Percentage of drivetrain loss. A myth?

#1

Burning Brakes

Thread Starter

I am curious because of discussion on another board dealing "percentage of drivetrain hp loss". Anyone who has even gone to a c/f driveshaft, lighter wheel/tire combo or lightweight flywheel will advise of a hp gain in doing so, depending on how heavy the original items were. The reverse is true for people who go for the 20" chromies and wonder why their car is slower.

Everybody seems to express their hp as "I got so much on the chassis dyno and once you add in the 15% for parastic drivetrain loss my actual hp is..."

So, the question is, when you added that blower did you also add weight to the reciprocating mass of the driveline? Of course not. The car does not lose 15% of it's hp to parasitic loss, it loses 80hp getting that hp to the ground and when you add another 150 hp at the engine the tax getting it to the ground is still 80hp. You could argue a small bit more loss due to heat and frictional pressure, like gear on gear contact or the resistance of fluids in the tranny and diff to accellerated motion but the mass of the driveline would not change. Because of this a percentage of drivetrain loss when comparing a 300 hp car and a 500 hp car would not work. As the engine hp rises, proportion or percentage of power lost to the drivline will be smaller so measuring that way is inaccurate.

The only way to prove this to an unbeliever is to find engines that were dynoed both in and out of a car. Does anyone know where I can find some dyno sheets to compare? It seems like almost all of the engine dynos results you see are on carbed engines, so C3 and earlier people are likely to be the ones who see this.

Has anyone dynoed on both an engine and chassis setup? If anyone sees a hole in my logic show me where I am wrong. Thks for any responses.

Everybody seems to express their hp as "I got so much on the chassis dyno and once you add in the 15% for parastic drivetrain loss my actual hp is..."

So, the question is, when you added that blower did you also add weight to the reciprocating mass of the driveline? Of course not. The car does not lose 15% of it's hp to parasitic loss, it loses 80hp getting that hp to the ground and when you add another 150 hp at the engine the tax getting it to the ground is still 80hp. You could argue a small bit more loss due to heat and frictional pressure, like gear on gear contact or the resistance of fluids in the tranny and diff to accellerated motion but the mass of the driveline would not change. Because of this a percentage of drivetrain loss when comparing a 300 hp car and a 500 hp car would not work. As the engine hp rises, proportion or percentage of power lost to the drivline will be smaller so measuring that way is inaccurate.

The only way to prove this to an unbeliever is to find engines that were dynoed both in and out of a car. Does anyone know where I can find some dyno sheets to compare? It seems like almost all of the engine dynos results you see are on carbed engines, so C3 and earlier people are likely to be the ones who see this.

Has anyone dynoed on both an engine and chassis setup? If anyone sees a hole in my logic show me where I am wrong. Thks for any responses.

#2

Team Owner

IN fact I think you are correct, as varrying drive/t losses due to more engine input makes no sense to me either....the tranny/diff MAY be using slightly more power, but it's more toward as high as 5 hp differance....certainly no where NEAR 15% of say your example of adding 100 hp....

I think 15% if awful high....for an automatic tranny that would mean it's loosing say 10% which means it goes up in heat, you take say 50 hp, at 750watts/hp....and you got ~40kw going up in tranny heat, and I say 40 kw will heat your house quite nicely....electric resistance heaters in air handlers are only 15 kw typically....so for that amount of heat dissipation, I say the auto tranny would self destruct quite rapidly....

they DO tend to self destruct, but it takes a few thousand miles...

GENE

I think 15% if awful high....for an automatic tranny that would mean it's loosing say 10% which means it goes up in heat, you take say 50 hp, at 750watts/hp....and you got ~40kw going up in tranny heat, and I say 40 kw will heat your house quite nicely....electric resistance heaters in air handlers are only 15 kw typically....so for that amount of heat dissipation, I say the auto tranny would self destruct quite rapidly....

they DO tend to self destruct, but it takes a few thousand miles...

GENE

#3

Melting Slicks

Have you ever felt a automatic after you've been driving it for a while ... they get quite hot, especially if you have an aftermarket converter! That's why you have to run tranny coolers, and they get hot too. Also, the rear differential in rear wheel drive cars are very ineffecient (almost all 90 degree gears are).

I do agree that the loss does not go up directly proportionally with HP, but if you spin the motor higher as with most high output engines your losses will increase. If your shift point goes up from 4800 rpm to 6500 rpm, the loss is greater at high speeds. Same torque to rotate a tranny at a higher speed = more HP loss.

