year Finalist (track prepared) 2019

Good work! Rewarding isn't it. I built the stroker in my Vette last year, it was my first engine as well, and I also used those same two Vizard books. Had a drama initially with a dud roller lifter (replaced under warranty by Crane), but I've put 4,000 miles on it since Christmas and love it! Mine is a very healthy modified engine, and I'm super happy with how it turned out. I took almost 11 months, I took it off the road - due to a failed clutch release bearing - in Feb last year, and only got it running right in late Dec, though I did also swap in a 5 speed box and convert to fuel injection while I was at it.

#7

Race Director

WOW that looks good, hope it works!

I only rebuilt one engine in '81 or so - a smallblock for a

'69 Camaro SS missing its motor. Had 4:11's.

I was too young for that.

I only rebuilt one engine in '81 or so - a smallblock for a

'69 Camaro SS missing its motor. Had 4:11's.

I was too young for that.

#8

Instructor

Thread Starter

Cheapest, best education I ever had.

d!

Last edited by LarMan; 03-30-2017 at 11:56 AM.

#9

Instructor

Thread Starter

Good work! Rewarding isn't it. I built the stroker in my Vette last year, it was my first engine as well, and I also used those same two Vizard books. Had a drama initially with a dud roller lifter (replaced under warranty by Crane), but I've put 4,000 miles on it since Christmas and love it! Mine is a very healthy modified engine, and I'm super happy with how it turned out. I took almost 11 months, I took it off the road - due to a failed clutch release bearing - in Feb last year, and only got it running right in late Dec, though I did also swap in a 5 speed box and convert to fuel injection while I was at it.

#10

Instructor

Thread Starter

Quick update and question.

2nd timeout with car. Car sounds like a monster. My face hurts from smiling so much.

Very, very minor oil leak seen at timing chain cover. Will try to tighten a bit but can live with it if needed.

Question. Oil Pressure is really high. 70 at idle, pegged out with any revs. Is this a problem? Every component in the motor is new. Maybe this is normal. Maybe it is a problem. I don't think I have an oil pressure sender. There is a small brass fitting and a small nylon line running from it to under dash.

Thanks for any help on oil pressure issues.

2nd timeout with car. Car sounds like a monster. My face hurts from smiling so much.

Very, very minor oil leak seen at timing chain cover. Will try to tighten a bit but can live with it if needed.

Question. Oil Pressure is really high. 70 at idle, pegged out with any revs. Is this a problem? Every component in the motor is new. Maybe this is normal. Maybe it is a problem. I don't think I have an oil pressure sender. There is a small brass fitting and a small nylon line running from it to under dash.

Thanks for any help on oil pressure issues.

#11

Dr. Detroit

Member Since: Mar 2012

Location: New Braunfels Texas

Posts: 9,963

Received 3,892 Likes

on

2,564 Posts

Quick update and question.

2nd timeout with car. Car sounds like a monster. My face hurts from smiling so much.

Very, very minor oil leak seen at timing chain cover. Will try to tighten a bit but can live with it if needed.

Question. Oil Pressure is really high. 70 at idle, pegged out with any revs. Is this a problem? Every component in the motor is new. Maybe this is normal. Maybe it is a problem. I don't think I have an oil pressure sender. There is a small brass fitting and a small nylon line running from it to under dash.

Thanks for any help on oil pressure issues.

2nd timeout with car. Car sounds like a monster. My face hurts from smiling so much.

Very, very minor oil leak seen at timing chain cover. Will try to tighten a bit but can live with it if needed.

Question. Oil Pressure is really high. 70 at idle, pegged out with any revs. Is this a problem? Every component in the motor is new. Maybe this is normal. Maybe it is a problem. I don't think I have an oil pressure sender. There is a small brass fitting and a small nylon line running from it to under dash.

Thanks for any help on oil pressure issues.

Jebby

#12

Dr. Detroit

Member Since: Mar 2012

Location: New Braunfels Texas

Posts: 9,963

Received 3,892 Likes

on

2,564 Posts

Quick update and question.

2nd timeout with car. Car sounds like a monster. My face hurts from smiling so much.

Very, very minor oil leak seen at timing chain cover. Will try to tighten a bit but can live with it if needed.

Question. Oil Pressure is really high. 70 at idle, pegged out with any revs. Is this a problem? Every component in the motor is new. Maybe this is normal. Maybe it is a problem. I don't think I have an oil pressure sender. There is a small brass fitting and a small nylon line running from it to under dash.

Thanks for any help on oil pressure issues.

2nd timeout with car. Car sounds like a monster. My face hurts from smiling so much.

Very, very minor oil leak seen at timing chain cover. Will try to tighten a bit but can live with it if needed.

Question. Oil Pressure is really high. 70 at idle, pegged out with any revs. Is this a problem? Every component in the motor is new. Maybe this is normal. Maybe it is a problem. I don't think I have an oil pressure sender. There is a small brass fitting and a small nylon line running from it to under dash.

Thanks for any help on oil pressure issues.

Jebby

#13

Instructor

Thread Starter

Crank freely turned over. Rods had side to side movement too. All oil passages were spotless. New gallery plugs, oil pump, etc.

thanks

#14

Dr. Detroit

Member Since: Mar 2012

Location: New Braunfels Texas

Posts: 9,963

Received 3,892 Likes

on

2,564 Posts

99% sure they were all ~0.0025 range. (it's been months since i put it together and I did not write them down). All measured with dial bore gauge by both machine shop and later by me during assembly. No plastigage was used.... ever.

Crank freely turned over. Rods had side to side movement too. All oil passages were spotless. New gallery plugs, oil pump, etc.

thanks

Crank freely turned over. Rods had side to side movement too. All oil passages were spotless. New gallery plugs, oil pump, etc.

thanks

Jebby

#15

Instructor

Thread Starter

https://summitracing.com/parts/slp-224-4143

Yes, factory gauge in car.

Thanks

#16

Dr. Detroit

Member Since: Mar 2012

Location: New Braunfels Texas

Posts: 9,963

Received 3,892 Likes

on

2,564 Posts

Used a sealed power pump, model #224-4143

https://summitracing.com/parts/slp-224-4143

Yes, factory gauge in car.

Thanks

https://summitracing.com/parts/slp-224-4143

Yes, factory gauge in car.

Thanks

Stock Corvette gauges are notoriously inaccurate....get a cheap oil gauge from the parts store and plumb it in....check against it.

I have oil, water temp and fuel pressure under the hood of my 72'......as well as the factory stuff.....

My factory gauge is about 20 psi high.....

Jebby

#17

I'm in the middle of doing this same swap right now. What pilot bushing did you use to mate the 4 speed to the vortec block?