I do agree that the loss does not go up directly proportionally with HP, but if you spin the motor higher as with most high output engines your losses will increase. If your shift point goes up from 4800 rpm to 6500 rpm, the loss is greater at high speeds. Same torque to rotate a tranny at a higher speed = more HP loss.

#4

The Amount of loss depends on a alot more than just the tranny.

Most dynopulls are with the "bare" engine, you need to look at the loss from items like airconditioning, Powersteering, mechanical fan, Alternator, etc.

It is possible to get a estimate on powerloss from the flywheel onward on a manual transmission, it's done by speeding the car up and then putting the clutch down, it is then possible for the dyno to measure how much hp loss on the drivetrain.

I had my old setup tested this way and a ~ 35 HP loss was the result through the muncie 4speed to the tires

Most dynopulls are with the "bare" engine, you need to look at the loss from items like airconditioning, Powersteering, mechanical fan, Alternator, etc.

It is possible to get a estimate on powerloss from the flywheel onward on a manual transmission, it's done by speeding the car up and then putting the clutch down, it is then possible for the dyno to measure how much hp loss on the drivetrain.

I had my old setup tested this way and a ~ 35 HP loss was the result through the muncie 4speed to the tires

#5

Drifting

Member Since: Oct 2003

Location: VetteMOD

Posts: 1,426

Likes: 0

Received 1 Like

on

1 Post

St. Jude Donor '05-'07

Anytime power is transmitted through a gear train, there is an associated power loss because of friction. This power loss is expressed as a percentage so the higher the HP the higher the loss.

As an example: Race cars use straight cut gears because there is less friction (and less loss) than hypoid gears.

As an example: Race cars use straight cut gears because there is less friction (and less loss) than hypoid gears.

#6

Melting Slicks

I toured Performance Friction yesterday and their head of motorsports mentioned an 8% increase in torque at the wheels in one case from a better brake package!  That is of course going from a very bad system to a very well engineered system but that is huge. I was blown away by the kind of engineering that goes into their designs. Seeing a NASCAR track "played back" on their brake dyno, I can believe it. Sparks flew and it got pretty toasty even 6 feet away. Their dyno is capable of the equivalent of 240 MPH

That is of course going from a very bad system to a very well engineered system but that is huge. I was blown away by the kind of engineering that goes into their designs. Seeing a NASCAR track "played back" on their brake dyno, I can believe it. Sparks flew and it got pretty toasty even 6 feet away. Their dyno is capable of the equivalent of 240 MPH

As for the original topic, percentage losses are just approximations for the "average" car. Just like saying so-and-so air filter increases power up to 10 HP. Well if you're making 200 HP maybe not. 400HP maybe so. 800HP, you could very well gain more by getting rid of that restriction. Just a rule of thumb will all that that implies.

-Chris

That is of course going from a very bad system to a very well engineered system but that is huge. I was blown away by the kind of engineering that goes into their designs. Seeing a NASCAR track "played back" on their brake dyno, I can believe it. Sparks flew and it got pretty toasty even 6 feet away. Their dyno is capable of the equivalent of 240 MPH

That is of course going from a very bad system to a very well engineered system but that is huge. I was blown away by the kind of engineering that goes into their designs. Seeing a NASCAR track "played back" on their brake dyno, I can believe it. Sparks flew and it got pretty toasty even 6 feet away. Their dyno is capable of the equivalent of 240 MPH

As for the original topic, percentage losses are just approximations for the "average" car. Just like saying so-and-so air filter increases power up to 10 HP. Well if you're making 200 HP maybe not. 400HP maybe so. 800HP, you could very well gain more by getting rid of that restriction. Just a rule of thumb will all that that implies.

-Chris

#7

Race Director

Drivetrain loss is a percentage, but it is not a fixed percentage. Using the 15-20% for a manual, 20-25% for an automatic is a simplification. However, it is not too bad of a simplification.

In your example of adding a blower and thereby 200hp, you are incorrect. You will indeed increase the amount of hp loss through the drivetrain. That's why stock engines get away without a separate tranny cooler, and hot rods burn trannies unless they add a cooler. The more power a drivetrain transmits, the more power is lost to the drivetrain.

Another point in your post about the rotating mass (wheels, driveshaft etc) chagning the reading: The reason for that is the dynojet chassis dyno measures power by how long it takes to spin up a known mass (the drum). The more rotating mass in your driveline, the lower the reading. This is a short coming of that particular dyno. A more sophisticated dyno would read exactly the same regardless of heavy wheels,driveshaft etc. These dynoes are called "steady state" and they can generate a load sufficient to where the engine cannot accelerate. Since the rpm is fixed rotating mass is not a factor.

In your example of adding a blower and thereby 200hp, you are incorrect. You will indeed increase the amount of hp loss through the drivetrain. That's why stock engines get away without a separate tranny cooler, and hot rods burn trannies unless they add a cooler. The more power a drivetrain transmits, the more power is lost to the drivetrain.

Another point in your post about the rotating mass (wheels, driveshaft etc) chagning the reading: The reason for that is the dynojet chassis dyno measures power by how long it takes to spin up a known mass (the drum). The more rotating mass in your driveline, the lower the reading. This is a short coming of that particular dyno. A more sophisticated dyno would read exactly the same regardless of heavy wheels,driveshaft etc. These dynoes are called "steady state" and they can generate a load sufficient to where the engine cannot accelerate. Since the rpm is fixed rotating mass is not a factor.

#8

Race Director

You hit on it when you started talking friction and heat. The chassis dyno uses calculated hp/torque on how fast the motor can accelerate the drum under the wheels. It takes continuous measurements of their speed and the time ( these numbers are not real dyno numbers just an example) If a car spun the drum from 1000 to 2000 RPM and it took 2 seconds then the computer would spit out that the motor was making 400RWHP in this range. In reality the computer would be making HP calculations between 1000 and 1001 and 1002RPM...

Now when the 400 HP motor is accelerating the drum there is drivetrain loss due to friction. THis loss is mostly heat. If you took the motor out and put it on a engine dyno it might make 500HP so you calculate that the 500HP motor loses maybe 5% spining alternator, water pump, through headers and 15% due to drivetrain loss ( heat ).

Now here is the important part. You test the same car and put in a more powerfull motor and it accelerates the drum faster, meaning it takes less time, lets say 1 second to spin the drum from 1000 to 2000RPM. Now the computer says that motor has 800HP. In accelerating the drum twice as fast as the 400HP it makes much more heat, meaning that it will lose much more HP through the drivetrain than the 400HP motor, and the drivetrain loss will still be 15% or so.

This means that the 800 HP motor in the same car will not see 700RWHP, it will be closer to 600RWHP.

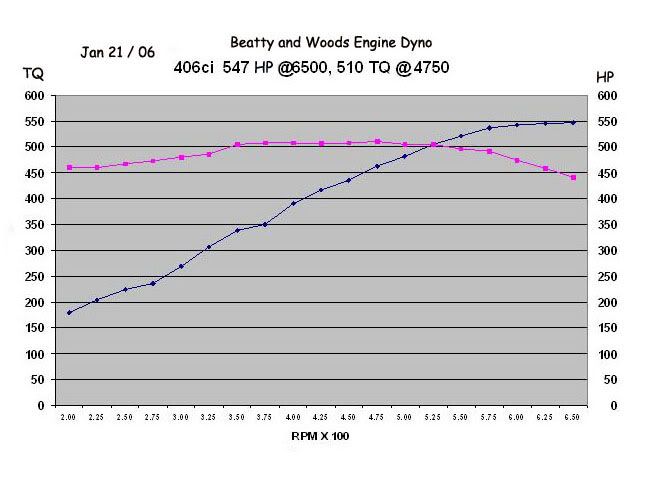

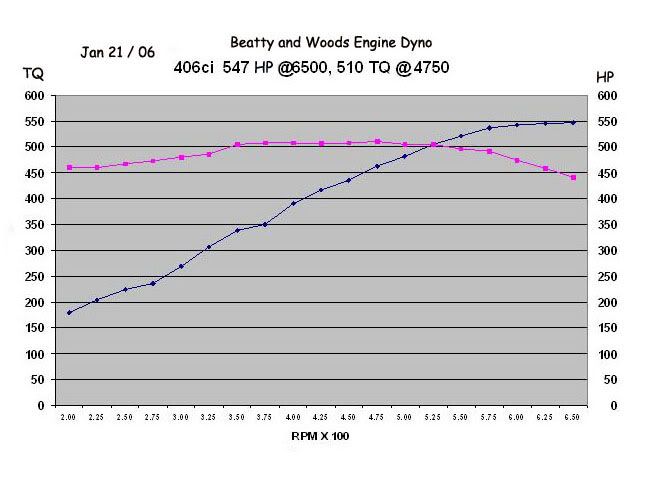

Any way these are my dyno graphs and I lose 546 - 427 = 119HP through the drivetrain as well as my accessories and exhaust. Which is 28% of 427HP or 22% of 546 depending on how you look at it. If you say I lost 22% of 546HP then I would break that down to about ( just an educated guess here ) 15-16% drivetrain loss and 6-7% accessories and exhaust ( I have a pretty good free flowing 3 inch system )

Engine Dyno

Chassis Dyno

Now when the 400 HP motor is accelerating the drum there is drivetrain loss due to friction. THis loss is mostly heat. If you took the motor out and put it on a engine dyno it might make 500HP so you calculate that the 500HP motor loses maybe 5% spining alternator, water pump, through headers and 15% due to drivetrain loss ( heat ).

Now here is the important part. You test the same car and put in a more powerfull motor and it accelerates the drum faster, meaning it takes less time, lets say 1 second to spin the drum from 1000 to 2000RPM. Now the computer says that motor has 800HP. In accelerating the drum twice as fast as the 400HP it makes much more heat, meaning that it will lose much more HP through the drivetrain than the 400HP motor, and the drivetrain loss will still be 15% or so.

This means that the 800 HP motor in the same car will not see 700RWHP, it will be closer to 600RWHP.

Any way these are my dyno graphs and I lose 546 - 427 = 119HP through the drivetrain as well as my accessories and exhaust. Which is 28% of 427HP or 22% of 546 depending on how you look at it. If you say I lost 22% of 546HP then I would break that down to about ( just an educated guess here ) 15-16% drivetrain loss and 6-7% accessories and exhaust ( I have a pretty good free flowing 3 inch system )

Engine Dyno

Chassis Dyno

#9

Team Owner

MH, not argueing the facts you posted above, just that I find it really amazing the DT losses are allways a constant .....

makes no sense to me....I can see a slight increase in absolute HP losses, due to increased gear friction/etc..but not as an absolute percentage of total HP....

anyway, sure auto trannies, indeed diffs and all trannies get hot, when running....I say that is a FAR cry from 45 KW though....

GENE

makes no sense to me....I can see a slight increase in absolute HP losses, due to increased gear friction/etc..but not as an absolute percentage of total HP....

anyway, sure auto trannies, indeed diffs and all trannies get hot, when running....I say that is a FAR cry from 45 KW though....

GENE

#10

Former Vendor

Member Since: Feb 2006

Location: Orlando/Oviedo FL

Posts: 1,943

Likes: 0

Received 2 Likes

on

2 Posts

Motorhead is 100 percent correct... Because a higher horsepower engine acclerates the drivetrain quicker (objects at a standstill resist acclerating) the drive train thus the creates more loss the quicker it is accelerated. Infact, engines vary torque output at different RPM's, so the more power the engine produces (and thus acclerates) the more it loses, so the number varys at rpm.

Also the 15-20 percent is also at wide open throttle, as the actual loss at smaller throttle openings (and thus less engine accleration) is much much less. To make matters worse, once the drive train is rotating, it is storing some of that engines power, so when you let off the throttle, the wheels can be recieving more power then engine is currently making...

Also the 15-20 percent is also at wide open throttle, as the actual loss at smaller throttle openings (and thus less engine accleration) is much much less. To make matters worse, once the drive train is rotating, it is storing some of that engines power, so when you let off the throttle, the wheels can be recieving more power then engine is currently making...

#11

Racer

Member Since: Jan 2004

Location: Everfrost Second Life

Posts: 428

Likes: 0

Received 2 Likes

on

2 Posts

Quite simple. If you don't have a chassis dyno AND engine dyno you can't make real comparisons just ball park calculations on what the drivetrain will rob against pure HP output of the engine.

I disagree with someone saying straight cut gears use less HP then helical cut gears. Not true at all. One shouldn't generalize. I have had the experiance of running a car equipped with a Jericho 4 speed on a chassis dyno and swapping out an M22 with a rollerized 1 gear. The M22 increased rear wheel HP by a wopping 8 percent. Certain pressure angles of spur gears are quite coggy and this leads to higher frictional losses. Semi helical gears maintain a better smoothness or transision from tooth to tooth since more gear teeth are in contact at a given time.

As far as Carbon Fiber driveshafts having any benefit I feel that the rotating mass thing is insignificant if your driveshaft unglues itself during a race. I do feel that by using CF driveshafts in road racing applications harmonic vibration and busted driveline components where diminshed.

Paul

I disagree with someone saying straight cut gears use less HP then helical cut gears. Not true at all. One shouldn't generalize. I have had the experiance of running a car equipped with a Jericho 4 speed on a chassis dyno and swapping out an M22 with a rollerized 1 gear. The M22 increased rear wheel HP by a wopping 8 percent. Certain pressure angles of spur gears are quite coggy and this leads to higher frictional losses. Semi helical gears maintain a better smoothness or transision from tooth to tooth since more gear teeth are in contact at a given time.

As far as Carbon Fiber driveshafts having any benefit I feel that the rotating mass thing is insignificant if your driveshaft unglues itself during a race. I do feel that by using CF driveshafts in road racing applications harmonic vibration and busted driveline components where diminshed.

Paul

#12

Zwede and motor head are right on. The loss is not static, it increases with the hp. Suppose the loss was static in a C3, and as you said from the crank to the wheels we lose 80hp. Which would mean that a corvette with a 4 cylinder toyota engine, producing 80hp would not even move. You see? Can't work that way.

#13

Drifting

Member Since: Oct 2003

Location: VetteMOD

Posts: 1,426

Likes: 0

Received 1 Like

on

1 Post

St. Jude Donor '05-'07

Originally Posted by 5speeds

I disagree with someone saying straight cut gears use less HP then helical cut gears. Not true at all. One shouldn't generalize. I have had the experiance of running a car equipped with a Jericho 4 speed on a chassis dyno and swapping out an M22 with a rollerized 1 gear. The M22 increased rear wheel HP by a wopping 8 percent. Certain pressure angles of spur gears are quite coggy and this leads to higher frictional losses. Semi helical gears maintain a better smoothness or transition from tooth to tooth since more gear teeth are in contact at a given time

Hypoid gears: Similar to spiral bevel gears, but connect non-parallel shafts that do not intersect. The pitch surface of a hypoid gear is a hyperboloid of revolution (rather than a cone, the pitch surface in bevel gears), hence the name. Hypoid pinions (the smaller driving gear) are stronger than spiral bevel pinions because the helix angle of the pinion is larger than that of the gear. Hypoid gears are stronger, operate more quietly, and can be used for higher reduction ratios than spiral bevel gears. They also have sliding action along the teeth, potentially reducing efficiency. Hypoid gears are found in auto differentials.

Last edited by BBShark; 02-12-2006 at 12:42 AM.

#14

Race Director

C5 losses:

manual 13%

Auto 16%

Knowing what a particular drivetrain losses is crucial. For instance, if I get 320 rwhp on my C5 and use a 20% loss thats 400 at the crank. Now, if I use 16% loss thats 383 rwhp.

Free gain/loss of HP by doing proper math!!!!

manual 13%

Auto 16%

Knowing what a particular drivetrain losses is crucial. For instance, if I get 320 rwhp on my C5 and use a 20% loss thats 400 at the crank. Now, if I use 16% loss thats 383 rwhp.

Free gain/loss of HP by doing proper math!!!!

#15

Le Mans Master

I've always had a problem with this too.

Say you have a 350ci engine that produces 400hp at 6000 rpm(flywheel) and you calculate drivetrain loss at 15%, for 340 rwhp with a manual tranny (no slip). Now say you turbocharge the engine, but leave the drivetrain and the accesories the same and the new engine makes 800 hp at 6000 rpm. Using the same 15% loss, how did the same drivetrain and accesory combo all of a sudden take 120hp to drive at the same rpm? It doesn't. Obviously friction increases as speed(rpm) increases, but at the same rpm the friction should be the same regardless of whether or not a 400 or 800hp is in front of it.

Say you have a 350ci engine that produces 400hp at 6000 rpm(flywheel) and you calculate drivetrain loss at 15%, for 340 rwhp with a manual tranny (no slip). Now say you turbocharge the engine, but leave the drivetrain and the accesories the same and the new engine makes 800 hp at 6000 rpm. Using the same 15% loss, how did the same drivetrain and accesory combo all of a sudden take 120hp to drive at the same rpm? It doesn't. Obviously friction increases as speed(rpm) increases, but at the same rpm the friction should be the same regardless of whether or not a 400 or 800hp is in front of it.

#16

Race Director

Member Since: Nov 2000

Location: NC,USA

Posts: 16,416

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by mrvette

MH, not argueing the facts you posted above, just that I find it really amazing the DT losses are allways a constant .....

makes no sense to me....I can see a slight increase in absolute HP losses, due to increased gear friction/etc..but not as an absolute percentage of total HP....

anyway, sure auto trannies, indeed diffs and all trannies get hot, when running....I say that is a FAR cry from 45 KW though....

GENE

makes no sense to me....I can see a slight increase in absolute HP losses, due to increased gear friction/etc..but not as an absolute percentage of total HP....

anyway, sure auto trannies, indeed diffs and all trannies get hot, when running....I say that is a FAR cry from 45 KW though....

GENE

Gene:

I'm gonna make an attempt at this... but your prolly gonna burn me at the stake, cause I follow the smoke theory of electronics! Wire wasnt big enough when the magic smoke comes out, try again!

Anyhoo...

If you have a 12 gauge awg wire of a fixed length, the resistance is dependent on the temperature. The temperature of the wire is dependent on how many amps you try to push through it... lets say the voltage is the same for this. Double the amp load and your going to smoke an unprotected circuit. Double the torque of the engine and the drivetrain gets that much closer to going up in smoke. The product is still heat. Everything that is connected has to carry that much more strain before it melts down.

The relation here is you are using the pre-existing "wiring" to handle more load than it was intended to handle. You may still be within the working limits, but its not ideal. The load on the circuit goes up when you pump up the HP/Torque out put of the engine.

Hope this helps, cant gurantee that I got the electronic speak right... been a while!

Monty:

The accessories dont take up extra power... They are satisfying the same requirements. *Check out how Zwede puts this, I was clear here*

The exhaust will not be up to the task, and the drivetrain will take more to turn. Your doing more work in less time. The extra friction stems from the fact that everything is flexing, slipping, and rubbing more that it used to. Clutches slip, tires slip, bearings wear faster, you oval out machined surfaces, snap axles, lug nuts... Everything complains more in the form of heat, till it breaks.

Take a stainless steel nut and a tight fitting stainless steel bolt, put the nut or bolt in a vice and grab a socket/ratchet. Run the nut up and down the shaft for a minute as fast as you can go... give it a feel.

Now grab an impact and do the same thing. That pup may very well weld together for you. Same time, same bolt/nut... different amount of work over the same amount of time.

Last edited by ZD75blue; 02-12-2006 at 03:18 PM.

#17

Race Director

Accessories rob power depending on rpm. If the engine makes 200 hp or 800 hp, doesn't matter. They will consume the same power.

A drivetrain is totally different because it is TRANSMITTING power. As such a fraction of that transmitted power will be lost. You put in a number of watts and sligthly less watts come out the other end. The more power you transmit, the more watts will be lost.

Even regular cogwheels will increase the losses as power goes up.

If it really took 80 hp to run the drivetrain the rear wheels would lock up when you depress the clutch! They don't because drivetrain losses are a percentage, not a fixed number.

A drivetrain is totally different because it is TRANSMITTING power. As such a fraction of that transmitted power will be lost. You put in a number of watts and sligthly less watts come out the other end. The more power you transmit, the more watts will be lost.

Even regular cogwheels will increase the losses as power goes up.

If it really took 80 hp to run the drivetrain the rear wheels would lock up when you depress the clutch! They don't because drivetrain losses are a percentage, not a fixed number.

#18

I think of it like this.

If you put a hand crank on a big fan and accelerate it slowly you will only lose a little of your energy. If you try and accelerate the fan as quickly as you can you will lose a lot more energy. Basically I believe it is a percentage in both cases, but smaller in the slower acceleration b/c you are putting out less energy. Once you get to your terminal velocity/speed it will take the same amount of energy to turn the fan no matter how fast you got there. I understand the feeling of frictional losses should have a ceiling(if you will) but things in motion tend to want to stay in motion(that goes for things that are sitting still as well...inertia).

I just wanted say that I am equating the fans wind resistance to the drivetraines frictional losses. I am no physics expert, but that is just how I think of it.

If you put a hand crank on a big fan and accelerate it slowly you will only lose a little of your energy. If you try and accelerate the fan as quickly as you can you will lose a lot more energy. Basically I believe it is a percentage in both cases, but smaller in the slower acceleration b/c you are putting out less energy. Once you get to your terminal velocity/speed it will take the same amount of energy to turn the fan no matter how fast you got there. I understand the feeling of frictional losses should have a ceiling(if you will) but things in motion tend to want to stay in motion(that goes for things that are sitting still as well...inertia).

I just wanted say that I am equating the fans wind resistance to the drivetraines frictional losses. I am no physics expert, but that is just how I think of it.

Last edited by 1972warship; 02-12-2006 at 03:03 PM.

#19

Team Owner

[QUOTE=zwede]Accessories rob power depending on rpm. If the engine makes 200 hp or 800 hp, doesn't matter. They will consume the same power.

A drivetrain is totally different because it is TRANSMITTING power. As such a fraction of that transmitted power will be lost. You put in a number of watts and sligthly less watts come out the other end. The more power you transmit, the more watts will be lost.

Zwede, I can agree with you to a point, but lets consider a stick shift with an unobtainable instant lockup clutch that will NOT slip under any circumstances....like a digger would use....

ok, engine making 400 hp looses a hypothetical 15%, under steady Nascar type loading....he's flying at nearly 200 mph....and loosing 60 hp in the driveline....

now we double the engine power to 800, same rpm's same speed, ...

what are the drive train losses, ONLY increased IF he is accelerating...

straining to go say 300 mph....conversationally....

so do the driveline losses really add up to 120 hp?? I can't see that has happening, I can see maybe ten additional HP loss for maybe that increased friction/loading/etc....but to double the losses?? I think not...

that's all I"m trying to say, I think the equations are not linear in relationship one bit, but rather a curve....

now for an automatic, especially my 700 here that I love to hate, yeh, the internal slippage alone would launch that thing into oblivian in about 10 seconds, if that much....

still the electronic/electrical equivalent is quite astounding, loosing 45kw thrhough ANY drive train is not understandable to me, sure they get HOT, but we not melting plastic, not destroying oil immediately, not melting seals, and frying cork all THAT rapidly....

45kw is a hell of a lot of hot metal, and those coils in your electric heater run at damn near 2000f or so, they ain't glowing for nothing...airflow is pretty good too, so the heat transferr is much better than over any tranny cooler or tranny case/diferential...

so I still fail to see 45kw going up in heat losses, which is about the only place it could go up....

where am I rong???

GENE

A drivetrain is totally different because it is TRANSMITTING power. As such a fraction of that transmitted power will be lost. You put in a number of watts and sligthly less watts come out the other end. The more power you transmit, the more watts will be lost.

Zwede, I can agree with you to a point, but lets consider a stick shift with an unobtainable instant lockup clutch that will NOT slip under any circumstances....like a digger would use....

ok, engine making 400 hp looses a hypothetical 15%, under steady Nascar type loading....he's flying at nearly 200 mph....and loosing 60 hp in the driveline....

now we double the engine power to 800, same rpm's same speed, ...

what are the drive train losses, ONLY increased IF he is accelerating...

straining to go say 300 mph....conversationally....

so do the driveline losses really add up to 120 hp?? I can't see that has happening, I can see maybe ten additional HP loss for maybe that increased friction/loading/etc....but to double the losses?? I think not...

that's all I"m trying to say, I think the equations are not linear in relationship one bit, but rather a curve....

now for an automatic, especially my 700 here that I love to hate, yeh, the internal slippage alone would launch that thing into oblivian in about 10 seconds, if that much....

still the electronic/electrical equivalent is quite astounding, loosing 45kw thrhough ANY drive train is not understandable to me, sure they get HOT, but we not melting plastic, not destroying oil immediately, not melting seals, and frying cork all THAT rapidly....

45kw is a hell of a lot of hot metal, and those coils in your electric heater run at damn near 2000f or so, they ain't glowing for nothing...airflow is pretty good too, so the heat transferr is much better than over any tranny cooler or tranny case/diferential...

so I still fail to see 45kw going up in heat losses, which is about the only place it could go up....

where am I rong???

GENE

#20

Race Director

Member Since: Jan 2000

Location: Corsicana, Tx

Posts: 12,615

Received 1,877 Likes

on

915 Posts

2020 C2 of the Year - Modified Winner

2020 Corvette of the Year (performance mods)

C2 of Year Winner (performance mods) 2019

2017 C2 of Year Finalist

Isn't this fun stuff? This argument has been going on a long time.

Just for reference, the first version of my 540 made 732 Hp on a Superflow engine dyno. It was tested with open headers, no carb spacers and a belt driven water pump.

On a Dynojet, it made 615 RWHP with open headers, no spacers and same belt driven pump. The only additional deal was the alternator and a cam driven fuel pump and the fixed 7 blade flex fan (didn't lose anywhere what magazines claim when I tested it by removing it). This was with Doug Nash 5 speed with helical gears (M-22 style) and a GM IRS.

Did anyone read the article in one of the mags this month where they interviewed the designer of the Dynojet? He went through all the stuff they worked on to come up with a "scientific" correction factor to equate engine Hp with Dynojet HP. problem was that they could never make it work using std, accleration/mass formulas and ended up "creating" a "happy number" that was close to what the bad boy crotch rocket bike was doing at the time. So to this day, the correction factors are based and fudged according to what an 80's bike did.

Anyway, that's not all bad when it is used as a tuning aid. I do find that I get very similar results from various Dynojets regardless of which one it is. Can't always say that with engine dyno's. So if you compare YOUR car and make changes it's a great measure of "if" you're heading the right way. Makes it pretty tough to compare your stuff against someone elses who has a different combo. Like C-5's to old C-2's and C-3's. Or Fixed axle Camaro's to IRS equiped cars etc etc.

I'm sure my current G-Force 5 speed with straight cut gears and Dana 60 IRS with heavy tree trunks for halfshafts is going to have a different drivetrain loss to a Muncie equiped stock C-3. Plus I usually make runs in 4th gear (underdrive) to keep tire speed down out of the 160+ mph range with my 3.07's.

So my numbers only mean much to ME and my car. Way too many folks out there "dyno racing" which is only slightly better than "bench racing". When they dyno NASCAR winners after the races, they often find the winner is down 50 RWHP over the others, but they found a way to get around the track faster.

Dyno's and flowbenches don't win races.

Best final test is the good 'ole drag strip and see what your MPH does. That will tell you if you need to go back to dyno and find more of it, or if you have enough and just need to figure out how to use it.

JIM

Just for reference, the first version of my 540 made 732 Hp on a Superflow engine dyno. It was tested with open headers, no carb spacers and a belt driven water pump.

On a Dynojet, it made 615 RWHP with open headers, no spacers and same belt driven pump. The only additional deal was the alternator and a cam driven fuel pump and the fixed 7 blade flex fan (didn't lose anywhere what magazines claim when I tested it by removing it). This was with Doug Nash 5 speed with helical gears (M-22 style) and a GM IRS.

Did anyone read the article in one of the mags this month where they interviewed the designer of the Dynojet? He went through all the stuff they worked on to come up with a "scientific" correction factor to equate engine Hp with Dynojet HP. problem was that they could never make it work using std, accleration/mass formulas and ended up "creating" a "happy number" that was close to what the bad boy crotch rocket bike was doing at the time. So to this day, the correction factors are based and fudged according to what an 80's bike did.

Anyway, that's not all bad when it is used as a tuning aid. I do find that I get very similar results from various Dynojets regardless of which one it is. Can't always say that with engine dyno's. So if you compare YOUR car and make changes it's a great measure of "if" you're heading the right way. Makes it pretty tough to compare your stuff against someone elses who has a different combo. Like C-5's to old C-2's and C-3's. Or Fixed axle Camaro's to IRS equiped cars etc etc.

I'm sure my current G-Force 5 speed with straight cut gears and Dana 60 IRS with heavy tree trunks for halfshafts is going to have a different drivetrain loss to a Muncie equiped stock C-3. Plus I usually make runs in 4th gear (underdrive) to keep tire speed down out of the 160+ mph range with my 3.07's.

So my numbers only mean much to ME and my car. Way too many folks out there "dyno racing" which is only slightly better than "bench racing". When they dyno NASCAR winners after the races, they often find the winner is down 50 RWHP over the others, but they found a way to get around the track faster.

Dyno's and flowbenches don't win races.

Best final test is the good 'ole drag strip and see what your MPH does. That will tell you if you need to go back to dyno and find more of it, or if you have enough and just need to figure out how to use it.

JIM